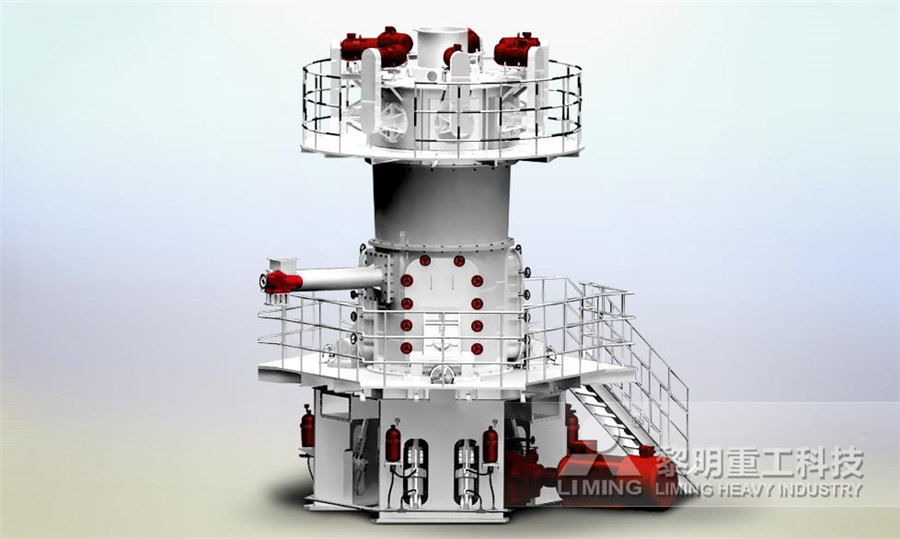

Energysaving and environmentally friendly mechanized vertical kiln price

.jpg)

Artisan Brick Kilns: StateoftheArt and Future Trends

2020年9月18日 Rahman and Kazi reported that Tunnel kiln and Hybrid Hoffman kiln are energyefficient brick kiln technologies These kiln technologies have lower SEC and therefore burn less fuel and release fewer greenhouse gases 2022年11月1日 Besides FCBTK, there exist several other energy efficient and environmentfriendly brick manufacturing technologies eg, vertical shaft brick kilns (VSBK), tunnel kilns Barriers and drivers for adoption of energy efficient and 2024年10月16日 Investigate its reason that the concentration of CO2 in flue gas jet can reach more than 35%, CO2 recovery cost is low Our Advantages: The vertical kiln was 100600tpd Mechanized EnergySaving Building Material Lime 2023年2月1日 Our results show that VSBK is the most energy efficient and environmentally friendly technology, closely followed by ZZK For the year 2050, ZZK can save up to 16 billion Forecasting environmental and social benefits of adopting cleaner

Assessment of longterm energy and environmental impacts of

2021年11月1日 Energy demand, fuel savings, emissions and social costs are evaluated Conventional brick kilns are not the leastcost option and perform worse Cleaner kilns offer 2021年4月29日 Various studies and monitoring has shown that (VSBK) Vertical Shaft Brick Kiln technology is an improved brick making process The major advantage of VSBK technology is its energy efficiency1018, 1122 Vertical Shaft Brick Kiln ResearchGateefficient heat transfer and minimal heat losses, VSBK is one of the most energy efficient brick kiln technologies A very efficient counter flow heat transfer arrangement between air and bricks, VERTICAL SHAFT BRICK KILN TECHNOLOGY (VSBK)the most energy efficient and cost effective brick firing processes in the world, with the added benefit of providing a better working environment for staff members The VSBK makes clay Intervention 2: Vertical Shaft Brick Kiln Technologies (VSBK) JSTOR

Barriers and Drivers for Adoption of Energy Efficient and

2022年1月1日 perception and decision of kiln owners for the adoption of cleaner ZZK technology Our results show fuel costs and yearround operations Other high impact drivers 2010年6月1日 Vertical Shaft Brick Kiln (VSBK) Technology, which is considered to be more cleaner, cheaper and advanced version of fire brick making technology appropriate for small and medium brickVertical Shaft Brick Kiln (VSBK) Technology for small Energy Saving Mixed Fired Lime Vertical Lime Kiln, Factory Manufacturer Price EnergySaving Design Chemical/Cement/Lime Rotary Kiln Lime Sleeve Kiln US$200,000001,000,00000 / Piece Factory Price and Good Environmental protection mechanized vertical shaft kilnEnergy Saving Mixed Fired Lime Vertical Lime Kiln3 Environmentally Friendly: The Vertical Lime Kiln is an environmentally friendly product, with low energy consumption and reduced emissions This makes it an ideal choice for businesses looking to reduce their environmental impact 4Vertical Lime Kiln China Vertical Lime Kiln

Mechanized EnergySaving Lime Shaft Kiln China Lime Vertical Kiln

Mechanized EnergySaving Lime Shaft Kiln, Find Details and Price about Lime Vertical Kiln Mining Machinery from Mechanized EnergySaving Lime Shaft Kiln Shandong Tianhang Machinery Equipment Co, Ltd Print This PageII EcoFriendly Machines: Revolutionizing Brick Manufacturing a) Efficient Kiln Technologies: Ecofriendly machines introduce innovative kiln technologies such as tunnel kilns and vertical shaft brick kilns (VSBK) These kilns optimize energy consumption, reduce emissions, and incorporate heat recovery systemsBuilding a Sustainable Future: EcoFriendly Machines in Brick Energysaving mechanized vertical kiln for cement manufacturing is from the fixed factor of shaft kiln own, from the structure of shaft kiln ratio of height to diameter is reduced to and to be equaled 252: 1, the expansion mouth diameter degree of depth, the angle of kiln, the blowability of blower fan, air quantity, blast, flow velocity, air supply duct diameter, air supply mode, the CNC Energysaving mechanized vertical kiln for 2022年1月1日 The concept of the developed design of a vertical kiln for firing bricks and other ceramic products [] is based on the technological combination of drying and firing processes, which ensures a decrease in heat losses of equipment and fuel gas consumptionFigure 1 shows a diagram of the furnace (view from the side of the loading mechanism and view one of its EnergyEfficient Vertical Kiln for the Firing of Ceramic

Schematic presentation of vertical shaft kiln; (a) preheating

Download scientific diagram Schematic presentation of vertical shaft kiln; (a) preheating zone, (b) reacting zone, and (c) cooling zone from publication: Energy optimisation of vertical shaft 2018年9月1日 Energy Optimisation o f Vertical Shaft Kiln Operation in 2128 THERMAL SCIENCE: Year 2018, Vol 22, No 5, pp 2123 2135 The raw dolom it e comp osit ion is 543% C a(PDF) Energy optimisation of vertical shaft kiln operation in the Active lime vertical kiln equipment supporting Calcination of limestone Qualified limestone goes to the top of the preheater through the belt conveyor, and the material is introduced into the body of the preheater from the silo at the top of the preheater through the discharge chute, and at the same time, the hightemperature flue gas from the rotary kiln preheats the material to 600°C Vertical Shaft Lime Kiln for Cement PlantVertical shaft lime kiln from AGICO CEMENT is widely used to Quick Lime Production, Get Price Annular shaft kiln Capacity: 300t/d, 500t/d, 600t/d, etc Fuel: gas, pulverized coal, etc Original design and energysaving operation 2Vertical Lime Kiln Lime Kiln Manufacturer Output: 501200TPD

Vertical Lime Kiln MadeinChina

China Vertical Lime Kiln wholesale Select 2024 high quality Vertical Lime Kiln products in best price from certified Chinese Vertical Machine manufacturers, Vertical Lathe suppliers, Energy Saving Mixed Fired Lime Vertical Lime Kiln US$ / Piece 1 Piece (MOQ)Vertical Kiln Price Select 2024 high quality Vertical Kiln Price products in best price from certified Chinese Vertical Mechanized Kiln manufacturers, Dust Collector suppliers, wholesalers and factory on MadeinChina Competitive Manufacturing Price Energy Saving Lime Vertical/Shaft Kiln US$ / Piece 1 Piece Vertical Kiln Price MadeinChina2013年3月1日 Cement production is an energyintensive industry that primarily relies on fossil fuels like coal and natural gas to meet energy needs Extreme usage of fossil fuels leads to depletion of their Energy and exergy assessments of a lime shaft kilnVertical Shaft Kiln is used for the calcination of cement clinker, limestone, bauxite and other materialsThe vertical kiln manufactured by Shandong Tianhang Machinery Equipment CO,LTD has the advantages, such as modern design, new technology, environmental protection,energy saving, higher machanization and automaticity etc We offer 50 TPD to 300 TPD vertical shaft 300tpd Vertical Shaft Active Lime Kiln Plant Quick Lime

.jpg)

EnergySaving and Environmental Friendly Intelligent Vertical Lime Kiln

EnergySaving and Environmental Friendly Intelligent Vertical Lime Kiln, Find Details and Price about Mining Machine Construction Machinery from EnergySaving and Environmental Friendly Intelligent Vertical Lime Kiln Shandong Tianhang Machinery Equipment Co, Ltd 2018年8月3日 As cities cope with rapid population growth—adding 25 billion dwellers by 2050—and grapple with destructive sprawl, politicians, planners, and architects have become increasingly interested (PDF) Sustainability and the 21st Century Vertical City: A Review Is kaolin rotary kiln environmentally friendly? The answer is yes, the kaolin rotary kiln meets national The mechanized shaft kiln is equipped with a distributor in the center of the coke vertical kiln, and energysaving vertical kiln, has an activity level of about 280ml Therefore, the kiln type for producing activated Energy Saving and Consumption Reduction for Large Kiln Competitive Manufacturing Price Energy Saving Lime Cement Vertical Kiln US$200,000001,000,00000: 1 Piece (MOQ)Competitive Manufacturing Price Energy Saving Lime Cement Vertical Kiln

.jpg)

(PDF) Traditional Brick Making, Environmental and SocioEconomic

2021年9月25日 To reduce environmental degradation, the incorporation of industrial and environmental wastes into brick making and the gradual transition to environmentally friendly technology such as Vertical Energy Optimisation of Vertical Shaft Kiln Operation THERMAL SCIENCE: Year 2018, Vol 22, No 5, pp XXXXXXXX 1 Expected energy savings margin is estimated to 1215%ENERGY OPTIMISATION OF VERTICAL SHAFT KILN OPERATION China Vertical Shaft Lime Kiln wholesale Select 2024 high quality Vertical Shaft Lime Kiln products in best price from certified Chinese Stainless Steel Vertical manufacturers, Environmental Protection and Energy Saving MultiFuel Lime Shaft Vertical Kiln US$ / Piece 1 Piece (MOQ)Vertical Shaft Lime Kiln MadeinChina2024年11月12日 The CLUM Series Ultrafine Vertical Mill sets a new standard in ultrafine powder production by combining advanced ecofriendly and energysaving technology with precision engineering CLUM Series Ultrafine Vertical Grinding Mill Key Advantages: CLUM Series Ultrafine Vertical Mill 1 UltraLow Operating Cost WearResistant Alloy Material: The CLUM Series Mill: EcoFriendly and EnergySaving, Leading Ultra

.jpg)

Experimental Study of the Bearing Characteristics of a Novel Energy

2024年2月2日 Experimental Study of the Bearing Characteristics of a Novel EnergySaving and Environmentally Friendly Pile: Drilling with Prestressed Z, M Tang, H Hu, J Li, S Zhang, X Xu, and C Liu 2021 “Comparative study on the vertical loadbearing capacity of the drilling with prestressed concrete pipe cased pile based on in With the continuous development and transformation of the cement industry, more and more efficient, energysaving and environmentally friendly cement making machines are being used in cement plants If you want to work in cement production, there are five crucial cement manufacturing machines you need to know, they are cement rotary kiln , shaft kiln, cement Cement Manufacturing Machine Cement Making MachineIt heats the limestone, reducing fuel consumption Phase Compared with the traditional lime kiln, the double lime kiln can save 20% to 30% of fuel l Environmentally friendly: Double lime kiln processEnergysaving Double Shaft Lime Kiln For Lime ManufacturingEnergySaving Vertical Lime Kiln with Gas Burning, Find Details and Price about Gas Burning Limekiln from EnergySaving Vertical Lime Kiln with Gas Burning Linyi Jinyong Kiln Co, Ltd Home Product Directory Manufacturing Processing Machinery Building Material Making Machinery Other Building Material Making MachineryEnergySaving Vertical Lime Kiln with Gas Burning

Research on an electric energy‐saving grain drying system with

2020年6月12日 Electric energy is a clean, highly efficient, convenient, and easy to control and convert energy form, as the grain drying process seeks clean heat sources and reduced pollutant emission, it is important to measure and develop lowcarbon, energysaving and environmentally friendly grain dryers and to study electric grain dryers that use electric energy as the heat sourceChina lime vertical shaft kilns catalog of Manufacturer and Design Price Sleeve Kiln Pulverized Coal Injection Vertical Lime Kiln Shaft Lime Kiln Rotary Kiln, Manufacturer Environmental Friendly Cement Clinker Nickel Zinc Oxide Lime Vertical Rotary Kiln Sleeve Kiln provided by China manufacturer Shandong Tianhang Machinery Equipment Co, Ltd, page1lime vertical shaft kilns Shandong Tianhang Machinery AC shaft kiln is an energysaving and environmentfriendly semidry clinker calcinating kiln developed by our company In the design, we took “environmental protection, energy conservation and consumption reduction, waste utilization” as the starting point, based on a number of independent invention patents and utility model patents, drew lessons from the design Vertical Shaft Kiln AGICO Cement PlantEnvironmental Friendly Biochar Charcoal Wood Saw Dust Retort Kiln for Sale, Find Details and Price about Wood Charcoal Kiln Vertical Charcoal Carbonizer from Environmental Friendly Biochar Charcoal Wood Saw Dust Retort Kiln for Sale Environmental Friendly Biochar Charcoal Wood Saw Dust Retort Kiln

Energy Saving Mixed Fired Lime Vertical Lime Kiln

Energy Saving Mixed Fired Lime Vertical Lime Kiln, Factory Manufacturer Price EnergySaving Design Chemical/Cement/Lime Rotary Kiln Lime Sleeve Kiln US$200,000001,000,00000 / Piece Factory Price and Good Environmental protection mechanized vertical shaft kiln3 Environmentally Friendly: The Vertical Lime Kiln is an environmentally friendly product, with low energy consumption and reduced emissions This makes it an ideal choice for businesses looking to reduce their environmental impact 4Vertical Lime Kiln China Vertical Lime Kiln Mechanized EnergySaving Lime Shaft Kiln, Find Details and Price about Lime Vertical Kiln Mining Machinery from Mechanized EnergySaving Lime Shaft Kiln Shandong Tianhang Machinery Equipment Co, Ltd Print This PageMechanized EnergySaving Lime Shaft Kiln China Lime Vertical Kiln II EcoFriendly Machines: Revolutionizing Brick Manufacturing a) Efficient Kiln Technologies: Ecofriendly machines introduce innovative kiln technologies such as tunnel kilns and vertical shaft brick kilns (VSBK) These kilns optimize energy consumption, reduce emissions, and incorporate heat recovery systemsBuilding a Sustainable Future: EcoFriendly Machines in Brick

CNC Energysaving mechanized vertical kiln for

Energysaving mechanized vertical kiln for cement manufacturing is from the fixed factor of shaft kiln own, from the structure of shaft kiln ratio of height to diameter is reduced to and to be equaled 252: 1, the expansion mouth diameter degree of depth, the angle of kiln, the blowability of blower fan, air quantity, blast, flow velocity, air supply duct diameter, air supply mode, the 2022年1月1日 The concept of the developed design of a vertical kiln for firing bricks and other ceramic products [] is based on the technological combination of drying and firing processes, which ensures a decrease in heat losses of equipment and fuel gas consumptionFigure 1 shows a diagram of the furnace (view from the side of the loading mechanism and view one of its EnergyEfficient Vertical Kiln for the Firing of CeramicDownload scientific diagram Schematic presentation of vertical shaft kiln; (a) preheating zone, (b) reacting zone, and (c) cooling zone from publication: Energy optimisation of vertical shaft Schematic presentation of vertical shaft kiln; (a) preheating 2018年9月1日 Energy Optimisation o f Vertical Shaft Kiln Operation in 2128 THERMAL SCIENCE: Year 2018, Vol 22, No 5, pp 2123 2135 The raw dolom it e comp osit ion is 543% C a(PDF) Energy optimisation of vertical shaft kiln operation in the

.jpg)

Vertical Shaft Lime Kiln for Cement Plant

Active lime vertical kiln equipment supporting Calcination of limestone Qualified limestone goes to the top of the preheater through the belt conveyor, and the material is introduced into the body of the preheater from the silo at the top of the preheater through the discharge chute, and at the same time, the hightemperature flue gas from the rotary kiln preheats the material to 600°C Vertical shaft lime kiln from AGICO CEMENT is widely used to Quick Lime Production, Get Price Annular shaft kiln Capacity: 300t/d, 500t/d, 600t/d, etc Fuel: gas, pulverized coal, etc Original design and energysaving operation 2Vertical Lime Kiln Lime Kiln Manufacturer Output: 501200TPD