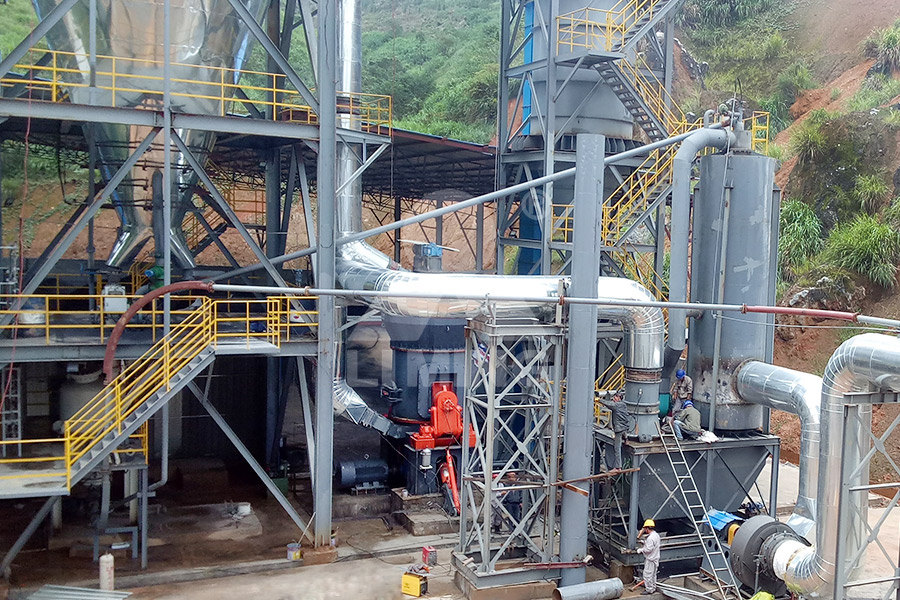

HOME→The market prospects for processing blast furnace slag by Liming Heavy Industry grinding machine are broad

The market prospects for processing blast furnace slag by Liming Heavy Industry grinding machine are broad

Comprehensive utilisation of blast furnace slag Taylor Francis

2023年7月21日 There is a technology abroad that can use for blast furnace slag to produce glassceramic products, the preparation of highgrade, highstrength, high valueadded glass 2023年6月1日 GBFS is a byproduct produced in the ironmaking process, where a mixture of iron ore, coke and limestone is reacted in a blast furnace at 1500°C, and the iron oxides in the Synergistic utilization of blast furnace slag with other industrial introduce the current status quo of comprehensive utilisation of blast furnace slag from the current blast furnace slag sensible heat recovery of molten steel 1 Overview of blast furnace Comprehensive utilisation of blast furnace slag Taylor Francis 2019年1月1日 In this regard, this review study aims to provide an overview of and a collective approach to various uses of blast furnace and steelmaking slag in diverse applications and An Overview of Utilization of Blast Furnace and Steelmaking Slag

2 µm 5 µm Loesche

Grinding of cement clinker and granulated blast furnace slag in roller grinding mills (vertical airswept grinding mills) is a technology introduced by Loesche The first use of a Loesche mill, 2023年12月6日 The CO 2 intensive blast furnace/basic oxygen furnace (BOF) route will be substituted by a combination of a Direct Reduced Iron plant (based on natural gas, at later Today's and future slags Potentials and Challenges Wiley 2019年12月9日 In this paper, the slag granulation and heat recovery options are reviewed and given a critical evaluation, aiming to provide a basis for future directions in slag handling The Granulation and Heat Recovery from Metallurgical Slags5 天之前 In this study, blast furnace slag (BFS), feldspar, and waste glass were recovered to manufacture glassceramic foams, without the use of additional foaming agents The impacts Innovative Conversion of Blast Furnace Slag into GlassCeramic

Synergistic preparation of highperformance composite blast

2024年1月12日 To address these challenges, this paper aimed to prepare highperformance composite blast furnace slag powder (CBFS) by incorporating red mud (RM), fly ash (FA), Industries We serve a wide range of industries internationally, including the automotive, appliance, packaging, and energy sectors Our innovations and highquality steel products are suitable for the most demanding applications such Using blast furnace slags sustainably thyssenkrupp 2016年8月31日 In last 5 years, an enhancement of over 18% for blast furnace slag and basic oxygen furnace slag has been achieved (GOI, 20132014) By continuing t hrust on so lid waste consumption at the Steel Slag Utilization — Overview in Indian 2022年3月31日 Inordinate levels of heavy metals in water sources have long been a matter of concern, posing serious environmental and public health risks Adsorption, on the other hand, is a viable technique for removing heavy metals from water due to its high efficiency, low cost, and ease of operation Blast furnace slag (BFS) is considered a cheap sorbent for the get rid of From waste to waste: iron blast furnace slag for heavy metal ions

.jpg)

Slag; Value Added Steel Industry Byproducts ResearchGate

2010年12月1日 Iron and steel making slag is classified as BF (Blast Furnace) slag or steelmaking slag, It obviously consists of silicates, alumina silicates, calcium aluminum silicates, iron oxides and 2019年7月15日 Slag structure, compositional effects, role of cations in structural modifications, parameters used to represent the structure, structural analysis techniques and effects of structure on (PDF) Understanding the Structure and Structural Effects on 2022年7月18日 Building manufacturing has played a significant part in the urbanization and industrialization that has occurred in recent decades Approximately 5–10% of global employment is provided by the construction industry, which also accounts for 5–15% of national GDP []About 40% of overall energy use and 30% of total natural resource depletion are attributed to the A Comprehensive Review on the Ground Granulated Blast Furnace Slag 2000年9月1日 Download Citation Granulated blast furnace slag grinding The characteristics of granulated blast furnace slags are compared with the properties of conventional Portland cement clinker Granulated blast furnace slag grinding ResearchGate

.jpg)

GGBFS Market Growth, Trade, Reports, Size Forecast 2035

The global Granulated Ground Blast Furnace Slag (GGBFS) market has reached around 408 million tonnes in 2022 and is expected to grow at a CAGR of 223% during the forecast Granulated Ground Blast Furnace Slag (GGBFS) Market Analysis: Industry Market Size, Plant Capacity, Production, Operating Efficiency, Demand Supply, EndUser Industries Highperformance slag glass–ceramics were prepared by melting method using rare earthcontaining blast furnace slag as the main raw material and Fe2O3 and Cr2O3 as composite nucleating agents The influence of ZnO on the structure and properties of glass–ceramics was studied by changing the addition amount of ZnO The existence state and solidification Preparation of glass–ceramics from blast furnace slag and its heavy 2020年7月20日 Carbide slag (CS) is the solid waste generated in the process of acetylene production and mainly contains Ca(OH) 2 and CaCO 3 as well as small amounts of MgO, SiO 2, Al 2 O 3, Fe 2 O 3 [49], [50]With the increase of acetylene demand, the emission of carbide slag is growing continuously and it is estimated that around 56 × 10 7 tonnes are produced Utilization of carbide slaggranulated blast furnace slag 2018年1月1日 Blast furnace slag (BFS) which is defined “as the nonmetallic product consisting essentially of silicates and alumina silicates of calcium and other bases, that is developed in a molten condition simultaneously with iron in a blast furnace” by ASTM C 12516 (2016) has been widely used in construction industry for more than 80 years When the mixture of ironore, Blastfurnace slag ScienceDirect

Furnace Slag an overview ScienceDirect Topics

Cement additives Johannes Fink, in Petroleum Engineer's Guide to Oil Field Chemicals and Fluids (Third Edition), 2021 Furnace slag A furnace slag cement slurry can have a density of 15001600 kg m −3A combination of silica flour and furnace slag may be used to achieve service temperatures exceeding 200 °C [100]A gas may be suitable as a foaming agent [101]Blast Furnace Slag You find here 12 suppliers from Germany Austria and Switzerland Please obtain more information on spare parts, servicing, Light Alloy Processing 159; Metal Industry 7,988; Metal Plants 10; Metal Processing 1,097; Metal Processing Facilities 64; Metal Systems 7; Metal plant 1; Metal reinforcement 2;Blast Furnace Slag Manufacturers, Traders, Suppliers2020年3月5日 Over the last few decades, the European steel industry has focused its efforts on the improvement of byproduct recovery and quality, based not only on existing technologies, but also on the Reuse and Recycling of ByProducts in the Steel Sector: Recent Market Overview: The global iron and steel slag market is expected to grow at a CAGR of 55% during the forecast period from 2018 to 2030 The market growth can be attributed to the increasing demand for steel in developing countries, growing construction and infrastructure activities, and rising awareness about the benefits of using slag as a fertilizerIron and Steel Slag Market Report Global Forecast To 2028

43.jpg)

Discussion of blast furnace slag recycling of a factory IEEE

A large amount of solid waste slag is generated in the production process in iron and steel enterprises As for enterprise which takes blast furnace as the process, blast furnace slag accounts for more than 50% Blast furnace slag disposal has experienced the following development: as a waste treatment, use in subgrade and foundation engineering, to the stage 2020年11月29日 The synthetic slag containing 268 % CaO, 381 % SiO 2 , 118 % Al 2 O 3 , 236 % MgO, simulating composition of slag from MMK blastfurnace smelting with the addition of 30 % of burnt siderites FactSage Studies to Identify the Optimum Slag Regime for Blast Furnace Crusher,Grinding,Mobile Crusher,Stone Production Line Henan Liming Heavy Industry Science Technology Co,Ltd VSI Sand Making Machine; Hydraulic Cone Crusher; PCL Sand Making Machine; Spring Cone Crusher; CS Series Cone Crusher; Crusher,Grinding,Mobile Crusher,Stone Production Line Liming heavy 2024年11月11日 The global steel slag market size was valued at USD 2566 billion in 2022 and is projected to grow from USD 2683 billion in 2023 to USD 3828 billion by 2030, exhibiting a CAGR of 52% during the forecast periodSteel Slag Market By Type By Application Report [2030]

2 µm 5 µm Loesche

2006 The 100th Loesche mill for grinding cement and granulated blast furnace slag was sold worldwide 2007 More than 140 Loesche mills for grinding cement and granulated blast furnace slag were sold worldwide Central grinding plant for granulated blast furnace slag LM 462+2, Dunkerque, France, 2005 22013年1月1日 The glassy state of blast furnace slag (the most common representative of the metallurgical slags) can serve as a source of silicon, but also of heavy metals, which can be efficiently leached out (PDF) Mechanochemical Processing of Blast Furnace SlagRequest PDF On Jan 1, 2018, Isa Yuksel published Blastfurnace slag Find, read and cite all the research you need on ResearchGateBlastfurnace slag Request PDF ResearchGate2020年3月1日 This study investigates the use of carbide slag (CS), an industrial byproduct generated in acetylene production, as a potential alternative to hydrated lime (HL) for activation of ground Use of carbide slag from acetylene industry for activation of

A zerowaste approach to blast furnace slag by synthesis of

2019年8月23日 Nanosilica has a number of properties that pose advantages in a range of applications In this study, we performed a series of experiments to prepare nanosilica particles from blast furnace slag The collected samples were initially treated using nitric acid to remove insoluble silica, and the influence of various key factors on the silica extraction efficiency was 2020年11月1日 Rotary kiln electric furnace (RKEF) is a wellproven technology for smelting nickel laterite into ferronickel [6] The process consisted of ore drying in a rotary dryer, as expressed in reaction Control of slag formation in the electric furnace smelting of 2016年2月5日 The quality of raw materials (iron ore, coal, and coke) has a clear impact on the carbon emissions of the hot metal production in steel making So far, very little work has been done to measure and quantify this impact Yet for benchmarking, technology choice and general carbon optimization are important elements The total slag production of a blast furnace gives The Carbon Cost of Slag Production in the Blast Furnace: A2014年5月1日 At the same time, Japan, the United States and some European countries also carried out many studies on fly ashbased mineral fiber [4] In China, related research started in the 1990s [5], after (PDF) Preparation of Slag Wool by Integrated WasteHeat

Identification of the Elemental Composition of Granulated Blast Furnace

2022年10月22日 Blast furnace slag is a key largetonnage waste product of metallurgical production, which is considered to be a promising alternative material in construction In order to determine the scope of potential use of slag as a marketable product, it is necessary to study its structure and composition, which is determined by means of modern analytical instrumental 2019年2月28日 The utilization of GBFS provides a large number of benefits that facilitate the improvement of durability, reduction of hydration heat, increment of compactness and conservation of energy and resources [8], [9], [10]However, cementitious materials with GBFS have certain disadvantages in comparison to cement without mineral admixture, such as Efficiency of wetgrinding on the mechanochemical activation of 2020年7月1日 In this study, granulated blastfurnace slag was treated by wet grinding to promote its reactivity (ie WGGBS), and carbide slag (CS), one kind of industrial wastes, was used as the alkaliUtilization of carbide slaggranulated blast furnace slag system Industries We serve a wide range of industries internationally, including the automotive, appliance, packaging, and energy sectors Our innovations and highquality steel products are suitable for the most demanding applications such Using blast furnace slags sustainably thyssenkrupp

Steel Slag Utilization — Overview in Indian

2016年8月31日 In last 5 years, an enhancement of over 18% for blast furnace slag and basic oxygen furnace slag has been achieved (GOI, 20132014) By continuing t hrust on so lid waste consumption at the 2022年3月31日 Inordinate levels of heavy metals in water sources have long been a matter of concern, posing serious environmental and public health risks Adsorption, on the other hand, is a viable technique for removing heavy metals from water due to its high efficiency, low cost, and ease of operation Blast furnace slag (BFS) is considered a cheap sorbent for the get rid of From waste to waste: iron blast furnace slag for heavy metal ions 2010年12月1日 Iron and steel making slag is classified as BF (Blast Furnace) slag or steelmaking slag, It obviously consists of silicates, alumina silicates, calcium aluminum silicates, iron oxides and Slag; Value Added Steel Industry Byproducts ResearchGate2019年7月15日 Slag structure, compositional effects, role of cations in structural modifications, parameters used to represent the structure, structural analysis techniques and effects of structure on (PDF) Understanding the Structure and Structural Effects on

A Comprehensive Review on the Ground Granulated Blast Furnace Slag

2022年7月18日 Building manufacturing has played a significant part in the urbanization and industrialization that has occurred in recent decades Approximately 5–10% of global employment is provided by the construction industry, which also accounts for 5–15% of national GDP []About 40% of overall energy use and 30% of total natural resource depletion are attributed to the 2000年9月1日 Download Citation Granulated blast furnace slag grinding The characteristics of granulated blast furnace slags are compared with the properties of conventional Portland cement clinker Granulated blast furnace slag grinding ResearchGateThe global Granulated Ground Blast Furnace Slag (GGBFS) market has reached around 408 million tonnes in 2022 and is expected to grow at a CAGR of 223% during the forecast Granulated Ground Blast Furnace Slag (GGBFS) Market Analysis: Industry Market Size, Plant Capacity, Production, Operating Efficiency, Demand Supply, EndUser Industries GGBFS Market Growth, Trade, Reports, Size Forecast 2035Highperformance slag glass–ceramics were prepared by melting method using rare earthcontaining blast furnace slag as the main raw material and Fe2O3 and Cr2O3 as composite nucleating agents The influence of ZnO on the structure and properties of glass–ceramics was studied by changing the addition amount of ZnO The existence state and solidification Preparation of glass–ceramics from blast furnace slag and its heavy

.jpg)

Utilization of carbide slaggranulated blast furnace slag

2020年7月20日 Carbide slag (CS) is the solid waste generated in the process of acetylene production and mainly contains Ca(OH) 2 and CaCO 3 as well as small amounts of MgO, SiO 2, Al 2 O 3, Fe 2 O 3 [49], [50]With the increase of acetylene demand, the emission of carbide slag is growing continuously and it is estimated that around 56 × 10 7 tonnes are produced