Nanchang pyrolytic carbon black threering micro powder mill

.jpg)

Tire pyrolysis carbon black deep processing grinding

2023年4月7日 For further processing of the coarse carbon black from tire pyrolysis, we can use the HGM series ultrafine ring roller mill and CLUM series vertical roller mill independently developed and produced by our SBM micro It features high efficiency and low energy consumption, with the capacity more than twice that of jet mills but the energy consumption lower by 30% Automatic feedback with fast and stable HGM Series Three Ring Micro Powder MillHGM series ultra fine powder grinding mill is a new type mining equipment for make micro powders with three ring rollers It is used to grind limestone, calcite, calcium carbonate, dolomite, gypsum, carbon black, gypsum, kaolin, marble HGM Micropowder Grinding Mill Baichy2023年2月5日 Hightemperature pyrolysis of waste tires is a promising method to produce highquality carbon black In this study, carbon black formation characteristics were investigated Production mechanism of highquality carbon black from high

carbon black processing machine, tyre pyrolysis carbon black

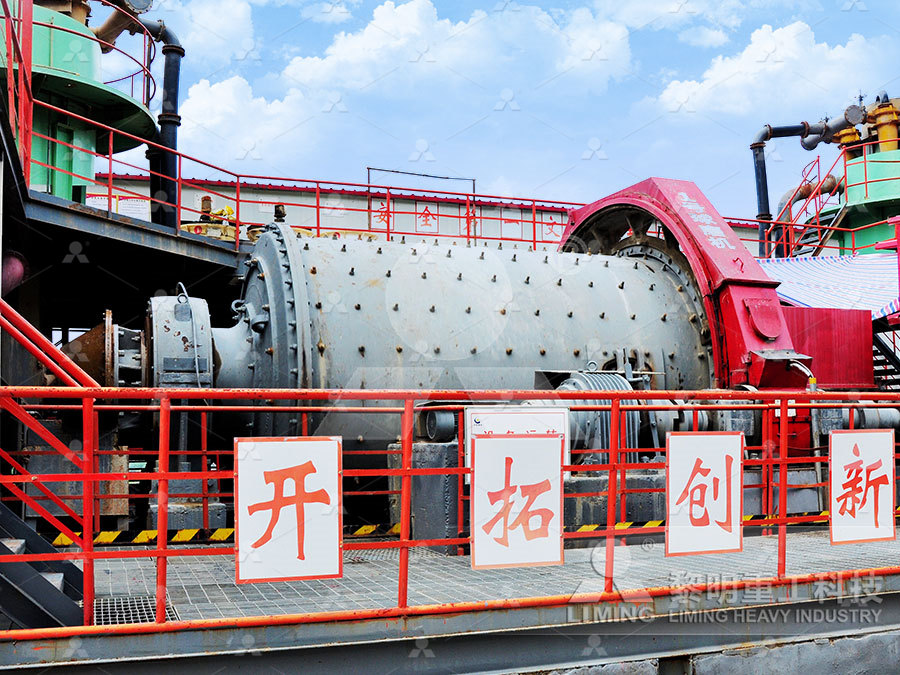

HGM series carbon black grinding mill adopts GCr15SiMn for Ring and Roller, which is better than normal 60Si2Mn So far, it is good at waste tyre pyrolysis carbon black micron powder making Carbon black grinding mill is the equipment specializing in producing fine and superfine powder of noninflammable, nonexplosive and brittle materials with Mohs’s hardness under six, such as Carbon black grinding mill ClirikThe JOYAL Threering Micro Powder Mill (ultrafine mill) is for superfine grinding materials with hardness less than 6 in Moh’s scale and humidity less than 6 percent such as kaolin, JoyalThreering Micro Powder Mill,Threering Micro Powder Mill Pyrolysis carbon black MW micro powder mill project, MW Micro Powder Mill Motor Type AC Motor Capacity(t/h) 12TPH Brand Name LIMING Color Black,White Output size 80 mesh Pyrolysis carbon black MW micro powder mill project

ThreeRing Micro Powder Mill China Mill and ThreeRing Micro

ThreeRing Micro Powder Mill, Find Details and Price about Mill ThreeRing Micro Powder Mill from ThreeRing Micro Powder Mill Shanghai Joyal Mining Machinery Co, Ltd Home 2019年8月30日 The pyrolysis carbon black (CBp) from waste tires accounts for more than 35% of pyrolysis products Its poor reinforcing ability and low additional value limit heavily the wide application of Pyrolytic preparation and modification of carbon sensitive products such as recovered carbon black › Low energy costs thanks to efficient use of pressure energy Solids Pulse Pneu: Plugs are created and as such gently pushed through the conveyor lines PNEUMATIC CONVEYING of powder and pellets With carbon black powder, flight conveying is possible 12 IRECOVERED CARBON BLACK Hosokawa AlpineCarbon black is a light, loose and fine black powder that contains carbon substances It can be used as a black dye to make ink, paint, rubber material, etc Carbon black ultrafine mill is also called (threering fourring) mediumspeed Coarse Powder Grinding Mill SBM Ultrafine Powder

Influence of pyrolytic carbon black and pyrolytic oil made from

2015年11月2日 Pyrolytic carbon black (CBp) and pyrolytic oil (Op) made from used tires were used in natural rubber (NR)/ styrenebutadiene rubber (SBR) blends2024年1月11日 Pyrolysis is a promising way to reuse of waste tires However, the carbon black generated in the process is often contaminated with various pyrolysis products This study aims to recycle lowquality recycled carbon black (rCB) from waste tire pyrolysis, addressing the challenges posed by organic residues (up to 5 wt% bituminous substances, 1122 mg/kg PAH)Recycling of LowQuality Carbon Black Produced by Tire Pyrolysis This article presents a comprehensive review of the manufacturing processes of micro/nanoarchitected pyrolytic carbon 6, and 7membered carbon rings However, in the majority of cases, the activated carbon is used as powder material and a binder is needed to prepare the electrode The binder often shields the actual surface A Review on 3D Architected Pyrolytic Carbon Produced by Additive Micro 2024年4月2日 1 Feeding: Bauxite ore is fed into the HGM micro powder grinding mill through the feeding device, typically via a conveyor belt or a bucket elevatorThe material is evenly and continuously fed into the grinding chamber of the mill 2 Grinding: Inside the grinding chamber, the bauxite ore is subjected to a series of grinding processes The grinding rollers and rings in How does HGM micro powder grinding mill process bauxite?

.jpg)

Thermal and kinetic behaviors of pyrolytic carbon black and

2018年11月30日 In this study, a combustion study of tire pyrolytic carbon black (CBp), gas coal (GC), and their blends was carried out by thermogravimetric analysis with four heating rates under air atmosphere And the structure characteristics of CBp and GC were studied using particle size distribution, scanning electron microscope, Xray diffraction, Raman spectra followed by peak 2023年3月6日 Thermal pyrolysis of waste tires is an industrially beneficial method for material and energy recovery Pyrolytic carbon black (CBp) is considered to be the secondary main product of this process In the present study, an ecofriendly and economically feasible autoclave reactorbased thermal pyrolysis method was employed for the pyrolysis of waste tire tread Recycling of waste tire by pyrolysis to recover carbon black: an Threering Micro Powder Mill >> EMail:joyal@crusherinc >> Http://crusherinc Features 1 Highefficiency and low consumption With the same endproducts fineness and motor power, its output is over 1 time of that of Jet Mill, Mix Mill, and Ball Mill 2 Easydamaged parts with longer working lifeThreering Micro Powder MillHGM series ultrafine powder mill (threering / fourring mediumspeed micropowder mill) Chalk micro powder mill can grind nonmetallic ores into fine powder up to 6000 meshes It is a highly efficient industrial micro powder Ultra Fine Powder Mill

.jpg)

Carbon Black Ultrafine Powder Grinding Mill Clirik

Carbon black ultrafine powder grinding mill can be used for grinding carbon black powder of 1502500 mesh Chinese website; Carbon black ultrafine powder grinding mill is also called micro powder grinding roller mill machine Ring 2014年1月1日 The rate of recovery is 45 wt % for fuel, 30 wt % for carbon black and 10 wt % for steel wires for each endoflife tyresIn this paper, the potential use of pyrolised carbon black generated from Physicochemical Properties of Pyrolitic Carbon 2015年6月3日 1 Threering micro powder mill Price threering micro powder mill description Capacity:0530t/h Feeding size:≤20mm Output Size:574um/mesh HGM Series threering micro powder mill is the equipment specializing in producing fine and superfine powder of noninflammable, nonexplosive and brittle materials with Mohs's hardness under six, such as Threering micro powder mill Price PDF Free Download2023年6月23日 Additive micro/nano‐manufacturing of polymeric precursors combining with a subsequent pyrolysis step enables the design‐controlled fabrication of micro/nano‐architected 3D pyrolytic carbon A Review on 3D Architected Pyrolytic Carbon Produced by Additive Micro

HGM Threering Grinding Mill vanguardtec

HGM series threering (fourring) micro grinder is a new type of ultrafine powder processing equipment, which is based on many years of mill production experience, absorbing Swedish advanced mechanical technology manufacturing technology, after more than 20 tests and improvements It is the latest product leading the world trend of grinderThe Mikro® EACM is specially designed for the grit reduction of carbon black It is a hybrid product that possesses many of the same design features of the Mikro® ACM Air Classifying Mill, which is an industry workhorse for a wide range of applications In addition, the Mikro® EACM features various improvements that overcome theCarbon Black Grit Reduction Mill Hosokawa Micron Powder Ring roller mill is a type of grinding equipment used in various industries such as mining, (micro powder roller mill,fine roller mill,ring roller mill,roller grinding machine,automatic roller mill) Air Classifying production line of carbon microspheres in a chemical plant in Hubei 2024年8月14日Ring Roller Mill Manufacturer EPIC Powder Machinery2021年9月30日 HGM micro powder mill The micro powder mill adopts a newly designed grinding roller grinding ring grinding curve, which improves the grinding efficiency The production capacity is 40% higher than that of jet mills and mixers, and the energy consumption is only 30% of that of jet mills HGM micro powder mill is equipped with a multihead cage Chalk Micro Powder Mill SBM Ultrafine Powder Technology

Grinding mill for carbon black powder production

Carbon black ultrafine grinding equipment generally refers to the threering fourring superfine grinding machine The threering fourring ultrafine grinding machine adopts the grading continuous grinding method to carry out multiple cycles of grinding on the material at the same time, realizing ultrafine grinding2024年11月5日 This study addresses the global issue of recycling used vehicle tires, typically burned out or trimmed to be reused in playground floors or road banks In this study, we explore a novel environmentally responsive approach to decomposing and recovering the carbon black particles contained in tires (25–30 wt%) by vacuum pyrolysis Given that carbon black is well Recycled Carbon Black/HighDensity Polyethylene Composite It is mainly suitable for micro powder processing of noninflammable and explosive brittle materials with medium and low hardness and Mohs hardness ≤6, such as calcite, limestone, dolomite, kaolin, bentonite, talc, mica, magnesite, Micro Powder Grinding Mill2023年7月27日 Pyrolytic carbon black (CBp) is the main byproduct of waste tire pyrolysis CBp has high ash content and poor surface activity which leads to the composites reinforced with CBp has lower Effect of surfactants on the properties of rubber

Micro Powder Roller Mill for Getting Ultrafine Powder DASWELL

Micro powder roller mill is also known as ultrafine powder grinding mill It is a new type of powder processing equipment, mainly used for crushing and processing nonmetallic minerals such as calcium carbonate, barite, talc, gypsum, calcite, limestone, calcium oxide, bentonite, dolomite and other nonmetallic minerals with Mohs hardness less than 5 and water content less than 5%HGM series Threering Micro Powder Grinding machine Performance and features: 1 high efficiency Under the same final size and power, the product capacity of ultrafine mill is twice than jet mill and agitation mill 2 Longer lifetime of spare parts The roller and ring are made of special material, which improve the grinding efficiency a lotHGM Series Threering Micro Powder Grinding Machine Clirik2022年3月9日 Increasing awareness regarding fossil fuel dependence, waste valorization, and greenhouse gas emissions have prompted the emergence of new solutions for numerous markets over the last decades The tire industry is no exception to this, with a global production of more than 15 billion tires per year raising environmental concerns about their endoflife recycling or Production and Upgrading of Recovered Carbon Black from theCarbon black Grinding Mill Supplier Shanghai Clirik Machinery Supply Carbon black Ultrafine Grinding Mill,Carbon black Vertical Roller Mill,Carbon black Ball Mill,Carbon black Raymond Mill,Carbon black HGM Series Threering Micr HGM90 Micro Powder Grindin Micro Powder Grinding Mill and become powder after production of three ringsCarbon black Grinding Mill Clirik

Characterization of Bitumen Modified with Pyrolytic Carbon Black

2019年3月18日 Pyrolytic carbon black (CBp) from scrap tire pyrolysis is a potential modifier for the bitumen industry Binders containing different contents of CBp were prepared and experimentally investigated to examine the effects of CBp on the electrical and thermal conductivity, conventional physical properties, rheological properties, hightemperature 2024年9月12日 For this study, unfilled virgin thermoformed HDPE was used under the same processing conditions with a range of virgin thermoformed HDPE composites filled with various nucleating agents, namely commercial carbon black, pyrolytic carbon black and two fillers of this pyrolytic carbon black processed in air at 385°C but with different grinding 2832 The aim of HDPE crystalline lamellae in composites involving pyrolytic carbon Brief Introduction HGM Ultra fine grinding mill (also called micro powder mill, superfine powder grinding mill, ultra fine powder grinder) is designed by SBM RD department on the basis of multiple innovations and testing It has been proved by thousands of customers that our ultra fine powder grinder has outstanding features, stable quality, easy operation, and maintenanceUltra Fine Grinding Mill SBM Ultrafine Powder Technology2019年8月30日 The pyrolysis carbon black (CBp) from waste tires accounts for more than 35% of pyrolysis products Its poor reinforcing ability and low additional value limit heavily the wide application of Pyrolytic preparation and modification of carbon

RECOVERED CARBON BLACK Hosokawa Alpine

sensitive products such as recovered carbon black › Low energy costs thanks to efficient use of pressure energy Solids Pulse Pneu: Plugs are created and as such gently pushed through the conveyor lines PNEUMATIC CONVEYING of powder and pellets With carbon black powder, flight conveying is possible 12 ICarbon black is a light, loose and fine black powder that contains carbon substances It can be used as a black dye to make ink, paint, rubber material, etc Carbon black ultrafine mill is also called (threering fourring) mediumspeed Coarse Powder Grinding Mill SBM Ultrafine Powder 2015年11月2日 Pyrolytic carbon black (CBp) and pyrolytic oil (Op) made from used tires were used in natural rubber (NR)/ styrenebutadiene rubber (SBR) blendsInfluence of pyrolytic carbon black and pyrolytic oil made from 2024年1月11日 Pyrolysis is a promising way to reuse of waste tires However, the carbon black generated in the process is often contaminated with various pyrolysis products This study aims to recycle lowquality recycled carbon black (rCB) from waste tire pyrolysis, addressing the challenges posed by organic residues (up to 5 wt% bituminous substances, 1122 mg/kg PAH)Recycling of LowQuality Carbon Black Produced by Tire Pyrolysis

.jpg)

A Review on 3D Architected Pyrolytic Carbon Produced by Additive Micro

This article presents a comprehensive review of the manufacturing processes of micro/nanoarchitected pyrolytic carbon 6, and 7membered carbon rings However, in the majority of cases, the activated carbon is used as powder material and a binder is needed to prepare the electrode The binder often shields the actual surface 2024年4月2日 1 Feeding: Bauxite ore is fed into the HGM micro powder grinding mill through the feeding device, typically via a conveyor belt or a bucket elevatorThe material is evenly and continuously fed into the grinding chamber of the mill 2 Grinding: Inside the grinding chamber, the bauxite ore is subjected to a series of grinding processes The grinding rollers and rings in How does HGM micro powder grinding mill process bauxite?2018年11月30日 In this study, a combustion study of tire pyrolytic carbon black (CBp), gas coal (GC), and their blends was carried out by thermogravimetric analysis with four heating rates under air atmosphere And the structure characteristics of CBp and GC were studied using particle size distribution, scanning electron microscope, Xray diffraction, Raman spectra followed by peak Thermal and kinetic behaviors of pyrolytic carbon black and 2023年3月6日 Thermal pyrolysis of waste tires is an industrially beneficial method for material and energy recovery Pyrolytic carbon black (CBp) is considered to be the secondary main product of this process In the present study, an ecofriendly and economically feasible autoclave reactorbased thermal pyrolysis method was employed for the pyrolysis of waste tire tread Recycling of waste tire by pyrolysis to recover carbon black: an

Threering Micro Powder Mill

Threering Micro Powder Mill >> EMail:joyal@crusherinc >> Http://crusherinc Features 1 Highefficiency and low consumption With the same endproducts fineness and motor power, its output is over 1 time of that of Jet Mill, Mix Mill, and Ball Mill 2 Easydamaged parts with longer working life