Ball mill hollow shaft

Ball Mill Trunnion – Cast Steel ZG230450 AGICO Ball

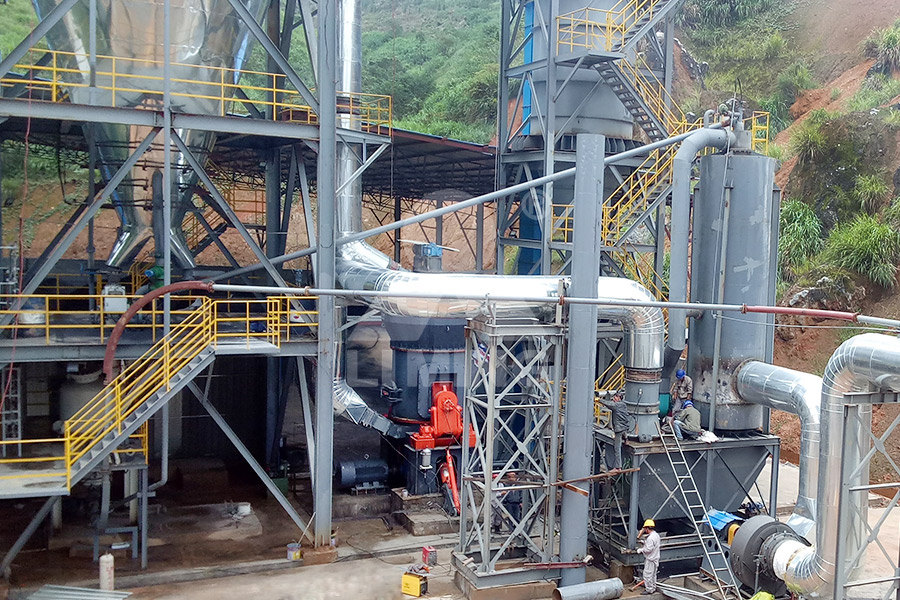

What is a ball mill trunnion? The ball mill trunnion, also called the ball mill hollow shaft, is an important part that carries the rotation of the ball mill cylinder It mainly plays the role of supporting and connecting the cylinder and is the inlet and Ball Mill Hollow Shaft with High Casting Technology, Find Details and Price about Ball Mill Hollow Shaft Hollow Shaft from Ball Mill Hollow Shaft with High Casting Technology Shanghai Ball Mill Hollow Shaft with High Casting TechnologyBall mill hollow shaft Weight: 530T Applicable device: ball mil, cement machinery Application: Cement, metallurgy, building material and others Customizable: Yes Introduction Hollow Ball Mill Hollow Shaft Supplier Mnaufacturer Special MetalGreat Wall Steel Casting customizes large spare parts of ball mill according to customers' drawings: ball mill hollow shaft (ball mill trunnion), ball mill trunnion bearing, ball mill end cover, Ball mill hollow shaft

.jpg)

Overflow Ball Mill, Wet Type Overflow Ball Mill Xinhai

Hollow shaft with the antispiral blade returns the steel ball and the coarse ore block Product Structure Wet type overflow ball mill works for fine fineness grindingBall mill is mainly made up of feeding part, discharging part, rotary part and driving part, including reducer, small drive gear, electrical machine and electronic control The hollow shaft adopts Ball mills, Ball millHenan Hongke Heavy Machinery Co,LtdBall mill hollow shaft Weight: 530T Applicable device: ball mil, cement machinery Application: Cement, metallurgy, building material and others Customizable: Yes Introduction Hollow shaft is an important part of ball mill Its function is bearing the rotary of ball mill shellBall Mill Hollow Shaft Supplier Mnaufacturer Special Metal2023年4月30日 According to the discharge methods of the ball mill, it can be divided into overflow ball mill, and discharge is through the hollow shaft Grate ball mill (Fig 3), the discharge end of the mill is set with a gratePeripheral discharge ball mill, and the products are discharged through the discharge port around the cylinderBall Mill SpringerLink

Ball Mill Maintenance Procedure Guide

Ball Mill Maintenance Procedure Guide Regular ball mill maintenance is an important factor to ensure the normal and stable operation of the ball mill must be repaired or replaced when there is a crack in the hollow shaft When the ball mill machine is Cement Ball Mill Structure When Ball Mill is working, raw material enters the mill cylinder through the hollow shaft of the feed The inside of the cylinder is filled with grinding media of various diameters (steel balls, steel segments, etc); when the cylinder rotates around the horizontal axis at a certain speed, Under the action of centrifugal force and friction force, the medium and the Ball Mill for Cement Grinding Process2019年11月26日 Difference Between SAG Mill and Ball Mill, from the working principle, application, The end cover and the hollow shaft can be made into an integral or split type according to the actual situation of the project No matter the integral or split type structure, What’s the Difference Between SAG Mill and Ball Mill2023年4月27日 Overflow ball mill equipment – medium and long barrel ball mill When the cylinder length is L=3D, it is a medium and long ball mill Generally, The ore slurry is higher than the lower edge of the hollow shaft at the ore discharging end and overflows by itselfHow an Overflow Ball Mill Works? JXSC Mineral

.jpg)

Ball mills, Ball millHenan Hongke Heavy Machinery Co,Ltd

Ball mills are suitable for grinding various ores and other materials, and are widely used in industries such as mineral processing, Materials go into the first cabin of the grinding machine spirally and evenly through the feeding hollow shaft from the feeding device, The hollow shafts used in the ball mill accessories we process are cast from highstrength steel Before casting, our professional engineers optimize the process structure of the ball mill end covers and hollow shafts based on the operational characteristics of the ball millsBall Mill End Cover and Ball Mill Head for Sale AGICO CEMENTBall Mill Ball Mills are mainly used in metallurgy, chemical industry, electric power, cement and other industrial and mining business to make all kinds of ores and other grindable materials by virtue of such characteristics as strong adaptability to raw materials, excellence in continuous production, high crushing ratio and easy to adjust the fineness of the finished productBall MillBall mill is composed of horizontal cylinder, inlet and outlet hollow shaft, grinding head and so on Ball mill’s cylinder is a long drum which is built of steel plate Inside the cylinder there is a grinding body The grinding body is a steel ball that is fixed with cylinder on a steel plateBall Mill Ball Mill Machine AGICO

Ball mill Wikipedia

A ball mill is a type of grinder filled with grinding balls, A ball mill consists of a hollow cylindrical shell rotating about its axis The axis of the shell may be either horizontal or at a small angle to the horizontal but small ones normally When the small ball mill is running, the materials enter the first chamber of the small ball mill evenly through the hollow shaft at the feeding end of the small ball mill There are ball mill ladder liners or corrugated liners in the chamber, which Small Ball Mill Mini Ball Mill for Small Scale Mineral According to the shape of the cylinder, the ball grinder can be divided into four types: short tube mill, long tube mill, tube mill, and cone mill Working Principle Ball Grinding Mill Principle The ball grinder is composed of a horizontal Ball Mill Henan Forui Machinery Technology Co, Ltd2023年7月16日 The grinding is carried out through impact and attrition of the balls as the cylinder rotates, and the material is fed through the hollow shaft Ball mills have advantages such as low installation cost, low production cost, and suitability for ball millspptx SlideShare

.jpg)

Ball millBAILING® Machinery

Henan Bailing Machinery CO,ltd is a professional manufacturer of ball mill More information about ball mill are here! sales@bljq 0086371 Whatsapp:+86 home; products crusher ; Mill; Dryer; Beneficiation ; Kiln; Materials enter the first cabin of ball mills via the feeding device across the hollow shaft uniformlyBall mill is widely used in mineral processing plants for wet or dry grinding materials and equipped with spiral classifier, high efficiency Materials are fed into the barrel of the ball mill through the hollow shaft A motor drives the barrel of the ball mill to rotateBall Mill Mining Grinding Mill JXSC MachineryBall mill design consists of feeding part, discharging part, rotary part, transmission part (reducer, small gear, motors, electrical control) and other major parts Hollow shaft is steel castings, and the liner is detachable Rotary gear is processed by casting hobbling The cylinder is lined wearresistant liner plate with good resistance to wearBall MillLattice ball mill is composed of feeding part, discharging part, rotating part, transmission part (reducer, small transmission gear, motor, electric control) and other main parts The hollow shaft is made of cast steel, and the inner lining is removable The large rotary gear is processed by casting gear hobbingLattice Ball MillHenan Hongke Heavy Machinery Co, Ltd

.jpg)

How to choose between ball mill and vertical roller mill?

2022年6月24日 The ball mill is a horizontal cylindrical rotating device, and the material is fed into the first silo of the ball mill by the feeding device through the feeding hollow shaft There is a stepped liner or corrugated liner in this warehouse, which is The ball mill trunnion, also known as the hollow shaft is an important part of the ball mill that carries the rotation of the ball mill barrel It mainly plays the role of supporting and connecting the cylinder in the whole ball mill, and is the entry and exit channel of the material In the working process of ball mill, the shaft diameter is Ball Mill Trunnion TenfayeThe ball mill is usually composed of cylinder, liner, feeder, hollow shaft, bearing, transmission device and lubrication system The hollow Journal of the ball mill is supported on the self aligning main sliding bearing The main bearing is Ball mill2017年2月13日 The apparent difference in capacities between grinding mills (listed as being the same size) is due to the fact that there is no uniform method of designating the size of a mill, for example: a 5′ x 5′ Ball Mill has a working Ball Mills 911Metallurgist

Ball Mill Manufacturer China Henan Zhengzhou

Ball mill is mainly used for grinding in mining (metallic minerals and nonmetallic minerals), cement, refractories, chemical, power plant, aluminum, building material, glass, ceramic, steel slag and fly ash, ectIt follows more crushing 2020年3月20日 This article introduces the differences between ball mills, rod mills and SAG mills from grinding media, crushing ratio, structures and so on Besides, the diameter of the hollow shaft at both ends of the barrel of the SAG mill is large and the length is short The diameter is large for its large feeding sizeWhat’s the Difference Between Ball Mill, Rod Mill and SAG Mill?2021年1月1日 ball mill through reducer, transmission shaft and hollow shaft by motor Through the continuous turnover movement of the cylinder , the grinding medium insi de the cylinder is driven to crush(PDF) Design of Threechamber Ball Mill ResearchGateMain function of ball mill trunnion is to support and connect cylinder, and it is also the access way for the material Weight: 530 t Material: ZG230450 Customized: Yes Ball mill trunnion (ball mill head) is an Hollow shaft; Industrial shaft; Shaft for heavyduty applicationsSteel shaft Ball mill trunnion Xinxiang Great Wall Machinery

Balls for ballmills : Alpha Grinding Media

2024年4月26日 Principle of ball mills The Ball Mill operates on the principle that it is a cylindrical device that rotates horizontally Around the exterior of the cylinder, a drive gear is in place to facilitate the rotation during operation Materials are fed spirally and uniformly into the mill’s first chamber via the hollow shaft at the feeding end大量翻译例句关于"hollow shaft" when the ball mill [] simplified turning, grinding body effect by the inertia and centrifugal force, the effect of friction make it for cylinder liner board near being carried away by cylinder, when was taken to a certain height, hollow shaft 英中 – Linguee词典Ball Mill Hollow Shaft เป็นส่วนประกอบหลักของเครื่องจักรซีเมนต์เป็นงาน Ball Mill Hollow Shaft ผู้ผลิตจากประเทศ 2013年4月1日 Ball mill hollow shaft diameter and ball mill cylinder clearance diameter is about 03~055 With the normal operating voltage, because the hollow shaft is la rger in size, so the (PDF) The Ball Mill Driving Device Fault and the Main Bearing

Ball Mill Hollow Shaft Supplier Mnaufacturer Special Metal

Ball mill hollow shaft Weight: 530T Applicable device: ball mil, cement machinery Application: Cement, metallurgy, building material and others Customizable: Yes Introduction Hollow shaft is an important part of ball mill Its function is bearing the rotary of ball mill shell2023年4月30日 According to the discharge methods of the ball mill, it can be divided into overflow ball mill, and discharge is through the hollow shaft Grate ball mill (Fig 3), the discharge end of the mill is set with a gratePeripheral discharge ball mill, and the products are discharged through the discharge port around the cylinderBall Mill SpringerLinkBall Mill Maintenance Procedure Guide Regular ball mill maintenance is an important factor to ensure the normal and stable operation of the ball mill must be repaired or replaced when there is a crack in the hollow shaft When the ball mill machine is Ball Mill Maintenance Procedure GuideCement Ball Mill Structure When Ball Mill is working, raw material enters the mill cylinder through the hollow shaft of the feed The inside of the cylinder is filled with grinding media of various diameters (steel balls, steel segments, etc); when the cylinder rotates around the horizontal axis at a certain speed, Under the action of centrifugal force and friction force, the medium and the Ball Mill for Cement Grinding Process

.jpg)

What’s the Difference Between SAG Mill and Ball Mill

2019年11月26日 Difference Between SAG Mill and Ball Mill, from the working principle, application, The end cover and the hollow shaft can be made into an integral or split type according to the actual situation of the project No matter the integral or split type structure, 2023年4月27日 Overflow ball mill equipment – medium and long barrel ball mill When the cylinder length is L=3D, it is a medium and long ball mill Generally, The ore slurry is higher than the lower edge of the hollow shaft at the ore discharging end and overflows by itselfHow an Overflow Ball Mill Works? JXSC MineralBall mills are suitable for grinding various ores and other materials, and are widely used in industries such as mineral processing, Materials go into the first cabin of the grinding machine spirally and evenly through the feeding hollow shaft from the feeding device, Ball mills, Ball millHenan Hongke Heavy Machinery Co,LtdThe hollow shafts used in the ball mill accessories we process are cast from highstrength steel Before casting, our professional engineers optimize the process structure of the ball mill end covers and hollow shafts based on the operational characteristics of the ball millsBall Mill End Cover and Ball Mill Head for Sale AGICO CEMENT

Ball Mill

Ball Mill Ball Mills are mainly used in metallurgy, chemical industry, electric power, cement and other industrial and mining business to make all kinds of ores and other grindable materials by virtue of such characteristics as strong adaptability to raw materials, excellence in continuous production, high crushing ratio and easy to adjust the fineness of the finished productBall mill is composed of horizontal cylinder, inlet and outlet hollow shaft, grinding head and so on Ball mill’s cylinder is a long drum which is built of steel plate Inside the cylinder there is a grinding body The grinding body is a steel ball that is fixed with cylinder on a steel plateBall Mill Ball Mill Machine AGICO