What procedures are required for limestone powder making

.jpg)

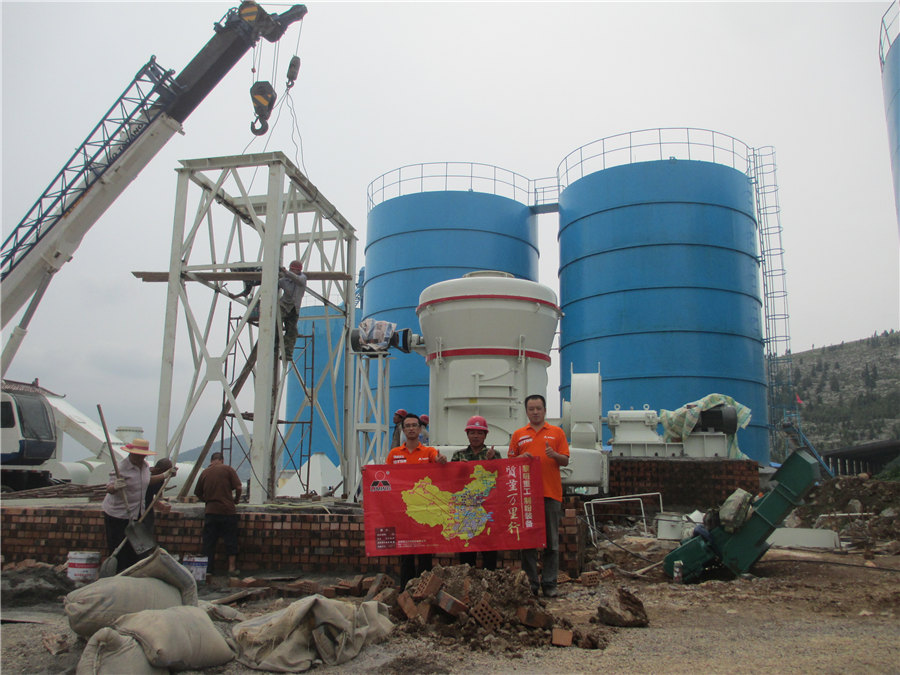

Introduction of limestone powder making process and

2024年2月23日 The production of limestone powder involves a series of carefully controlled steps to transform raw limestone into a versatile and valuable material Here's an overview of the typical limestone powder making process: In this blog post, we will explore the limestone powder production process and its benefits The production process involves four main stages: quarrying, crushing, grinding, and packaging Limestone Powder Making Process NPK Plant Cost2024年8月26日 At present, most of the limestone powder used in the building materials industry is limestone or stone chips generated in the production of aggregates, etc, which are ground Limestone Powder Grinding Process ALPA Powder Equipmentprocedures begin with initial cutting, followed by application of a finish, and conclude with a second cutting or shaping step Due to the array of stone products, the second and/or third stepsLimestone Quarrying and Processing: A LifeCycle Inventory

Which Grinding Mill Is Suitable For Processing

2022年8月26日 While designing a complete limestone grinding plant, there are several steps: First of all, we should consider about the max feed size of limestone to be processed The feed size of limestone decides if we should 2017年7月7日 The basic processes in the production of limestone are (i) quarrying of raw limestone, (ii) preparing mined limestone for its use by crushing and sizing, (iii) calcining of raw Limestone – Its Processing and Application in Iron and IspatGuru2024年11月6日 Here's how to use one effectively: Load the ball mill: Fill your ball mill cylinder to the appropriate point with crushed limestone Add grinding media (like stainless steel balls) to Ball Mills Create Limestone Powder Economy Ball Mill2023年5月27日 As an important cement raw material and cement admixture, the importance of limestone to the cement industry is selfevident Therefore, making full use of limestone resources can guarantee productivity and sustainability of 2 Major Roles of Limestone in Cement Manufacturing

Pelletized Lime Production: A Detailed Howto Guide

2024年7月12日 The process of limestone pelletizing is a method of transforming powdered limestone into granular products with specific shapes and sizes Pelletized limestone, also 2018年8月30日 Limestone powder (LS) has been widely used in cementbased materials; and reportedly, can influence their properties by filler, nucleation, dilution and chemical effects The A review on use of limestone powder in cementbased materials In addition, grinding and milling operations, used upstream (limestone crushing and grounding) and downstream (milling of clinker into cement powder) also requires significant amounts of energy The amount of CO2 produced for 1 ton of cement can vary depending on a number of factors, including the specific production process, the type of kiln used, and the source of the Cement Production Demystified: StepbyStep Process and Carbon Lime stone powder improves the coverage of the paint, reducing the number of coats required for a desired finish It enhances the overall appearance and visual appeal of the painted surface The process of making limestone powder is closely watched from start to finish Tests are done to check the powder’s chemical makeup, size, 9 important Uses of limestone powder

Practical guide for the assessment of glass making limestones and

limestone containing batches required higher melting temperatures to achieve a given viscosity than limestone batches and dolomite batches 2 Sampling It is vital that the sampling procedure generates a laboratory sample from the bulk material that is representative of that delivered Granular materials, such2023年10月21日 The heat test is a fundamental procedure to determine the calcium oxide (lime) content in limestone The steps involved are as follows: Weigh a sample of dry limestone Heat the sample for four hours in an open fire Observe and record the reduction in weight after heating to calculate the calcium oxide content 3Limestone Tests: Properties and Testing Methods Building and 2024年11月23日 Cement Extraction, Processing, Manufacturing: Raw materials employed in the manufacture of cement are extracted by quarrying in the case of hard rocks such as limestones, slates, and some shales, with the aid of blasting when necessary Some deposits are mined by underground methods Softer rocks such as chalk and clay can be dug directly by Cement Extraction, Processing, Manufacturing BritannicaFind production technology for making Limestone, and connect directly with leading machine manufacturers worldwide Products; Where a standalone bagger is required for filling large, Short switching times are often required when diverting or combining powder or granular soli Limestone Processing Equipment Making

Limestone and Dolomite and their Use in Iron and Steel Plant

2013年5月8日 Specification of limestone and dolomite for iron making is less rigid But for steelmaking limestone need to have very low SiO2 and Al2O3 since these elements require additional flux to neutralize them which increases the slag volumes Further additional heat is required for keeping fluid this amount of additional slagDownload scientific diagram Specifications of limestone for industrial uses from publication: Geochemical Assessment of Middle Eocene Limestone Deposits in Wadi Tanhalin, Eastern Yemen, for Specifications of limestone for industrial usesStandard Test Methods for Chemical Analysis of Limestone, Quicklime, and Hydrated Lime 1 × Close Log In Log in with Facebook Log in with Google or Password Remember me on this computer or reset password Enter the address you (PDF) Standard Test Methods for Chemical Analysis of Limestone 2018年10月25日 Here's my full answer for the process diagram task below The diagrams below show the stages and equipment used in the cementmaking process, and how cement is used to produce concrete for building purposes (This task comes from Cambridge IELTS book 8) The first diagram illustrates the process of cement manufacture, and the second diagram shows the IELTS Writing Task 1: process diagram answer IELTS Simon

What Are Uses of Limestone Powder One Must Know

2023年4月25日 Limestone powder is one of the most commonly used natural stone powders around the world Moreover, it is extracted from limestone, a sedimentary rock composed of calcium carbonate that has been formed over 2024年6月3日 It is relatively soft compared to other rocks, making it easy to cut and carve However, it becomes harder when exposed to heat and pressure, making it ideal for various applications Uses of Limestone Limestone is a Limestone Storage: Best Practices for Preserving 2024年10月10日 High Calcium Content: Limestone Powder is rich in calcium, making it a valuable supplement in animal feed to promote healthy bone development and overall growth Thermal Insulation: With its excellent thermal insulation properties, Limestone is utilized in the production of insulation materials for buildings and construction projectsWhat Are Uses of Limestone Powder One Must Know2024年9月10日 Benefits of Limestone Powder Limestone offers several benefits that make it a popular choice in various industries Some of the key benefits of this powder are: 1 Improves Soil Quality Limestone powder is a natural soil conditioner that What Are Uses of Limestone Powder One Must Know

Cement Standards and Concrete Standards Standards Products

ASTM's cement and concrete standards are instrumental in the evaluation and testing of concrete, cement, and aggregates Concrete can have different properties depending upon the mixture that is used in creating it, which contains cement, chemical admixtures, and aggregatesMaking colored classroom chalk 7 Pigments (dry, natural, colored materials) are mixed in with the calcium carbonate while both are dry (the procedure is similar to sifting flour and baking powder together before adding liquid, as in a cake recipe)How chalk is made material, making, used, processing, procedure An English bricklayer made the first portland cement early in the 19th century by burning powdered limestone and clay on his kitchen stove With this crude method, Joseph Aspdin of Leeds laid the foundation for an industry that annually processes literally mountains of limestone, clay, cement rock, and other materials into a powder so fine, it will pass through a sieveHow Cement is Made Portland Cement Association2022年2月20日 You can easily create your own scouring powder at home with a few basic ingredients Making your own scouring powder is helpful because you can avoid using toxic chemicals such as formaldehyde, benzene, chloroform and toluene, which are often added to commercial products To make the powder, use baking soda as your baseHow to Make Scouring Powder at Home: 13 Steps (with Pictures)

What Are Uses of Limestone Powder One Must Know

2024年10月10日 High Calcium Content: Limestone Powder is rich in calcium, making it a valuable supplement in animal feed to promote healthy bone development and overall growth Thermal Insulation: With its excellent thermal insulation properties, Limestone is utilized in the production of insulation materials for buildings and construction projectsThe tests with the procedure are explained in this article Tests on Limestone Following four tests are conducted on limestone/powdered limestone Physical test; Heat Test; Acid Test; Ball Test; 1 Physical test The physical properties Tests on Limestone – theconstructorThe iron ore production has significantly expanded in recent years, owing to increasing steel demands in developing countries However, the content of iron in ore deposits has deteriorated and lowgrade iron ore has been processed Iron Ore Pelletizing Process: An Overview IntechOpenLimestone powder has excellent abrasion resistance, making it suitable for use in flooring, countertops, and other surfaces that are subject to wear and tear Thermal stability: Limestone powder is thermally stable at high temperatures, Limestone Powder Suppliers in India: Quality

Limestone Powder Making Process NPK Plant Cost

– Lime: Limestone powder can be calcined (heated) to produce lime (CaO), which is used for various purposes such as soil stabilization, water treatment, flue gas desulfurization, paper making, etc – Plaster: Limestone powder can be mixed with water and gypsum to produce plaster (CaSO42H2O), which is used for coating walls and ceilingsThe first step in making concrete is to prepare the cement One type of cement, Pordand cement, is considered superior to natural cement because it is stronger, more durable, and of a more consistent quality To make it, the raw materials are crushed and ground into a fine powder and mixed togetherHow concrete is made material, manufacture, making, how to 2020年5月8日 Crushed limestone is used in the manufacturer of asphalt, which is used as a coating for roads It is also used to construct a solid base of roads and railways 16) Making of Toothpaste Limestone is used in the manufacturer of toothpaste It has two main functions in a toothpaste; to work as a white pigment and a filler 17) Making of Carvings25 uses of limestoneLime stone powder improves the coverage of the paint, reducing the number of coats required for a desired finish It enhances the overall appearance and visual appeal of the painted surface The process of making limestone powder is closely watched from start to finish Tests are done to check the powder’s chemical makeup, size, 9 important Uses of limestone powder

Introduction of limestone powder making process and application

2024年2月23日 The limestone powder making process and its versatile applications highlight the importance of this finely ground material across multiple industries From construction to agriculture, environmental remediation, and various manufacturing sectors, limestone powder plays a crucial role in enhancing products and processes, contributing to sustainable and 2021年3月3日 Lime is the least expensive and one of the most heavily used alkali in the world, being essential to our society It is a nonhydraulic binder, excepting the socalled hydraulic lime, meaning that it will not set under waterFor this reason, lime is sometimes called air lime since it hardens on exposure to air It was used for thousands of years in masonry mortars to bind the Lime SpringerLink2024年10月10日 High Calcium Content: Limestone Powder is rich in calcium, making it a valuable supplement in animal feed to promote healthy bone development and overall growth Thermal Insulation: With its excellent thermal insulation properties, Limestone is utilized in the production of insulation materials for buildings and construction projects7 Surprising Uses for Limestone Powder You Need to KnowIn addition, grinding and milling operations, used upstream (limestone crushing and grounding) and downstream (milling of clinker into cement powder) also requires significant amounts of energy The amount of CO2 produced for 1 ton of cement can vary depending on a number of factors, including the specific production process, the type of kiln used, and the source of the Cement Production Demystified: StepbyStep Process and Carbon

9 important Uses of limestone powder

Lime stone powder improves the coverage of the paint, reducing the number of coats required for a desired finish It enhances the overall appearance and visual appeal of the painted surface The process of making limestone powder is closely watched from start to finish Tests are done to check the powder’s chemical makeup, size, limestone containing batches required higher melting temperatures to achieve a given viscosity than limestone batches and dolomite batches 2 Sampling It is vital that the sampling procedure generates a laboratory sample from the bulk material that is representative of that delivered Granular materials, suchPractical guide for the assessment of glass making limestones and 2023年10月21日 The heat test is a fundamental procedure to determine the calcium oxide (lime) content in limestone The steps involved are as follows: Weigh a sample of dry limestone Heat the sample for four hours in an open fire Observe and record the reduction in weight after heating to calculate the calcium oxide content 3Limestone Tests: Properties and Testing Methods Building and 2024年11月23日 Cement Extraction, Processing, Manufacturing: Raw materials employed in the manufacture of cement are extracted by quarrying in the case of hard rocks such as limestones, slates, and some shales, with the aid of blasting when necessary Some deposits are mined by underground methods Softer rocks such as chalk and clay can be dug directly by Cement Extraction, Processing, Manufacturing Britannica

.jpg)

Limestone Processing Equipment Making

Find production technology for making Limestone, and connect directly with leading machine manufacturers worldwide Products; Where a standalone bagger is required for filling large, Short switching times are often required when diverting or combining powder or granular soli 2013年5月8日 Specification of limestone and dolomite for iron making is less rigid But for steelmaking limestone need to have very low SiO2 and Al2O3 since these elements require additional flux to neutralize them which increases the slag volumes Further additional heat is required for keeping fluid this amount of additional slagLimestone and Dolomite and their Use in Iron and Steel PlantDownload scientific diagram Specifications of limestone for industrial uses from publication: Geochemical Assessment of Middle Eocene Limestone Deposits in Wadi Tanhalin, Eastern Yemen, for Specifications of limestone for industrial usesStandard Test Methods for Chemical Analysis of Limestone, Quicklime, and Hydrated Lime 1 × Close Log In Log in with Facebook Log in with Google or Password Remember me on this computer or reset password Enter the address you (PDF) Standard Test Methods for Chemical Analysis of Limestone

.jpg)

IELTS Writing Task 1: process diagram answer IELTS Simon

2018年10月25日 Here's my full answer for the process diagram task below The diagrams below show the stages and equipment used in the cementmaking process, and how cement is used to produce concrete for building purposes (This task comes from Cambridge IELTS book 8) The first diagram illustrates the process of cement manufacture, and the second diagram shows the