HOME→Potassium feldspar processing method potassium feldspar processing method potassium feldspar processing method

Potassium feldspar processing method potassium feldspar processing method potassium feldspar processing method

Review on KFeldspar Mineral Processing for Extracting

2024年2月4日 This review summarizes the main methods, ie, the hydrothermal, hightemperature pyrolysis, microbial decomposition, and lowtemperature methods, for potassium extraction from Kfeldspar The 2018年4月1日 In this paper, the process of extracting potassium from Kfeldspar ore based on low temperature molten salt method was studied systematically The factors that affect the The extraction of potassium from Kfeldspar ore by low 2020年1月16日 An optimized process of the hydrothermal treatment of potassium feldspar (K‐feldspar) and lime to obtain a potash alternative is reported The optimization did not Process Optimization of Potassium Release from K–Feldspar by 2020年6月16日 Feldspar is an aluminosilicate mineral that bears potassium in the interstitial sites To unlock the potassium from the interstitial sites, it was roasted with calcium chloride prepared bySustainable Process for the Extraction of Potassium

An efficient millingassisted technology for Kfeldspar processing

2016年5月15日 An economical potassium feldsparderived adsorbent (PFDA) was synthesized using potassium feldspar as the main raw material through ball millingthermal activation 2017年9月28日 The process and mechanism of dissolution reaction of potassium feldspar with CaO as the reactant in a hydrothermal sys tem were studied The experimental results show The extraction of potassium from Kfeldspar ore by low 2019年4月24日 A creative approach for the hydrothermal decomposition of Kfeldspar for the extraction of potassium (K) in mixed alkaline solutions containing NaOH and CaO pretreated by microwave was studied Under the same Microwaveassisted extraction of potassium from K 2024年2月4日 This review summarizes the main methods, ie, the hydrothermal, hightemperature pyrolysis, microbial decomposition, and lowtemperature methods, for potassium Review on KFeldspar Mineral Processing for Extracting Metallic

Process Optimization of Potassium Release from

2020年1月10日 An optimized process of the hydrothermal treatment of potassium feldspar (Kfeldspar) and lime to obtain a potash alternative is reported The optimization did not change a twokeystep process and only Abstract An optimized process of the hydrothermal treatment of potassium feldspar (K‐feldspar) and lime to obtain a potash alternative is reported The optimization did not change a Process Optimization of Potassium Release from K–Feldspar by 2024年2月4日 An improved method for producing highpurity quartz (Qtz) and potassium feldspar (Kfs) concentrates was developed using various chemical reagents Froth flotation experiments on a Qtz–Kfs mixture showed that quartz A Comparative Study of Quartz and Potassium 2021年12月3日 Extraction of Potassium from Feldspar by Roasting with CaCl2 Obtained from the Acidic Leaching of WollastoniteCalcite Ore(PDF) Extraction of Potassium from Feldspar by

Laboratory and Pilot Scale Studies of Potassium Extraction from K

2016年2月1日 Processes for potassium extraction from abundant Kfeldspar have recently attracted interest to ensure potash selfsufficiency for developing countries Concurrently, distiller waste and soda residue formed in the ammoniasoda process (Solvay method) have resulted in serious pollution A method of potassium extraction from Kfeldspar with distiller waste and 2023年1月1日 Common acid leaching methods for potassium extraction are the introduction of phosphate ore, fluorosilicic acid, fluorite and other fluorinecontaining substances, to destroy the stable structure of potassium feldspar (Ding, 1996)Sun et al (2011) established a coleaching reaction system of phosphate rock, potassium feldspar and phosphoric acidResearch on the strengthening mechanism of potassium leaching 2017年9月1日 The low temperature molten salt method was used to extract potassium from Kfeldspar ore, and some related factors including mass ratio between NaNO3, NaOH, H2O and Kfeldspar ore, particle size The extraction of potassium from Kfeldspar ore by low 2019年1月22日 The watersoluble potassium content of feldspar in each treatment increased during mechanical grinding, from 2164 mg kg−1 to 149581 mgkg−1, by adding NaOH 5% weight of potassium feldspar Fertilizing Properties of Potassium Feldspar Altered Hydrothermally

.jpg)

Extraction of KCl from Potassium Feldspar by Various Inorganic

2023年9月14日 Feldspar, which is one of the main inputs of the ceramic and glass industries, has widespread sources in Turkey and thus forms a large component of the country’s mineral exportation In addition to this, potassium feldspars are one of the raw materials suitable for the production of potash, which is a vital component of the agricultural industry In our work, the DOI: 101016/JCJCHE201709006 Corpus ID: ; The extraction of potassium from Kfeldspar ore by low temperature molten salt method @article{Wang2017TheEO, title={The extraction of potassium from Kfeldspar ore by low temperature molten salt method}, author={Zhao Wang and Zhang Quanyou and Ying Yao and Yongzhong Jia and Bin Xie}, The extraction of potassium from Kfeldspar ore by low 2024年2月4日 The Kfeldspar mineral is an insoluble potassium resource with a high potassium content and the most extensive and abundant reserves To address the insufficient supply of soluble potassium fertilizers in China, the application of appropriate processing methods to extract potassium from Kfeldspar and transform it into a soluble potassium fertilizer is of great Review on KFeldspar Mineral Processing for Extracting Metallic 2024年7月18日 Zhang et al have extracted more than 80% potassium from roasting feldspar with calcium chloride and calcium carbonate followed by water leaching11 Shekhar et al have reported 98% recovery of potassium from glauconitic sandstone using sulfation roasting followed by water leaching12 At 900 °C, the extraction of potassium is about 93% w/wFeldspar Properties, Uses, Types, Facts Hebei Yayang

.jpg)

An efficient millingassisted technology for Kfeldspar processing

2016年5月15日 This paper describes an environmentally friendly and efficient millingassisted technology to produce soluble potassium from natural Kfeldspar with the additive of calcium salts, and capture CO 2 via mineralization The millingassisted process could facilitate the extraction of potassium from Kfeldspar under mild conditions (eg 30–40 °C), and mineralize CO 2 with To recover potassium from feldspar, a biowaste, ie, eggshell, was used The chief composition of eggshells is calcite As it is a rich source of Ca, hence it is used with HCl to produce calcium chloride Feldspar is an aluminosilicate Sustainable Process for the Extraction of Potassium 2019年6月1日 Potassium chloride (KCl) is widely used in many fields of the processing industry The application in the food industry, as well the one in the pharmaceutic sector, requires very pure KCl crystals (PDF) Production of Potassium Chloride from K 2019年4月24日 A creative approach for the hydrothermal decomposition of Kfeldspar for the extraction of potassium (K) in mixed alkaline solutions containing NaOH and CaO pretreated by microwave was studied Under the same processing conditions, a systematic comparison of microwave pretreatment and traditional hydrothermal reaction showed that K+ dissolution Microwaveassisted extraction of potassium from Kfeldspar

(PDF) A Comparative Study of Quartz and Potassium Feldspar

2024年2月4日 An improved method for producing highpurity quartz (Qtz) and potassium feldspar (Kfs) concentrates was developed using various chemical reagents2018年11月1日 China is the second largest producer of feldspar and the largest feldspar consumer in the world (Tanner, 2012)Unfortunately, most of feldspar resources in China reportedly are characterized with fine liberation size consisting quartz, mica, and iron minerals (Hu et al, 2005, Zhou et al, 2013)Owing to the lack of advanced processing and mechanism to Systematic review of feldspar beneficiation and its comprehensive 2018年1月1日 Thermodynamic calculation shows that the temperature range of the thermal decomposition of potassium feldspar is 800890°C with stoichiometric additive of sodium carbonate or potassium carbonateQuantitative Assessment of Potassium from kFeldspar ore by Keywords: chemical reagents; froth flotation; potassium feldspar; quartz 1 Introduction Quartz and potassium feldspar usually occur associated in nature They have large industrial applications, which depend on their purity Quartz is mainly used in the manufacture of glass, as a filter material for water, and as a filler for the ceramic A Comparative Study of Quartz and Potassium Feldspar Flotation

.jpg)

Decomposition of Kfeldspar by potassium hydroxide solution in

2022年3月15日 Among these routes, the hydrothermal alkaline process is the most feasible technique for its relatively low processing temperatures and high potassium recovery rate (Liu et al, 2015, Su et al, 2015) However, the hydrothermal alkaline process is only used as the development and utilization of potassium from Kfeldspar and alumina is not utilizedfeldspar is more than 7%, it is classified as sodium feldspar, and it is named as potassium feldspar when the K 2 O content is above 10% These two feldspars are the most important inputs in the glassThe Correlation of Roasting Conditions in Selective Potassium 2016年9月14日 The existing methods of potassium extraction from Kfeldspar involve the using hydrofluoric acid digestion (Ma et al 2016(Ma et al , 2016a, hydrothermal processing (C J, Ma, and Gao 2019;Liu Studies on Extraction of Potassium from Feldspar by Roastleach Method 2015年11月11日 Researchers in the lab of Antoine Allanore, the Thomas B King Assistant Professor of Metallurgy at MIT, have been working on potash alternatives for three years In a paper published Oct 20 in Research finds feldspar releases potassium at a higher

The Extraction of Potassium from Feldspar by Molten Salt

2012年5月1日 Effects of ratios of feldspar to CaCl2 to NaCl, roasting temperature ,roasting time and particle size on the meltingout rate of potassium from feldspar was studied by roasting Results showed that the highest meltingout rate of potassium reached at 9535% under the ratio of 18:11:06 of feldspar to CaCl2 to NaCl, particle size 220mesh, roasting temperature where X can alter as Na, K, and Ca The feldspar group has nearly 20 recognized members but only two of them (sodium and potassium feldspars) are used commercially When the Na2O content in feldspar is more than 7%, it is classified as sodium feldspar, and it is named as potassium feldspar when the K2O content is above 10%Potassium Extraction from KFeldspar Oreis often preferred over other methods for recovery of potassium from feldspar Calcium and sodium often get coleached with potassium as chloride salts of these metals are soluble in water To produce pure KCl, potassium needs to be separated from other impurity metals present in leach liquor Extraction of potassium from leach liquor through Production of Potassium Chloride from KFeldspar ThroughHardrock mining for feldspars is done by openpit methods, either by jaw crusher, and the particle size is about 10mm There are many options for fine crushing and grinding machines of the feldspar processing plant, mainly on the other hand, it can increase the content of potassium and sodium in feldspar ore Common ore washing Feldspar Mining Process Equipment Flow Cases JXSC

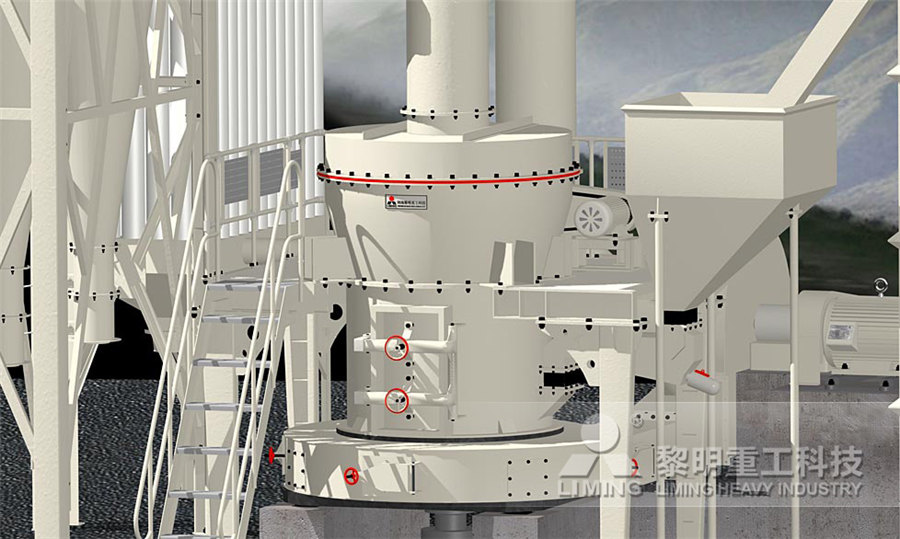

CFB石灰石脱硫剂制备64.jpg)

Process Optimization of Potassium Release from K–Feldspar by

2020年1月10日 Abstract An optimized process of the hydrothermal treatment of potassium feldspar (Kfeldspar) and lime to obtain a potash alternative is reported The optimization did not change a twokey Process Optimization of Potassium Release from K–Feldspar by Combining Calcination and Hydrothermal Method Dr Shanke Liu, Corresponding 2020年8月17日 This paper aims to characterize and interpret the trends in reserves, resources, and mine production of feldspar and feldspathoid rocks during 2005–2019 in the Czech RepublicProduction, Reserves, and Processing of Feldspar and Feldspathoid Rocks 2023年12月27日 To improve the potassium availability of feldspar at ordinary temperatures, the mechanical grinding and addition of sodium hydroxide/salts were employed to study the effects of mechanical activation and strong alkali addition on particle characteristics, watersoluble potassium, and the available potassium of feldspar A laser particle size analyzer was utilized Mechanism of Potassium Release from Feldspar by Mechanical Agus et al EXTRACTION OF POTASSIUM FROM FELDSPAR AND LEUCITE BY TWO DIFFERENT ACTIVATION METHODS: MECHANICAL ACTIVATION (MILLING) AND HIGH TEMPERATURE ACTIVATION (ROASTING) AGUS WAHYUDI, DESSY AMALIA and HADI PURNOMO R D Centre for Mineral and Coal Technology Jalan Jenderal Sudirman 623 (PDF) Extraction of Potassium from Feldspar and Leucite by Two

.jpg)

A Comparative Study of Quartz and Potassium

2024年2月4日 An improved method for producing highpurity quartz (Qtz) and potassium feldspar (Kfs) concentrates was developed using various chemical reagents Froth flotation experiments on a Qtz–Kfs mixture showed that quartz 2021年12月3日 Extraction of Potassium from Feldspar by Roasting with CaCl2 Obtained from the Acidic Leaching of WollastoniteCalcite Ore(PDF) Extraction of Potassium from Feldspar by 2016年2月1日 Processes for potassium extraction from abundant Kfeldspar have recently attracted interest to ensure potash selfsufficiency for developing countries Concurrently, distiller waste and soda residue formed in the ammoniasoda process (Solvay method) have resulted in serious pollution A method of potassium extraction from Kfeldspar with distiller waste and Laboratory and Pilot Scale Studies of Potassium Extraction from K 2023年1月1日 Common acid leaching methods for potassium extraction are the introduction of phosphate ore, fluorosilicic acid, fluorite and other fluorinecontaining substances, to destroy the stable structure of potassium feldspar (Ding, 1996)Sun et al (2011) established a coleaching reaction system of phosphate rock, potassium feldspar and phosphoric acidResearch on the strengthening mechanism of potassium leaching

The extraction of potassium from Kfeldspar ore by low

2017年9月1日 The low temperature molten salt method was used to extract potassium from Kfeldspar ore, and some related factors including mass ratio between NaNO3, NaOH, H2O and Kfeldspar ore, particle size 2019年1月22日 The watersoluble potassium content of feldspar in each treatment increased during mechanical grinding, from 2164 mg kg−1 to 149581 mgkg−1, by adding NaOH 5% weight of potassium feldspar Fertilizing Properties of Potassium Feldspar Altered Hydrothermally2023年9月14日 Feldspar, which is one of the main inputs of the ceramic and glass industries, has widespread sources in Turkey and thus forms a large component of the country’s mineral exportation In addition to this, potassium feldspars are one of the raw materials suitable for the production of potash, which is a vital component of the agricultural industry In our work, the Extraction of KCl from Potassium Feldspar by Various Inorganic DOI: 101016/JCJCHE201709006 Corpus ID: ; The extraction of potassium from Kfeldspar ore by low temperature molten salt method @article{Wang2017TheEO, title={The extraction of potassium from Kfeldspar ore by low temperature molten salt method}, author={Zhao Wang and Zhang Quanyou and Ying Yao and Yongzhong Jia and Bin Xie}, The extraction of potassium from Kfeldspar ore by low

.jpg)

Review on KFeldspar Mineral Processing for Extracting Metallic

2024年2月4日 The Kfeldspar mineral is an insoluble potassium resource with a high potassium content and the most extensive and abundant reserves To address the insufficient supply of soluble potassium fertilizers in China, the application of appropriate processing methods to extract potassium from Kfeldspar and transform it into a soluble potassium fertilizer is of great 2024年7月18日 Zhang et al have extracted more than 80% potassium from roasting feldspar with calcium chloride and calcium carbonate followed by water leaching11 Shekhar et al have reported 98% recovery of potassium from glauconitic sandstone using sulfation roasting followed by water leaching12 At 900 °C, the extraction of potassium is about 93% w/wFeldspar Properties, Uses, Types, Facts Hebei Yayang