Which model is the jaw plate of mediumspeed coal mill Raymond mill

Modeling of a medium speed coal mill ScienceDirect

2017年8月1日 This model can be used to estimate the key parameters that are difficult to measure or cannot be measured: 1) coal powder or raw coal contents in coal mills, which can be used as the main basis for coal block and break diagnosis; 2) moisture content in coal powder, Abstract: The paper presents development and validation of coal mill model (including the action of classifier) to be used for improved coal mill control The model is developed by using the Modeling and Control of Coal Mill2017年8月1日 This paper presents a multisegment coal mill model that covers the whole milling process from mill startup to shutdown This multisegment mathematical model is derived Modeling of a medium speed coal mill Semantic ScholarThe work presented in this paper focuses on modeling Mill Parter Shiptype coal mills that are widely used in the coalfired power plants in China The unknown model parameters are Modeling of a medium speed coal mill,Powder Technology XMOL

.jpg)

Schematic of medium speed coal mill [5] ResearchGate

Medium speed mills are widely used in largescale thermal power plants, which run at a setting speed of 50∼300 r/min, owing to their efficiency The schematic of a medium speed coal mill is2017年5月1日 Simulation results indicate that the model effectively represents the midhigh process of coal mill dynamics and can be used to estimate the key parameters in coal mills, Modeling of a medium speed coal mill ResearchGateJXSC raymond mill is a complete set that can form a production system independently We support providing complete powder grinding plant equipment, including cyclone powder Raymond Mill JXSC MachineryIn this paper, a brannew GAIFCMIDHGF assessment method is proposed Genetic algorithm (GA) is first applied to optimize initial parameters, which is fundamental and significant step to The structure of MPS mediumspeed coal mill system

.jpg)

Coal Mill an overview ScienceDirect Topics

Coal mills or pulverizers play a very essential part in the coalfired power production system Coal mills grind the coal into fine powder, and the primary air entering the mill dries and drives the Laboratory grade jaw crushers for powerful crushing of medium hard materials Laboratory Jaw Crusher The rocking motion jaw plate pushes material against fixed jaw plate that results size reduction of samples that falls into drawer Laboratory Jaw Crusher Manufacturers India StericoxGenerally, the outlet temperature of the mediumspeed coal mill is controlled at 100 to 120 degrees Celsius The material processed by the mediumspeed mill barrel is particles of various sizes and hardnesses These materials move inside the mediumspeed mill, constantly causing friction, scouring and impact on various parts of the mediumspeed The cylinder of the mediumspeed coal mill is lined with wear 2017年8月1日 Semantic Scholar extracted view of "Modeling of a medium speed coal mill" by Yaokui Gao et al This paper presents a multisegment coal mill model that covers the whole milling process from mill startup to shutdown This multisegment mathematical model is derived through analysis of energy Modeling of a medium speed coal mill Semantic Scholar

CFB石灰石脱硫剂制备——磨机公众号12.8 推送案例(8)51.jpg)

Schematic of medium speed coal mill [5] ResearchGate

Download scientific diagram Schematic of medium speed coal mill [5] from publication: Early Warning of Critical Blockage in Coal Mills Based on Stacked Denoising Autoencoders Coal mills have Raymond mill is a common type of cement mill used in cement plant and lime calcination plant, and generally apply for the production of mineral powder or coal powder, such as the fine powder processing of raw ore, gypsum, coal and other materials Why choose Raymond mill from AGICO? AGICO Cement is one of leading raymond mill suppliers in China, we can offer any Raymond Mill, Raymond Mill For Sale For Cement and Lime Plant5 What Shapes do Jaw Plates Have? Several different types of Jaw Plates are available, each suited for various applications and crushing requirements In the following, we'll use the example of Metso® Nordberg® C Series™ jaw plates to explain how different shapes of jaw plates correspond to the application sites and the materials being crushedThe Complete Guide to Jaw Plates: 10 Essential Facts Stellar HeavyZGM medium speed roller mill 1 Introduction 11 Purpose ZGM type medium speed roller mill is widely used in coal powder preparation system of electric power, metallurgy, cement, chemical industry and other industries, as well as coal pulverizing system of cement, chemical industry, mining and other industriesZGM type Mediumspeed Rolling coal millpower plant equipment

.jpg)

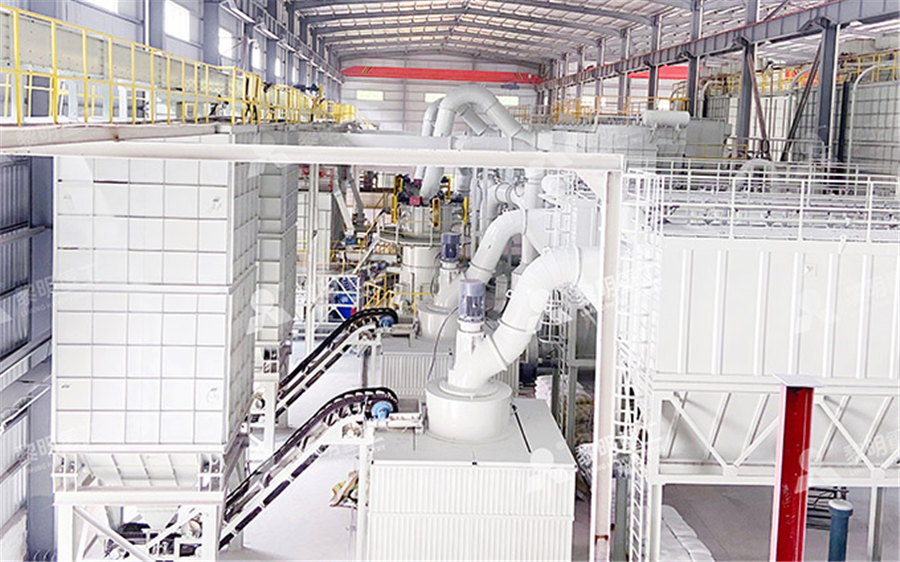

Application of Alumina Ceramic Plate on Medium Speed Coal Mill

2023年6月15日 Alumina ceramic plate can significantly reduce the wear of medium speed coal mills As an important coal powder preparation equipment, the medium speed coal mill can cause severe wear and tear to The MTM Medium Speed Trapezium Mill is the world's leading industrial mill Feed particle size: 035mm Production As high quality Raymond mill, MTM Medium Speed Trapezium Mill is applicable to powder pulverization in metallurgy, They purchased a MTW110 Model firstly Afterwards, due to capacity expansion, they purchased a MTW138 againMTM Series Medium Speed Trapezium MillAs an important pulverized coal preparation equipment, medium speed mill has been facing the test of wear since its birth According to statistics, about 80% of the parts that fail in medium speed grinding belong to the direct or indirect consequences caused by metal wearMediumspeed coal mill wearresistant ceramic liner Composite ObserverBased and Regression ModelBased Detection of Emerging Faults in Coal Mills Peter Fogh Odgaard, Sten Bay Jørgensen, in Fault Detection, Supervision and Safety of Technical Processes 2006, 2007 2 THE COAL MILL The work presented in this paper, is based on a Babcock MPS 212 coal mill used at Elsam’s Nordjyllandsværktet Unit 3 However, the Coal Mill an overview ScienceDirect Topics

.jpg)

Fault Diagnosis of a Mediumspeed Coal Mill Based on Grey Box Model

2018年3月15日 A grey box model was established for mediumspeed coal mill by combining the mechanism analysis method with data identification algorithm, which has higher accuracy and stronger robustness and 2023年9月3日 PEW Jaw Crusher is a new crushing machine developed by SBM, the jaw crusher manufacturer, after the release of traditional jaw crusher This jaw crusher is a perfect combination of modern science and technology PEW Jaw Crusher SBM Mill Crusher2014年9月1日 Power consumption and therefore efficiency of crushing equipment are becoming increasingly important mainly due to the continuous and rapid increase of energy costs and efforts to minimise CO 2 Assessing the energy efficiency of a jaw crusher Request PDFDownload scientific diagram Schematic structure of the MPS mediumspeed mill from publication: Application of ModelBased Deep Learning Algorithm in Fault Diagnosis of Coal Mills The coal Schematic structure of the MPS mediumspeed mill

.jpg)

Jaw Plates: How to Choose the Right One for Different Types of Jaw

2023年2月15日 Model and specifications of jaw crushersWhat types of jaw plate material you should choose may depend on different specifications, feed size and impact load The hardness of the material The hardness of the material is also an important factor in choosing the jaw plateWhat are the jaw materials of the jaw crusher? High manganese steel High manganese steel is the traditional material of the jaw plate of jaw crusher, which has good impact load resistanceHowever, due to the structure of the crusher, the opening angle between the movable and fixed jaws is too large, which is easy to cause abrasive sliding and deformation due to What are the Materials of the Jaw Crusher Plates and EB Castworld2023年2月16日 If you’re in the market for a jaw crusher, you’re likely to come across the term “jaw plates” Jaw plates are an essential component of the jaw crusher that is responsible for crushing the material In this article, we’ll provide you with a comprehensive guide to jaw plates, including what they are, how they work, and what factors to consider when choosing the right Jaw Plates: Everything You Should Know Crusher Wear PartsMPG medium speed coal mill is the product of upgrading MPS and MP medium speed coal mills In 1984, it cooperated with Germany Babcock Company for Liaoning Chaoyang Power Plant 2 × 200MW unit Augmentation Project provides 12 sets of MPS 212 medium speed coal mills, from which production and manufacture of MPS medium speed coal mills beganMPG Medium Speed Coal Mill北方重工 NHI

The construction of mediumspeed mills ResearchGate

Coal mills consume a huge amount of station service electricity power of a coalfired power plant Meanwhile, the operation of coal mills also has a large influence on boiler combustion2022年8月10日 Mediumspeed coal mill wearresistant ceramic plate Vertical mill lining plate is used to protect the coal mill barrel and shell from direct impact and frictionMediumspeed coal mill wearresistant ceramic plate Composite plate 2015年1月15日 To improve the safety and economy of coal mill operation, a dynamic mathematical model was established for MPS medium speed coal mill based on mass and energy balanceModeling and simulation of MPS medium speed coal mills2022年7月14日 Figure of the numerical simulation process diagram (a) Figure of finite element model; (b) figure of grid partition; (c) figure of observation point positionDynamic Response of the Steel Plate Under the Impact

.jpg)

Integrated rotating nozzle ring of mediumspeed coal mill

Background technology: our domestic mediumspeed pulverizer generally uses the swivel nozzle ring as the coal pulverizer nozzle at presentThis swivel nozzle gyration ring puts together on to use through flange bolt with the coal pulverizer mill sees that figure one, this kind swivel nozzle ring structure have following 2 major defects: 1, receive its structure influence, between swivel 【Raymond Mill Plant】 The Raymond mill plant usually contains a cyclone collector, pipe fittings, dust collector, storage hopper, elevator, crusher, electric control cabinet, feeder, main plant, blower, separator, etc, Structural Features The whole mill is of spatial structure, less premise and systemic strong The whole system from roughing, transportation, powder collecting to Raymond Grinding Mill JXSC Machine2023年2月21日 Discover everything you need to know about jaw crushing machines, from the various types such as single and double toggle, hydraulic and portable models, to their working principles, advantages, and disadvantages This comprehensive guide also provides expert tips on maintenance and selecting the right machine for your specific applicationThe Ultimate Guide to Jaw Crushing Machines: Types More Tips 2021年8月1日 Yukio et al [7] proposed a model consisting of blending, grinding and classifying processes for pulverizer control Agarawal et al [8] differentiated coal powder into ten size groups, divided the bowl mill into four zones, and developed a unified model Palizban et al [9] derived nonlinear differential mass equations of raw coal, recirculation coal and suspension coal in Coal mill model considering heat transfer effect on mass

.jpg)

How to Optimize Reduction Ratio in Jaw Crusher? AGICO

2023年2月28日 In this article, we'll explore the concept of reduction ratio of jaw crusher, its importance in the crushing process, and how to optimize it for maximum efficiency Learn how to optimize the reduction ratio of your jaw crusher for improved efficiency and quality Discover tips for reducing wear and tear and performing regular maintenance to maximize the lifespan of Introduction This article concerns itself with vertical grinding mills used for coal pulverization only (coal pulverizers), although vertical grinding mills can and are used for other purposes The 3D model in the saVRee database represents a vertical grinding bowl millOther grinding mill types include the ball tube mill, hammer mill, ball and race mill, and , roll and ring millVertical Grinding Mill (Coal Pulverizer) Explained saVRee2023年7月4日 The Raymond grinding mill, Raymond mill for short, is a roller mill in which the central spindle drives the multiple grinding rollers installed on the plumblossom rack to swing outwardly under the action of centrifugal force and press the grinding ring on the inner wall of the casing to grind the materialRoller Mill SpringerLinkLaboratory grade jaw crushers for powerful crushing of medium hard materials Laboratory Jaw Crusher The rocking motion jaw plate pushes material against fixed jaw plate that results size reduction of samples that falls into drawer Laboratory Jaw Crusher Manufacturers India Stericox

The cylinder of the mediumspeed coal mill is lined with wear

Generally, the outlet temperature of the mediumspeed coal mill is controlled at 100 to 120 degrees Celsius The material processed by the mediumspeed mill barrel is particles of various sizes and hardnesses These materials move inside the mediumspeed mill, constantly causing friction, scouring and impact on various parts of the mediumspeed 2017年8月1日 Semantic Scholar extracted view of "Modeling of a medium speed coal mill" by Yaokui Gao et al This paper presents a multisegment coal mill model that covers the whole milling process from mill startup to shutdown This multisegment mathematical model is derived through analysis of energy Modeling of a medium speed coal mill Semantic ScholarDownload scientific diagram Schematic of medium speed coal mill [5] from publication: Early Warning of Critical Blockage in Coal Mills Based on Stacked Denoising Autoencoders Coal mills have Schematic of medium speed coal mill [5] ResearchGateRaymond mill is a common type of cement mill used in cement plant and lime calcination plant, and generally apply for the production of mineral powder or coal powder, such as the fine powder processing of raw ore, gypsum, coal and other materials Why choose Raymond mill from AGICO? AGICO Cement is one of leading raymond mill suppliers in China, we can offer any Raymond Mill, Raymond Mill For Sale For Cement and Lime Plant

The Complete Guide to Jaw Plates: 10 Essential Facts Stellar Heavy

5 What Shapes do Jaw Plates Have? Several different types of Jaw Plates are available, each suited for various applications and crushing requirements In the following, we'll use the example of Metso® Nordberg® C Series™ jaw plates to explain how different shapes of jaw plates correspond to the application sites and the materials being crushedZGM medium speed roller mill 1 Introduction 11 Purpose ZGM type medium speed roller mill is widely used in coal powder preparation system of electric power, metallurgy, cement, chemical industry and other industries, as well as coal pulverizing system of cement, chemical industry, mining and other industriesZGM type Mediumspeed Rolling coal millpower plant equipment2023年6月15日 Alumina ceramic plate can significantly reduce the wear of medium speed coal mills As an important coal powder preparation equipment, the medium speed coal mill can cause severe wear and tear to Application of Alumina Ceramic Plate on Medium Speed Coal MillThe MTM Medium Speed Trapezium Mill is the world's leading industrial mill Feed particle size: 035mm Production As high quality Raymond mill, MTM Medium Speed Trapezium Mill is applicable to powder pulverization in metallurgy, They purchased a MTW110 Model firstly Afterwards, due to capacity expansion, they purchased a MTW138 againMTM Series Medium Speed Trapezium Mill

.jpg)

Mediumspeed coal mill wearresistant ceramic liner Composite

As an important pulverized coal preparation equipment, medium speed mill has been facing the test of wear since its birth According to statistics, about 80% of the parts that fail in medium speed grinding belong to the direct or indirect consequences caused by metal wear