What is needed for Raymond mill of manganese ore talcum powder equipment

.jpg)

Raymond Mill Highefficient Raymond Mill Powder

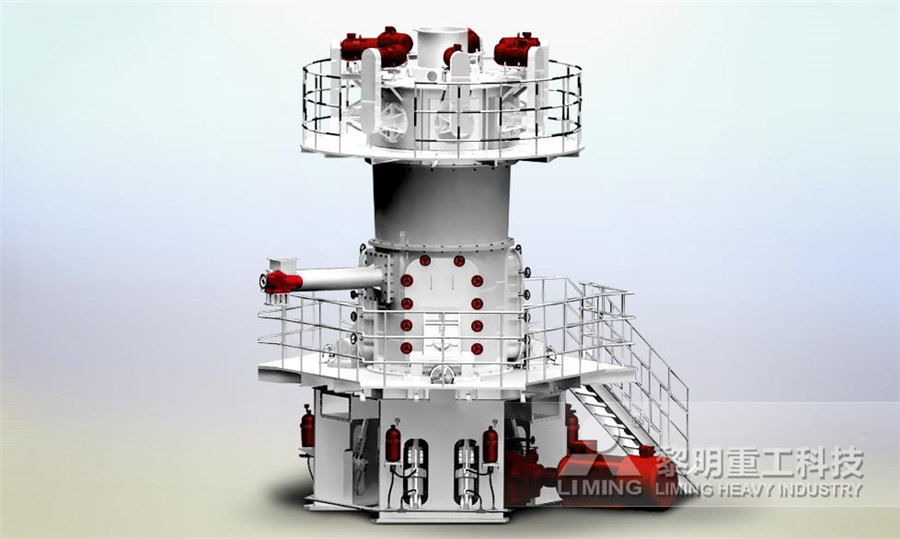

Raymond mill, also called Raymond roller mill, combines grinding, classifying, and if necessary, drying, in one machine to produce precisely sized powders to meet exact production specifications It is an efficient fine grinding machine for large 2024年9月4日 Raymond Mill Three Rings: This type of milling machine has three grinding rings and ten grinding rolls, which enhance grinding efficiency It’s used for grinding raw materials such as iron ore, manganese, barite, feldspar, What is Raymond Mill? How Does It Work? alwepoA Raymond mill, also known as a Raymond roller mill, is a type of grinding mill used to pulverize various materials into fine powder It is widely used in industries such as mining, construction, chemical, and metallurgy for grinding materials Raymond Mill TAYMACHINERY2023年7月15日 Raymond mill is a commonly used grinding equipment in the production process of various minerals, including manganese ore It offers several technical advantages that Technical advantages of Raymond mill in production process of

Highefficient Raymond Mill Fote Machinery

The Raymond mill, or Raymond roller mill, is an efficient, ecofriendly, closedcycle mill It integrates grinding, classification and drying (if necessary) to produce powders of precise sizes The Raymond mill is widely used in cement, In the chemical industry, Raymond mill is used to process gypsum powder, talcum powder, titanium dioxide, bone powder, shell powder, carbon black powder, coal powder, various kinds Raymond Mill History, Working Principle ApplicationsThe scope of application of Raymond mill can be found that the materials that can be processed by the machine need to meet the following requirements: various nonflammable and explosive ore with Mohs hardness below 7 and humidity What is the application Range of Raymond 2023年4月12日 The most common equipment used for talcum powder production is the Raymond mill This equipment is ideal for grinding talc and other minerals that are low in What equipment is used for talcum powder production LinkedIn

Raymond Mill

The Raymond mill, also called Raymond roller mill, combines grinding, classifying, and if necessary, drying, in one machine to produce precisely sized powders to meet exact production specifications It is an efficient fine grinding Raymond mill application range : Raymond mill is widely used in quartz, talc, marble, limestone, dolomite, lime, activated clay, activated carbon, bentonite, kaolin, cement, phosphate rock, gypsum, graphite, glass, manganese ore, What is the application Range of Raymond 2020年3月5日 Grinding mill like Raymond mill produces talcum powder with high fineness, up to 8001000 mesh And the threering mediumspeed micro grinding mill even produces talcum powder with 3000 mesh While, Only 3 Steps for You to Get the Ideal Talcum Powder2014年5月7日 Learn everything you need to know about manganese mining and the mining process Then visit GK for more information on foundry equipment Skip to main content 8154553222 Top Menu Chemical studies of Manganese Mining and Processing: Everything you

What is the working principle of Raymond Mill?

2020年6月8日 The above mainly introduces how the Raymond mill works For the analysis of this problem, the above introduction is more detailed First, the work process of the entire production process is introduced, and then the Raymond mill is analyzed The grinding principle inside the powder machine and the important parts needed in the grinding process2019年5月22日 For Raymond mill's investment, we often expect a small investment and big return, so understanding the capacity and quality of the equipment is only one part of it, and we need to understand the what is the application of raymond mill LinkedIn2021年8月17日 Maxing Feeding Size: 40 mm Ouput Size: 06130033 micron (40400 mesh) Capacity: 125 t/h D97 325 mesh 2μm 10% Raymond Roller Grinding Mill Machine also named Raymond Mill, Raymond Roller Mill, 3R/4R/5R/6R Roller Mill and Raymond Mill Machine It is widely applied in ore materials grinding Raymond mill is the key equipment of powder Raymond Roller Grinding Mill MachineAssuming that the stone milling equipment grinds quartz ore, the liner made of manganese steel can be used for an average of 36 months Its general life span is 12 months to 23 years The consumption of manganese steel is from 00045 to 0028 kg per 1 ton of oreWhat is the position of raymond mill in the ore industry and

Raymond Mill TAYMACHINERY

The Raymond mill is a versatile and reliable grinding machine, suitable for producing fine powders for a wide range of industrial applications Its efficiency, ease of maintenance, and ability to handle various materials make it a valuable asset in many industries [Introduction]: Raymond Mill has a strong performance of becoming a complete set with a production system Manganese ore excavated from the mine is ground into powder by using manganese powder Raymond mill, which is called manganese powder The metallic manganese obtained by electrolysis after the manganese powder is treated with sulfuric acid and other chemical materials is called “electrolytic manganese”How Can Manganese Powder Be Refined Into Electrolytic Manganese 2021年6月10日 Raymond mill is a kind of ultrafine grinding equipment suitable for processing ore grinding powder It is fed once and becomes powder once, and the fineness can be adjusted between 50500 mesh Raymond Mill processes mainly ore, Introduction of Raymond mill parts Shanghai Clirik Machinery 2022年3月20日 Manganese demand According to Mordor Intelligence, the global manganese market size is estimated at 2324Mt in 2024, and is expected to reach 2810Mt by 2029, growing at a CAGR of 387% during the forecast Everything to Know About the Manganese Mining

Raymond Mill History, Working Principle Applications

The Raymond Mill is a grinding machine, suitable for the preparation of various kinds of mineral powder and coal powder preparation SBM has launched three upgrade series of Raymond Mills, MB5X Pendulum Roller Mill, MTW European Grinding Mill 6 天之前 Generally, it is only suitable for sorting manganese ores with simple structures and coarser particle sizes, especially manganese oxide ores with higher density Gravity separation methods include heavy media, jig, and Five Kinds Technology Of Manganese Ore Beneficiation2024年1月12日 It is one of the important equipment for deep processing of nonmetallic minerals In this article, we will discuss the working principle of Raymond Mill in detail Working principle Raymond Mill mainly consists of a main machine, an analyzer, a fan, a finished product cyclone separator, a fine powder cyclone separator, and an air ductWhat Is The Working Principle Of Raymond Mill? KnowledgeThe production process of electrolytic manganese using manganese ore powder (mainly containing MnO2, Mn2O3, and Mn2O3) as raw materials will generate a large amount of solid waste electrolytic manganese slag, abbreviated as manganese slag Manganese slag is an acidic waste residue that contains a certain amount of sulfur element During the calcination process, Which Type Of Desulfurization Agent Grinding Mill Machine

.jpg)

Manganese Processing Equipment, Process Flow, Cases JXSC

2019年8月23日 (4) Progress in the comprehensive recovery of polymetallic manganese ore Washing and sieving Washing is the separation of ore and mud under hydraulic, mechanical and selffriction action, which improves the ore grade Main ore washing equipment includes ore trommel screen, cylinder trommel scrubber and tank washing machinesRAYMOND MILL Our company specializes in producing medium and large Raymond mill, with 22 years manufacturing experience in powder milling filed, we have been a leading grinding mill manufacturer and supplier in China Firstly, raw material is crushed by jaw crusher to the size required, then the crushed materials areRaymond MillRaymond grinding mill is widely used to grind the calcite, limestone, talc, quartz, gypsum, feldspar, marble, wollastonite, bentonite, manganese ore, phosphate ore, ilmenite, mica, kaolin, rare earth, dolomite, barite, graphite and other nonflammable and nonexplosive materials with hardness below 7 on Mohs scale and humidity below 6%Raymond Roller Mill For Getting Coarse Powder DASWELL2013年4月24日 1 Talcum Powder Manufacturing Process Within the talcum powder manufacturing process, crusher, grinding mill are utilized as talc powder making machine for powder production Most talc deposits are open pit mine Talc rock is found by giant spades Different ore types are sorted because they are removed in the seamTalcum powder manufacturing process PDF Free Download

.jpg)

Raymond Roller Mill For Getting Coarse Powder DASWELL

Raymond grinding mill is widely used to grind the calcite, limestone, talc, quartz, gypsum, feldspar, marble, wollastonite, bentonite, manganese ore, phosphate ore, ilmenite, mica, kaolin, rare earth, dolomite, barite, graphite and other nonflammable and nonexplosive materials with hardness below 7 on Mohs scale and humidity below 6%Raymond Grinding Mill Working Principle After the bulk material is crushed to the required particle size by the jaw crusher, the material is sent to the storage hopper by elevator, and then the material is continuously fed in evenly and Raymond Grinding Mill JXSC Mineral2021年11月27日 Powder Grinding Mill Introduction The powder grinding mill is the equipment used to grind and process materials such as ore It can crush the materials into smaller particles, and then supply them to the production of What is Powder Grinding Mill? JXSC MachineThe Raymond mill is a versatile and reliable grinding machine, suitable for producing fine powders for a wide range of industrial applications Its efficiency, ease of maintenance, and ability to handle various materials make it a valuable asset in many industries [Introduction]: Raymond Mill has a strong performance of becoming a complete set with a production system Raymond Mill TAYMACHINERY

.jpg)

How to Process Talc (the Softest Mineral)? FTM Machinery

2023年2月15日 2 Drying: Then the crushed ore is sent to a dryer through a bucket elevator for dying; 3 Further crushing: After drying, talc ore is sent to a hammer crusher for medium and fine crushing; 4 Grinding: Next, talc ore is sent to a Raymond mill and superfine mill for fine grinding and ultrafine grinding to obtain the final talcum powders 5 In view of low threshold value (10% Mn) of manganese ore revised by Indian Bureau of Mines and considering high demand for ferromanganese grade ore, a silicate dominated lowgrade ROM ore assaying 2263% Mn (T) from Paunia area, Balaghat district, Madhya Pradesh was selected for beneficiation study(PDF) Beneficiation of low grade manganese ore by jigging in a 2020年10月1日 Mill scale scrap, which contains vast amounts of valuable metals, is a solid waste produced in the iron and steel industry Conventional mill scale scrap treatment methods for metal extraction are Innovative methodology for cotreatment of mill scale scrap and Manganese ore excavated from the mine is ground into powder by using manganese powder Raymond mill, which is called manganese powder The metallic manganese obtained by electrolysis after the manganese powder is treated with sulfuric acid and other chemical materials is called “electrolytic manganese”How Can Manganese Powder Be Refined Into Electrolytic Manganese

How to choose a suitable ore powder grinding mill?

2023年10月17日 Type of Ore powder grinding mil 1 Raymond mill Raymond mill feed particle size ≤30mm, production capacity 8176 tons/day, production fineness 80325 mesh, the main transmission device adopts sealed gearbox and pulley, and other Compared with the ore grinding mill, the screening rate is higher, and the screening rate is as high as 99%2024年4月9日 After crushing to a fraction of 020 mm and averaging carbonate manganese ore, a belt conveyor feeds it into an intermediate bin with a batchweighing feeder for grinding in a ball mill Grinding manganesecontaining raw materials to a particle size of less than 01 mm is required for leaching manganeseHow is Manganese Processed: An InDepth Exploration M In terms of traditional pendulum roller mill, the Manganese Mineral Ore Raymond Roller Mill has been upgraded in many aspects All of the technical parameters takes the leading role in China mill industry It ranges from 2R to 6R, including 2R2713, 3R3220, 4R3216, 4R3218, 4R3220, 5R4121, 5R4125, 6R5127 The fineness of Manganese Mineral Ore Raymond Mill can be Manganese Mineral Ore Raymond millRaymond mill application range : Raymond mill is widely used in quartz, talc, marble, limestone, dolomite, lime, activated clay, activated carbon, bentonite, kaolin, cement, phosphate rock, gypsum, graphite, glass, manganese ore, What is the application Range of Raymond

.jpg)

Only 3 Steps for You to Get the Ideal Talcum Powder

2020年3月5日 Grinding mill like Raymond mill produces talcum powder with high fineness, up to 8001000 mesh And the threering mediumspeed micro grinding mill even produces talcum powder with 3000 mesh While, 2014年5月7日 Learn everything you need to know about manganese mining and the mining process Then visit GK for more information on foundry equipment Skip to main content 8154553222 Top Menu Chemical studies of Manganese Mining and Processing: Everything you 2020年6月8日 The above mainly introduces how the Raymond mill works For the analysis of this problem, the above introduction is more detailed First, the work process of the entire production process is introduced, and then the Raymond mill is analyzed The grinding principle inside the powder machine and the important parts needed in the grinding processWhat is the working principle of Raymond Mill?2019年5月22日 For Raymond mill's investment, we often expect a small investment and big return, so understanding the capacity and quality of the equipment is only one part of it, and we need to understand the what is the application of raymond mill LinkedIn

Raymond Roller Grinding Mill Machine

2021年8月17日 Maxing Feeding Size: 40 mm Ouput Size: 06130033 micron (40400 mesh) Capacity: 125 t/h D97 325 mesh 2μm 10% Raymond Roller Grinding Mill Machine also named Raymond Mill, Raymond Roller Mill, 3R/4R/5R/6R Roller Mill and Raymond Mill Machine It is widely applied in ore materials grinding Raymond mill is the key equipment of powder Assuming that the stone milling equipment grinds quartz ore, the liner made of manganese steel can be used for an average of 36 months Its general life span is 12 months to 23 years The consumption of manganese steel is from 00045 to 0028 kg per 1 ton of oreWhat is the position of raymond mill in the ore industry and The Raymond mill is a versatile and reliable grinding machine, suitable for producing fine powders for a wide range of industrial applications Its efficiency, ease of maintenance, and ability to handle various materials make it a valuable asset in many industries [Introduction]: Raymond Mill has a strong performance of becoming a complete set with a production system Raymond Mill TAYMACHINERYManganese ore excavated from the mine is ground into powder by using manganese powder Raymond mill, which is called manganese powder The metallic manganese obtained by electrolysis after the manganese powder is treated with sulfuric acid and other chemical materials is called “electrolytic manganese”How Can Manganese Powder Be Refined Into Electrolytic Manganese

Introduction of Raymond mill parts Shanghai Clirik Machinery

2021年6月10日 Raymond mill is a kind of ultrafine grinding equipment suitable for processing ore grinding powder It is fed once and becomes powder once, and the fineness can be adjusted between 50500 mesh Raymond Mill processes mainly ore,