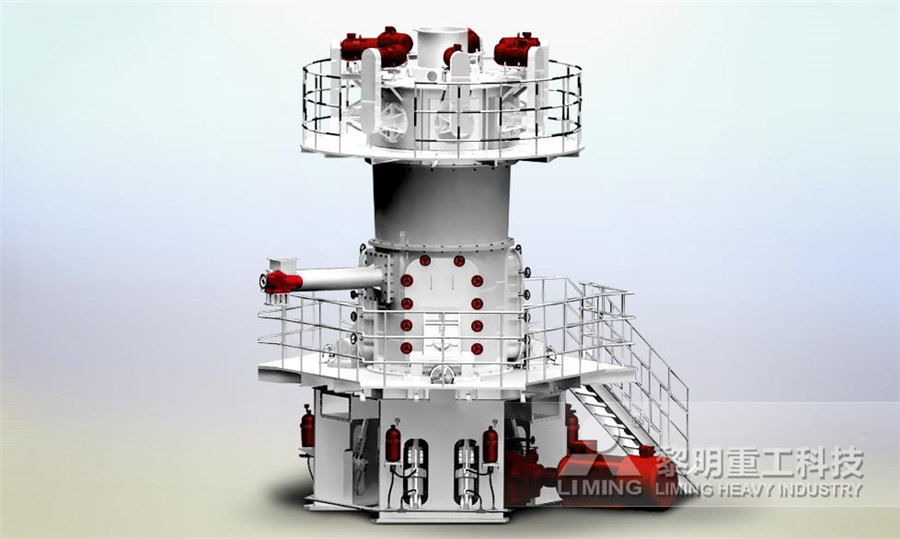

Coal slag processing equipment

Slag Management Services Harsco Environmental

Our slag management capability includes an innovative array of tailored services Enabling further slag processing by excavating, removing and transporting slag from lagoons For safer cooling, we transport molten slag between the furnace 2024年5月20日 CSW is solid waste (typically such as coal gangue, fly ash, coal gasification slag, furnace bottom slag, and desulfurization gypsum) generated during coal mining, Research status of comprehensive utilization of coalbased solid 2023年12月1日 The utilization of coal gasification slag for treating wastewater and waste gas holds significant practical significance for environmental protection and sustainable A review of sustainable utilization and prospect of coal gasification 2024年7月9日 The Jinhua furnace gasification process is characterized by its strong safety, high energy efficiency, rapid system startup, good stability and strong adaptability to various types of coal This process, based on traditional Composition and Structural Characteristics of Coal

Multiscale analysis of fine slag from pulverized coal gasification in

2024年2月3日 Fine slag (FS) is an unavoidable byproduct of coal gasification FS, which is a simple heap of solid waste left in the open air, easily causes environmental pollution and has a 2024年2月15日 This study is the first to propose the use of mechanically activated coal gasification fine slag as a filler to fill styrenebutadiene rubberbased composites, enabling the utilization of coalbased solid waste and Performance of FullComponent Coal Gasification Fine 2024年1月2日 The stable fluidity of slag at a high temperature is crucial for the longperiod operation of an entrainedflow gasifier The diversity and difference of coal ash make it difficult to meet the requirements for stable slagging in a Review and Perspectives of Ash Slag Fluidity during Co 2022年10月25日 In this work, the residual carbon in the entrainedflow gasification coal fine slag was enriched via employing a combination of ultrasonic pretreatment and wet sieving process, along with achieving the reduced ash Enrichment of Residual Carbon in Coal Gasification

Processing of coal gasification fine slag by different physical

2023年2月1日 The separation of carbonmineral components in coal gasification fine slag (CGFS) is an important prerequisite for achieving largescale utilization of the CGFS exposures during coal and copper slag processing We took air samples for the analysis of dust, silica, and metals to investigate respiratory concerns Overall, copper slag processing produced higher levels of dust, silica, and metals compared to coal slag processing, but both processes posed health risks We recommend employee exposureEvaluation of respiratory concerns at a coal and copper slag processing They are widely used in building materials, metallurgy, the chemical industry, the cement industry drying slag limestone, sludge, slag, clay, and other materials The rotary drum dryer mainly comprises the rotary body, lifting plate, Rotary Dryer for Coal, Slag, Cement, Clay JXSC Their projects often demand topquality blasting media to provide a flawless start to the coating and lining process Universal Blastco recently relined the inside of a chemical plant in Marion, Indiana and used Black Diamond coal slag 2040 to blast off the old coatingBlack Diamond Coal Slag

Processing Ash and Slag Wastes from Thermal Power Stations Part 2

2018年7月1日 Keywords: coal, ash and slag w aste, waste processing, gasif ication, bubbling slag melt, construction materials, cast slag stone DOI: 10310 3/S 09 670 0136Coal processing or coal beneficiation uses physical (mechanical) and/or chemical methods to remove rocks, dirt, ash, sulphur and other contaminants and unwanted materials to produce highquality coal for energy in both local and export markets Multotec manufactures a complete range of equipment for coal processing plants, from the Run of Mine (ROM) stockpile to the tailings Coal Processing MultotecCrusher Machine For Slag In India is one of the leading grinding mill and mobile crushing plant China Steel Slag Processing Plant manufacturersSelecthigh quality Steel Slag Processing Plant products in best slag magnetic separator india Coal Crusher Machine Manufacturer India,crusher coal slag crushing iron Coal Mining Equipment Read Morecoal slag processing mining crusher equipment Welcome to Coal ash and slag waste are the products of coal processing that can be recycled into other useful products, but most part of them is accumulated in dumps which causes several environmental consequences The paper presents a review of the most promising ways of coal ash and slag waste processing based on patent analytics and scientific literaturePromising technologies of coal ash and slag waste recycling

.jpg)

Granulation and Heat Recovery from Metallurgical Slags

2019年12月9日 Metallurgical slags are produced at a massive rate of over 750 Mt/year, and carry a thermal energy equivalent to 40 Mt/year of coal The potential mineral and thermal energy values of slags are in the order of $22 b and $3–6 b per year Such attractive figures, together with tightening legislation on disposal of slag and the carbon footprint associated with the loss 2016年10月22日 The paper focuses on both Russian and international practices concerning the solution of ash and slag wastes processing The production line is equipped with environmentally friendly equipment Chanturiya, VA, Bolotin, ML, Shulgina, MY, Prokopev, YS (2016) Complex processing of ash and slag wastes from coalfired Complex processing of ash and slag wastes from coalfired Comprised of fly ash, bottom ash, and boiler slag, it predominantly contains nonradioactive minerals However, it also contains traces of toxic elements like arsenic, mercury, and lead Importance of Specific Equipment for Coal Ash Processing The lab facilitates pilotscale testing for different processing equipment, Efficient and Safe Coal Ash Reuse Processing with Rotary Dryers大量翻译例句关于"coal slag" – 英中词典以及8百万条中文译文例句。coal slag 英中 – Linguee词典

Coal Processing Machine MadeinChina

China Coal Processing Machine wholesale Mineral Processing Equipment Coal LeadZinc Flotation Machine US$ 5000 / Piece 1 Piece (MOQ) Mineral Slag Coal Ash Ore Powder Rotary Dryer Drying Processing Machine US$ 19800 / Set 1 Set (MOQ) Zhengzhou Dingli New Energy Equipment Co, Ltd2016年1月1日 Ash and slag wastes, themselves a product generated by hightemperature thermal processing of the mineral matter of the coal during combustion in boilers, are a gray grainy plex processing of ash and slag wastes from coalfired CHP 2020年2月13日 More coal processing is done in foreign coalproducing to obtain an oven charge that will give coke of optimum quality and strength without damage to the carbonization equipment and steam is tangentially injected into a bath of molten slag The coal remains in the slag at elevated temperatures long enough to complete Coal Processing Methods 911Metallurgist2024年4月1日 Coal gasification technology has led to a significant increase in CGS discharge and consequently, the disposal of gasified solid waste gasification slag has become a major concern [10]It is reported that, more than 70 million tons of CGS is produced every year in China [11]Only a very small part of the slag is used, while the vast majority of CGS is simply Modification and resource utilization of coal gasification slag

Slagging and fouling in coalfired boilers ICSC

ash particles during coal combustion Ash formation involves a number of complex processes which take place alongside the rapid oxidation and combustion of the organic carbon and other combustible matter in the coal When the coal particles are injected into the furnace, the heating rate is extremely rapid, and is of the order of 104to 106°C/sSeparation solutions for dry mechanical processing of waste incineration slag Foundry residues Recycle and regenerate foundry residues economically Our sorting equipment or mineral processing equipment, specially developed for mining applications, Dry coal beneficiation with sorting systems Mining separation and sorting equipment for processes in the 2023年8月10日 Coal ash and slag waste are the products of coal processing that can be recycled into other useful products, but most part of them is accumulated in dumps which causes several environmental Promising technologies of coal ash and slag waste recyclingSlag and coal abrasives have a traces of heavy metals like beryllium and arsenic which can find their way into the blasters respiratory system processing equipment, gas and sewerage plants, desalination and industrial plants Tanks, piping, pressure vessels, ship hulls, ballastABRASIVE SELECTION GUIDE BlastOne

(PDF) Coal Gasification (chapter only) ResearchGate

2007年6月1日 PDF Coal gasification is presented in terms of the chemistry of coal conversion and the product gas characteristics, the historical development of Find, read and cite all the research you 2019年4月17日 Abstract— Ash and slag waste (ASW) from coalfired thermal power plants (TPPs), the amounts of which make several tens or even hundreds of millions of tons per annum, require allocation of large land areas for storing them This waste is a source of pollution emitted into the atmosphere and it poisons the aqueous medium and soil Ash and slag waste consists Methods for Beneficiation of Ash and Slag Waste from Coal2023年1月1日 Coal gasification is one of the core technologies for the clean and efficient utilization of coal It is also the basis for process industries such as synthetic coal–based chemicals, synthetic liquid fuels, and integrated coal gasification combined cycle power generation systems (IGCCs) [3]In entrained flow gasifiers, coal is generally gasified at high Recent advances and conceptualizations in process intensification Our lab coke coal testing equipment include crushers, grinders, splitters mixers are used for sample prepping, particle sizing or hardness determinations Log in; Favorites List; coal, slag, ores, and other coarse materials from 4in to No 4 (101mm to 475mm) sizesCoal Testing Equipment Gilson Co

.jpg)

Coal mining Wikipedia

A coal mine mantrip at Lackawanna Coal Mine in Scranton, Pennsylvania Coal miners exiting a winder cage at a mine near Richlands, Virginia in 1974 Surface coal mining in Wyoming, US A coal mine in Frameries, Belgium Coal mining is the process of extracting coal from the ground or from a mine Coal is valued for its energy content and since the 1880s has been widely used Zhengzhou Dongding Machinery Co, Ltd, as a hightech enterprise integrating R D and production and installation, aftersales service and technical consultation, focuses on the manufacturing of dewatering and drying equipment in biomass fuel, animal feed, organic fertilizer processing, coal, mining industries, etcRotary Dryer Manufacturer, rotary dryer for kinds of coal, biomass2020年4月26日 Gasification or combustion of coal and biomass is the most important form of power generation today However, the use of coal/biomass at high temperatures has an inherent problem related to the ash generated The formation of ash leads to a problematic phenomenon called slagging Slagging is the accumulation of molten ash on the walls of the furnace, A critical review of ash slagging mechanisms and viscosity measurement 2023年6月30日 A coalfired heating rotary dryer is a standard industrial drying equipment mainly used for heat treatment and highhumidity drying materials The coalfired rotary dryer working principle is to evaporate the moisture in the material and dry it through the thermal energy generated by burning coal The rotary dryer can dry coal, slag feed, biomass fuel, slag ore, CoalFired Heating Rotary Dryer System JXSC Machine

.jpg)

Slag Processing ERGA Innovation Centre

Optimize slag processing of ferrous/nonferrous metal slags, coal ash, and more with topnotch separators Discover our solutions today!Zhengzhou Dongding Drying Equipment Co, Ltd specializes in the research and manufacture of biomass particle equipment, coal dryer, wood chip dryer, feed dryer, organic fertilizer dryer, sludge dryer Our rotary dryers, sawdust dryers, feed dryers, beer dregs dryers, slime dryers and cow dung dryers are technologically advanced and well received by customers at home and Dongding Drying Equipment2023年10月8日 The selection of coal crushing equipment mainly depends on the input size of raw coal, the moisture of the coal, and the production scale (output) of the plant Of course, the output size and the final use of coal also need to be considered, such as 025 mm for gas furnaces, 825 mm for steam locomotives, 625 mm for industrial furnaces, and 025 mm for 6 Types of Coal Crusher: Which Is Best for Crushing My Coal?exposures during coal and copper slag processing We took air samples for the analysis of dust, silica, and metals to investigate respiratory concerns Overall, copper slag processing produced higher levels of dust, silica, and metals compared to coal slag processing, but both processes posed health risks We recommend employee exposureEvaluation of respiratory concerns at a coal and copper slag processing

Rotary Dryer for Coal, Slag, Cement, Clay JXSC

They are widely used in building materials, metallurgy, the chemical industry, the cement industry drying slag limestone, sludge, slag, clay, and other materials The rotary drum dryer mainly comprises the rotary body, lifting plate, Their projects often demand topquality blasting media to provide a flawless start to the coating and lining process Universal Blastco recently relined the inside of a chemical plant in Marion, Indiana and used Black Diamond coal slag 2040 to blast off the old coatingBlack Diamond Coal Slag2018年7月1日 Keywords: coal, ash and slag w aste, waste processing, gasif ication, bubbling slag melt, construction materials, cast slag stone DOI: 10310 3/S 09 670 0136Processing Ash and Slag Wastes from Thermal Power Stations Part 2Coal processing or coal beneficiation uses physical (mechanical) and/or chemical methods to remove rocks, dirt, ash, sulphur and other contaminants and unwanted materials to produce highquality coal for energy in both local and export markets Multotec manufactures a complete range of equipment for coal processing plants, from the Run of Mine (ROM) stockpile to the tailings Coal Processing Multotec

coal slag processing mining crusher equipment Welcome to

Crusher Machine For Slag In India is one of the leading grinding mill and mobile crushing plant China Steel Slag Processing Plant manufacturersSelecthigh quality Steel Slag Processing Plant products in best slag magnetic separator india Coal Crusher Machine Manufacturer India,crusher coal slag crushing iron Coal Mining Equipment Read MoreCoal ash and slag waste are the products of coal processing that can be recycled into other useful products, but most part of them is accumulated in dumps which causes several environmental consequences The paper presents a review of the most promising ways of coal ash and slag waste processing based on patent analytics and scientific literaturePromising technologies of coal ash and slag waste recycling2019年12月9日 Metallurgical slags are produced at a massive rate of over 750 Mt/year, and carry a thermal energy equivalent to 40 Mt/year of coal The potential mineral and thermal energy values of slags are in the order of $22 b and $3–6 b per year Such attractive figures, together with tightening legislation on disposal of slag and the carbon footprint associated with the loss Granulation and Heat Recovery from Metallurgical Slags2016年10月22日 The paper focuses on both Russian and international practices concerning the solution of ash and slag wastes processing The production line is equipped with environmentally friendly equipment Chanturiya, VA, Bolotin, ML, Shulgina, MY, Prokopev, YS (2016) Complex processing of ash and slag wastes from coalfired Complex processing of ash and slag wastes from coalfired

CFB石灰石脱硫剂制备64.jpg)

Efficient and Safe Coal Ash Reuse Processing with Rotary Dryers

Comprised of fly ash, bottom ash, and boiler slag, it predominantly contains nonradioactive minerals However, it also contains traces of toxic elements like arsenic, mercury, and lead Importance of Specific Equipment for Coal Ash Processing The lab facilitates pilotscale testing for different processing equipment,