What should be paid attention to in the safety of calcite ore powder processing plants

Powder Processing Challenges: Mastering force and flow

2024年1月13日 Ensuring safety in Powder Processing environments requires a dual focus on both robust safety protocols and heightened human awareness Particularly crucial in industries handling explosive hazards, such as chemical processing plants, safety measures extend This new CCPS guidelines book will discuss the types of hazards that can occur in a wide range of process equipment and with a wide range of substances, and will present measures to Guidelines for Safe Handling of Powders and Bulk Solids2015年1月1日 Chemical process safety involves both the technical and the management aspects of the chemical industry, and this chapter addresses both It is not enough to be Safety Considerations in the Chemical Process IndustriesPay attention to the potential safety implications of subtle changes to experimental procedures Slight changes to commonly performed operations often present unrecognized hazards Working with Chemicals Prudent Practices in the Laboratory

.jpg)

GUIDELINES FOR Safe Handling of Powders and Bulk Solids

391 Chronic Exposure Scenarios during Processing and Material Handling 138 139 393 Fire and Explosion Exposure Scenarios 142 934 Incident Cleanup Exposure Scenarios 144 2017年12月22日 Before streamlining production, analyzing finances, pursuing Research Development, or embracing new technology, the first priority must be safety Strong safety 5 tips for creating a strong safety culture in processing plantsThis module covers several basic topics relating to process safety, including methods for occupational hazard control, layers of protection, and regulatory symbols and documentation Process Safety Fundamentals – Visual Encyclopedia of Chemical 2009年3月1日 Over past decades a fundamental need has grown for change regarding safety control in the process industries Traditionally, strong focus exists on identification and control Journal of Loss Prevention in the Process Industries ScienceDirect

.jpg)

Guidelines for Safe Handling of Powders and Bulk Solids

2004年11月1日 This new CCPS guidelines book will discuss the types of hazards that can occur in a wide range of process equipment and with a wide range of substances, and will present Powder pressing operations, including uniaxial compaction and isostatic compaction, are effective methods for making shapes from powders They are used in ceramic processing and are at Powder Process an overview ScienceDirect Topics2023年5月22日 Associated gold in polymetallic ores often contains minerals such as arsenic and carbon, which have a certain impact on the flotation of gold ores The beneficiation methods include cyanide leaching, flotation separation, gravity separation and so on In this article, we will answer three questions one by one: how to deal with goldbearing sulfide ores, how to deal What Should be Paid Attention to When Processing These 3 Types of Gold Ore?2024年10月15日 This includes safety goggles, lab coats, gloves, and closedtoed shoes PPE helps protect against chemical splashes, spills, and other accidents Key Points: Wear safety goggles at all times to protect your eyes 20 Lab Safety Rules and Hazards You Need to Know

The Dairy Industry: Process, Monitoring, Standards,

2018年11月5日 Sampling and analysis occur along the milk processing train: from collection at farm level, to intake at the diary plant, the processing steps, and the end products Milk has a short shelf life; however, products such as milk 2023年10月23日 New pollutants, which have been gaining increasing attention in China in recent years, are largely results of the production, use, and disposal of chemicals that are of great economic value Managing new pollutants requires a high degree of policy coordination through the life cycle of chemicals and a balanced consideration of multiple social objectives From the Managing the Risks of New Pollutants in China: The Perspective of 2022年2月2日 The slope stability has already become one of the most important factors directly related to the safety production and development of a mine, which is principally controlled by the properties of geological discontinuities of slope, such as bedding planes, faults, cleavage and joints In this study, a new approach for the evaluation of slope stability in large openpit mines Case study: Yangtaowu Slope at Dexing Copper Mine, ChinaEvery institution, irrespective of size, should have a safety program Such a program should be designed, when appropriate, to ensure compliance with (1) Occupational Safety and Health Administration (OSHA) requirements for health and safety, (2) Nuclear Regulatory Commission (NRC) requirements for safe handling of radioactive isotopes, (3) Environmental Protection Safety Management Biosafety In The Laboratory NCBI Bookshelf

The Five Pillars of a Highly Effective Safety Management Process

2021年2月1日 Excellence in safety can only be achieved through a strategydriven, performancebased safety management process that is supported by operational excellence, driven by principle centered 2012年8月31日 Better mining corporations want to adopt “Responsible Mining” This paper outlines the essentials of responsible mining and offers a guide to corporations who want become responsible Eight principles are discussed: (1) Social and environmental assessment, (2) Transparency, (3) Acceptance by stakeholders, (4) Food production trumps questionable Responsible Mining: The Key to Profitable Resource Development2021年11月1日 Moreover, as much as possible, the recovery rate of mineral processing should be improved, the tailings discharge level should be reduced, and the amount of unusable ore resources components should be minimized by means of the highlevel treatment of mineral processing and metallurgyKey Engineering Technologies to Achieve Green, Intelligent, and 2024年1月13日 Particularly crucial in industries handling explosive hazards, such as chemical processing plants, safety measures extend beyond standard procedures Rigorous safety protocols involve the deployment of specialized equipment to counter electrostatic charges, the use of explosionproof enclosures, and comprehensive training programs for personnelPowder Processing Challenges: Mastering force and flow

Mining and Beneficiation of Phosphate Ore

2016年1月8日 The first commercial production of phosphate rock began in England in 1847 A wide variety of techniques and equipment is used to mine and process phosphate rocks in order to beneficiate lowgrade ores and remove 2023年7月1日 To inject safety into all mining operations, comprehensive safety procedures must be integrated into feasibility studies for all activities taking place during mineral exploration, development, exploitation, and rehabilitation (Dong et al, 2022)For example, blasting being a key process for rock fragmentation, improper practices using rudimentary techniques are likely to Safe mining operations through technological advancement2022年3月21日 Geology, deposit types, and ore minerals There are more than 200 minerals that contain REE 7,8 The most common rareearth minerals are monazite and bastnäsite (Figure 1a–b and Table II)Monazite exists as a group of arsenates, phosphates, and silicates, but the primary REEbearing monazite is a complex phosphate 5 Bastnäsite, also known as Processing the ores of rareearth elements MRS Bulletin2014年1月1日 To achieve optimal performance of a crushing plant, not only the design of the individual machines but also the cost of running them should be taken into accountIn this paper a novel method for Factors affecting the performance of crushing plant operations

.jpg)

Hazards associated with an ore processing Plant

2023年3月21日 An ore processing plant presents numerous safety hazards throughout its various stages of operation, including haulage, primary stockpiles, crushing, screening, conveyors, surge piles, washing plants, electricity, plant maintenance, and general mining hazards These risks encompass vehicle accidents, falling materials, machineryrelated 2022年10月8日 22 Weight Modification for Safety Assessment: Variable Weight The core idea of the variable weight theory is that the indicator weight changes over its value It should be noted that the indicator weight indicates the importance of the corresponding indicator in the evaluation decision []The variable weight vector is the Hadamard product of the constant weight vector Safety Assessment of Dam Failure of Tailings Pond Based on 2023年10月17日 The design of the mineral processing plant is an important part of the construction of the mineral processing plant It involves the physical properties, chemical properties, mineral composition How to Judge Whether the Design of the Mineral Processing Plant 2024年3月1日 According to projections from the Global Mineral Resources Research Center of the Chinese Academy of Geological Sciences, the global demand for SMs is expected to surge dramatically over the next decade or so [6]By 2025, the annual global demand for crude steel, copper, aluminum, lithium, and cobalt is projected to reach 207 billion t, 3054 million t, 689 Guidance and review: Advancing mining technology for enhanced

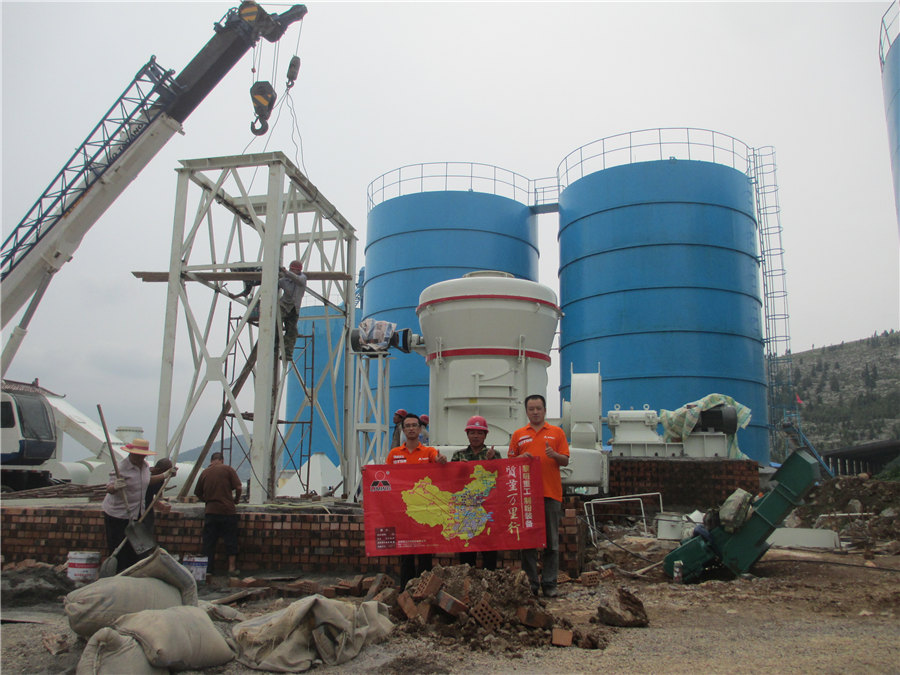

(PDF) Best practices to improve construction site safety, in the

2020年1月1日 Author experienced such practices in specific conditions during processing plant construction Such facilities are characterized by installation of special largescale mineral processing equipment 7 Safety aspects of bulk storage should be discussed with the powder or paste supplier SAFETY PRINCIPLES FOR HANDLING ALUMINUM POWDER AND PASTE Rule I – Avoid any condition that will suspend or float powder particles in the air, creating a dust cloud 1 In transferring aluminum powder, dust clouds should be kept at an absolute minimum Recommendations TR2 for storage and handling of aluminum powders and The Culture of Safety Imperative iii Introduction 1 Recommendations for Use of This Guide 4 A Culture of Safety: The Six Domains 5 Establish a Compelling Vision for Safety 6 Value Trust, Respect, and Inclusion 9 Select, Develop, and Engage Your Board 13Leading a Culture of Safety: A Blueprint for Success2022年12月16日 Milling machines use rotating milling cutters and other cutting tools to remove material from metal, wood, and different workpieces These tools often run at high cutting speeds, causing chips and other flying debris to exit The Most Important Milling Machine Safety Precautions

SAFETY IN MATERIAL STORAGE AND HANDLING OF ALUMINIUM POWDER

1 In transferring aluminium powder, dust clouds should be kept at an absolute minimum Powder should be transferred from one container to another using a nonsparking, conductive metal scoop, with as little agitation as possible Handling should be slow and deliberate to hold dusting to a minimum Both containersBecause the areas feature extremes in temperatures, air quality and impacts, safety is a major consideration for mining operations Factoring in the range of risks on the job can be difficult, but improving mine safety can be easier with these safety tips Through testing and experience, the mining process has been tweaked to add resources and Safe Mining Practices: 18 Mine Safety Tips TMI TM2019年10月24日 size of the mine, scale of actual operation and size of processing plant Koahnken (2018 ) in a report to the Worldwide Fund for Nature reveals several ecological impacts due to sand miningEnvironmental Impacts of the Mining Industry : A literature review2021年6月21日 paying attention to the issue of safety in mini ng activities, much attention should be paid to the environment as a platform for development in t oday's world, because the most important human (PDF) Providing Health, Safety and Environmental Management

.jpg)

The 5 Steps of a Successful Safety Inspection Process Pulpstream

Before conducting a safety inspection, it’s imperative to plan for it Creating a safety inspection plan involves the following elements: A schedule Since inspections should be regular, the first step would be to decide how regularly you're going to conduct them (ideally, one every six months or so) and when these inspections would be2020年7月30日 Industries all around the world have started investing in energy storage and pollution control technologies as the demand for energy is increased with a consumption rate of 29% while the carbon emission is increased by 2% in the year 2018 []Ever since the evolution of nanotechnology, tremendous developments in the field of energy, environmental, and Nanomaterials through Powder Metallurgy: Production, Processing2020年6月16日 The idea of green mining was proposed as a practical approach to make the mining industry more sustainable than before Green mining is a contemporary mining model centered on the sustainability of resources, environment, and socioeconomic benefits Its purpose is to develop and apply technologies and processes that increase environmental Evaluation and future framework of green mine construction 2020年10月2日 Schrörs B (2012) Safety techniques based on process control, In: Hauptmanns U (ed) Plant and process safety, 5 Engineered safety measures, Ullmann’s Encyclopedia of Industrial Chemistry, 8th edition, Wiley, Weinheim doi: 101002/q20q04Safety of Process Plants by Process Control SpringerLink

.jpg)

What Should be Paid Attention to When Processing These 3 Types of Gold Ore?

2023年5月22日 Associated gold in polymetallic ores often contains minerals such as arsenic and carbon, which have a certain impact on the flotation of gold ores The beneficiation methods include cyanide leaching, flotation separation, gravity separation and so on In this article, we will answer three questions one by one: how to deal with goldbearing sulfide ores, how to deal 2024年10月15日 This includes safety goggles, lab coats, gloves, and closedtoed shoes PPE helps protect against chemical splashes, spills, and other accidents Key Points: Wear safety goggles at all times to protect your eyes 20 Lab Safety Rules and Hazards You Need to Know2018年11月5日 Sampling and analysis occur along the milk processing train: from collection at farm level, to intake at the diary plant, the processing steps, and the end products Milk has a short shelf life; however, products such as milk The Dairy Industry: Process, Monitoring, Standards, 2023年10月23日 New pollutants, which have been gaining increasing attention in China in recent years, are largely results of the production, use, and disposal of chemicals that are of great economic value Managing new pollutants requires a high degree of policy coordination through the life cycle of chemicals and a balanced consideration of multiple social objectives From the Managing the Risks of New Pollutants in China: The Perspective of

.jpg)

Case study: Yangtaowu Slope at Dexing Copper Mine, China

2022年2月2日 The slope stability has already become one of the most important factors directly related to the safety production and development of a mine, which is principally controlled by the properties of geological discontinuities of slope, such as bedding planes, faults, cleavage and joints In this study, a new approach for the evaluation of slope stability in large openpit mines Every institution, irrespective of size, should have a safety program Such a program should be designed, when appropriate, to ensure compliance with (1) Occupational Safety and Health Administration (OSHA) requirements for health and safety, (2) Nuclear Regulatory Commission (NRC) requirements for safe handling of radioactive isotopes, (3) Environmental Protection Safety Management Biosafety In The Laboratory NCBI Bookshelf2021年2月1日 Excellence in safety can only be achieved through a strategydriven, performancebased safety management process that is supported by operational excellence, driven by principle centered The Five Pillars of a Highly Effective Safety Management Process2012年8月31日 Better mining corporations want to adopt “Responsible Mining” This paper outlines the essentials of responsible mining and offers a guide to corporations who want become responsible Eight principles are discussed: (1) Social and environmental assessment, (2) Transparency, (3) Acceptance by stakeholders, (4) Food production trumps questionable Responsible Mining: The Key to Profitable Resource Development

Key Engineering Technologies to Achieve Green, Intelligent, and

2021年11月1日 Moreover, as much as possible, the recovery rate of mineral processing should be improved, the tailings discharge level should be reduced, and the amount of unusable ore resources components should be minimized by means of the highlevel treatment of mineral processing and metallurgy2024年1月13日 Particularly crucial in industries handling explosive hazards, such as chemical processing plants, safety measures extend beyond standard procedures Rigorous safety protocols involve the deployment of specialized equipment to counter electrostatic charges, the use of explosionproof enclosures, and comprehensive training programs for personnelPowder Processing Challenges: Mastering force and flow