Fly ash crushing and grinding system equipment

.jpg)

Fly Ash Processing Equipment FEECO International Inc

FEECO provides custom, highquality agglomeration and bulk material handling equipment for dedusting fly ash and turning it into a more 展开The fly ash processing plant produced by AGICO includes a ball mill grinding system, conveying system, dust collecting system, ash classifying system and ash storing system It helps our customers realize reasonable solid waste Fly Ash Processing Plant Cement Equipment Fly Ash Processing Plant Equipment Equipment for a fly ash processing plant mainly includes raw material silos, a scale machine, a belt conveyor, a feeder, a grinding machine, a bag filter, a bucket elevator, and a dust collector Among Fly Ash Processing Plant Superfine Final ProductWelcome to Benny Enterprises, a pioneer in manufacturing and supplying highquality fully automatic flyash bricks machines Our stateoftheart machines are designed to produce topgrade flyash bricks efficiently and costeffectively, Fully Automatic Flyash Bricks Machine Benny

Ash Handling Systems Sumitomo Heavy Industries, Ltd

SPE offers optimized fly ash transport systems with a range of vacuum and pressuredriven transport options Fly ash is transported by air from electrostatic precipitator, air preheaters, and coal economizers to fly ash silos, where the 2024年11月26日 UCC has nearly a century of experience and expertise in the design, engineering and installation of pneumatic fly ash handling systems The NUVEYOR® Dry Vacuum transfer System is the industry standard for efficient Fly Ash Handling Systems Vacuum Material Ash In this article, we will discuss the fly ash processing flow, equipment used, and application values in detail Fly Ash Collection and Conditioning: The fly ash is first collected from the flue gas Fly ash processing process flow, fly ash equipment and application 2023年1月9日 How to process fly ash? The fly ash processing system is composed of dryer, elevator, silo, grinding mill, fan, powder concentrator, dust collector, pipeline device, etc The How to Process Fly Ash and What Is It Used for

.jpg)

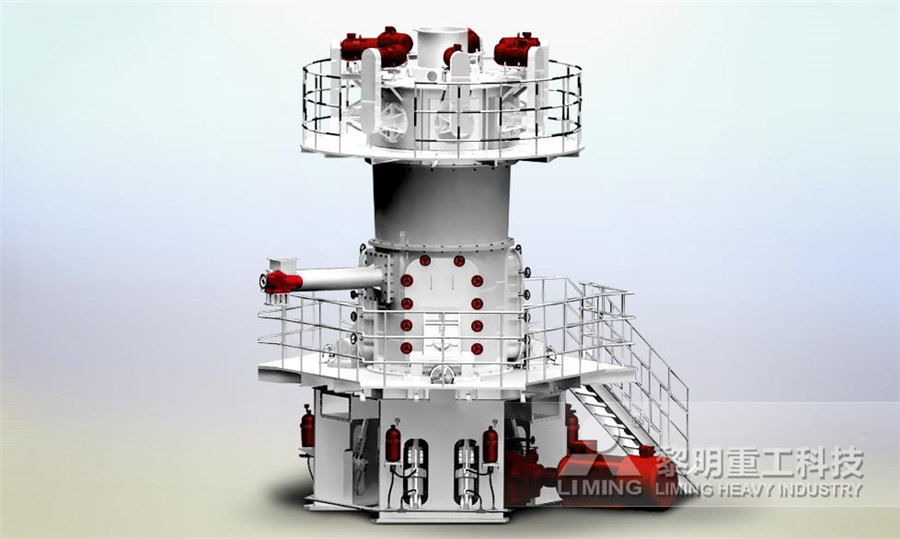

Grinding Fly Ash Process and Equipment with Vertical Milling

PDF On Jan 1, 2015, Rui fang Li and others published Grinding Fly Ash Process and Equipment with Vertical Milling Machine Find, read and cite all the research you need on ResearchGateAesha Conveyors and Crushing Equipment Manufacturers, exporters and suppliers of industrial belt conveyors, sand processing plant, cement conveying system, cement dryer, coal handling system, sand processing equipment, Industrial Belt Conveyors,Sand Processing Robust machined design to tackle light and heavyduty crushing applications fly ash, minerals and other mining by products with ease Built for durability, Franklin Miller’s service personnel are available to make field visits to assess Mining Crusher and Lump Breakers Mining AGICO offers highquality Portland pozzolana cement plants and different Portland pozzolana cement equipment Skip to content Blog Contact About Cases Factory CONTACT US info@cementplantequipment fly ash, Portland Pozzolana Cement Manufacturing

Grinding Mill Grinding Equipment Cement Mill AGICO

The ultrafine grinding system manufactured by AGICO is mainly used for grinding pulverized coal and cement To meet the need for further grinding and 3D printing, in 2015, our company built an ultrafine powder grinding production line of 12t/d — 20t/d The ultrafine grinding mill is the important equipment in this production lineValue in Waste: Fly Ash Reuse and Recovery Opportunities Fly ash has proven to offer a wide range of benefits when used as a LWA, to the extent that it has become a key material in the construction industry; the use of fly ash as a LWA can provide economic benefits such as reduced structural, shipping, and handling costs, as well as environmental benefits that come along fly ash handling equipmentThe cement grinding unit manufactured by our company combines drying, grinding, powder classification, dust collection and cement packing It can grind cement clinker and process cement mixtures such as gypsum, fly ash, furnace slag, coal gangue, etc, realizing stable, highquality, and automatic cement productionCement Grinding Plant Manufacturers NT EngitechFU chain conveyor is used in material crushing and grinding system, its performance is obviously better than screw conveyor, submerged scraper conveyor and other conveying equipments, it is a kind of ideal new equipmentFU chain conveyor is a new product for conveying powdery and small granular materials horizontally (or at an inclination of 15 degrees), with high operational FU chain conveyor (for material crushing and grinding system)

Grinding Fly Ash Process and Equipment with Vertical Milling

Grinding Fly Ash Process and Equipment with Vertical Milling Machine RUI FANG LI DONG YA SONG Zhengzhou University of Industrial Technology,Zhengzhou Keywords: vertical milling machine; grinding system; fly ash Abstract: A new ash grinding process was proposed,with the application of vertical grinding millCrushing The fly ash raw material is conveyed by the vibrating machine to the jaw crusher for crushing This step is mainly to crush large particles of fly ash to small particles that can meet the size of the fly ash ball mill Fine grinding The fly ash raw material that meets the feed size is sent to the feed hopper of the fly ash ball millUse Fly Ash Ball Mill Make Flyash Cement Ball Mill Machine After the clinker, limestone and gypsum are weighed and mixed in a certain proportion by the belt weigher, they will be sent into the pregrinding system by the belt conveyor and elevator Then the ground materials and the weighed fly ash will be further ground in the ball mill grinding systemCement Grinding Unit Clinker Grinder AGICO CementThe flushing equipment serves to mix the ash with the water and discharge the ash in the form of slurry The Dry fly ash system consists of a two stage ESP and duct hopper ash removal conveying system The first stage includes extraction of dry fly ash from under the various ESP / duct hoppers to intermediate hoppers located near the ESPsfly ash handling equipment

Fly Ash Processing Plant Ball Mill, Raymond Mill, EPC

Fly ash is generally a solid waste generated by the incineration boilers in thermal power plants, coalfired power plants, paper mills, and chemical factories, as well as the collection of ash from dust collectors It consists of tiny ash particles Summary:The fly ash processing system is composed of dryer, elevator, silo, grinding mill, fan, powder concentrator, dust collector, pipeline device, etc How to Process Fly Ash and What Is It Used for Fly ash is the fine ash collected from How to Process Fly Ash and What Is It Used forCement manufacturing mainly includes five steps: raw material preparation, raw material calcination, clinker grinding, cement packaging, and transportation Besides, we may need some other production lines to cooperate with the production of cement, such as the stone crushing plant, cement grinding unit, and fly ash processing plantCement Plant Equipment Cement Making Machines AGICO 2024年7月17日 Crushing is a multistage process that includes primary crushing, secondary crushing, and tertiary crushing Different types of crushing equipment are used at each stage to meet various crushing requirements Primary crushing breaks down large raw materials into mediumsized pieces for easier handling in subsequent processesTypes of Crushers: Choosing the Right One for Each Stage

.png)

Cement Crusher – Crusher In Cement Plant AGICO Cement

But if the material is very difficult to break, it is necessary to consider a twostage crushing system that takes jaw crusher as the primary crushing equipment and hammer crusher as the medium crushing equipment Materials with weak abrasiveness are usually broken by impact or grinding method The crushing part should have sharp teetharticle about Different cement grinding systems , and comparison between them regarding FINENESS , grindability , Fly ash, pozzolana, blast furnace slag, limestone, easy operation, less investment in process equipment Capacity :20380t/h Feeding Granularity :≤25mm Loading Reply Leave a ReplyCancel replyCEMENT GRINDING SYSTEMS INFINITY FOR CEMENT EQUIPMENTFor different stages in the cement manufacturing process, AGICO offers various EPC projects of cement manufacturing plants: cement production lines, stone crushing plants, cement grinding units, fly ash processing plants, automatic cement storage systems, modular cement grinding plants, and VSK cement plantsCEMENT MANUFACTURING PLANT cementplantequipmentThe Comparison between Opencircuit Closedcircuit Grinding System of Ball Mill Opencircuit Grinding System The opencircuit grinding system of the ball mill is shown as follows: materials (including clinker, gypsum, mixed materials, etc) mixed according to a certain proportion will be directly stored in the steel silo as finished cement Ball Mill In Cement Plant Cement Ball Mill AGICO Cement

.jpg)

A critical review on mechanochemical processing of fly ash and fly ash

2023年2月20日 Substantial amounts of solid residue, known as coal fly ash (CFA), are produced during coal combustion Fly ash (FA), the main component of coal ash, is generated in enormous quantities all over the world due to its increasing production Fly ash (FA) comprises powdery, fine particles mainly of spherical shape, which may be hollow or solid2023年1月9日 Fly ash is a kind of active mineral fine powder resource The research shows that different fineness of fly ash has different effects on silicate hydration products SBM manufactures different types of grinding equipment for fly ash grinding process They can grind fly ash into different fineness for different applications 1, used in concreteHow to Process Fly Ash and What Is It Used for2024年4月5日 Vertical Roller Mills (VRM) have become a pivotal piece of equipment in the processing of fly ash, a byproduct of coal combustion in power plants The efficient grinding of fly ash is crucial for its utilization in various Fly ash grinding techniques specification of vrm2024年11月1日 Liquidsolid grinding system: Grinding kinetics of coal fly ash as ultrafine supplementary cementitious materials Author links open overlay panel Jin Yang a b, Yong Huang a, Xingyang He a b, Nevertheless, decreased grinding efficiency later on is the outcome of a weakened volumetric crushing action based on impact and extrusionLiquidsolid grinding system: Grinding kinetics of coal fly ash as

.jpg)

Rock grinder machine

2022年12月1日 SBM Factory SBM Micropowder Technology Co, Ltd is an excellent manufacturer of ore grinding equipment in China, and has made great achievements in the field of ultrafine powder grinding SBM is recognized by many customers at home and abroad for its professional industry knowledge and skills, highquality ore grinding equipment, and perfect AGICO dry process cement production line comprehensively adopts the IT technology, multifunction grinding system, newtype wearresisting and heatresisting materials, mechanical powder conveying device, and some other modern technologies to realize quality cement production It has the characteristic of energy saving, high efficiency, environmental protection, Cement Production Line Cement Manufacturing Plant AGICO Established in year 2018, Straben Equipment Private Limited is engaged in manufacturing and exporting of Cement And Fly Ash Silo, Conveyor Parts, Concrete Batching Plant, Silo Accessories, Industrial Conveyors, Ready Mixed Concrete Batching And Mixing Plant, Conveyor Belt, Bulker Unloading System, Concrete Trailer Pump, Wet Mix Macadam Plant, Asphalt Straben Equipment Private Limited Manufacturer of Cement And Fly Ash 2012年6月1日 As the cylinder starts to rotate, the grinding balls inside the cylinder crush and grind the feed material, generating mechanical energy that aids in breaking bonds, activating the catalyst, and Grinding in Ball Mills: Modeling and Process Control

Fly Ash Grinding Mill News of Joyal Crusher

2011年11月4日 Fly Ash Grinding Mill (Rating: 393 / 5 total 15 votes) if discharged into the water system, the fly ash can cause the rivers blockage and the toxic chemicals contained in it will be harmful to the human body and lifeforms At present the main mill equipment to process fly ash include the following ones:Fly Ash and Bottom Ash Safety Data Sheet According To Federal Register / Vol 77, No 58 / Monday, H372 Causes damage to organs (lung/respiratory system) through prolonged or repeated exposure (Inhalation) Precautionary Statements (GHSUS crushing or grinding crystalline silicabearing materials may release respirable crystalline Fly Ash and Bottom Ash LafargeFly Ash Graded Impact Mill Mechanical Mill Jfc Crushing and Grading Equipment High Efficiency and Energy Saving High Yield, Find Details and Price about Battery Material Crusher Medical Grinding Machine from Fly Ash Graded Impact Mill Mechanical Mill Jfc Crushing and Grading Equipment High Efficiency and Energy Saving High Yield Shandong Shengbao Heat Fly Ash Graded Impact Mill Mechanical Mill Jfc Crushing and Aesha Conveyors and Crushing Equipment Manufacturers, exporters and suppliers of industrial belt conveyors, sand processing plant, cement conveying system, cement dryer, coal handling system, sand processing equipment, Industrial Belt Conveyors,Sand Processing

Mining Crusher and Lump Breakers Mining

Robust machined design to tackle light and heavyduty crushing applications fly ash, minerals and other mining by products with ease Built for durability, Franklin Miller’s service personnel are available to make field visits to assess AGICO offers highquality Portland pozzolana cement plants and different Portland pozzolana cement equipment Skip to content Blog Contact About Cases Factory CONTACT US info@cementplantequipment fly ash, Portland Pozzolana Cement ManufacturingThe ultrafine grinding system manufactured by AGICO is mainly used for grinding pulverized coal and cement To meet the need for further grinding and 3D printing, in 2015, our company built an ultrafine powder grinding production line of 12t/d — 20t/d The ultrafine grinding mill is the important equipment in this production lineGrinding Mill Grinding Equipment Cement Mill AGICOValue in Waste: Fly Ash Reuse and Recovery Opportunities Fly ash has proven to offer a wide range of benefits when used as a LWA, to the extent that it has become a key material in the construction industry; the use of fly ash as a LWA can provide economic benefits such as reduced structural, shipping, and handling costs, as well as environmental benefits that come along fly ash handling equipment

Cement Grinding Plant Manufacturers NT Engitech

The cement grinding unit manufactured by our company combines drying, grinding, powder classification, dust collection and cement packing It can grind cement clinker and process cement mixtures such as gypsum, fly ash, furnace slag, coal gangue, etc, realizing stable, highquality, and automatic cement productionFU chain conveyor is used in material crushing and grinding system, its performance is obviously better than screw conveyor, submerged scraper conveyor and other conveying equipments, it is a kind of ideal new equipmentFU chain conveyor is a new product for conveying powdery and small granular materials horizontally (or at an inclination of 15 degrees), with high operational FU chain conveyor (for material crushing and grinding system)Grinding Fly Ash Process and Equipment with Vertical Milling Machine RUI FANG LI DONG YA SONG Zhengzhou University of Industrial Technology,Zhengzhou Keywords: vertical milling machine; grinding system; fly ash Abstract: A new ash grinding process was proposed,with the application of vertical grinding millGrinding Fly Ash Process and Equipment with Vertical Milling Crushing The fly ash raw material is conveyed by the vibrating machine to the jaw crusher for crushing This step is mainly to crush large particles of fly ash to small particles that can meet the size of the fly ash ball mill Fine grinding The fly ash raw material that meets the feed size is sent to the feed hopper of the fly ash ball millUse Fly Ash Ball Mill Make Flyash Cement Ball Mill Machine

Cement Grinding Unit Clinker Grinder AGICO Cement

After the clinker, limestone and gypsum are weighed and mixed in a certain proportion by the belt weigher, they will be sent into the pregrinding system by the belt conveyor and elevator Then the ground materials and the weighed fly ash will be further ground in the ball mill grinding system