Dry gypsum powder coating

When to Use Setting Compounds vs Ready Mix

2022年7月30日 Ready mix, often called drywall mud, consists of gypsum powder and a vinyl base, and is the most used drywall finishing product Drywall finishers spread it to fill seams, nail holes and other gaps in drywall to create a 2019年8月30日 Silica of different types was used to treat the surface of gypsum particles Hydrophobic nanosilica effectively enhanced the flowability of gypsum powder The quality of gypsumbased products was improved in the field of 3DPP 3D powder printing (3DPP) Effect of different silica particles on flowability of gypsum powder 2014年1月1日 This chapter includes a brief history of gypsum plasters Then, several types of gypsumbased coatings are presented Gypsum plasters’ performance characteristics, in fresh and hardened state, are described, focusing on requirements, testing methods andGypsum Plasters SpringerLinkFor quality control of ground, fine powder coating in the laboratory, HELOS laser diffraction with RODOS dry dispersion is used Pressurized air dispersion and measurement of the free aerosol jet delivers reliable, reproducible measuring Powder Coating Sympatec

.jpg)

Gypsum Powder Boero USA

The Boero Water Resistant, Gypsum Powder is the perfect finishing product for bare sheetrock installed in high humidity and coastal environments This coating is compatible with waterbase primers and paintsPowder coating is a surface finishing technique that applies a dry polymer or ceramic powder to a part via an electrostatic charge Unlike traditional liquid paints, powder coating does not require solvents to keep a liquid suspension of binder and filler parts and is instead cured either Powder Coating: Definition, Importance, and the Different TypesUSG Industrial Gypsum Product Catalog 5 ARCHITECTURAL ORNAMENTATION • Highstrength gypsum cement specially formulated for use with glass fiber for fabricating glassreinforced architectural details • Exceptionally quick setting; accepts most coatings and USG Industrial Gypsum Product Catalog (English) IG5146EASYCOAT 30 SettingType Gypsum Powder is a setting interior use compound specially formulated for applying onto gypsum board, precast wall, masonry wall and ceiling Its unique formulation consists of gypsum plaster mixed together with special additives to provide high EASYCOAT 30 SETTINGTYPE

.jpg)

Gypsum Dry Mortar Cement Additives Sika

Gypsum Gypsum, chemically known as calcium sulphate dihydrate, is one of the most important minerals used in the production of construction materials Today, the majority of gypsum binder, socalled calcined gypsum, is used for the Or, you can browse our documents section for your powder Transfer Efficiency: percentage (1100%) that your powder will adhere to your part Mil Thickness: number used to determine how many "mils" or how thick your coating will be Cost per lb (optional): financial cost of powder per 1 lb Shown on each of our powder product pagesPowder Coating Coverage Calculator Cost per Sq/Ft Prismatic 2022年8月28日 It’s a gypsumbased mix that connects drywall seams and corner beads, mud on this list However, it makes for a good finishing coat and is often used for texture applications and skim coating DAP Fast Patch Fast Drying Joint Compound, Choosing the Right Ready mix, often called drywall mud, consists of gypsum powder and a vinyl base, and is the most used drywall finishing product Drywall finishers spread it to fill seams, nail holes and other gaps in drywall to create a desired finish as a base for paint, wallpaper or wall textureWhen to Use Setting Compounds vs Ready Mix National Gypsum

43.jpg)

Color dry powder coating system Supply Drymixed mortar

Color dry powder coating is suitable for painting industrial and civil buildings’ interior and exterior walls, gypsum boards, GRC boards, and lightweight concrete wallboards (3) Construction technology Color dry powder paint is usually packaged in 20kg powder bags When using it, first add about 14kg of water into a clean container2024年2月25日 Powder coating is a popular and effective method of adding durability and aesthetic appeal to various products It involves applying a dry powder to a surface and then curing it under heat to create a hard and protective coating However, even with careful application, defects can occur during the powder coating process8 Powder Coating Defects And Causes and Solutions2018年3月14日 Gypsum plaster is produced by heating the gypsum to about 150 °C: CaSO42H2O + heat → CaSO405H2O + 15H2O (released as vapor) The chemical reaction that occurs when plaster is mixed with water is exothermic When the plaster hardens, it can reach temperatures above 60 °C When dry gypsum powder is mixed with water, it reforms Gypsum Plaster / Plaster of Paris iDesignWiki2015年3月9日 Reliant Finishing Systems specializes in manufacturing highperformance powder coating supplies – powder coating booths, curing ovens and related equipment With years of experience, dedicated engineers on staff and redundant US production lines, Reliant can provide you with the perfect powder coating equipment for your businessPowder Coating Equipment Reliant Finishing Systems

.jpg)

GYPSUM POWDER (WATER RESISTANT) TECHNICAL DATA SHEET

GYPSUM POWDER (WATER RESISTANT) TECHNICAL DATA SHEET STUCCO IN POWDER FORM FOR SKIM COATING AND USE AS A FILLER • White lime cementbased stucco in powder form for use as a filler and for skim coating walls, DRYING Touch dry: 12 hours (at 70°F and 65% HR) Fully dry: 24 hours2022年2月1日 Dry coating [14], being a solventless coating technique of pharmaceutical drug dose structures, has been broadly explored as an option in contrast to liquid coating [15, 16]As of now, the dry coating has been created an elective innovative coating technique, whereby the core particles are coated straightforwardly with coating powder particlesAn overview on dry powder coating in advancement to electrostatic dry We provide Custom Powder Coating solutions! Custom Cutters Powder Coating process is proud to offer over 6,000 colors and textures for our customers to choose from Our ovens, sizes 8’Hx10’Wx20’L and 8’Hx11’Wx31’L, are Custom Cutters Mount Vernon, OH Metal FabricatorsSupplying top quality Plaster of Paris and Gypsum Powder to contractors and developers in UAE Inquire from us Today Tel: 04 220 8220 It is used for coating walls and ceilings and also for creating architectural designs Plaster BHMK Plaster of Paris / Gypsum Powder

What is the use of Powder Coating? BuildersMART

2019年12月6日 Powder coating is a finishing process that consists of dry powder being used as a surface coating Unlike paint, that takes a while to dry after being applied, powder coating is electrostatic, and can be applied 2 Technical Advice Measuring Dry Film Thickness (DFT) of Powder Coatings What is dry film thickness (DFT)? Dry film thickness (DFT) is the thickness of a coating as measured above the substrate This can consist of a single layer or multiple layers DFT measures the total (not the individual layers) DFT is measured on curedPowder Coaintgs Measuring Dry Film Thickness of Powder Coatings2021年12月8日 Difficulty was experienced with the production scaleup of true dryondry powder coatings processes due to the interspersion of disparate powder particles (primer and topcoat) during application Recently powder manufacturers have finessed this concept into a four step process consisting of: 1New Trends in Powder Coatings > Powder Coated Tough The technology for coating products with dry powder rather than conventional liquids has been available since the 1950s The powder used for the process is a mixture of finely ground particles of pigment and polymeric resin The powder is either: Sprayed electrostatically onto a Powder Coatings: Process, Types, Benefits Application

.jpg)

Ready Mixed Jointing Compound vs Powder Gypsum Tools

2023年11月30日 Since powder jointing compound is stored in a dry, powdered form, it takes up less space and generally has a longer shelf life compared to ready mixed This means large quantities of dry powder can be neatly stored for extended periods without degrading CostEffective Powder jointing compound tends to be cheaper than its ready mixed counterpartsWe provide the highquality gypsum powder to buy online Also, contact for One Coat gypsum Coating Thickness: 115mm: Water to Material Ratio: 1 : 15: Coverage (1kg) 075 080 sqft with 15mm Thickness: Shelf Life: 12 months From the date of manufacturing, when stored is dry conditions (*All tested results are under lab condition Gypsum Plaster Gypsum Manufacturers, Suppliers Dealers in Joint compound – also known as drywall mud – is a gypsumbased mixture that helps give your wall a seamless look by securing drywall tape, sealing the joints between the drywall panels and covering up nails and screw heads Compare the different kinds of joint compound available to find the right one best suited for your applicationJoint Compound The Home DepotHeatsensitive carbon fiber tubes coated with a UV curable powder coating Powder coating is a type of coating that is applied as a freeflowing, dry powderUnlike conventional liquid paint, which is delivered via an evaporating solvent, powder coating is typically applied electrostatically and then cured under heat or with ultraviolet lightPowder coating Wikipedia

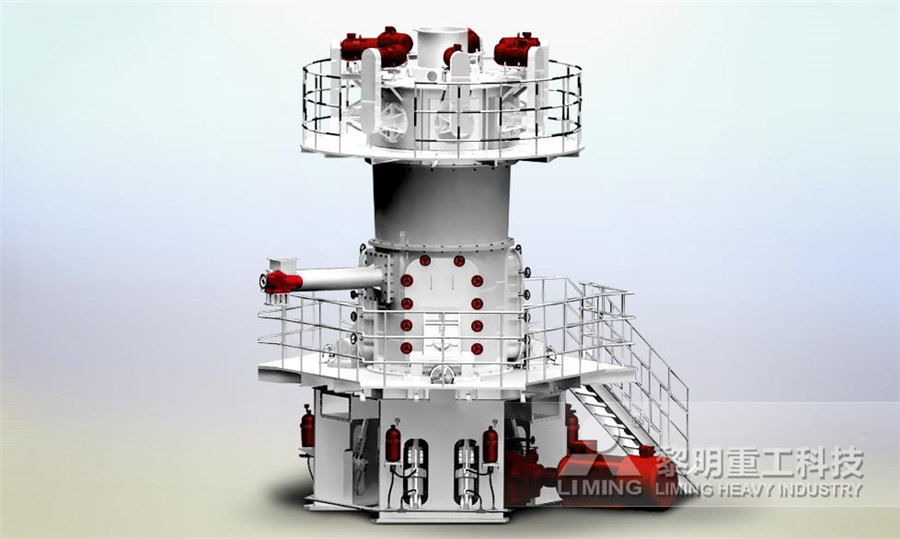

CFB石灰石脱硫剂制备——磨机公众号12.8 推送案例(8)53.jpg)

Efficient Gypsum Mixing Drying Solutions

Discover Hosokawa Micron's cuttingedge mixing and drying solutions for production of gypsum powder, ideal for fertilizers, construction materials, GCC – HIGHLY PROFITABLE – Fully Optimized Coating; GCC – HIGHLY 2024年2月21日 Powder coating has revolutionized the finishing industry with its durability, versatility, and ecofriendliness Unlike traditional liquid coatings, powder coating is applied as a dry powder and cured to form a protective finishPowder Coating Explained: Colors, Ingredients and Although they have different beginnings – natural gypsum is extracted from mines, while synthetic gypsum is produced as a byproduct of industrial waste or energy – both are crushed into a fine powder before undergoing pelletization The Basics of Drying Gypsum FEECO International Inc2011年10月2日 Efficient handling and transport of fineparticle powders can be difficult because of the highly cohesive nature of the bulk powder mass It is well reported in the literature that the application of nanosized guest dry powder coatings, such as silicon dioxide, onto the surfaces of these cohesive host particles can effectively reduce the attractive forces between them (1–5)Applying Dry Powder Coatings PharmTech

Gypsum Plaster Best Plaster for Walls and Ceilings Magicrete

The superior quality gypsum contained in Magicrete Gypsum Plaster requires only a single coating White Powder; Pot Life 12mins 15mins; Dry Bulk Density 900 Kg/m 3 650710 kg/m 3; Initial Setting Time 1012 mins 1215mins; Coverage at Thickness 13mm 1820 sqft / bag of 25kg 2224 Sqft/bag of 25kg;How To Powder Coat? Understanding the Powder Coating Process Steps Powder coating is a dry finishing process that involves the application of fine, electrostatically charged powder particles to a substrate's surface This application method ensures an even and consistent coating, free from drips, sags, or unevennessPowder Coating Process Explained – A Detailed Breakdown2020年11月5日 The objective of modern seedcoating technology is to uniformly apply a wide range of active components (ingredients) onto crop seeds at desired dosages so as to facilitate sowing and enhance crop performance There are three major types of seed treating/coating equipment: dry powder applicator, rotary pan, and pelleting pan with the provisions to apply Modern Seed Technology: Seed Coating Delivery Systems for2013年2月18日 Download Citation Dry Powder Coating of Pharmaceuticals: A Review Over the last half century, film coating technology has evolved significantly in terms of compositions and manufacturing Dry Powder Coating of Pharmaceuticals: A Review

.jpg)

Everything You Need to Know About Powder Coating ABITL

2019年9月19日 Powder coatings are applied as a dry powder using an electrostatic process before being cured with heat They are known for providing a highquality finish, both when it comes to the overall look and functionality of a piece These coatings are known for their sturdiness and flexibility2023年11月3日 The results suggest that 10% gypsum replacement by silica flour or talc powder modifies gypsum’s physical and gypsum powder and talc powder (or silica flour) were drymixed well for 1 min in a lab mixer at "Physicomechanical Properties of Gypsum with Mineral Additions at Elevated Temperatures" Coatings 13, no 12: 2091 Physicomechanical Properties of Gypsum with Mineral Additions Gypsum Gypsum, chemically known as calcium sulphate dihydrate, is one of the most important minerals used in the production of construction materials Today, the majority of gypsum binder, socalled calcined gypsum, is used for the Gypsum Dry Mortar Cement Additives SikaOr, you can browse our documents section for your powder Transfer Efficiency: percentage (1100%) that your powder will adhere to your part Mil Thickness: number used to determine how many "mils" or how thick your coating will be Cost per lb (optional): financial cost of powder per 1 lb Shown on each of our powder product pagesPowder Coating Coverage Calculator Cost per Sq/Ft Prismatic

Fast Drying Joint Compound, Choosing the Right

2022年8月28日 It’s a gypsumbased mix that connects drywall seams and corner beads, mud on this list However, it makes for a good finishing coat and is often used for texture applications and skim coating DAP Fast Patch Ready mix, often called drywall mud, consists of gypsum powder and a vinyl base, and is the most used drywall finishing product Drywall finishers spread it to fill seams, nail holes and other gaps in drywall to create a desired finish as a base for paint, wallpaper or wall textureWhen to Use Setting Compounds vs Ready Mix National GypsumColor dry powder coating is suitable for painting industrial and civil buildings’ interior and exterior walls, gypsum boards, GRC boards, and lightweight concrete wallboards (3) Construction technology Color dry powder paint is usually packaged in 20kg powder bags When using it, first add about 14kg of water into a clean containerColor dry powder coating system Supply Drymixed mortar 2024年2月25日 Powder coating is a popular and effective method of adding durability and aesthetic appeal to various products It involves applying a dry powder to a surface and then curing it under heat to create a hard and protective coating However, even with careful application, defects can occur during the powder coating process8 Powder Coating Defects And Causes and Solutions

Gypsum Plaster / Plaster of Paris iDesignWiki

2018年3月14日 Gypsum plaster is produced by heating the gypsum to about 150 °C: CaSO42H2O + heat → CaSO405H2O + 15H2O (released as vapor) The chemical reaction that occurs when plaster is mixed with water is exothermic When the plaster hardens, it can reach temperatures above 60 °C When dry gypsum powder is mixed with water, it reforms 2015年3月9日 Reliant Finishing Systems specializes in manufacturing highperformance powder coating supplies – powder coating booths, curing ovens and related equipment With years of experience, dedicated engineers on staff and redundant US production lines, Reliant can provide you with the perfect powder coating equipment for your businessPowder Coating Equipment Reliant Finishing SystemsGYPSUM POWDER (WATER RESISTANT) TECHNICAL DATA SHEET STUCCO IN POWDER FORM FOR SKIM COATING AND USE AS A FILLER • White lime cementbased stucco in powder form for use as a filler and for skim coating walls, DRYING Touch dry: 12 hours (at 70°F and 65% HR) Fully dry: 24 hoursGYPSUM POWDER (WATER RESISTANT) TECHNICAL DATA SHEET 2022年2月1日 Dry coating [14], being a solventless coating technique of pharmaceutical drug dose structures, has been broadly explored as an option in contrast to liquid coating [15, 16]As of now, the dry coating has been created an elective innovative coating technique, whereby the core particles are coated straightforwardly with coating powder particlesAn overview on dry powder coating in advancement to electrostatic dry