gp100 barite mill hydraulic and lubrication system structure video

Mill Lubrication System PPT Free Download SlideShare

2014年1月13日 The document discusses the hydraulic lubrication system of a SAG mill It provides definitions and discusses the importance of lubrication in reducing friction and wear 2015年4月30日 This paper describes the function and operation of lubrication systems for Ball Mill and SAG Mill Drives Provided within this paper are hydraulic schematics, functional Ball mill/SAG mill drive lubrication system IEEE Conference 2016年1月10日 On a 11’6” x 22’0” Ball Mill, the trunnion bearing lubrication system provides continuous low pressure flood oil for cooling and lubrication of the bearings, and high pressure Ball Mill Trunnion Bearing Lube System 911MetallurgistAdding a Bijur Delimon lubrication system increases equipment life by decreasing wear on vital components Pressurized lubrication, replacing the bath type lubrication, is used to lubricate Oil Circulating Systems for Ball Mills Bijur Delimon

.jpg)

Oil/Air Lubrication Systems for Steel Production Facilities

conventional lubrication used in steel mill applications, oil/air lubrication reduces environmental pollution, increases lubricating and sealing performance, improves the highspeedIn order to calculate the load support required by bearings, there is a need to study the structure and nature of fluid flow This book discusses the theories and applications of hydrodynamic Fundamentals of Engineering Tribology with ApplicationsThe wide range of Bijur Delimon products for commercial steel lubrication means you can tailor a lubrication system to your exact needs From a Farval® Dualine pump and feeder valves to a Commercial Steel Lubrication Systems Bijur DelimonDualine DD and DM lubricating valves are completely hydraulic in operation and will deliver either oil or grease They are also fully and individually adjustable in regard to discharge quantity and Farval Lubrication Systems Bijur Delimon International

G[R.jpg)

ROLLING MILL LUBRICATION SYSTEMS Primetals Technologies

This modular lubrication system for nonferrous rolling mills arrives fully assembled and factory tested The Primetals Technologies system is supplied with standby pumps and motors and a 2023年4月1日 A detailed list of additives is focused in this review which will enhance the performance and working of the hydraulic fluid by enhancing lubrication, modifying viscosity and cleaning engine depositsPerformance of hydraulic oils and its additives in fluid 2006年10月15日 Hydraulic systems may use a variety of fluids ranging from water (with or without additives) to hightemperature fireresistant typesAgain the fluid is different but the operating characteristics change little Pneumatic CHAPTER 5: Pneumatic and Hydraulic Systems•to transfer power in the application (hydraulic, automatic transmission, breaks) [6, 8] Functionality of lubricants is defined by their chemical structure and their physical properties Basics of lubrication are covered by organic chemistry to a major and inorganic chemistry to a minor extent [2, 3]Fundamentals of Lubricants and Lubrication IntechOpen

630 Lubrication System for Rolling Mill Gear Reducer

630 Lubrication System for Rolling Mill Gear Reducer, highquality carbon steel, carbon structural steel, lowalloy steel; annual production of 2050 million tons Highspeed wire rod production line the round steel rolling φ55φ25 specifications wire rod, Hydraulic Parts Solenoid Cylinder for Steel Rolling Mill Production LineMill Bearings and Lubrication (TST) Free download as Powerpoint Presentation (ppt), PDF File (pdf), Text File (txt) or view presentation slides online The document discusses ball mill bearings and lubrication systems It describes the two main types of bearings used slide shoe bearings and trunnion bearings It explains the lubrication principles and components of the lubrication Mill Bearings and Lubrication (TST) PDF Scribd2016年1月10日 On a 11’6” x 22’0” Ball Mill, the trunnion bearing lubrication system provides continuous low pressure flood oil for cooling and lubrication of the bearings, and high pressure oil for hydrostatic lift of the feed and discharge trunnions during startup of the mill System monitors including pressure switches and flow monitors are provided, along with temperature sensors Ball Mill Trunnion Bearing Lube System 911MetallurgistTYPES OF ENGINE LUBRICATION SYSTEM: There are mainly four types of lubrication systems used in automotive engines which are: 1 Petroil System 2 Splash System 3 Pressure system 4 DrySump System COMPONENTS OF ENGINE LUBRICATION SYSTEM: 1 Oil Sump 2 Engine oil filter 3 Piston cooling nozzles 4 Oil Pump 5 The Oil Galleries 6 Oil Cooler 7Engine Lubrication System Working Principle , Types and

.jpg)

Designing and manufacturing an automated lubrication control system

2014年2月1日 Nevertheless, the actual pressure of lubricant reaching the spindle and other critical areas of the machine tools was not considered Additionally, an automated lubrication system was developed to 2023年12月5日 I found that this series provides some very useful and specific informationtheir endorsement of TW25B and showing the specific lubrication points and amounts to be applied was much appreciated Fieldstripping a Ruger doubleaction revolver (in my case, a Security Six and GP100) isn't inordinately difficult, but in addition to the videos, I recommend having on Cleaning and Lubricating A Ruger GP100Maintenance contracts for the service of hydraulic systems, updating of hydraulic diagrams, drafting of spare parts lists and checklists; Recharge of hydraulic accumulators with nitrogen, also directly at the Customer premises for pressures up to 400 bars; Replacement of hoses complete with holding system according to current standards; Replacement of filter elementsSystem Fluid Manufacture of hydraulic, pneumatic and lubrication systemlubrication system, seal contact pressure is reduced As a result, the starting torque is reduced by approximately 1/6 This is effective in preventing damage from roll slippage 3 2 Structure of Koyo Oil/Air Lubrication System2) The Koyo oil/air lubrication system is a general purpose unit designed to enable construction of a flexible systemOil/Air Lubrication Systems for Steel Production Facilities

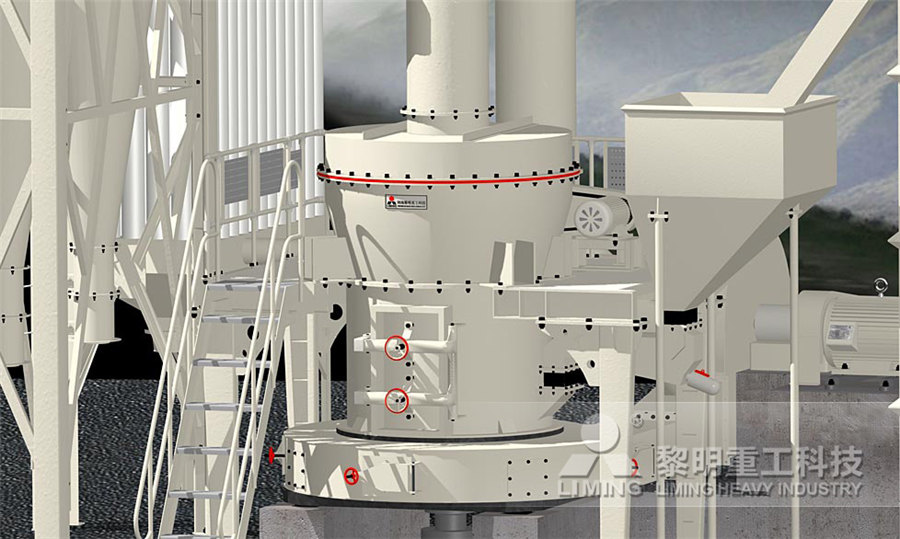

HPC Hydraulic cone crusher Baichy Machinery

The special thin oil lubrication system design of the multicylinder hydraulic cone crusher improves the lubrication performance of the equipment and prolongs the service life of the equipment 4 The special crushing chamber designed by 2021年3月18日 Abstract A mathematical modeling approach to determine fluid film thickness on the vane tip in a vane pump transmission is developed The transmission is based on a doubleacting vane pump with an additional output shaft coupled to a floating ring Owing to the floating ring design, the internal viscous friction helps to drive the output shaft, whereas the friction is Lubrication and Fluid Film Study on the Vane Tip in a Vane Pump During operation, these bearings require hydraulic oil pumped at pressures up to 15,000 psig or higher for lubrication The Dynex PF4200 series pump provides the necessary pressure required to lift and lubricate these bearings, while also providing the durability needed during periods of high temperature and contamination found in steel millsHydraulic Pumps for Steel Mill Bearing Lubrication System DynexThe two systems differ in the way they alternately pressurized and relieve (reverse) the two supply lines as well as in the way they control maximum system pressure and end the lubrication cycle On DC41 systems, pressure is controlled by a pressure switch (one is installed in each line) that actuates the reversing valve (FR20) and stops the pump motor when system pressure rises to Farval Lubrication Systems Bijur Delimon International

roller mill hydraulic system KOOKS

Hydraulics OperationCoalMillpdf Mill (Grinding) Valve structure lubrication hydraulic cabinet connecting pipeline from the hydraulic cabinet to the roller roller with bearings to be lubricated Process and operation – LOESCHE Vertical Roller Mill Main assembly groups RM mill: Roller lubrication system HSMS Type Coal and Raw material 2022年12月7日 The internal combustion engine contains numerous friction parts Friction wears them out and causes them to overheat To reduce friction and remove heat, carEngine lubrication system / How does it work? (3D animation)2015年4月26日 This paper describes the function and operation of lubrication systems for Ball Mill and SAG Mill Drives Provided within this paper are hydraulic schematics, functional description and a general overview of system layout as well as some of the important features and factors relevant to improving the reliability of this very critical part of the grinding mill drive Ball mill/SAG mill drive lubrication system Semantic Scholar2023年11月28日 As shown in Fig 3, where m denotes the mass of the roll system, k 0 is the equivalent stiffness of the roll system, c 0 is the equivalent damping, f s (y) is the hydraulic cylinder nonlinear spring force, f c (ẏ) is the hydraulic cylinder nonlinear frictional force, and ΔPcos(ωt) is the external excitation of the mill system, where ΔP is the external excitation Dynamics and stability analysis of rolling mill system during

.jpg)

ROLLING MILL LUBRICATION SYSTEMS Primetals Technologies

OTHER RELATED PRODUCTS • Entry shear and table • Rolling mill stands • Hydraulic roll mounting • Rolling mill lubrication systems • Coil forming equipment • Coil handling solutions • Dual reel coiler and automatic unloader Inline duplex filter Vacuum dehydrator Primetals Technologies USA LLC A joint venture of Mitsubishi Heavy Industries and partners2013年5月22日 Low viscous hydrocarbons from ISO VG 10, 15, 22, 32, 46, 68 and 100 are in use as hydraulic oils Common hydraulic oil viscosity is around ISO VG 32, 46 and 68 Hydrocarbons with higher viscosities are part of Fundamentals of Lubricants and LubricationFor use on large machinery, effective in harsh conditions Dualline systems dispense a precise, metered amount of lubricant to up to 2 000 lubrication points over long distances up to 120 m (131 yd) and more Even if one pair of outlets becomes blocked inside one metering device, dualline systems provide sufficient lubrication for the rest of the system’s lubrication pointsDualline lubrication systems SKF Lincoln SKF2019年5月17日 To prevent the dangers of incendiary oil, steel mills use fireresistant hydraulic fluids Water glycol fluids commonly find their home in mills for their inherent safety and excellent properties as a hydraulic fluid Water glycol provides good lubrication and antiwear properties, and is readily available by most hydraulic fluid manufacturersHydraulics and steel production go handinhand

.jpg)

Danieli Hydraulics Industrial Hydraulic and Lubrication

Industrial Hydraulic and Lubrication Equipment danielihydraulics CuttingEdge Technology Center for Hydraulic Systems and much more 18/26 Vision; History; Milestones Thanks to the expertise and knowhow gained in the steel industry, Danieli Hydraulics can provide any stage of engineering, production and commissioning BRANT HYDRAULICS has extensive experiences and capabilities on building heavyduty cylinders for steel mill applications Steel mills cylinders have been one of our strength over years and our customers are always satisfy with our cylinders Over the years, our steel mill applications has covered the whole steel making production line We have experiences in doing ALL the Steel Mill applications Brant HydraulicsLubricators and Lubrication Systems PurgeX Circulating Oil System with 1 gal Acrylic Reservoir, 2 Feeds, Motor Operated, 120V/60Hz, 6 RPM, Bracket B43602BMill Lubrication Systems Products Suppliers GlobalSpec41434 Cleanliness requirements for lubrication and hydraulic components 104 41435 Limiting solid particle contamination through the use of highquality lubrication or hydraulic filters 106Operating fluids for stationary and mobile lubrication and hydraulic

Design and Development of a Dry Sump Lubrication System for a Formula

2019年1月9日 The entire engine lubrication system has been represented by a seriesparallel network of flow passages and flow elements The pressure distribution and flow rates in the network were computed 2010年8月6日 Monoblock Dual Line System: The dual line distributors have adjustable output They have operating pressure of max 300 bar and min 30 bar The output can be adjusted as per requirement with the help of external output volume adjusterAUTOMATIC LUBRICATION SYSTEM Dual Line Distributors 2023年4月1日 A detailed list of additives is focused in this review which will enhance the performance and working of the hydraulic fluid by enhancing lubrication, modifying viscosity and cleaning engine depositsPerformance of hydraulic oils and its additives in fluid 2006年10月15日 Hydraulic systems may use a variety of fluids ranging from water (with or without additives) to hightemperature fireresistant typesAgain the fluid is different but the operating characteristics change little Pneumatic CHAPTER 5: Pneumatic and Hydraulic Systems

.jpg)

Fundamentals of Lubricants and Lubrication IntechOpen

•to transfer power in the application (hydraulic, automatic transmission, breaks) [6, 8] Functionality of lubricants is defined by their chemical structure and their physical properties Basics of lubrication are covered by organic chemistry to a major and inorganic chemistry to a minor extent [2, 3]630 Lubrication System for Rolling Mill Gear Reducer, highquality carbon steel, carbon structural steel, lowalloy steel; annual production of 2050 million tons Highspeed wire rod production line the round steel rolling φ55φ25 specifications wire rod, Hydraulic Parts Solenoid Cylinder for Steel Rolling Mill Production Line630 Lubrication System for Rolling Mill Gear ReducerMill Bearings and Lubrication (TST) Free download as Powerpoint Presentation (ppt), PDF File (pdf), Text File (txt) or view presentation slides online The document discusses ball mill bearings and lubrication systems It describes the two main types of bearings used slide shoe bearings and trunnion bearings It explains the lubrication principles and components of the lubrication Mill Bearings and Lubrication (TST) PDF Scribd2016年1月10日 On a 11’6” x 22’0” Ball Mill, the trunnion bearing lubrication system provides continuous low pressure flood oil for cooling and lubrication of the bearings, and high pressure oil for hydrostatic lift of the feed and discharge trunnions during startup of the mill System monitors including pressure switches and flow monitors are provided, along with temperature sensors Ball Mill Trunnion Bearing Lube System 911Metallurgist

Engine Lubrication System Working Principle , Types and

TYPES OF ENGINE LUBRICATION SYSTEM: There are mainly four types of lubrication systems used in automotive engines which are: 1 Petroil System 2 Splash System 3 Pressure system 4 DrySump System COMPONENTS OF ENGINE LUBRICATION SYSTEM: 1 Oil Sump 2 Engine oil filter 3 Piston cooling nozzles 4 Oil Pump 5 The Oil Galleries 6 Oil Cooler 72014年2月1日 Nevertheless, the actual pressure of lubricant reaching the spindle and other critical areas of the machine tools was not considered Additionally, an automated lubrication system was developed to Designing and manufacturing an automated lubrication control system 2023年12月5日 I found that this series provides some very useful and specific informationtheir endorsement of TW25B and showing the specific lubrication points and amounts to be applied was much appreciated Fieldstripping a Ruger doubleaction revolver (in my case, a Security Six and GP100) isn't inordinately difficult, but in addition to the videos, I recommend having on Cleaning and Lubricating A Ruger GP100Maintenance contracts for the service of hydraulic systems, updating of hydraulic diagrams, drafting of spare parts lists and checklists; Recharge of hydraulic accumulators with nitrogen, also directly at the Customer premises for pressures up to 400 bars; Replacement of hoses complete with holding system according to current standards; Replacement of filter elementsSystem Fluid Manufacture of hydraulic, pneumatic and lubrication system