Central control cement mill operation

The Cement Plant Operations Handbook International Cement

Cement milling Finish milling is the grinding together of clinker with some 35 per cent gypsum, natural or synthetic, for set control, and quite often other components:2020年10月30日 This article will briefly summarise how the methods of HighLevel Control (HLC) have been used in the cement industry in the early 2000s and how they manage to control ever more complex closedloopcontrolled Highlevel control in cement production World Cement1983年1月1日 A great many open and closed loop controls can be found in the cement production, however, the proper control of the operationstriplet proportioningburninggrinding Control in Cement Production ScienceDirect2011年7月12日 To optimise cement production, the EO uses neural networks, fuzzy logic and predictive control models Divided into areas such as milling, kiln and cooler, it becomes a Cement plant control systems World Cement

OPTIMIZING THE CONTROL SYSTEM OF CEMENT MILLING:

Abstract Based on a dynamical model of the grinding process in closed circuit mills, efficient efforts have been made to optimize PID controllers of cement milling The process simulation 2023年9月5日 Mastering process control for the cement industry involves a deep understanding of the process, the control principles, and the operation of the process control instruments It requires a systematic approach to problem Mastering Process Control Instrumentation in Cement 2021年1月1日 This paper describes two cement related industrial MPC applications and outlines the oxyfuel combustion CO2 capture process for cement kilns as well as Power2X Digitalization, Control and Optimization for Cement Plantsvariability and raising cement quality, or balancing kiln performance, it streamlines complex and multivariable cement plant processes, boosting productivity and averting unnecessary Building Main Head an intelligent cement plant ABB

Chapter 4 Cement Manufacturing and Process Control

41 Cement Manufacturing: Basic Process and Operation To design the Refractory for the lining of different equipments in a cement plant, it is necessary to understand the total operational 2019年8月27日 The measured values of those parameters that are the most important for kiln operation are herein called the control parameters To keep the control parameters close to a Cement Manufacturing and Process Control SpringerLink2014年3月1日 Optimizing the control system of cement milling: bustness have been a central theme in th e develop operation of a cement mill, directly extracted from Optimizing the control system of cement milling: Scheduling of the cement mill in most cement plants is normally managed by the operator in charge, Communication between process controllers and central operator stations is via control networks Integrated systems Cement Plant Everything you need to know about Automation and

Nyati Cement Quality Control

central control room sophisticated instrumentation controls for monitoring the operation of the entire plant High efficiency classifiers have been installed at the overgrinding and enhance the mill's energy efficiencyCement Plant Operation Handbook Free ebook download as PDF File (pdf), Text File (txt) or read book online for free Cement Plant Operation HandbookCement Plant Operation Handbook PDF Mill (Grinding) Scribd2020年10月30日 Case study 1: Fully autonomous mill operation at EQIOM Ciments Autonomous mill operation using modules of AI is no longer science fiction In 2009 MILLMASTER was implemented in a VRM automation project in Northern France At its plant in Dunkerque, EQIOM Ciment’s Loesche type LM 462+2 S VRM mainly produces slag cement, Highlevel control in cement production World Cement1995年10月29日 The control system, based on a 2S4265 CNC unit, allows the milling machine to be operated in universal mode (with manual control), automatic mode (to a set program), copying mode, gauging mode (PDF) Cement mill optimization: Design parameters

.jpg)

The Decision Algorithm of Cement Mill Operation Index Based

2023年1月25日 Abstract An improved differential evolutionary cement mill operation index decision algorithm based on constraint control and selection strategy is proposed to address the problem that the operation index is usually decided by manual experience in the cement mill operation process, which causes unqualified cement specific surface area and excessive The vertical roller mill (VRM) is a type of grinding machine for raw material processing and cement grinding in the cement manufacturing processIn recent years, the VRM cement mill has been equipped in more and more cement plants around the world because of its features like high energy efficiency, low pollutant generation, small floor area, etc The VRM cement mill has a Vertical Roller Mill Operation in Cement Plant1983年1月1日 The paper deals with control in the cement manufacturing A short description of the technology is given first, then the control problems and applied Control in Cement Production ScienceDirectAUTOMATION PROCESS CONTROL 1 APRIL 2020 INTERNATIONAL CEMENT REVIEW Building an intelligent cement plant Max Tschurtschenthaler, cement lead, and Gregor Schuetz, product manager, ABB Process Industries, explain the company’s vision for a digital future in the cement industry and the solutions it offers to get thereBuilding Main Head an intelligent cement plant ABB

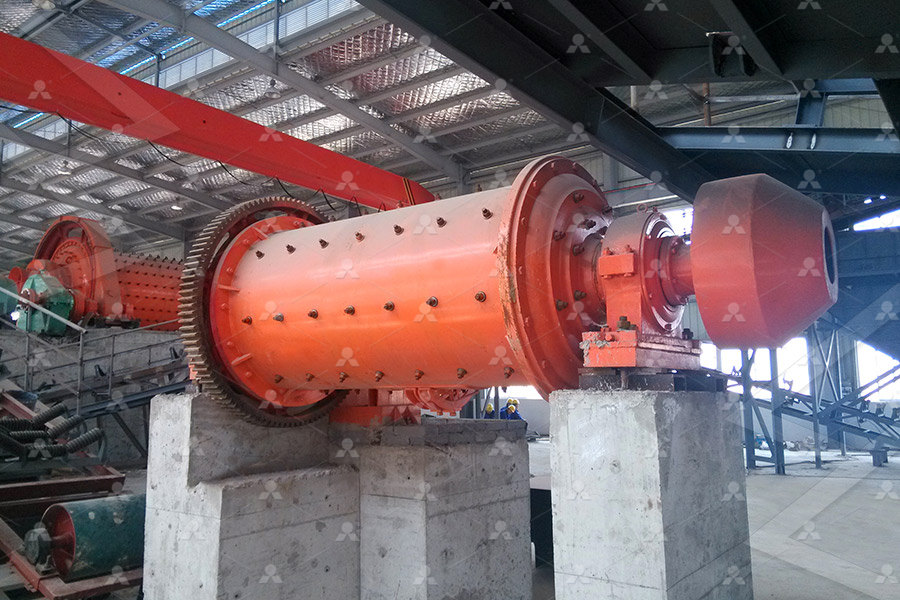

Raw mill Cement Plant

Raw mill is generally called cement raw mill, raw mill in cement plant, it refers to a common type of cement equipment in the cement plantIn the cement manufacturing process, raw mill in cement plant grind cement raw materials Difference between good poor mill operation maintenance can results in performance variation of +/10%, o Large central opening low ΔP maximizes mill ventilation; o Flow control optimizes material levels to maximize grinding Improvements in New Existing Cement Grinding The central control room concentration of cement raw realize freestanding roller mill production process of realtime monitoring, analysis, management and control It consists of two operator Design and Realization Of Roller Mill Control System2024年9月2日 Job Title: Central Control Room Operator (2 Fresher Jobs) Organisation: Hima Cement Limited Duty Station: Kasese, Uganda Vacancy Code: CCROX02 Reports to: Production Coach About the Company: Hima Cement Limited is a cement manufacturer in Uganda It is a subsidiary of the Sarrai Group, a diversified manufacturing conglomerate headquartered in 2 Fresher Central Control Room Operator Career Jobs Hima Cement

Everything you need to know about Remote Access and Control in Cement

Everything you need to know about Remote Access and Control in Cement Plants Over the last few years, central control rooms have been located out of sight of the kiln Currently, control rooms are being sited “Remote Access to Plant Control Systems,” Mill Session Papers, Manufacturing Technical Committee, Portland Cement OPERATION OF COOLER FANS Now consider control of the rate of air flow in the cooler The prime requirement in cooler control is to make sure that the air flow through the clinker bed is never restricted completely, because such a restriction leads directly to insufficient cooling of the clinker and possible damage to the cooler componentsEVERYTHING YOU NEED TO KNOW ABOUT OPERATION AND CONTROL A 10 MW cement mill, output 270 tonnes per hour A cement mill (or finish mill in North American usage [1]) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cementMost cement is currently ground in ball mills and also vertical roller mills which are more effective than ball millsCement mill Wikipedia2014年3月1日 Based on a dynamical model of the grinding process in closed circuit mills, efficient efforts have been made to optimize PID controllers of cement milling The process simulation is combined with an autoregressive model of the errors between the actual process values and the computed ones Long term industrial data have been used to determine the Optimizing the control system of cement milling: process

Grinding in Ball Mills: Modeling and Process Control

2012年6月1日 The process control in a ball mill grinding circuit faces severe difficulties due maintain a stable operation at fixed setpoi nts of the output Mill – Cement and Concrete Research, V olThe control room is where operators perform plant operations using control systems every day, and a safe, comfortable, and functional environment helps operators to run the plant more efficiently The control room must therefore be designed accordingly Yokogawa has been designing control rooms for various industries for over 30 yearsControl Room Design for Efficient Plant Operation YokogawaHighly energy intensive unit operation of size reduction in cement industry is intended to provide a homogeneous and super fine (30004000 Blain) Water spray installed generally in second compartment of ball mill to control cement temperature Feed is fed over the total width of the rollers by a central chuteCement Grinding Cement Plant OptimizationDigital technology will be a central factor in realising these as its intuitive approach supports cooperation between control room personnel and their digital tools, ensuring the plant runs consistently at peak performance Learn more Building an intelligent cement plant Advanced

Optimization of Cement Grinding Operation in Ball

Optimization of the Cement Ball Mill Operation The purpose of the central diaphragm is to retain the grinding media in their respective chambers, provide adequate opening for the airflow and, in some special types, regulate the feed Knowledgeable in all facets of operation in the cement plant while demonstrating competence in all aspects of control room operation WHAT YOU'LL BE DOING Control Room Operator Mill Creek Limestone Nights Martin Marietta Mill Creek, OK 74856 Typically responds within 4 Cement plant control room operator jobs IndeedCement Plant Operation Handbook Free ebook download as PDF File (pdf), Text File (txt) or read book online for freeCement Plant Operation Handbook PDF Mill (Grinding) ScribdRaw mill sweep with preheater exhaust is called compound operation The raw grinding and clinker burning operations become interdependent and constant kiln operation is required to ensure control of mill temperature and pressure When the kiln is down, the mill must also stop unless auxiliary heat is providedRaw milling and blending INFINITY FOR CEMENT EQUIPMENT

Operator Certification Program The Cement Institute

The efficient performance of a cement plant depends on the precise operation of the different manufacturing areas One of the keys to a successful, profitable, and sustainable operation relies on the skills, competency, and knowledge of the Control Room Operators (CRO) and BALL MILL OPERATION Free download as Powerpoint Presentation (ppt), PDF File (pdf), Text File (txt) or view presentation slides online This document provides guidelines for operating ball mills, including prerequisites and operating principles Some key points covered include: Material specifications for raw mills and cement mills in terms of granulometry, moisture, and temperatureBall Mill Operation PDF Cement ScribdTherefore, provision is made for controlled spray water inside the mill During mill operation magnetic separator and metal detector should be always functional to ensure to exclude tramp metal which can damage the grinding surfaces Primary roller mill controls are: Mill drive power or mill differential pressure to control mill feed rateRaw Material DryingGrinding Cement Plant OptimizationMonitoring and controlling mill operation: Realtime monitoring and control of mill operation can help identify inefficiencies and take corrective actions Advanced process control systems, such as mill optimization software, can analyze various operational data and provide recommendations for optimizing mill performance For instance, using Cement Mill Optimization: Practical Strategies for Enhanced

Optimizing the control system of cement milling:

2014年3月1日 Optimizing the control system of cement milling: bustness have been a central theme in th e develop operation of a cement mill, directly extracted from Scheduling of the cement mill in most cement plants is normally managed by the operator in charge, Communication between process controllers and central operator stations is via control networks Integrated systems Cement Plant Everything you need to know about Automation and central control room sophisticated instrumentation controls for monitoring the operation of the entire plant High efficiency classifiers have been installed at the overgrinding and enhance the mill's energy efficiencyNyati Cement Quality ControlCement Plant Operation Handbook Free ebook download as PDF File (pdf), Text File (txt) or read book online for free Cement Plant Operation HandbookCement Plant Operation Handbook PDF Mill (Grinding) Scribd

.jpg)

Highlevel control in cement production World Cement

2020年10月30日 Case study 1: Fully autonomous mill operation at EQIOM Ciments Autonomous mill operation using modules of AI is no longer science fiction In 2009 MILLMASTER was implemented in a VRM automation project in Northern France At its plant in Dunkerque, EQIOM Ciment’s Loesche type LM 462+2 S VRM mainly produces slag cement, 1995年10月29日 The control system, based on a 2S4265 CNC unit, allows the milling machine to be operated in universal mode (with manual control), automatic mode (to a set program), copying mode, gauging mode (PDF) Cement mill optimization: Design parameters2023年1月25日 Abstract An improved differential evolutionary cement mill operation index decision algorithm based on constraint control and selection strategy is proposed to address the problem that the operation index is usually decided by manual experience in the cement mill operation process, which causes unqualified cement specific surface area and excessive The Decision Algorithm of Cement Mill Operation Index BasedThe vertical roller mill (VRM) is a type of grinding machine for raw material processing and cement grinding in the cement manufacturing processIn recent years, the VRM cement mill has been equipped in more and more cement plants around the world because of its features like high energy efficiency, low pollutant generation, small floor area, etc The VRM cement mill has a Vertical Roller Mill Operation in Cement Plant

Control in Cement Production ScienceDirect

1983年1月1日 The paper deals with control in the cement manufacturing A short description of the technology is given first, then the control problems and applied AUTOMATION PROCESS CONTROL 1 APRIL 2020 INTERNATIONAL CEMENT REVIEW Building an intelligent cement plant Max Tschurtschenthaler, cement lead, and Gregor Schuetz, product manager, ABB Process Industries, explain the company’s vision for a digital future in the cement industry and the solutions it offers to get thereBuilding Main Head an intelligent cement plant ABB