HOME→Air pressure ballistic micro powder mill operation method Air pressure ballistic micro powder mill operation method Air pressure ballistic micro powder mill operation method

Air pressure ballistic micro powder mill operation method Air pressure ballistic micro powder mill operation method Air pressure ballistic micro powder mill operation method

.jpg)

Air Classifying Mill

The Mikro ACM® Air Classifying Mill is an air swept mechanical impact mill with a dynamic air classifier designed to grind an extensive range of materials down to a D97 of 20 microns The Mikro ACM Classifier Mill – The most versatile mill In 1962 the Mikro ACM came on the market as the first air classifier mill and since then it has been continuously developed further and MIKRO ACM Air Classifier Mills LabWrench2007年1月1日 Air jet milling, or more correctly fluid energy milling, uses high velocity jets of gas to impart energy to particles for size reduction Air jet mills have mainly been developed for Chapter 8 Air Jet Milling ScienceDirectAn air classifier mill applies impact grinding and air classification in one step The mill uses airflow to convey feed material to the mill’s grinding chamber, classifies the material into fine How to operate an air classifier mill to meet your fine grinding goals

.jpg)

Air Jet Milling Fluid Energy Processing and Equipment

Below is a schematic of a JetOMizer process showing the main pieces of equipment Compressor: Air compressor raises air pressure from ambient to 100125 psi Air pressure of Mikro ACM® Air Classifying Mill is available in 15 model sizes from 1 HP up to 600 HP for small batches and large production systems They offer narrow particle size distributions and wear Hosokawa Mikro ACM Easy Access Air Classifying Millparameters such as feed rate, grinding air pressure, physical characteristics of the solids (density, hardness, abrasiveness, or tenacity), physical characteristics of the mill shell liner, as well as Process optimization of jet mills for metallurgical powder production2019年11月2日 The compressed air generated from a high temperature of 150° C introduces the pulverization energy of the jet stream to have the ceramic powder grind under 7–8 μm, which Improvement of pulverization efficiency for microsized particles

.jpg)

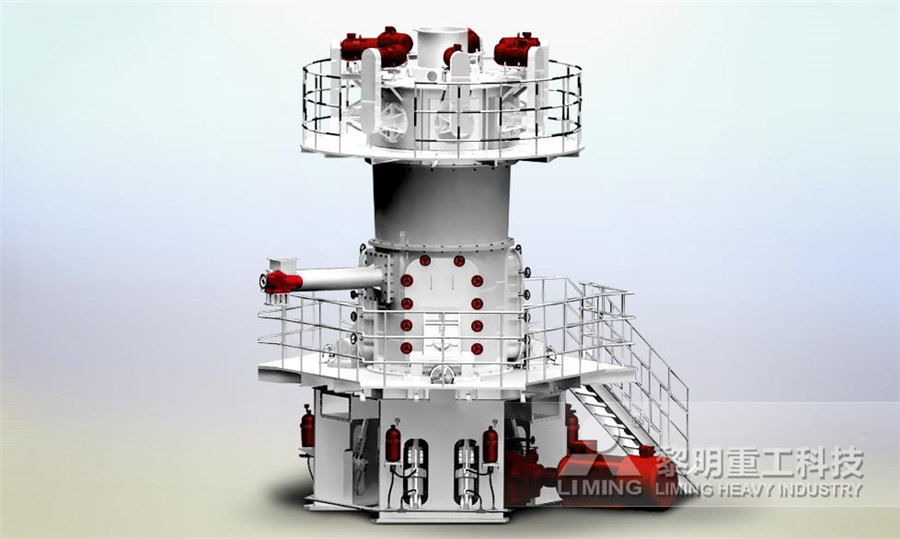

Ball Mill And Air Classifier Production System EPIC Powder

The classifier is equipped with speed sensor and control system to measure, evaluate and compensate the air temperature, air pressure, air volume and filter pressure difference, so as RIECO’s Air classifier Mill (ACM) is an air classifying mill with integrated grinding, classifying, conveying, and collecting operations for achieving ultrafine grinding (up to 2 micron*) Air Classifying Mill ACM Air Classifier Mill Manufacturer Rieco2021年6月29日 Effects of Mill Speed and Air Classifier Speed uses in building materials The micro ceramic powder can be taken as a supplementary and the economic benefits of the operationEffects of Mill Speed and Air Classifier Speed on The Ultrafine Grinding Mill, also known as a Micro Powder Grinding Mill or Ultra Fine Powder Grinding Machine, is a highefficiency and lowconsumption grinding mill that is widely used in the powder processing of various materials Bellian Mining Machinery offers a range of Ultrafine Grinding Mills, including the Ultrafine Vertical Mill and Fine Powder Mill Grinder, designed to Ultrafine Grinding Mill, Micro Powder Grinding Mill Bellian

Micro Powder Mill Shanghai Joyal Machinery Co, Ltd

Threering Micro Powder Mill >> EMail:joyal@crusherinc >> Http://joyalcrusher Features 1 Highefficiency and low consumption With the same endproducts fineness and motor power, its output is over 1 time of that of Jet Mill, Mix Mill, and Ball Mill 22023年6月14日 The crushing chamber of the flat jet mill is in the shape of a horizontal disc, and it is also called a horizontal disc jet mill It is composed of grinding chamber, separation device, feeding device, air duct, etc (Fig 1)The working principle is like this: the compressed gas (air, superheated steam, or inert gas) generates a highspeed jet through the feeding ejector, and Jet Mill SpringerLink2013年10月30日 The document describes a threering micro powder mill manufactured by Shanghai Joyal Mining Machinery Co It consists of a main frame, reducer, classifier, blower, feeder and other components The mill can grind materials into a fine powder size of 3252500 meshes It has high efficiency and low energy consumptionMicro powdermill PDF Free Download SlideShareAir enters through the Air Inlet opening located on the back of the MAJSx2 Air continues through the duct to the hollow rotation wand Air exits the special shaped slot in the top of the rotating wand with sufficient velocity to pass through the Test Sieve ScreenMikro Air Jet Sieve

.jpg)

JoyalThreering Micro Powder Mill,Threering Micro Powder Mill

The JOYAL Threering Micro Powder Mill(ultrafine mill) is for superfine grinding materials with hardness less than 6 in Mohs scale and humidity less than 6 percent such as kaolin, The high pressure centrifugal blower inhales air from the outside and blow the materials which are ground in the third ring to powder SeparatorMicro powder roller mill is also known as ultrafine powder grinding mill It is a new type of powder processing equipment, mainly used for crushing and processing nonmetallic minerals such as calcium carbonate, barite, talc, gypsum, calcite, limestone, calcium oxide, bentonite, dolomite and other nonmetallic minerals with Mohs hardness less than 5 and water content less than 5%Micro Powder Roller Mill for Getting Ultrafine Powder DASWELLHigh Crushing ratio High Energy Utilization Primary processing D97 ≤ 10 μ M fine powder, and 3 µ m fine powder accounts for about 40%, with a large specific surface area; It not only has the advantages of high efficiency and low consumption of highspeed impact crusher, but also has the fineness close to that of air millHCH Ultrafine Grinding Mill, Micro powder grinding mill, Ultra The classifier is equipped with speed sensor and control system, which can measure, evaluate and compensate the air temperature, air pressure and air volume, as well as the pressure loss caused by the increase of filter pressure difference, so Ball Mill and Air Classifier Production Line ALPA micro silica

Jet Mills Hosokawa Alpine

HighPressure Roller Mill ECP Hammer Mills Hammer Mills Hammer Mills (All) Analyze powder quick and easy Air Jet Sieve E200 LS More information Air Jet Sieve Lab Units Air Jet Sieve Lab Units (All) Principle of operation 2016年9月1日 Furthermore, VRM separator speed (rpm) is one of the key operational parameters that determines product particle size Increasing the classi er rotor speed from 60 to 80 rpm decreases the particle Operational parameters affecting the vertical roller mill Product Introduction of micro powder grinding mill: Hongrun micro powder grinding mill is the equipment specializing in producing fine and superfine powder of noninflammable, nonexplosive and brittle materials with Mohs hardness Micro Powder Grinding Mill2021年10月18日 Analysis and troubleshooting methods of seven major failures of highpressure mill (Raymond mill) (Rating: 500 / 5 total 1 votes) Removal method: (1) Check and adjust the powder locker, and seal it well to block the leaks found; (2) Small troubleshooting and maintenance of Micro powder mill;Analysis and troubleshooting methods of seven major failures

An investigation of performance characteristics and energetic

2020年8月12日 Obtained results indicate that grinding pressure, primary air (PA) temperature and mill motor current have a tendency to rise by increasing coal feeding mass flow rates for all used coalHosokawa’s Mikro® UMP Universal Milling Systems is a high speed impact mill designed to grind a wide range of materials Contact us today to learn more 9082736360; Efficient operation/Low energy An upstream pressure blower pumps the feed material conveying air in high pressure piping through the Mikro® UMP to the downstream Mikro ® UMP Universal Mill Hosokawa Micron Powder SystemsLownoise operation › Tangential air inlet › Aircooled liner for temperaturesensitive products › Also available in CL design The combination of the Mikro ACM EC with the design features of the CL type mill combines the benefits of both types in one machine Die Mikro ACM EC (Easy Clean) was developed as a response to the rising demandClassifier Mill Hosokawa Micron Ltd2023年7月4日 The basic structure of the roller mill includes the grinding roller, the grinding body, the force generation and transmission mechanism, airflow, and the device for easy replacement It can be divided into vertical roller mill, horizontal cylinder roller mill, high pressure roller mill, Raymond mill, and column millRoller Mill SpringerLink

Refining of copper powder by a novel microabrasive milling method

2022年8月1日 The pure copper powder was milled by conventional highenergy ball milling (CM) and microabrasive milling (MAM) methods in the air or vacuummill with a dynamic air classifier Ideal for largevolume continuous processing, the mill is one of today’s most widely used grinding machines for reducing dry fine chemicals, food products, and other materials After describing the air classifier mill’s applications, operation, and common variations, this articleHow to operate an air classifier mill to meet your fine grinding goals2022年1月23日 grinding and powder selection, including a grinding unit and an air classifier, and can be divided into two categories, one airswept and the other an overflow type without air involved [ 5 ]Analysis and Optimization of Grinding Performance of 4 Negative pressure operation, no dust, low noise and vibration 5 Eliminate the oversize and superfine particle existing in product, particle size is uniform 6 In conjunction with multiple classifiers to get different particle sizes 7 The AF Air Classifier – Mills Powder Engineering

Jet Milling Material Milling AVEKA

One Model DPM1 Fluidized Bed Jet Mill; One Model 20 opposedjet pulverizer, coupled with Model 100 High Efficiency Centrifugal Air Classifier Labscale machine for running small quantity feasibility tests for jet milling and/or air classification; Minimum quantity for a trial run is 200 grams; Tolling/Test Run Guidelines:Jet mill pulverization is a technology that can grind powder to micron or even nanometer particles, The specific method may vary between Spiral Jet Mill and Fluidized Bed Jet Mill Air consumption Grinding pressure Product Fineness Capacity; AS50: 0609 cum/min: 0610 Mpa: D90=120 μm: 0105 kg/h:Jet Mill – Micronizer2017年7月7日 Their production represents 90 percent of the sizereduction methods used to produce powder materials today: air Cohesive and sticky products may build up on mill internals and upset airflow and increase pressure drop across the mill The material bed height in these mills will completely cover the nozzles during operationTop 5 productspecific milling technologies used in industrial 2013年5月15日 12 Control of grinding pressure: the pressure is affecting the grinding mill out put,power mill grinding efficiency and the main factor vertical roller mill is to impose by means of the material bed crushing pressure and the pressure to increase production increased, but reached a certain critical value does not change, the pressure increase followed by a increase Vertical raw mill pradeep kumar PPT Free Download SlideShare

Home Hosokawa Micron Powder Systems

2024年9月27日 Explore Hosokawa Micron Powder Systems for advanced size reduction and powder processing solutions across industries like chemical, pharmaceutical, Increasing pressure from legislative and environmental efforts is pushing drivers Introducing the NEW Hosokawa SFW Air Classifying Mill As one of the leading compressed air micronizer manufacturers and suppliers in China, we warmly welcome you to buy bulk cheap compressed air micronizer in stock here from our factory All equipment are with high quality and competitive priceChina Compressed Air Micronizer Suppliers, ManufacturersCompared with other powder mills, the grinding pressure on materials of highpressure micro powder mill increase 800kg1200kg under the effect of high pressure spring The fineness of final products can be adjusted in a large range Product advantage Reasonable structure, small floor area Reliable performance, convenient maintenanceHigh Pressure Micro Powder Mill for Fine Powder Grinding2021年6月29日 Effects of Mill Speed and Air Classifier Speed uses in building materials The micro ceramic powder can be taken as a supplementary and the economic benefits of the operationEffects of Mill Speed and Air Classifier Speed on

.jpg)

Ultrafine Grinding Mill, Micro Powder Grinding Mill Bellian

The Ultrafine Grinding Mill, also known as a Micro Powder Grinding Mill or Ultra Fine Powder Grinding Machine, is a highefficiency and lowconsumption grinding mill that is widely used in the powder processing of various materials Bellian Mining Machinery offers a range of Ultrafine Grinding Mills, including the Ultrafine Vertical Mill and Fine Powder Mill Grinder, designed to Threering Micro Powder Mill >> EMail:joyal@crusherinc >> Http://joyalcrusher Features 1 Highefficiency and low consumption With the same endproducts fineness and motor power, its output is over 1 time of that of Jet Mill, Mix Mill, and Ball Mill 2Micro Powder Mill Shanghai Joyal Machinery Co, Ltd2023年6月14日 The crushing chamber of the flat jet mill is in the shape of a horizontal disc, and it is also called a horizontal disc jet mill It is composed of grinding chamber, separation device, feeding device, air duct, etc (Fig 1)The working principle is like this: the compressed gas (air, superheated steam, or inert gas) generates a highspeed jet through the feeding ejector, and Jet Mill SpringerLink2013年10月30日 The document describes a threering micro powder mill manufactured by Shanghai Joyal Mining Machinery Co It consists of a main frame, reducer, classifier, blower, feeder and other components The mill can grind materials into a fine powder size of 3252500 meshes It has high efficiency and low energy consumptionMicro powdermill PDF Free Download SlideShare

.jpg)

Mikro Air Jet Sieve

Air enters through the Air Inlet opening located on the back of the MAJSx2 Air continues through the duct to the hollow rotation wand Air exits the special shaped slot in the top of the rotating wand with sufficient velocity to pass through the Test Sieve ScreenThe JOYAL Threering Micro Powder Mill(ultrafine mill) is for superfine grinding materials with hardness less than 6 in Mohs scale and humidity less than 6 percent such as kaolin, The high pressure centrifugal blower inhales air from the outside and blow the materials which are ground in the third ring to powder SeparatorJoyalThreering Micro Powder Mill,Threering Micro Powder Mill Micro powder roller mill is also known as ultrafine powder grinding mill It is a new type of powder processing equipment, mainly used for crushing and processing nonmetallic minerals such as calcium carbonate, barite, talc, gypsum, calcite, limestone, calcium oxide, bentonite, dolomite and other nonmetallic minerals with Mohs hardness less than 5 and water content less than 5%Micro Powder Roller Mill for Getting Ultrafine Powder DASWELLHigh Crushing ratio High Energy Utilization Primary processing D97 ≤ 10 μ M fine powder, and 3 µ m fine powder accounts for about 40%, with a large specific surface area; It not only has the advantages of high efficiency and low consumption of highspeed impact crusher, but also has the fineness close to that of air millHCH Ultrafine Grinding Mill, Micro powder grinding mill, Ultra

.jpg)

Ball Mill and Air Classifier Production Line ALPA micro silica

The classifier is equipped with speed sensor and control system, which can measure, evaluate and compensate the air temperature, air pressure and air volume, as well as the pressure loss caused by the increase of filter pressure difference, so