extrusion mill

.jpg)

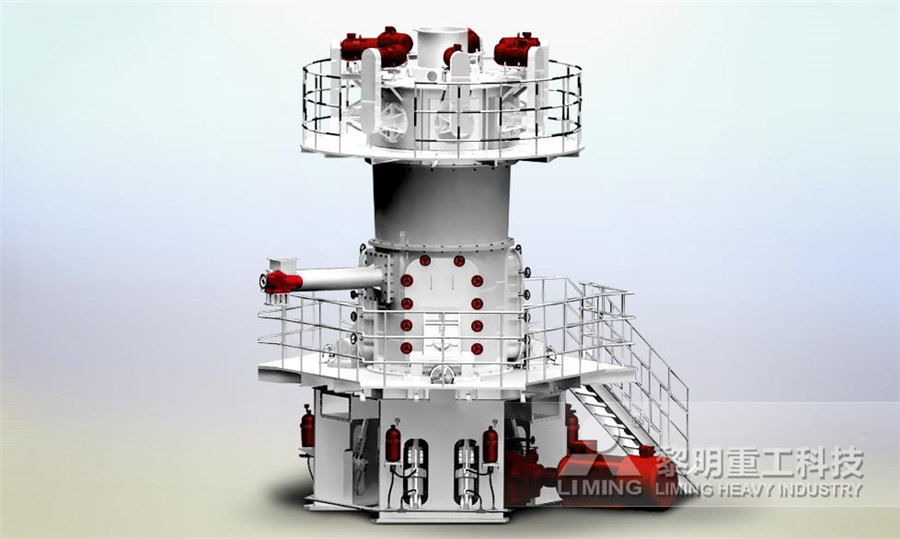

Extrusion Mill MTC Precision Engineering Machine

The Extrusion Mill, powered by a multithread Aluminum Extrusion Machining Centers 45 axis Single or multispindle Complete parts in one setup Turnkey solutions Full automation options are available ROI 1113 months MODIG Machine Tool, the pioneer in extrusion Aluminum Extrusion Machining Centers Modig Taber Extrusions offers ultraprecision extrusions ® Our microextrusion manufacturing lines have a production envelope with a circle size of 3 inches or less and a weight per foot of 008 up to 5 lbs ft For comparison, the 8,600 Ultra Precision Aluminum Extrusions Taber ExtrusionsWe are a fully integrated aluminum extrusion mill, delivering custom shapes in a broad range of finishes With extensive inhouse capabilities, we’re able to quickly provide our customers with Sierra Aluminum Home Comprehensive Aluminum Solutions

Extrusion Machining Learn About Extrusion

An extrusion machining center is a machine used to precisely cut and shape the extrusion to a finished part To achieve the desired shape with pockets, holes, and other features the extrusion machining center utilizes various techniques The ForestLiné MGP™150 is a modular machine capable of drilling, milling, chamfering, routing and endmachining from short and simple to long and complex aluminum extrusions The ForestLiné MGP™ 150 features three Extrusion profile Fives GroupMilacron offers inhouse designed and built full extrusion systems tailored to your needs From sheet and pellets to complex shapes, our single and twin screw extrusion machines deliver unparalleled productivity and costefficiencyExtrusion Machines: Customizable, HighPerformance Taber Extrusions MicroExtrusion Capabilities Our microextrusion manufacturing lines have a production envelope with a circle size of 3 inches or less and a weight per foot of 008 up to 5 lbs ft For comparison, the 8,600 ton press in Ultra Precision Aluminum Extrusions Taber Extrusions

.jpg)

aluminum mill finish

It is raw aluminum from our mill and it can be field primed and painted Typically, Mill Finish has a shiny or “mirrorlike” appearance with some visible manufacturing lines What is meant by “Mill Finish” is aluminum in its original form and appearance as its comes directly from the rolling mill or an aluminum extrusion millSpecialty Copper Extrusion Process As a Specialty Copper Mill, our high quality extruded shapes, rods, and bars are produced from billets we cast inhouse The necessary materials are carefully combined in our two large induction Copper Extrusion Manufacturing Bronze Brass HHV EXTRUSION MILL LEADING THE MARKET REDUCED CYCLE TIME HHV delivers high productivity with extraordinary precision and repeatability This small footprint universal machining center accommodates aluminum and carbon fiber parts up to 60 feet long with a cross section of 10x6 inches HHV features a revolutionary patented rotary chuck design making it possible to HHV EXTRUSION MILL Modig Machine Tool DirectIndustryThe Natural Aluminum Surface Mill finish refers to the raw, unprocessed surface of aluminum profiles as they exit the extrusion die This finish is the natural appearance of aluminum, characterized by its silver tone Since it undergoes no additional surface treatment, some die lines and marks are often visible, giving it an untreated and functionalEXTRUSION – MILL FINISH Bayer Aluminum

.jpg)

Understanding Aluminium Extrusion Mill Finish: Characteristics

Aluminium extrusion mill finish is straight out of the extrusion press, that is often further processed by our customers as it has not been treated or finished in any way Mill finish typically has a slightly rough texture and is dull in colour compared to brushed or anodised aluminiumMost aluminum extrusion profiles request only mill finish or clear anodizing surface for basic corrosion resistance They emphasize the mechanical properties of aluminum material that can meet the application requests Different aluminum alloy and temper is with different mechanical properties There are 6060, 6063, 6061, 6082, Aluminum Extrusion Profiles Manufacturer Supplier FONNOVZarbana Aluminum Extrusions was founded in 2005 It was originally introduced as Zarbana Industries, Inc, and was a fabricationonly shopIn 2016, Zarbana was purchased as an offshoot of the Extral Technology Group (producer of complete extrusion systems and aluminum foundries) and operates in the production of aluminum alloy extrusionZarbana Aluminum Extrusions, LLCStarting with the design we cooperate with reliable die makers and extrusion partners to offer you the best extrusion solution We can make new dies and approve samples in 23 weeks depending on the section and our leadtime for mill finish profiles into Europe is 4 weeks and just 5 weeks for anodised profilesALUMINIUM EXTRUSION

Capral Mill Catalogue PDF Extrusion Australia

Capral Mill Catalogue Free download as PDF File (pdf), Text File (txt) or read online for free This document is a catalogue from Capral, Australia's largest aluminium extruder, listing various extruded aluminium angle profiles available It provides information on the dimensions, radii, mass, and state of manufacture for over 100 angle profiles available in sizes ranging from Ye Fong Aluminum Industrial Ltd is the aluminum alloy manufacturer/mill in TAIWAN Ye Fong has established indirect/direct extrusion pressers, and integrated with straightening, cold drawing lines and heat treating processes Ye Fong Aluminium Aluminum Alloy Wire/Rod, Bar, Mifa produces completely finished precision extrusion profiles with size tolerances as low as ±002 mm Read about our capabilities and expertise hereSpecialist in precision extrusion profiles Mifa Mifa 2024年10月28日 Aluminum extrusion plays a critical role in many industries In the automotive sector, it is used to make lightweight yet durable parts, improving fuel efficiency by reducing overall vehicle weight Aerospace companies rely Aluminum Extrusion Process: Techniques, Benefits,

.jpg)

Aluminum Extrusion Company Nanshan America

Nanshan America is your goto aluminum extrusion company for large scale projects! See our custom projects—complete with ontime delivery#1 – Mill Finish At first, all aluminum extrusions have a mill finish This reflects the state of the aluminum after it leaves the extrusion die Die and tooling marks, a dull appearance, oxidation, and white “rust” can all be present on the aluminum after extrusion9 Types of Aluminum Finishes That Will Enhance Your Product2021年9月6日 The aluminum extrusion industry has seen a lot of changes over the past few years There are more and more companies using aluminum, including those who never used it before, all because there is a demand for this type of product Aluminum extrusions can be produced in many ways – from cutting to bending – and each process will give you a slightly 8 Different Surface Finishes that are used on Aluminum ExtrusionsOur mill facility features two presses with capabilities to produce straight rod and coils, in a range of sizes Here, brass billets are heated to the proper temperature and placed into the press container for the extrusion process All extrusion processes are highly automated and monitored to ensure the maintaining of consistent parametersBrass Processing Mill Wieland Chase

Products Kaiser Aluminum

At Kaiser, we don’t just make a wide spectrum of aluminum mill products We make them better Our products are highly sophisticated based on the metallurgy and physical properties of the metal and special characteristics that are required for particular applicationsWe could provide our customers with a comprehensive range of products and services such as mill finish, Extrusion presses range from 660 tons to 2000 tons, up to 7 EXTRUSION Aluminium Alloy Series AA6063, AA6060 Temper:TF, T4, T5, T6 Extrusion Application: Architectural, Electronic Parts and General PurposeExtrusion PT STARMAS INTI ALUMINIUM INDUSTRYZarbana Aluminum Extrusions was founded in 2005 It was originally introduced as Zarbana Industries, Inc, and was a fabricationonly shopIn 2016, Zarbana was purchased as an offshoot of the Extral Technology Group (producer of complete extrusion systems and aluminum foundries) and operates in the production of aluminum alloy extrusionZarbana Aluminum Extrusions, LLC6 天之前 The feeds are made either using a pellet mill or extrusion The choice of the process primarily depends on what type of feed would be made for most part of equipment running time The feeds are generally divided into different types based on their buoyancy sinking, slow sinking or floating typeFish Feed Production: Pellet Mill Vs Extrusion

.jpg)

Mill Finish Aluminum vs Clear Anodized Aluminum

2023年11月23日 In consumer goods, aluminum foil, cans, and packaging are all examples of millfinished aluminum Aluminum Extrusion Extruded aluminum, produced through hydraulic extrusion processing, is frequently utilized directly HighPressure Roller Mill The highpressure roller mill, also called the roller presser or the extrusion mill, is a grinding equipment based on the principle of material layer crushing It was successfully designed in 1984, the first high pressure roller mill was applied in the cement industry in 1985, and by 2015 it hadRoller Mill Springer4 or 5axis Single spindle Extrusion or bar machining Max part size: Extrusion 6 x 10” (150 x 250 mm) Bar 5 x 5” (127 x 127 mm) with option for larger size of bar/extrusion Horizontal machining center with 3 rotary tables Options: Spindle power and torque, 4 or 5axis, tool magazine and tool holderHHV3 Modig Machine ToolAmerican Aluminum Extrusion Company provides an engaging work environment based on our culture and core values Our objective is to develop, implement, and maintain a quality Management system that guarantees the highest standard of products and services for our customers Click here to get a quote Facebook Xtwitter Instagram Follow us on our social Welcome AMERICAN ALUMINUM EXTRUSION COMPANY, LLC

Rat Rig Mill

Introducing the Rat Rig Mill an allmetal, compact, and sturdy desktop CNC machine designed to meet the demands of hobbyists, makers and fabricators The 40 series extrusion based frame, M8 fasteners, and the full size XY plates provides a sturdy and stable platform for your work, allowing you to cut aluminium and steelService Extrusion Die Co Inc specializes in solid aluminum extrusion dies and components with fast turnaround times Established in 1956, we provide quality die services throughout Western and Mid 3648 Mill Creek Dr NE Comstock Park, MI 49321 (616) 7846933; Business Hours; Mon: 7:00 AM – 3:15 PM Tue: 7:00 AM – 3:15 PM Wed: 7:00 AM Service Extrusion Die Co Home Service Extrusion Die Co IncMillEx delivers up to 15G accelerations and high feed rates, making it the perfect choice for the demanding needs of aluminum machining Spindle configuration: 2 or 4 Industries: Automotive, Aerospace, Electronics, Extrusion, and more Product information Highlights Technical specification Request a quote Lowest cost per partMillEx Modig Machine ToolElite Extrusion LLC P O BOX: 86025, Ras Al Khaimah UAE T +971 7 244 7668 F +971 7 244 7669 : Open in Google Maps TOP WE HOLD AN UNPARALLELED POSITION IN THE EXTRUSION

.jpg)

Millennium Legacy Aluminium (MILLAC) Corp Aluminium Extrusion

Millennium Legacy Aluminium (MILLAC) Corp It's all about worldclass manufacturing excellence MILLAC is the aluminium extrusion company that encompasses the entire production process from smelting of virgin aluminium ingots, customized diemaking, to the finecrafting of standard and special aluminium profiles, MILLAC has situated itself as the forthrunner in this industry, Taber Extrusions MicroExtrusion Capabilities Our microextrusion manufacturing lines have a production envelope with a circle size of 3 inches or less and a weight per foot of 008 up to 5 lbs ft For comparison, the 8,600 ton press in Ultra Precision Aluminum Extrusions Taber ExtrusionsIt is raw aluminum from our mill and it can be field primed and painted Typically, Mill Finish has a shiny or “mirrorlike” appearance with some visible manufacturing lines What is meant by “Mill Finish” is aluminum in its original form and appearance as its comes directly from the rolling mill or an aluminum extrusion millaluminum mill finishSpecialty Copper Extrusion Process As a Specialty Copper Mill, our high quality extruded shapes, rods, and bars are produced from billets we cast inhouse The necessary materials are carefully combined in our two large induction Copper Extrusion Manufacturing Bronze Brass

HHV EXTRUSION MILL Modig Machine Tool DirectIndustry

HHV EXTRUSION MILL LEADING THE MARKET REDUCED CYCLE TIME HHV delivers high productivity with extraordinary precision and repeatability This small footprint universal machining center accommodates aluminum and carbon fiber parts up to 60 feet long with a cross section of 10x6 inches HHV features a revolutionary patented rotary chuck design making it possible to The Natural Aluminum Surface Mill finish refers to the raw, unprocessed surface of aluminum profiles as they exit the extrusion die This finish is the natural appearance of aluminum, characterized by its silver tone Since it undergoes no additional surface treatment, some die lines and marks are often visible, giving it an untreated and functionalEXTRUSION – MILL FINISH Bayer AluminumAluminium extrusion mill finish is straight out of the extrusion press, that is often further processed by our customers as it has not been treated or finished in any way Mill finish typically has a slightly rough texture and is dull in colour compared to brushed or anodised aluminiumUnderstanding Aluminium Extrusion Mill Finish: Characteristics Most aluminum extrusion profiles request only mill finish or clear anodizing surface for basic corrosion resistance They emphasize the mechanical properties of aluminum material that can meet the application requests Different aluminum alloy and temper is with different mechanical properties There are 6060, 6063, 6061, 6082, Aluminum Extrusion Profiles Manufacturer Supplier FONNOV

Zarbana Aluminum Extrusions, LLC

Zarbana Aluminum Extrusions was founded in 2005 It was originally introduced as Zarbana Industries, Inc, and was a fabricationonly shopIn 2016, Zarbana was purchased as an offshoot of the Extral Technology Group (producer of complete extrusion systems and aluminum foundries) and operates in the production of aluminum alloy extrusionStarting with the design we cooperate with reliable die makers and extrusion partners to offer you the best extrusion solution We can make new dies and approve samples in 23 weeks depending on the section and our leadtime for mill finish profiles into Europe is 4 weeks and just 5 weeks for anodised profilesALUMINIUM EXTRUSIONCapral Mill Catalogue Free download as PDF File (pdf), Text File (txt) or read online for free This document is a catalogue from Capral, Australia's largest aluminium extruder, listing various extruded aluminium angle profiles available It provides information on the dimensions, radii, mass, and state of manufacture for over 100 angle profiles available in sizes ranging from Capral Mill Catalogue PDF Extrusion Australia