Feldspar processing equipment Feldspar processing equipment Feldspar processing equipment

.jpg)

Feldspar Processing Equipment, Flow, Cases JXSC

2019年8月23日 Feldspar processing description from its geology mineral property to how to extract mineral from rock and placer deposit, related processing plant flow chart and layout designFeldspar Mining The top states producing feldspar are North Carolina, Virginia, California, Oklahoma, Idaho, Georgia and South Dakota, in descending order of estimated tonnage Feldspar processors reported coproduct recovery of mica Feldspar Mining Process Equipment Flow CasesFeldspar beneficiation production line is the production line to separate and purify feldspar from the raw ore Process flow The process flow of feldspar beneficiation production line includes Feldspar Processing PlantZOOMJOThe specific choice of processing plant and equipment for feldspar is determined by the types of feldspar deposits and the properties of the ore By customizing the processing plant and equipment accordingly, it becomes possible to achieve Feldspar Processing Plant Zoneding Machine

.jpg)

Feldspar Mining Process JXSC Mineral

The desliming operation aims to remove the primary slime in the potassium feldspar ore and the secondary slime produced by grinding through desliming buckets, hydrocyclones, and other equipment These slimes will affect Feldspar grinding plant is also called feldspar grinding machine Feldspar grinding is the required process when size reduction of below 520 mm is needed Feldspar grinding is a powdering or Feldspar processing plant sbmchina2023年4月20日 Required equipment for feldspar processing Depending on the type of feldspar being processed and the desired end result, we may require a variety of equipment In the process of feldspar processing, we often use the Several Steps And Required Equipment For Feldspar Feldspar Processing SBM offers complete feldspar processing solutions to all enrichment and upgrading applications including classification, agitation, flotation, magnetic separation, Feldspar processing plant for feldspar dressing by SBM

What are the processing equipment for feldspar powder?

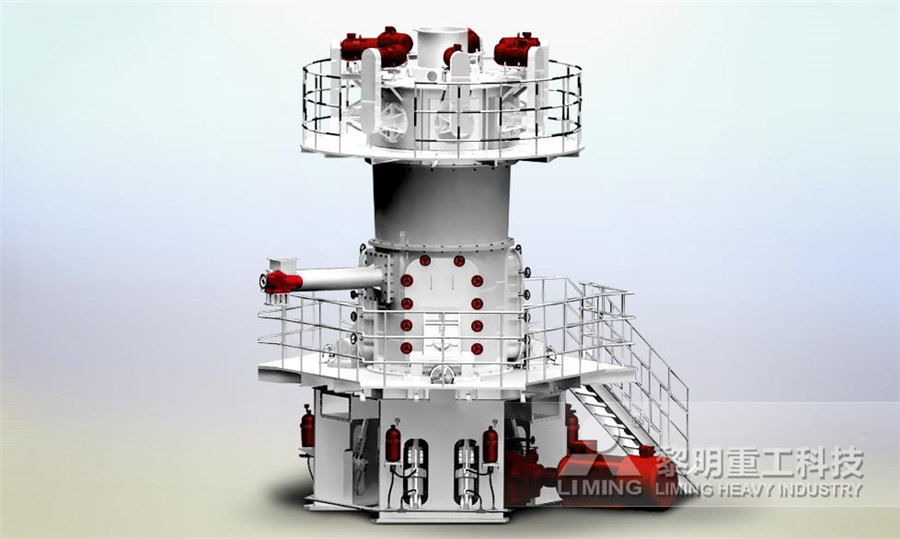

Processing equipment for feldspar powder typically includes a range of machinery designed for crushing, grinding, separation, and refining the raw feldspar material into fine powder Here Feldspar Processing Plant Feldspar is a mineral that primarily contains iron minerals, along with impurities such as clay, quartz, mica, garnet, beryl, By customizing the processing plant and equipment accordingly, it becomes Feldspar Processing Plant Zoneding MachineThe plant is configured for dry feeding, composed of bulk feed hopper (22 x 28 x 10) meters, designed for feeding by earth moving equipment Ore is continuously transported by screw conveyor with capacity of 30 TPH and 10 meters length to high pressure grinding mill with maximum feed size (30 mm) and discharge output of 150 mesh (0105 mm)DIATOMITE FELDSPAR DRY PROCESSING PLANT THAILAND 2024 DOVE Equipment 2022年5月7日 Potassium feldspar is a potassiumrich silicate mineral with the advantages of low melting point, long melting interval and high melt viscosityIt is one of the main production raw materials in the glass and ceramic industries The main raw material of potash fertilizer can be widely used in industrial fields such as processing and extracting potash fertilizer, and it is an What are the uses of potassium feldspar? What equipment is

Emission Factor Documentation for AP42 Section 827 Feldspar Processing

EMISSION FACTOR DOCUMENTATION FOR AP42 SECTION 827 Feldspar Processing 1 INTRODUCTION The document Compilation of Air Pollutant Emission Factors (AP42) has been published by the Reference 4 was not used in calculating emission factors because of problems with equipment failures and high sampling velocities that resulted in data of 2024年11月21日 3 Acid Leaching Process The acid leaching process is a method of using acid to selectively dissolve ironbearing minerals and remove iron from feldspar It is an effective method to process feldspar containing impurities embedded in the Which Processes Remove Impurities In Feldspar? JXSC JXSC Potassium feldspar mining equipment mainly include jaw crusher, ball mill, desliming bucket, hydrocyclone, strong and week magnetic separator, flotation cell, etc the main process is curshingmillingmagneticflotation, etc 1 Crushing: firstly, use the jaw crusher to crush massive ore 2 Ball mill: after crushing, use ball mill to grind ore 3Potassium feldspar process flowsheet Yantai Jinpeng Mining equipment 【Process Introduction】 Feldspar is a kind of silicate minerals which contains calcium, sodium and potassium, there are many categories of Feldspar including albite, anorthite, Mineral Processing EPC and Equipment Tel: +33 Email: xhxu@xinhaiminingfeldspar mining process, feldspar processing plant, beneficiation

Feldspar Beneficiation Process Magnetic Flotation JXSC

2019年6月25日 The feldspar separation process through gravity separation, It is definitely an effective machine for dressing highgrade feldspar products, but the equipment cost and operation cost are higher than that of other magnetic separators 4 Flotation Flotation is an effective way to remove impurities in feldsparWe are a Professional Feldspar processing plant manufacturer,Our Feldspar processing plant has been exported 167 countries,Click here to get price ! Feldspar processing equipment Typically, jaw crusher is used in the primary crushing, and the Feldspar stone processing plant sbmchinaFeldspar Mineral Processing Feldspar ore is the main source of highpurity feldspar mineral concentrate used in the manufacture of glass and ceramics, including highend ceramics and electronicgrade glass fibers The glass and Feldspar Mineral Processing domain Arkema2023年12月14日 Due to the increasing demand for potassium feldspar powder in recent years, processing potassium feldspar to 80200 mesh powder will generate relatively objective economic benefits Utilizing this process and Feldspar Powder Crushing Grinding Production Line

Feldspar Processing Industry Business Opportunities in Minerals

The primary source of feldspar mineral concentrate or purified feldspar utilised in the production of various grades of glass and ceramics, including highend ceramics and electronicgrade glass fibres, is feldspar ore The glass and ceramic industries, in particular, are important feldspar consumers, accounting for about all of the overall 2024年2月23日 2 Flotation process The flotation process can effectively remove iron from clay and finegrained ironcontaining minerals, but the effect is not good for hard ores For severely weathered ores, secondary sludge may be produced during the crushing and grinding stage, which may easily cause the flotation foam to be highly viscous, resulting in reduced collector Beneficiation Process For Removing Impurities From Feldspar2024年2月4日 The Kfeldspar mineral is an insoluble potassium resource with a high potassium content and the most extensive and abundant reserves To address the insufficient supply of soluble potassium fertilizers in China, the application of appropriate processing methods to extract potassium from Kfeldspar and transform it into a soluble potassium fertilizer is of great Review on KFeldspar Mineral Processing for Extracting Metallic Feldspar is a kind of silicate minerals which contains calcium, sodium and potassium, there are many categories of Feldspar including albite, anorthite, etc Feldspar mining process mainly applying flotation process, and Feldspar mining machines mainly including jaw crusher, ball mill, spiral chute, and concentrating table, etcfeldspar extraction, feldspar processing, process of feldspar, feldspar

Recovery of Some Critical Raw Materials from Processing Waste

2021年4月26日 Feldspar ore processing waste thus presents potential source of CRMs; however, semiindustrial and fullscale trial must follow in order to prove the economic and environmental suitability of the 2024年10月21日 The equipment required for the potassium feldspar mineral processing process includes a jaw crusher, cone crusher, grinding machine, vibrating feeder, spiral classifier, ore color separator, artificial intelligence separator, magnetic separator, flotation machine, dryer, vibrating screen and conveyorHow to Deironing and Mineral Separation of Potassium FeldsparFeldspar crushing processing equipments Feldspar is commonly piled in town road So we must much better select mobile crusher since the principal crushing plant on this process mobile Feldspar crusher or easily transportable Feldspar crusher is a single of SBM principal productsFeldspar processing plant, crushing, grinding, processing equipment2018年11月1日 In the case of the sandy or weathered feldspar, washing processing is essential, and the waste residue floating on the water surface after the washing process is Kfeldspar washed waste (KFW) [40]Systematic review of feldspar beneficiation and its comprehensive

.jpg)

feldspar extraction, feldspar processing, process of feldspar, feldspar

Feldspar Mining Process 【Introduction】:Feldspar is a kind of silicate minerals which contains calcium, sodium and potassium, there are many categories of Feldspar including albite, anorthite, etc Feldspar mining process mainly applying flotation process, and Feldspar mining machines mainly including jaw crusher, ball mill, spiral chute, and concentrating table, etc2020年5月22日 Potassium fertilizers (potash) are mined in a handful of countries in the Northern Hemisphere Potash is either expensive or unavailable to the farmers of the Southern Hemisphere Alkaline alteration of Kfeldspar rock (ultrapotassic syenite) in autoclave in the presence of Ca2+ generates a mixture of Kbearing calciumaluminumsilicatehydrate (CAS Role of Processing Temperature and Time on the Hydrothermal Alteration 2023年4月20日 Required equipment for feldspar processing Depending on the type of feldspar being processed and the desired end result, we may require a variety of equipment In the process of feldspar processing, we often use the following equipment: Crushers: Used to break up big feldspar boulders into smaller particles for subsequent processingหลายขั้นตอนและอุปกรณ์ 1127 Feldspar Processing 11271 General1 Feldspar consists essentially of aluminum silicates combined with varying percentages of potassium, sodium, and calcium, and it is the most abundant mineral of the igneous rocks The two types of feldspar are soda feldspar (7 percent or higher Na2 O) and potash feldspar (8 percent or higher K2 O)(PDF) Feldspar Processing meret meret Academia

A Comparative Study of Quartz and Potassium Feldspar Flotation Process

suggest that HF plays an essential role in the process, and different possible mechanisms have been proposed [18] This occurs because HF removes positively charged cations from the feldspar surface while depositing fluoride ions [15] As a result of this mechanism, feldspar tends to be effectively depressed in the presence of collectorsThis process involves several stages, including crushing, grinding, magnetic separation, flotation, etc Magnetic separation removes ironcontaining minerals from the ore, while froth flotation helps separate feldspar particles based on surface characteristics JXSC can custom mineral processing plants, equipment and maximize mineral recovery rateAnalysis Of The Fine Crystal Rock Feldspar Ore Beneficiation Process2 Flotation Process The flotation process involves adding reagents to the pulp, causing physical and chemical changes on the surfaces of potassium feldspar and iron impurities to achieve separationExploring Various Processes for Iron Removal from Potassium FeldsparFeldspar Feldspar is the most important rockforming mineral of surface rocks Feldspar is a general term for the feldspar minerals It is a common class of aluminosilicatebased rock minerals containing calcium, sodium and potassium Feldspar is an aluminosilicate mineral containing calcium, sodium and potassiumfeldspar grinding mill, feldspar grinding machine, feldspar processing

.jpg)

1127 Feldspar Processing

1127 Feldspar Processing 11271 General1 Feldspar consists essentially of aluminum silicates combined with varying percentages of potassium, sodium, and calcium, and it is the most abundant mineral of the igneous rocks The two types of feldspar are soda feldspar (7 percent or higher Na O) and potash feldspar (8 percent or higher K O)2024年2月4日 An improved method for producing highpurity quartz (Qtz) and potassium feldspar (Kfs) concentrates was developed using various chemical reagents Froth flotation experiments on a Qtz–Kfs mixture showed that quartz could be selectively floated from Kfs in diluted hydrofluoric acid (HF) using a frother Similarly, feldspar could be selectively floated A Comparative Study of Quartz and Potassium Feldspar Flotation Process Feldspar Processing Plant Feldspar is a mineral that primarily contains iron minerals, along with impurities such as clay, quartz, mica, garnet, beryl, By customizing the processing plant and equipment accordingly, it becomes Feldspar Processing Plant Zoneding MachineThe plant is configured for dry feeding, composed of bulk feed hopper (22 x 28 x 10) meters, designed for feeding by earth moving equipment Ore is continuously transported by screw conveyor with capacity of 30 TPH and 10 meters length to high pressure grinding mill with maximum feed size (30 mm) and discharge output of 150 mesh (0105 mm)DIATOMITE FELDSPAR DRY PROCESSING PLANT THAILAND 2024 DOVE Equipment

.jpg)

What are the uses of potassium feldspar? What equipment is

2022年5月7日 Potassium feldspar is a potassiumrich silicate mineral with the advantages of low melting point, long melting interval and high melt viscosityIt is one of the main production raw materials in the glass and ceramic industries The main raw material of potash fertilizer can be widely used in industrial fields such as processing and extracting potash fertilizer, and it is an EMISSION FACTOR DOCUMENTATION FOR AP42 SECTION 827 Feldspar Processing 1 INTRODUCTION The document Compilation of Air Pollutant Emission Factors (AP42) has been published by the Reference 4 was not used in calculating emission factors because of problems with equipment failures and high sampling velocities that resulted in data of Emission Factor Documentation for AP42 Section 827 Feldspar Processing2024年11月21日 3 Acid Leaching Process The acid leaching process is a method of using acid to selectively dissolve ironbearing minerals and remove iron from feldspar It is an effective method to process feldspar containing impurities embedded in the Which Processes Remove Impurities In Feldspar? JXSC JXSC Potassium feldspar mining equipment mainly include jaw crusher, ball mill, desliming bucket, hydrocyclone, strong and week magnetic separator, flotation cell, etc the main process is curshingmillingmagneticflotation, etc 1 Crushing: firstly, use the jaw crusher to crush massive ore 2 Ball mill: after crushing, use ball mill to grind ore 3Potassium feldspar process flowsheet Yantai Jinpeng Mining equipment

.jpg)

feldspar mining process, feldspar processing plant, beneficiation

【Process Introduction】 Feldspar is a kind of silicate minerals which contains calcium, sodium and potassium, there are many categories of Feldspar including albite, anorthite, Mineral Processing EPC and Equipment Tel: +33 Email: xhxu@xinhaimining2019年6月25日 The feldspar separation process through gravity separation, It is definitely an effective machine for dressing highgrade feldspar products, but the equipment cost and operation cost are higher than that of other magnetic separators 4 Flotation Flotation is an effective way to remove impurities in feldsparFeldspar Beneficiation Process Magnetic Flotation JXSC We are a Professional Feldspar processing plant manufacturer,Our Feldspar processing plant has been exported 167 countries,Click here to get price ! Feldspar processing equipment Typically, jaw crusher is used in the primary crushing, and the Feldspar stone processing plant sbmchina