Aluminum slag grinding machine process flow

Process flow diagram of alumina production (Bayer

In recent years, it is a hot research direction to improve the internal structure and properties of smelting slag by physical grinding and to prepare filling cementitious materials suitable forAbout 2 million tons of aluminum slag are generated during the process of primary aluminum smelting, fabrication and processing, and waste aluminum recycling in China The main Technical Report International Aluminium2023年4月1日 The process was based on four stages: (i) initial screening of the aluminum slag into particles smaller than 1 mm, (ii) crushing of particles to a size less than 100 µm, (iii) Synthesis strategies of alumina from aluminum saline slagsAnalyzing the melting process of a metallurgy at the industrial complex in Manaus, we saw that during the cleaning of the furnaces a metal tool is used to remove the slag, which brings with itAluminum Slag Separation Process Analysis Through a Vibratory

The aluminium industry: A review on stateoftheart technologies

2020年2月1日 Aluminium is becoming more frequently used across industries due to its beneficial properties, generally within an alloyed form This paper outlines the entire As the electric current flows through the electrolyte, it breaks down the dissolved alumina into its component elements as metallic aluminum and oxygen gas The oxygen reacts with the Chapter 2 Production and Processing of Aluminum The Minerals, 2024年1月31日 This study develops an intelligent datadriven approach for optimising slag grinding systems Slag grinding exhibits complex nonlinear dynamics that challenge control Intelligent process control system for predicting operating In the production of aluminium from bauxite, the intermediate alumina (Al2O3) is produced by a combination process; the alumina is subsequently smelted to aluminium via a THE ALUMINIUM STORY BAUXITE TO ALUMINA: THE BAYER

.jpg)

Grinding Machine an overview ScienceDirect Topics

A grinding machine is a device that is defined by its ability to control parameters such as rotor speed, feed rate, and grinding time to efficiently reduce the size of particles through various 2024年1月31日 Slag grinding exhibits complex nonlinear dynamics that challenge control The proposed system monitors key operating parameters to assess machine health and automate control adjustments Operating data are Intelligent process control system for predicting 2024年1月31日 Intelligent process control system for predicting operating conditions of slag grinding machines: a data mining approach for improved efficiency and energy savings Anping Wan , Chenyu Du , [] , Ting Chen , Jiabo He [ protected] , and Khalil AlBukhaiti [ protected] +2 2 View all authors and affiliationsIntelligent process control system for predicting operating Aluminium dross recovery machine Aluminium dross recovery machine The Aluminum Dross Recovery Machine is a crucial tool in the aluminum recycling industry, dedicated to reclaiming valuable aluminum from a byproduct known Aluminium dross recovery machine Aluminum

.jpg)

Multiscale analysis of fine slag from pulverized coal gasification in

2024年2月3日 Fine slag (FS) is an unavoidable byproduct of coal gasification FS, which is a simple heap of solid waste left in the open air, easily causes environmental pollution and has a low resource utilization rate, thereby restricting the development of energysaving coal gasification technologies The multiscale analysis of FS performed in this study indicates typical grain size A grinding machine is a device that is defined by its ability to control parameters such as rotor speed, feed rate, Jinchuan mineral processing branch plant copper aluminum slag recovery copper process flow chart Figure 123Grinding Machine an overview ScienceDirect TopicsHIGHEST SCREENING QUALITY FOR YOUR PROCESS SPALECK screening machines and conveying technologyplay an indispensable role in the processing of slag from steelworks and waste incineration plantsWe not only enable you to efficiently recover metals, ferrous and nonferrous components, but also to precisely separate the many other components and resources Screening machines for slag processing SPALECKAbout 2 million tons of aluminum slag are generated during the process of primary aluminum smelting, fabrication and processing, and waste 31 The new process flow scheme The aluminum element, which weighted approximately 40% in the secondary aluminum dross is the most valuable part for recycling, mainlyTechnical Report International Aluminium

Abrasive Flow Machining Systems Winbro Flow Grinding

High production fixtures are made from steel or aluminum and use polyurethane coated inserts to protect the workpiece from abrasive scratching or grooving Depending on part size and machine size fixtures can hold from 1 to 50 or more Machines A flow Chapter 2 Production and Processing of Aluminum 21 Extraction of Aluminum The extraction of aluminum from its ore and subsequent processing into finished products takes place in a series of successive operations, each largely independent of the other Generally the various processes are carried out at different plant sites A summary ofChapter 2 Production and Processing of Aluminum The 2023年8月13日 Why is welding aluminum considered one of the most challenging tasks in metalworking? Aluminum's unique properties—like its high thermal conductivity, oxidation susceptibility, and tendency for hot cracking—demand specific techniques and materials to ensure strong, defectfree welds This article explores the intricacies of welding aluminum, from Welding of Aluminum and Aluminum Alloys: ExplainedSlag is actually a term in a broad sense, which can generally refer to the waste slag discharged from all smelting furnaces or incinerators What is the purpose of slag grinding and what is the specific process flow of slag grinding? The following is a detailed explanation of the process flow of using the slag vertical roller mill to complete the slag grinding:Application Of Slag Grinding Mill Introduction To Treatment Process

Aluminium dross processing technology innovation

2017年10月2日 * High efficiency for recycling rate (91% of aluminum from the slag), short working time 4 Equipment and machines Aluminum dross processing machine and dust collector The loading capacity can be 150 to 2024年2月1日 Aluminum metal was produced using the cryolitealumina molten salt electrolysis method (Ishak et al, 2017)A large amount electrolytic aluminum slag (EAS) is generated during the electrolysis process, as the falling of carbon particles on the anode into the electrolysis cells and the accumulation of lithium fluorine result in energy consumption and electrolyte scrapping Efficient lithium recovery from electrolytic aluminum slag via an 2022年1月10日 Selective comminution and grinding mechanisms of spent carbon anode from aluminum electrolysis using ball and rod mills January 2022 Physicochemical Problems of Mineral Processing 58(3):Selective comminution and grinding mechanisms of 2023年10月19日 Process flow of ultrafine slag grinding The process scope of the ultrafine composite mineral admixture grinding system includes the following steps: starting from the bottom of the storage at What is a ultrafine slag grinding plant? ultrafine slag grinding

2FD{P}PC]854]XQ.jpg)

Steel Slag Processing Plant Equipment Selection

2023年12月27日 The impact crusher is widely used in highway construction, water conservancy engineering, construction gravel, machine sand processing, and other fields the common steel slag grinding equipment is steel slag ball mills Magnetic separator; The purpose of the steel slag process is to recover useful ironcontaining components 2023年2月15日 Slag bricks Slag brick production process Slag brick is made by mixing, watering, grinding and pressing slag and limestone In the production process of slag brick, the particle size of the slag is generally smaller than 8 mm, and the steam temperature injected into the kiln is about 80 ℃ to 100 ℃, the maintaining time is about 12 hoursHow to Process Slags (with detailed process)? Fote Machinery2018年12月14日 Results are provided for a study of porous ceramic materials prepared in the course of chemical and exothermic reactions based on a system containing secondary resources (chamotte scrap, mullite (PDF) THE USE OF ALUMINUM SLAG RECYCLING PRODUCTS IN 2021年5月10日 In this study, material flow analysis (MFA) was used to characterize the flow of aluminum in China during its life cycle (ie, the process from cradle to grave: ore mining, beneficiation, refining, smelting, rolling, manufacturing, trading, use, waste management, and recycling, which is shown in Fig 1)MFA is an effective means of industrial metabolic research Aluminum material flow analysis for production, consumption,

The effect of hydrochloric acid (HCl) on the structure and wear

2024年2月23日 In this study, the wear rate of a selfmanufactured grinding stone made from aluminum slag treated with HCl as the abrasive material was compared to grinding stones from previous studies and commercial grinding stones sold on the market using the ASTM D3702 standard wear testJune 2022; ARCHIVE Proceedings of the Institution of Mechanical Engineers Part C Journal of Mechanical Engineering Science 19891996 (vols 203210) 236(2):1107(PDF) A comprehensive review on the grinding process: 2023年7月30日 Countermeasure: Adjust the process flow, such as polishing, buffing, reacid washing or alkali washing, etc IV Chemical and Electrochemical Polishing of Aluminum 1 Briefly describe the similarities and differences in the Aluminum Alloy Anodizing Surface Treatment: Recovery of carbon and cryolite from spent carbon anode slag of electrolytic aluminum by flotation based on the evaluation of selectivity index Yemin Wang1, Xuexia Wang1* and Muhammad Bilal2 Recovery of carbon and cryolite from spent carbon anode slag of

.jpg)

Preparation and Melting of Scrap in Aluminum

2018年1月9日 This work provides an overview of the aluminum (Al) recycling process, from the scrap upgrading to the melting process Innovations and new trends regarding the Al recycling technologies are highlighted Aluminum Usually none Waterjet is a coldcutting process that leaves a satin smooth edge Plasma: Typically, yes Slag grinding for removal of HAZ (heataffected zone) flattening to eliminate distortion from heat Assist gas used impacts depth of HAZ Laser: Sometimes yes Removal of oxidized edge and HAZ Gases used impact depth of HAZ EDM: Usually Waterjet Cutting Compared to Other Technologies Flow Waterjet2019年8月23日 Mica processing description from its geology mineral property to how to extract mineral from rock and placer deposit, related processing plant flow chart and layout design Gold Mining Equipment Chat on WhatsAppMica Processing Equipment, Process Flow, Cases JXSC MachineCompared with the open flow system, the circular flow system can easily adjust the product fineness, reduce the material overgrinding phenomenon, and improve the grinding efficiency However, the system of this grinding process is complex, and the disadvantages of small singlemachine capacity and low efficiency still existGGBS Production Line Slag Mill for Slag Powder Grinding AGICO

.jpg)

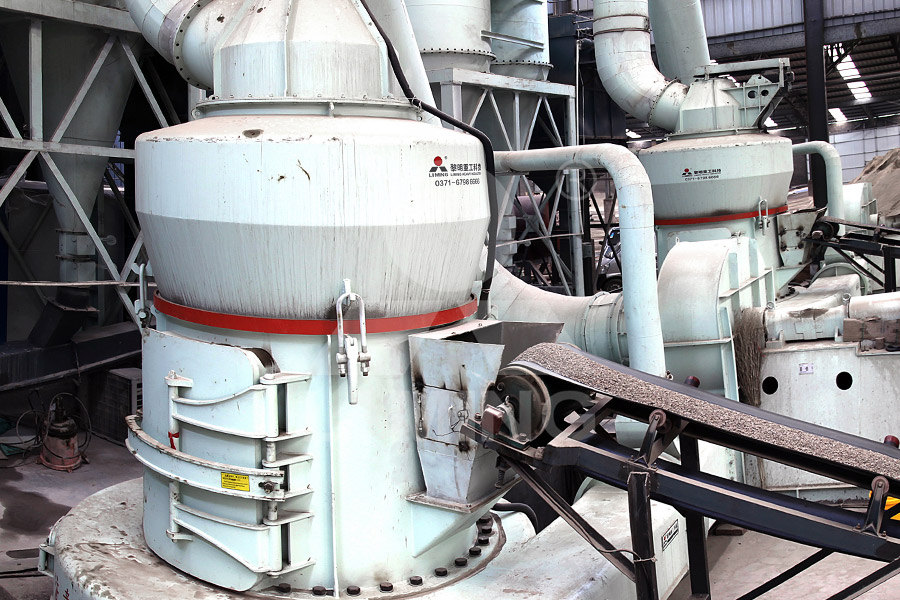

Slag Grinding Production Line TAYMACHINERY

The slag grinding production line is a production system specially used to process slag and make slag powder Slag, as a byproduct in the industrial production process, can be converted into valuable resources through grinding processing and used in cement mixtures, highperformance concrete admixtures, etc2024年3月12日 Leading Technology: We have advanced steel slag processing technology and equipment that can efficiently and environmentally recycle steel slag Rich Experience: With over 40 years of experience in steel slag processing and machinery manufacturing, we have provided professional solutions and services to numerous clients in the fieldSteel Slag Recycling: The Definitive Processing Solution2024年6月2日 Aluminum dross and aluminum slag enter the sorting workshop, and after threescreen and twomill sorting, the sorted aluminum enters the smelting workshop to be melted into aluminum ingots The sorting residue is mixed with limestone powder in a certain proportion, preheated and calcined in a rotary kiln to become a refining agent, which is then cooled, The comprehensive treatment process of secondary aluminum 2018年4月8日 This work provides an overview of the aluminum (Al) recycling process, from the scrap upgrading to the melting process Innovations and new trends regarding the Al recycling technologies are Preparation and Melting of Scrap in Aluminum Recycling: A Review

Intelligent process control system for predicting operating

2024年1月31日 Intelligent process control system for predicting operating conditions of slag grinding machines: a data mining approach for improved efficiency and energy savings Anping Wan , Chenyu Du , [] , Ting Chen , Jiabo He [ protected] , and Khalil AlBukhaiti [ protected] +2 2 View all authors and affiliationsAluminium dross recovery machine Aluminium dross recovery machine The Aluminum Dross Recovery Machine is a crucial tool in the aluminum recycling industry, dedicated to reclaiming valuable aluminum from a byproduct known Aluminium dross recovery machine Aluminum 2024年2月3日 Fine slag (FS) is an unavoidable byproduct of coal gasification FS, which is a simple heap of solid waste left in the open air, easily causes environmental pollution and has a low resource utilization rate, thereby restricting the development of energysaving coal gasification technologies The multiscale analysis of FS performed in this study indicates typical grain size Multiscale analysis of fine slag from pulverized coal gasification in A grinding machine is a device that is defined by its ability to control parameters such as rotor speed, feed rate, Jinchuan mineral processing branch plant copper aluminum slag recovery copper process flow chart Figure 123Grinding Machine an overview ScienceDirect Topics

.jpg)

Screening machines for slag processing SPALECK

HIGHEST SCREENING QUALITY FOR YOUR PROCESS SPALECK screening machines and conveying technologyplay an indispensable role in the processing of slag from steelworks and waste incineration plantsWe not only enable you to efficiently recover metals, ferrous and nonferrous components, but also to precisely separate the many other components and resources About 2 million tons of aluminum slag are generated during the process of primary aluminum smelting, fabrication and processing, and waste 31 The new process flow scheme The aluminum element, which weighted approximately 40% in the secondary aluminum dross is the most valuable part for recycling, mainlyTechnical Report International AluminiumHigh production fixtures are made from steel or aluminum and use polyurethane coated inserts to protect the workpiece from abrasive scratching or grooving Depending on part size and machine size fixtures can hold from 1 to 50 or more Machines A flow Abrasive Flow Machining Systems Winbro Flow GrindingChapter 2 Production and Processing of Aluminum 21 Extraction of Aluminum The extraction of aluminum from its ore and subsequent processing into finished products takes place in a series of successive operations, each largely independent of the other Generally the various processes are carried out at different plant sites A summary ofChapter 2 Production and Processing of Aluminum The

Welding of Aluminum and Aluminum Alloys: Explained

2023年8月13日 Why is welding aluminum considered one of the most challenging tasks in metalworking? Aluminum's unique properties—like its high thermal conductivity, oxidation susceptibility, and tendency for hot cracking—demand specific techniques and materials to ensure strong, defectfree welds This article explores the intricacies of welding aluminum, from Slag is actually a term in a broad sense, which can generally refer to the waste slag discharged from all smelting furnaces or incinerators What is the purpose of slag grinding and what is the specific process flow of slag grinding? The following is a detailed explanation of the process flow of using the slag vertical roller mill to complete the slag grinding:Application Of Slag Grinding Mill Introduction To Treatment Process