Highfine vertical mill dianlutu working principle

.jpg)

Vertical roller mill for raw Application p rocess materials

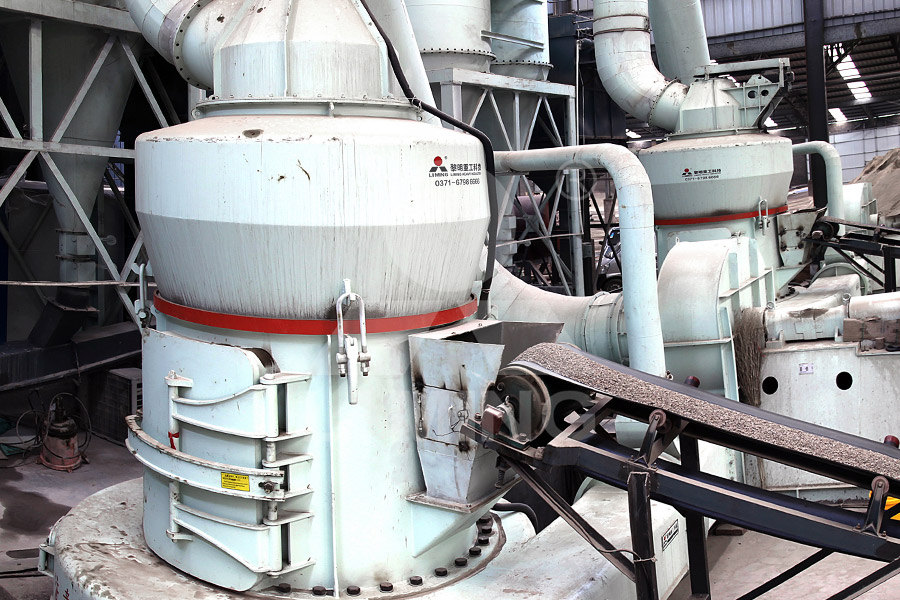

Vertical roller mills are adopted in 20 cement plants (44 mills) in Japan In the vertical roller mill which is widely used in the raw material grinding process, raw materials input grinding table are crushed and pulverized on it and transported to separator by kiln exit gas introduced into the 2022年5月31日 The vertical roller mill (VRM) is commonly used for secondary and tertiary crushing processes in numerous industries In this study, the discrete element method (DEM) Analysis of vertical roller mill performance with changes in material a vertical roller mill (VRM) • Surpasses the classic methods if the controlled process demonstrates significant disturbances • A high degree of attention to the process states is required in order PROCESS OPTIMISATION FOR LOESCHE GRINDING PLANTS11 The Working Principle of Vertical Mill The material enters the vertical mill from the upper feed inlet, the material is sent between the grinding roller and the grinding disc by the sealing Solid Edge’s Application in Vertical Mill Design Springer

(PDF) Performance Evaluation of Vertical Roller Mill in

2017年9月11日 Grinding and separation efficiency of vertical roller mill were evaluated In addition to these, performance figures of vertical roller mill and conventional closed ball mill Vertical stirred milling is a wellrecognized technology for the secondary, regrind and fine grinding applications and are increasingly replacing coarser ball mill applications in secondary and RECENT DEVELOPMENTS IN COARSE GRINDING USING VERTICAL 2019年4月16日 The paper demonstrates why the Loesche VerticalRollerMill (VRM) is a serious alternative to conventional grinding technologies and where the limitations of the system are (PDF) LEARNING FROM OTHER INDUSTRIES; WHY THE VRM2017年4月1日 In this study, pilot scale tests were performed with a mobile verticalrollermill grinding plant to investigate the relationships between operational parameters The Operational parameters affecting the vertical roller mill

Roller Mill SpringerLink

2024年1月1日 Structure diagram of vertical roller mill Working principle: the motor drives the grinding table to rotate through the reducer, the material falls into the center of the grinding Vertical roller mill is a type of grinder used to grind materials into extremely fine powder for use in mineral dressing processes, paints, pyrotechnics, cements and ceramics It is an energy Vertical roller mill WikipediaWhen a mill with a production capacity of 420 t/h was newly constructed, the total cost was about 25 million US$ [1US$=¥110] Related matters Reference Raw materials Vertical Fine product Mill circulation fan Raw Mill EP Raw Mill EP fan Chimney Kiln IDF (Kiln gas exhaust fan) Raw materials Fine product Chimney Vertical Raw Mill EP Raw Mill EP Vertical roller mill for raw Application p rocess materialsVertical Roller Mill Working Principle Finished products have high whiteness, fine particle size, narrow particle size distribution, and good particle sphericity The fineness D97 of the finished powder can reach 3000 meshes, and the Vertical Roller Mill SBM Ultrafine Powder Technology

Vertical Machining Center (VMC): Definition,

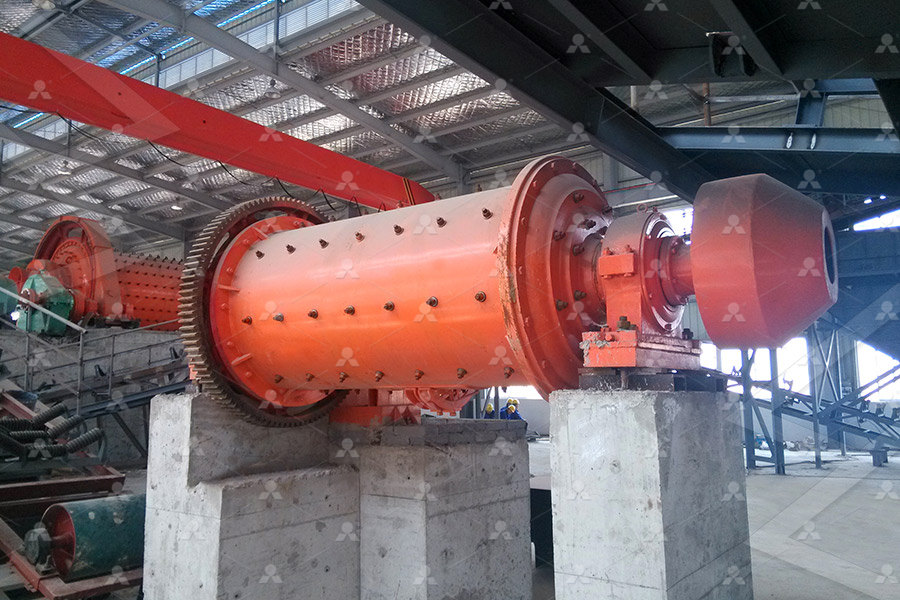

Introduction Vertical Machining Center: Definition, Components, Uses, Working Principle, Advantages Disadvantages: – The vertical machining center has existed for quite a while and stays a fundamental part of modern CNC 2022年3月30日 Various components and machines are used for grinding applications and that’s where highenergy ball mill comes into play Overview of Ball Mill Ball mill, also known as tumbling or pebble mill is milling equipment that encompasses cylindercontaining balls and is mounted on a metallic frame that can be rotated along with a longitudinal axisIntroduction to HighEnergy Ball Mill: Working Principle, Ultrafine vertical mill is a highefficient industrial grinding mill, be used to grind hard stones into ultrafine powder, like talc, mica, etc +17 [ protected]Ultrafine Vertical MillLimestone ultrafine vertical mill is a high quality ores material powder grinding mill +17 [ protected] Working Principle Of Limestone Ultrafine Vertical Mill HGM series Ultra Fine Powder Mill CLRM Series Enhanced Roller Grinding Mill YGM series Raymond Mill Hammer crusherLimestone Ultrafine Vertical Mill

.jpg)

Barite Ultrafine Vertical Roller Mill

Barite ultrafine vertical roller mill is an industrial vertical grinding mill that can grind nonmetallic ore into fine powder The mill has a high production capacity, high fine powder content +17 [ protected] Working PrincipleWorking Principle The ultrafine vertical mill is composed of several components, each of which plays a critical role in the operation of the machine And they must work together in harmony to produce highquality, ultrafine powder These components include: Grinding chamber, Agitator, Feed inlet, Discharge outlet, Motor, Calcium Carbonate Ultrafine Powder Vertical Mill2023年12月4日 New Vertical Boring Mill: Pros: Comes with the latest technology, warranty, and no wear and tear Cons: Can be significantly more expensive Used Vertical Boring Mill: Pros: More budgetfriendly and sufficient for less frequent or less demanding tasks Cons: Potential wear and tear, outdated technology, and usually no warranty Popular Brands Vertical Boring Mills: A Comprehensive Guide Machine Tool The coal vertical mill, also referred to as the vertical roller coal mill, is an advanced equipment developed by our company It combines modern technology with our extensive experience in powder manufacturing This coal pulverizer efficiently integrates coal grinding and drying, providing highperformance and energysaving featuresHighEfficiency Vertical Coal Mill Enhancing Coal Pulverization

.jpg)

Limestone Powder Ultrafine Vertical Roller Mill

Limestone Powder Ultrafine Vertical Roller Mill Modle : CLUM Series Finished Size: 4003000 mesh Processing Ability: 3 – 45t/h Max Feeding Size: 10 mm M 1 Set Price: $ Range Of Application: Limestone, 2024年10月31日 Ultrafine impact mill site picture The working principle of the ultrafine impact mill is as follows: After the material enters the machine body from the feed port at the bottom of the machine body, it is quickly broken up by the hammer head on the rotor, scattered around the stator, and enters the crushing area composed of the rotor and statorWorking principle of ultrafine impact mill JINGHUA2023年9月28日 The principle of fluid energy milling, also known as jet milling, involves using highvelocity jets of compressed gas (typically air or nitrogen) to grind and disperse particles into fine powders In fluid energy milling, the Working principle of jet millThe ultrafine vertical mill is currently the superlarge ultrafine grinding equipment in Asia, which has been successfully applied in the market and has mature technology It can replace imported equipment and is an ideal equipment for largescale production of ultrafine powder with high efficiency, high yield, environmental protection and energy savingTable Roller Mill Vertical Mill

Vertical roller mill Hengtu Machinery

The working principle of vertical roller mill: The graded fine powder that meets the fineness requirements is used as the finished product After the airflow is taken to the upper outlet of the casing and enters the dust collector, Brief description of vertical roller mill operation:The LM Vertical Grinding Mill, launched by ZENITH, integrates five functions of crushing, grinding, powder selection, drying and material conveying It is characterized by centralized technological process, small occupational area, low investment, high efficiency, energy conservation and environment protectionVertical Mill Shanghai Zenith CompanyCompared with the vertical sand mill, the horizontal sand mill has a relatively high price, but its advantages are also obvious • Grinding fineness From the perspective of grinding fineness, the grinding effect of horizontal sand mills is often better, which can meet the fineness requirements of Comparison of the vertical sand mill and horizontal sand millIt has outstanding characteristics such as high grinding efficiency, convenient maintenance, low operating cost, It can be used for largescale ultrafine dry powder processing of nonmetallic minerals such as calcite, marble, limestone, Working Principle of Ultrafine Vertical MillCalcium Carbonate Ultrafine Vertical Mill SBM Ultrafine

.jpg)

Activated Carbon Ultrafine Vertical Mill

The fine particles of the material ground by the ultrafine vertical mill are sorted, and the fineness range of the sorting is 2um45um A vertical mill can produce products of different specifications, and can also produce products of the same fineness quickly and stablyBall Mill, Working Principle, Types, Parts, Applications and Advantages Ball Mill Grinding Machines: Exploring the Working Principle, Types, Parts, Applications, Advantages, and Recent Developments Ball mill grinding machines are widely used in various industries for the comminution of materials into fine powdersBall Mill Grinding Machines: Working Principle, Types, Parts Setup: Before starting, secure the workpiece on the table and choose the appropriate cutting tool for the desired operation Tool Selection: Depending on the operation, select the suitable cutting tool and mount it on the spindle Milling Machine Working Principle And OperationsCyclone separators are utilised in many applications due to their low cost, simple design and high efficiency Cyclone separators require no bags or filters and require only low maintenance Dirty Filters A typical application would include Cyclone Separator Working Principle (Dust

.jpg)

LUM Ultrafine Vertical Mill: Working Principle and Efficiency

2024年2月29日 Working Principle: Feeding: Material is fed into the mill’s hopper and falls onto a rotating grinding disc at the bottom Grinding: The disc spins at high speed, creating a centrifugal force that pushes the material against a stationary grinding ring 2022年8月25日 The high pressure roller mill is the same as the roller crusher in that there are two working rollers, but the working principles of the two are different The high pressure roller mill is mainly composed of frame, extrusion roller, transmission device and feeding deviceWorking principle of high pressure roller mill LSmojv2013年4月12日 Muyang, as one of the best grinding machine manufacturers, provides large of great feed machinesNow, I am here to introduce SWFL82B vertical ultrafine pulverizer SWFL82B vertical ultrafine pulverizer is a new type of equipment for large, medium and smallsized feed mills to process various coarse ground materials after preliminary cleaning, Working Principle on Muyang Vertical Pulverizer Blogger2022年6月15日 The working principle of ultrafine Raymond mill adopts closedcircuit air circulation system, which has low noise, low energy consumption and easy maintenance The representative model is HCQ ultrafine Raymond mill, which can process hundreds of ores with a fineness of 600 meshThe working principle of ultrafine Raymond mill

Vertical Roller Mill Summary

Vertical Roller Mill Summary Free download as PDF File (pdf), Text File (txt) or view presentation slides online Ball mill vs vertical mill Operations Structure of a vertical mill Working Process Components Dam Ring Armour Ring Louver Ring Grinding Table Rollers Separators Maintenance Performance ImprovementUnderstanding Vertical Roller Mill Technology Vertical roller mill (VRM) is a type of grinding machine used to grind materials into extremely fine powder, commonly used in the cement industry VRMs are also used in the power generation and steel industries, among othersApplication of Vertical Roller Mill in Cement ProductionLM vertical mill adopts new milling devic and automatic electric control system, integrating drying, Working Principle The main motor drives the grinding table to rotate through the reducer, The collected powder is the product of the ultrafine vertical grinding RELATED CASE 30tph LM170K Vertic LM190K Vertical RolLM Vertical Roller MillGrinding mill machine, mineral mill, 2023年3月21日 At present, the nonmetallic ore dry ultrafine grinding process equipment mainly includes Raymond mill, stirring mill, vibration mill, ring roller mill, ball mill and ultrafine vertical mill Ball mill can process 40200 mesh powder, the production capacity of a single machine is large, the performance is stable and reliable, but the energy consumption is slightly higherThe advantages of ultrafine vertical mill in the processing and

Vertical roller mill for raw Application p rocess materials

When a mill with a production capacity of 420 t/h was newly constructed, the total cost was about 25 million US$ [1US$=¥110] Related matters Reference Raw materials Vertical Fine product Mill circulation fan Raw Mill EP Raw Mill EP fan Chimney Kiln IDF (Kiln gas exhaust fan) Raw materials Fine product Chimney Vertical Raw Mill EP Raw Mill EP Vertical Roller Mill Working Principle Finished products have high whiteness, fine particle size, narrow particle size distribution, and good particle sphericity The fineness D97 of the finished powder can reach 3000 meshes, and the Vertical Roller Mill SBM Ultrafine Powder TechnologyIntroduction Vertical Machining Center: Definition, Components, Uses, Working Principle, Advantages Disadvantages: – The vertical machining center has existed for quite a while and stays a fundamental part of modern CNC Vertical Machining Center (VMC): Definition, 2022年3月30日 Various components and machines are used for grinding applications and that’s where highenergy ball mill comes into play Overview of Ball Mill Ball mill, also known as tumbling or pebble mill is milling equipment that encompasses cylindercontaining balls and is mounted on a metallic frame that can be rotated along with a longitudinal axisIntroduction to HighEnergy Ball Mill: Working Principle,

.jpg)

Ultrafine Vertical Mill

Ultrafine vertical mill is a highefficient industrial grinding mill, be used to grind hard stones into ultrafine powder, like talc, mica, etc +17 [ protected]Limestone ultrafine vertical mill is a high quality ores material powder grinding mill +17 [ protected] Working Principle Of Limestone Ultrafine Vertical Mill HGM series Ultra Fine Powder Mill CLRM Series Enhanced Roller Grinding Mill YGM series Raymond Mill Hammer crusherLimestone Ultrafine Vertical MillBarite ultrafine vertical roller mill is an industrial vertical grinding mill that can grind nonmetallic ore into fine powder The mill has a high production capacity, high fine powder content +17 [ protected] Working PrincipleBarite Ultrafine Vertical Roller MillWorking Principle The ultrafine vertical mill is composed of several components, each of which plays a critical role in the operation of the machine And they must work together in harmony to produce highquality, ultrafine powder These components include: Grinding chamber, Agitator, Feed inlet, Discharge outlet, Motor, Calcium Carbonate Ultrafine Powder Vertical Mill

Vertical Boring Mills: A Comprehensive Guide Machine Tool

2023年12月4日 New Vertical Boring Mill: Pros: Comes with the latest technology, warranty, and no wear and tear Cons: Can be significantly more expensive Used Vertical Boring Mill: Pros: More budgetfriendly and sufficient for less frequent or less demanding tasks Cons: Potential wear and tear, outdated technology, and usually no warranty Popular Brands The coal vertical mill, also referred to as the vertical roller coal mill, is an advanced equipment developed by our company It combines modern technology with our extensive experience in powder manufacturing This coal pulverizer efficiently integrates coal grinding and drying, providing highperformance and energysaving featuresHighEfficiency Vertical Coal Mill Enhancing Coal Pulverization