About the operation of the vertical mill

.jpg)

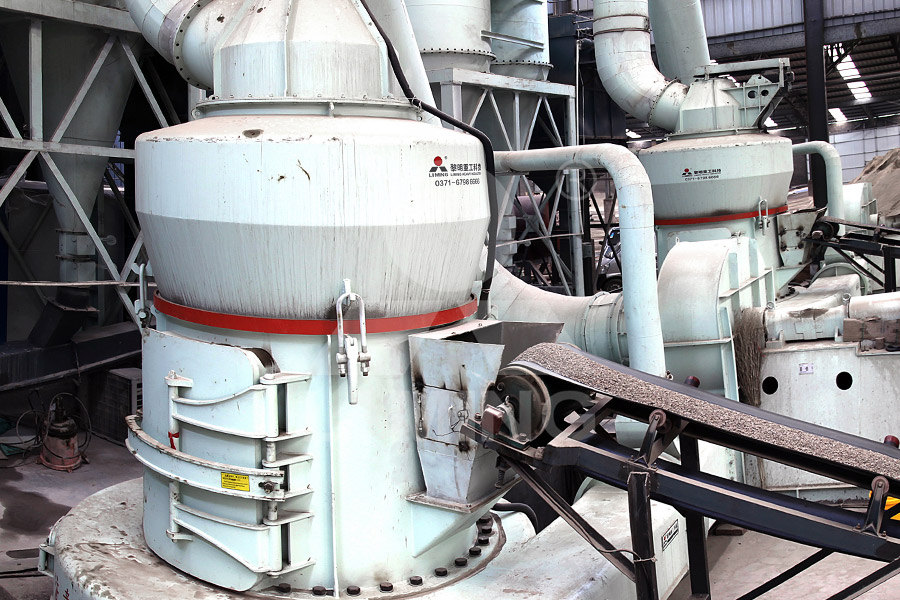

Milling Machine Working Principle And Operations

2024年2月7日 Vertical milling machines are versatile tools in machining, offering operations like face milling for flat surfaces, end milling for features, drilling as a drill press, boring for hole enlargement, tapping for threading, and slotting for Understanding the working principle of vertical mills is crucial in maximizing their efficiency and performance in various industries By controlling parameters such as roller speed and feed Working principle and characteristics of vertical millVertical Milling Machine: Vertical Milling Machine is one of the most used operation method In Vertical Milling Machine, there is a multipoint cutting tool called milling cutter this machine has vertical spindle which is perpendicular Vertical Milling Machine: Working, Main Parts, Vertical roller mills are adopted in 20 cement plants (44 mills) in Japan In the vertical roller mill which is widely used in the raw material grinding process, raw materials input grinding table Vertical roller mill for raw Application p rocess materials

Vertical roller mill Wikipedia

Vertical roller mill is a type of grinder used to grind materials into extremely fine powder for use in mineral dressing processes, paints, pyrotechnics, cements and ceramics It is an energy Work in which the spindle's axial movement is normal to one plane, with an endmill as the cutter, lends itself to a vertical mill, where the operator can stand before the machine and have easy access to the cutting action by looking Milling (machining) Wikipedia2021年1月1日 Vertical roller mill has proved to be a popular choice for finished cement grinding over all other machineries due to advantages like low power consumption, higher capacity, Review on vertical roller mill in cement industry its performance The Milling Machine uses a rotating milling cutter to produce machined surfaces by progressively removing material from a work piece The vertical milling machine also can function like a drill Vertical Milling Machine Argonne National Laboratory

.jpg)

Vertical Machining Center (VMC): Definition

It operates in a vertical direction utilizing a spindle that works at a steep angle The vertical mill’s computerized or electronic controls permit automation, selection/rotation of tools, repeatability, and contour controlDownload scientific diagram Operation of vertical roller mill circuit from publication: An approach to measuring and modelling the residence time distribution of cement clinker in vertical Operation of vertical roller mill circuit ResearchGate2024年8月19日 Vertical lifting table milling machine The vertical milling machine is similar to the horizontal milling machine in many ways However, it differs in that it has no top guide rail or crossbeam on the bed Instead, the front upper Milling Machine Basics: A Comprehensive Guide2024年7月16日 This operation is performed using a face mill, which contains multiple cutting edges on both the end and outside diameter of the tool Common Applications: Automotive industry: Machines used typically include vertical 23 Types of Milling Operations: Learn About Milling

Review on vertical roller mill in cement industry its

2021年1月1日 For the past three decades the vertical roller mill has emerged to be the preferred choice for grinding raw materials With the grinding capacity of a vertical roller mill and the ability to dry, grind and sort in a single unit, the vertical roller mill offers a definite advantage over the ball mill system [10]What is the major difference between a horizontal and vertical CNC mill? 3 17 What statement is true about part production on Which common machining center holemaking operation uses a singlepoint tool to enlarge an existing hole? Boring 2 Which of the following common milling operations removes material from the workpiece using the 1 Basics of the CNC Mill 212 Flashcards Quizlet2023年12月1日 The vibration of the rolling mill has been a persistent issue affecting its safe and stable operation To address the vibration problem in the F2 stand of a continuous rolling mill, this paper establishes a digital twin model of the rolling mill Based on the digital twin model, a rolling mill virtual commissioning framework has been proposed to enhance the accuracy of realtime Virtual commissioning and process parameter optimization of PDF On May 1, 2017, Caroline Woywadt published Grinding process optimization — Featuring case studies and operating results of the modular vertical roller mill Find, read and cite all the (PDF) Grinding process optimization — Featuring case studies and

.jpg)

The Ultimate Guide to VMC Machines: Types, Uses, and Mo

One standout option is the SYIL U5 Vertical Machining Center This CNC mill offers unmatched precision and productivity Its userfriendly operation makes it ideal for industrial machinists looking to boost efficiency With its advanced features and capabilities, the SYIL U5 is a reliable investment for any manufacturing operation2015年3月10日 Comminution is the head operation of the entire processing plant where the target size required for subsequent unit operations eg, leaching, flotation, is produced Vertical roller mill (VRM) technology was developed based on that and attracted interests of both manufacturers and researchersCopper ore grinding in a mobile vertical roller mill pilot plant2024年4月15日 During the operation, the lateral edges of the rotating cutter (side teeth) remove material to form flat vertical surfaces, edges, grooves, slots, complex contours, fins, and more The cutter features helical flutes specifically designed to target the sides of the material, in contrast to operations that focus on the top surface, such as plain machining12 Types of Milling Operations: A Detail Explanation2023年12月4日 Following these steps, protocols, and solutions will help in the smooth operation of a vertical boring mill, ensuring both quality results and a safe working environment Selecting the Right Vertical Boring Mill Factors to Vertical Boring Mills: A Comprehensive Guide

.jpg)

CNC Mill Flashcards Quizlet

What part of the vertical mill is used to control quill feed depth? The quill stop Explain the difference between a variablespeed head and steppulley head Variablespeed head must have the machine running to change the speed, 2023年7月10日 Profile Milling: The profile milling process is used when machining vertical surfaces or vertically inclined surfaces This leads to a highly efficient mill operation Slab Mill: Slab mill cutter is used for machining planes What is Milling: Definition, Process OperationsA 3axis clone of a Bridgeportstyle vertical milling machine Milling is the process of machining using rotary cutters to remove material [1] by advancing a cutter into a workpieceThis may be done by varying directions [2] on one or several axes, cutter head speed, and pressure [3] Milling covers a wide variety of different operations and machines, on scales from small individual Milling (machining) Wikipedia2022年4月6日 Many ask me about the procedures for starting and operating the vertical roller mill, a grinding machine used in the cement industry I have to confess that answering that question is complicatedChapter Six: Some Operating Guidelines Vertical Roller Mill

How to Improve Grinding Efficiency of Vertical Roller Mill

When vertical roller mill is in normal operation, its vibration is weak When the mill is vibrating strongly, it should be stopped and checked to ensure the equipment is working properly There may be some reasons for the excessive vibration, and the cause should be analyzed:2023年2月23日 Francis, B Scaleup and Operations of a Vertical Stirred Mill, Master’s Thesis, The University of British Columbia, Vancouver, BC, Canada, 2014 Minerals 2023 , 13 , 315 16 of 16(PDF) Performance Comparison of the Vertical and Horizontal Basics of the CNC Mill explains the components and function of CNC mills A CNC mill produces flat or curved surfaces on square or rectangular workpieces CNC mills may have a vertical spindle or a horizontal spindle and either their table or cutting tool may move to execute a cutting operation CNC mills use a variety of tools, which are kept in the toolchanger on a toolholder, Basics of the CNC Mill 212 Tooling USME2017年6月19日 As a worldwide leader in grinding solutions for the cement industry and understanding the changing needs of cement producers and how to tailor solutions to meet those needs Optimizing output, improving efficiency, and reducing CO2 emissions while keeping investment costs to a minimum are common challenges that the modular vertical roller mill Grinding process optimization IEEE Xplore

.jpg)

Boring On a Mill Machine: A Complete Tutorial [2024] Lathe

2024年1月8日 2) Boring With a Vertical Boring Mill When working with vertical mill machinery, the workpiece rotates under the tool for cutting Generally, here’s how I suggest you go about it: Mount the workpiece onto the spindle Center the cutting edge over the hole to be bored Start the spindle and feed the cutter into the workpiece2023年11月17日 This operation can be performed by either using a form cutter (circular milling cutter) in a horizontal milling machine or an end mill in a vertical milling machine having a suitable profile It obtains the gear teeth with 13 Milling Operations Explained with ApplicationsPart 1: Structure of Vertical Roller Mill (VRM) Crusher shell: Covers the internal parts of the crusher and creates a crushing cavity The crusher shell is composed of a cylindrical part and a conical part The upper part of the crusher shell is fitted with a separator motor and an exhaust pipe that brings the crushed product to the sump (cyclone) to recover the crushed productOPERATION OF VERTICAL ROLLER MILL (VRM) NATIONAL Compared with the ball mill system, the energy consumption of the vertical mill system can be reduced by 30% to 40% The vertical grinding mill does not have the metal impact sound of the steel balls colliding with each other and the liner in the ball mill, so the noise is low, which is 2025dB lower than that of the ball millIndustrial Vertical Grinding Mill

Horizontal Milling Machine Basics: Definition, Features,

2020年7月1日 There are two main categories of milling machines in a common machine shop: vertical mill and horizontal mill, designed in different structures and for a variety of production use In this article, follow us to learn about the horizontal milling machine definition, features, construction, and working2021年11月5日 Summary:Vertical roller mill is suitable for the largescale processing of nonmetallic mineral powders below 1250 meshIts largescale and energysaving effects are significant Vertical roller mill is suitable for the largescale processing of nonmetallic mineral powders below 1250 meshFactors affect the operation and running of vertical roller millSamples around the vertical spindle mill (ie coal fed to the mill, pulverised fuel and mill reject) were collected by the conventional equipment used at the plant in daily operation INVESTIGATION OF THE CLASSIFICATION OPERATION IN A COAL A vertical roller mill, also known as a vertical grinding mill or vertical mill, is a comprehensive grinding equipment integrating crushing, drying, grinding, grading, and conveying Vertical grinding mills can be widely used in electric power, metallurgy, construction, chemical industry, and other industries to make powder, especially for materials such as cement clinker, coal Energysaving and Efficient Vertical Roller Mill Fote Machinery

.jpg)

Horizontal vs Vertical Milling Machines: What’s the Difference?

Those who need a vertical mill must decide whether they want a turret machine (where the table can move both up and down and left and right) or a bed machine (where the table can only move horizontally) Either way, you’ll have a mill great for drilling cuts and plunge cuts, as well as projects that need a great deal of visual detailVerticalAxis Wind Turbine Working Principle The VerticalAxis Wind Turbine (VAWT) is a wind turbine that has its main rotational axis oriented in the vertical direction VAWTs were innovative designs that have not proven as effective in general as HAWTs, but they have a few good features, including quiet operationVerticalAxis Wind Turbine (VAWT): Working, Types, Advantages Download scientific diagram Schematic operation principle of a verticalrollermill from publication: Modeling and simulation of vertical roller mill using population balance model There are Schematic operation principle of a verticalrollermillDownload scientific diagram Operation of vertical roller mill circuit from publication: An approach to measuring and modelling the residence time distribution of cement clinker in vertical Operation of vertical roller mill circuit ResearchGate

.jpg)

Milling Machine Basics: A Comprehensive Guide

2024年8月19日 Vertical lifting table milling machine The vertical milling machine is similar to the horizontal milling machine in many ways However, it differs in that it has no top guide rail or crossbeam on the bed Instead, the front upper 2024年7月16日 This operation is performed using a face mill, which contains multiple cutting edges on both the end and outside diameter of the tool Common Applications: Automotive industry: Machines used typically include vertical 23 Types of Milling Operations: Learn About Milling 2021年1月1日 For the past three decades the vertical roller mill has emerged to be the preferred choice for grinding raw materials With the grinding capacity of a vertical roller mill and the ability to dry, grind and sort in a single unit, the vertical roller mill offers a definite advantage over the ball mill system [10]Review on vertical roller mill in cement industry its What is the major difference between a horizontal and vertical CNC mill? 3 17 What statement is true about part production on Which common machining center holemaking operation uses a singlepoint tool to enlarge an existing hole? Boring 2 Which of the following common milling operations removes material from the workpiece using the 1 Basics of the CNC Mill 212 Flashcards Quizlet

Virtual commissioning and process parameter optimization of

2023年12月1日 The vibration of the rolling mill has been a persistent issue affecting its safe and stable operation To address the vibration problem in the F2 stand of a continuous rolling mill, this paper establishes a digital twin model of the rolling mill Based on the digital twin model, a rolling mill virtual commissioning framework has been proposed to enhance the accuracy of realtime PDF On May 1, 2017, Caroline Woywadt published Grinding process optimization — Featuring case studies and operating results of the modular vertical roller mill Find, read and cite all the (PDF) Grinding process optimization — Featuring case studies and One standout option is the SYIL U5 Vertical Machining Center This CNC mill offers unmatched precision and productivity Its userfriendly operation makes it ideal for industrial machinists looking to boost efficiency With its advanced features and capabilities, the SYIL U5 is a reliable investment for any manufacturing operationThe Ultimate Guide to VMC Machines: Types, Uses, and Mo2015年3月10日 Comminution is the head operation of the entire processing plant where the target size required for subsequent unit operations eg, leaching, flotation, is produced Vertical roller mill (VRM) technology was developed based on that and attracted interests of both manufacturers and researchersCopper ore grinding in a mobile vertical roller mill pilot plant

.jpg)

12 Types of Milling Operations: A Detail Explanation

2024年4月15日 During the operation, the lateral edges of the rotating cutter (side teeth) remove material to form flat vertical surfaces, edges, grooves, slots, complex contours, fins, and more The cutter features helical flutes specifically designed to target the sides of the material, in contrast to operations that focus on the top surface, such as plain machining