How to replace the roller bearings of vertical mills

How to Replace Bearings of a Roller of Verical Roller

This video explains how to replace bearings of a Roller on a vertical roller mill in detail Following the replacement of the bearing, this video also explains how to disassemble the rollers,This video focuses on: How to change the bearings of the main motor, spindle head and spindle How to determine the causes of the noise (from the bearing, How to change the defective bearings of the Vertical 2020年4月2日 Gypsum pendulum roller grinding mill is integrated into a complete system that simultaneously grinding and drying, accurately classifying, and conveying materials in one continuous, automated How to Solve Excessive Temperature of Vertical Mill 2024年4月3日 Types of bearings 1 Ballbearing 2 Roller bearing 3 Plain bearing 4 Linear bearing 5 Fluid bearing 6 Magnetic The axis of the shaft may be vertical or horizontal If the axis of the shaft is vertical, the thrust 15 Types of Bearings and Their Applications [Pictures

.jpg)

Atox Vertical Roller Mill, Maintenance and Repair

The document discusses maintenance and repair of an ATOX Vertical Mill It describes systematic and conditionbased maintenance approaches Systematic maintenance consists of regular cleaning, lubrication and visual inspections in the world’s largest vertical roller mill MVR 6700 C6: The largest vertical mill in the world, producing in Barroso, Brazil 000A86E4 Gebr Pfeiffer is one of the technology leaders in the field of cement grinding and hard milling Vertical roller mills are used to grind cement raw material, cement clinker, blast furnace slag and pozzolan Rolling bearings in the world’s largest vertical roller mill2015年3月25日 1 The working principle of the hydraulic system vertical roller mill The hydraulic system ofvertical mill is an important system, the main function ofthe hydraulic system is to break the grinding roller, which is when the internal grinding cavity wear parts wear, can stop open on both sidesofthe grinding roller mill, to replace the inside parts or repairThis type vertical roller Hydraulic system vertical roller mill operation PDF SlideShareheatmounted bearing in place against the shaft shoulder until it cools and locks in place Otherwise, the bearing may creep away from the proper position 4 Use a similar replacement bearing Replacement bearing should interchange to the bearings they replace While replacing it may be a good time to upgrade your bearing to a higher quality Bearing Handbook for Electric Motors

.jpg)

Crossed Roller Precision Bearings Timken Company

of the bearing itself Able to withstand high overturning moments, the crossed roller bearing is ideal for the table bearing of machine tools, including vertical boring and Applications Precision rotary and indexing tables for machine tools Vertical and horizontal boring mills Vertical grinding machines Rotary surface grinding machines2021年1月1日 Grinding Mill Vertical Roller Mill or Ball Mill: The reclaimed raw mix fed to Raw Mills, for drying and fine grinding of Raw meal for kiln feed: 4: Coal Grinding: Grinding Mill Vertical Roller Mill or Ball Mill: Coal is ground in Coal mill, which is a fuel for use in Kiln firing: 5: Pyro Section, Clikerization: In line calciner six stage Review on vertical roller mill in cement industry its Separable bearings such as tapered roller bearings may be checked by individually examining their rolling elements and the outer ring raceway Large bearings cannot be rotated manually; however, the rolling elements, raceway surfaces, cages, and contact surface of the ribs should be carefully examined visuallyBearing Inspection NSK GlobalVertical roller mills are large grinding machines developed, designed and manufactured by Sinomatec; Sinomatec vertical mills feature a rational and reliable structure as well as an advanced process that combines drying, grinding, separation and conveying, which is suitable for grinding materials of different types and sizesVertical Roller Mills LNV TECHNOLOGY

How to Replace a Bearing on the Woodmizer LT40

2021年10月4日 I had a bearing go bad under the mill so it was time to get it replaced before returning to milling!The main roller bearings under the mill as well as those CARB ® toroidal roller bearing Spherical roller thrust bearing Y bearing 10 11 Mounting and dismounting of bearings General information To provide proper bearing performance and prevent premature failure, skill and cleanliness when mounting ball and roller bearings are necessaryBearing installation and maintenance guide SKFVertical roller mills are adopted in 20 cement plants (44 mills) in Japan Results Table Energy saving effect of the vertical roller mill Ball mill Specific power Cost estimation About 14million US$ [Newlybuilt] and about 230 million US$ [retrofitted], including the cost of supplemental facilities [200tRM/h] [1US$=¥110] Related matters Vertical roller mill for raw Application p rocess materialsCylindrical Roller Bearings Cylindrical Roller Designator NN: Double Row, Inner Ring Guided Rollers N: Single Row, Inner Ring Guided Rollers Width Series Diameter Series Bore code Material RS: Bearing Steel (SUJ2) (rings and rolling elements) RX: Heat Resistant Steel (SHX) (rings and rolling elements)MACHINE TOOL SPINDLE BEARING SELECTION MOUNTING

.jpg)

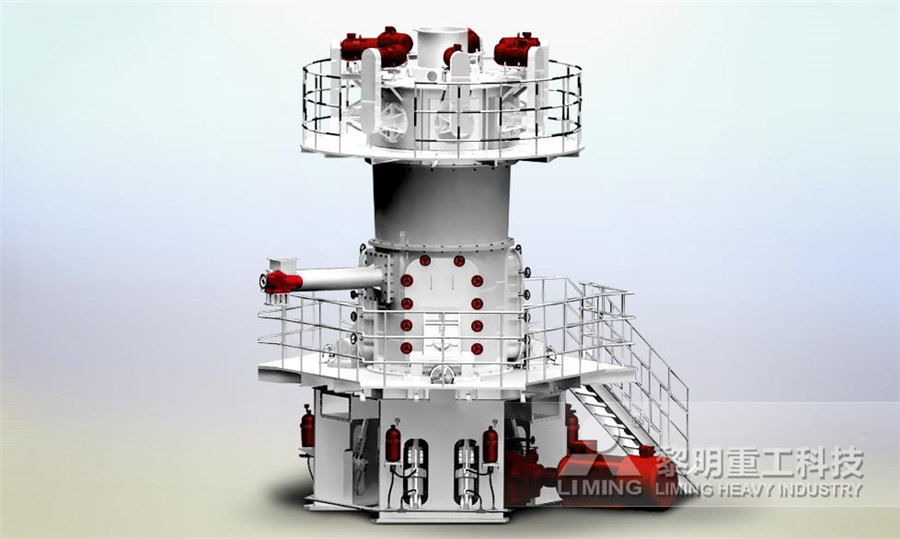

DRIVE SELECTION FOR LARGE LOESCHE VERTICAL ROLLER MILLS

1 A background to drives of vertical roller mills The drive of a vertical roller mill – essentially the mill gearbox – has to fulfill two tasks: The first is to reduce the speed of the electric motor to the selected mill speed and to transmit the torque created by the motor Secondly, the gearbox hasRoller Mill Maintenance Mark Heimann Roskamp Champion 2975 Airline Circle Waterloo, Iowa USA 50703 Tel 319 232 8444 Fax 319 236 0481 sales@cpmroskamp cpmroskamp 2 solution is to replace the straight bore bearings with new bearings using a tapered sleeveCPM Roller Mill MaintenIn vertical roller mills, high temperatures and high particulate concentrations make maintenance a difficult challenge for operators Especially when trying to prevent the problems that can lead to bearing failure and costly unplanned downtimeVertical grinding mills SKF2022年5月31日 The vertical roller mill (VRM), including powder separation and crushing subsystems, is used extensively for intermediate crushing of minerals in several industries such as cement, electric power, and chemical Compression crushing is also the main crushing mechanism in the VRM, but there is also shear force between grinding roller and particlesAnalysis of vertical roller mill performance with changes in

Operational parameters affecting the vertical roller mill

Request PDF On Sep 1, 2016, Deniz Altun and others published Operational parameters affecting the vertical roller mill performance Find, read and cite all the research you need on ResearchGateROLLER MILLS With more than 125 years of experience, Raymond is a leader in the design and manufacture of industrial milling equipment and has set the standard in size reduction THE INDUSTRY STANDARD FOR OVER A CENTURY Raymond Roller Mills: More than 2,000 roller mills have been supplied since the first mills were designed in the late 1800’sRAYMOND® ROLLER MILLS PDF4PRO2006年6月14日 These are standard tapered roller bearings with an inner and outer race and roller cage, and so far as I know they are standard tolerance bearings as opposed to machine tool spindle grade bearings My first rebuild was a 10" model mfg ca1953, and when the original bearings were pulled out were found to be Timken standard gradeReplacing Timken Bearings on an Atlas 12" The Home Roller shell dimension of different roller, as shown in table 1 tjprc editor@tjprc 830 R R Karthi L Emmanual Table 1: Shell Dimensions Rollers Outer Diameter (mm) Groove Depth (mm) Pitch Circle Diameter (mm) (PDF) DESIGN AND ANALYSIS OF ROLLER SHAFTS FOR

Determining relubrication intervals Mobil

2016年2月21日 Unfortunately, there is no single answer to this question This diagram is valid for bearings on horizontal shafts, in stationary machines, operating under normal loads and at a temperature not exceeding 711°C Needle roller bearings, are a type of rolling bearing characterized by their slender and elongated needleshaped rollers Compared to ball bearings, needle roller bearings have a smaller crosssectional area and volume but possess higher loadcarrying capacity This makes needle roller bearings excel in applications with limited space How to Install Bearings on a Shaft? The Beginner's Guide2020年10月2日 How to replace the ball bearing of treadmill motor / by Vlogs guide#trademillreplaceball bearing If you have a noisy treadmill most probably the motor bearinHow to replace the ball bearing of treadmill motor / by Vlogs advantage for online mill operation As each of the roller units can be driven individually, the mill can switch automatically from 4roller operation to 2roller operation Whenever maintenance work on one roller unit is required during operation, this roller and the roller facing it, including the sealing frame, can be lifted hydraulically,Special Rolling Bearings in the New Polysius Vertical Roller Mill

The Ultimate Guide To Flange Bearings AUBEARING

As mentioned above, flange ball bearings consist of balls, cages, inner and outer rings, and outer flanges The materials generally used to manufacture flange ball bearings include high carbon chromium steel 52100, stainless steel 440, stainless steel 316, ceramic materials (silicon nitride, zirconia, silicon carbide) and various plasticsThis video will show you how to replace the insert of a solid housed mounted roller bearing If you have questions or need more information, please visit httHow to Replace a Roller Bearing Insert YouTubevertical roller grinding mills for grinding: • Coal • Cement raw material • Clinker / granulated slag • Industrial minerals, and • Ores The core elements of these plants are the Loesche vertical mills for drygrinding the abovementioned grinding stock Loesche has PROCESS OPTIMISATION FOR LOESCHE GRINDING PLANTS2024年7月14日 Vertical SelfAligning Bearings with Housings: Rolling Mill Roller Tables: Ensure the proper movement and alignment of rollers in rolling mills This unique capability allows a single fourpoint contact ball bearing to replace a combination of angular contact ball bearings arranged in either a backtoback or facetoface 14 Types of Bearings and Their Applications MachineMFG

How to Solve Excessive Temperature of Vertical Mill

2020年4月2日 Gypsum pendulum roller grinding mill is integrated into a complete system that simultaneously grinding and drying, accurately classifying, and conveying materials in one continuous, automated 2024年4月3日 Types of bearings 1 Ballbearing 2 Roller bearing 3 Plain bearing 4 Linear bearing 5 Fluid bearing 6 Magnetic The axis of the shaft may be vertical or horizontal If the axis of the shaft is vertical, the thrust 15 Types of Bearings and Their Applications [Pictures The document discusses maintenance and repair of an ATOX Vertical Mill It describes systematic and conditionbased maintenance approaches Systematic maintenance consists of regular cleaning, lubrication and visual inspections Atox Vertical Roller Mill, Maintenance and Repairin the world’s largest vertical roller mill MVR 6700 C6: The largest vertical mill in the world, producing in Barroso, Brazil 000A86E4 Gebr Pfeiffer is one of the technology leaders in the field of cement grinding and hard milling Vertical roller mills are used to grind cement raw material, cement clinker, blast furnace slag and pozzolan Rolling bearings in the world’s largest vertical roller mill

.jpg)

Hydraulic system vertical roller mill operation PDF SlideShare

2015年3月25日 1 The working principle of the hydraulic system vertical roller mill The hydraulic system ofvertical mill is an important system, the main function ofthe hydraulic system is to break the grinding roller, which is when the internal grinding cavity wear parts wear, can stop open on both sidesofthe grinding roller mill, to replace the inside parts or repairThis type vertical roller heatmounted bearing in place against the shaft shoulder until it cools and locks in place Otherwise, the bearing may creep away from the proper position 4 Use a similar replacement bearing Replacement bearing should interchange to the bearings they replace While replacing it may be a good time to upgrade your bearing to a higher quality Bearing Handbook for Electric Motorsof the bearing itself Able to withstand high overturning moments, the crossed roller bearing is ideal for the table bearing of machine tools, including vertical boring and Applications Precision rotary and indexing tables for machine tools Vertical and horizontal boring mills Vertical grinding machines Rotary surface grinding machinesCrossed Roller Precision Bearings Timken Company2021年1月1日 Grinding Mill Vertical Roller Mill or Ball Mill: The reclaimed raw mix fed to Raw Mills, for drying and fine grinding of Raw meal for kiln feed: 4: Coal Grinding: Grinding Mill Vertical Roller Mill or Ball Mill: Coal is ground in Coal mill, which is a fuel for use in Kiln firing: 5: Pyro Section, Clikerization: In line calciner six stage Review on vertical roller mill in cement industry its

Bearing Inspection NSK Global

Separable bearings such as tapered roller bearings may be checked by individually examining their rolling elements and the outer ring raceway Large bearings cannot be rotated manually; however, the rolling elements, raceway surfaces, cages, and contact surface of the ribs should be carefully examined visuallyVertical roller mills are large grinding machines developed, designed and manufactured by Sinomatec; Sinomatec vertical mills feature a rational and reliable structure as well as an advanced process that combines drying, grinding, separation and conveying, which is suitable for grinding materials of different types and sizesVertical Roller Mills LNV TECHNOLOGY