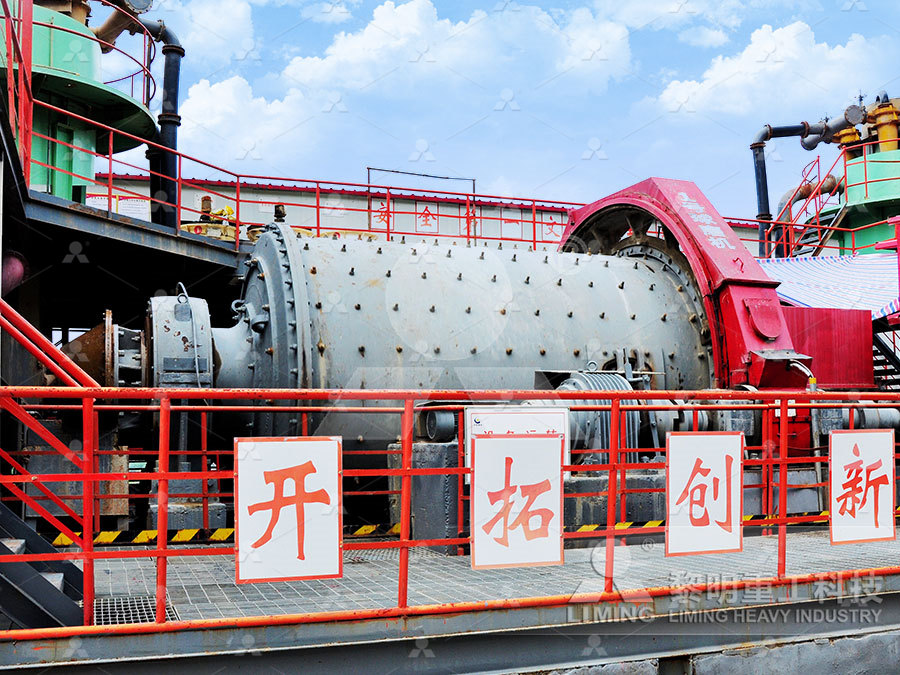

Ball mill transmission

Ball Mill Drives Crushing Grinding Drives David

Designed to deliver exceptional levels of performance and value, David Brown Santasalo ball mill drives are optimised for primary and secondary grinding applicationsThe MAAG® GEAR SYMETRO™ TwoStage Gear Unit operates at close to 99% productivity while showcasing exceptional reliability and costefficiency for your ball mill Rotating parts MAAG® GEAR Symetro™ Gear MAAG GearFlexible drive solutions for use in ball mills A ball mill is a horizontal cylinder filled with steel balls or the like This cylinder rotates around its axis and transmits the rotating effect to the balls The material fed through the mill is crushed by the Industrial gear unit drive solution for ball mills SEW 2024年1月1日 The ball mill in a concentrator is mainly composed of feeding part, discharging part, rotating part, and transmission part (speed reducer, small drive gear, motor, and electric Ball Mill SpringerLink

.jpg)

Design and simulation of gear box for stone crushing ball mill

2022年1月1日 The gear box is a setup intended for making the power transmission from the electric motor to the ball mill During this stage the gear box plays a crucial role in terms of 2024年5月27日 Ball mills’ efficiency and performance can be optimised through proper design, maintenance, and advanced technologies like MechProTech’s TITAN Ball Mill and TITAN Automatic Ball Charger Investing in cuttingedge Ball Mills in the Mineral Processing Industry2013年11月1日 Many factors affect the reliability of ball mill gear transmission, such as the normal module, the Helix angle, and so on The computations for gear transmission reliability are tedious and the formula is not precise; as such, to reduce the values for calculation accuracy, the Kriging model is considered the real calculation functionGlobal optimization of reliability design for large ball mill gear Transmission device: The ball mill is a heavyduty, lowspeed and constantspeed machine Generally, the transmission device is divided into two forms: edge drive and center drive, including motor, reducer, drive shaft, edge drive gears and V Ball Mill SBM Ultrafine Powder Technology

Ball Mill Maintenance Process and Methods Miningpedia

2023年7月18日 When maintaining the ball mill, the following tools and equipment may be helpful: 1 Wrench: used to disassemble and install fastening bolts, nuts, and other components 2 Lubricating oil gun: used to add lubricating oil to bearings, gears, transmission devices, and other parts 3 Lubricating oil: selecting appropriate lubricating oil is crucial for ball mill Ball Mill Drives We can provide all elements of a mill drive system as a fully optimised solution to suit your process exactly, or individual mill drive gearboxes, Pinions are designed to give the highest torque transmission capability and are available as integral or bored designs;Ball Mill Drives Crushing Grinding Drives David Brown 2012年6月1日 PDF The paper presents an overview of the current methodology and practice in modeling and control of the grinding process in industrial ball mills Find, read and cite all the research you Grinding in Ball Mills: Modeling and Process Control2019年10月19日 Ball mills are extensively used in the size reduction process of different ores and minerals The fill level inside a ball mill is a crucial parameter which needs to be monitored regularly for optimal operation of the ball mill In this paper, a vibration monitoringbased method is proposed and tested for estimating the fill level inside a laboratoryscale ball mill A vibration Monitoring the fill level of a ball mill using vibration sensing and

.jpg)

Modeling Impulsive Ball Mill Forces Effects on the Dynamic

2022年3月23日 Gearboxes are frequently used in the mining industry, especially for power transmission between the electric drive and the ball mill; besides the extreme complexity of a ball mill gear transmission system, the fault diagnosis by vibration analysis can be easily distorted by the presence of impulsive noises due to the ball pulses on the mill shell Although several It meshes with the pinion and drives the entire ball mill cylinder to rotate for a long time through the transmission shaft, which withstands large torque and axial force Therefore, we have higher quality requirements for the girth gear castings AGICO is an experienced ball mill and ball mill spare part manufacturer5 Mustknow Ball Mill Parts And Functions2022年10月5日 Ball Mill menjadi salah satu mesin yang sangat penting dalam proses produksi di suatu industri seperti dalam pembuatan cat, keramik, semen, kembang api, batu bara, pigmen feldspar dan serbuk material 3d printing, dll Transmission Ball Mill Adalah? Prinsip Kerja, Bagian, Komponen Dan FungsinyaBall mill girth gear Rotary kiln thrust roller Ball mill trunnion Rotary kiln pinion Ball mill head Rotary kiln roller shaft Ball mill bearing bush Rotary kiln bearing housing Ball mill bearing housing ManufacturerFactory Rotary kiln spring plate ManufacturerFactory Ball mill transmission connection ManufacturerFactoryBall Mill Rotary Kiln Vertical Roller Mill Manufacturer Tongli

Global optimization of reliability design for large ball mill gear

2013年11月1日 @article{Zhang2013GlobalOO, title={Global optimization of reliability design for large ball mill gear transmission based on the Kriging model and genetic algorithm}, author={Guanyu Zhang and Guoqiang Wang and Xuefei Li and Yunpeng Ren}, journal={Mechanism and Machine Theory}, year={2013}, volume={69}, pages= {321336 Mill Shell: The foundation of the Center drive ball mill, the mill shell, is a cylindrical structure made of premiumgrade steelTongli heavy machinery is equipped with a large annealing furnace of 65x65x20m and a 65x65x20m large sandblasting room, which can conduct overall heat treatment and sandblasting on the ball mill to ensure the service life and appearance of the Center drive ball millBall millPRODUCTTongli MachinerySAG Ball Mills Gearboxes Conveyors Fasteners Expert Troubleshooting for the Mining Sector and ultimately save you money Transform your mining operations with Transmission Dynamics – where predictive maintenance meets savings for a prosperous future in mining Get in Touch ProductsMining Condition Monitoring Sag Mill Optimisation Transmission 2019年5月21日 Processing in planetary ball mills is well suited to a large number of applications because they are easy to operate and versatile, grinding faster than other mills Research related to planetary mills are mainly about the process evaluation, and there are few studies on the mechanical design of such equipment This paper describes the decision process in the Planetary Mill with Friction Wheels Transmission Aided by an

(PDF) Design of Threechamber Ball Mill ResearchGate

2021年1月1日 ball mill through reducer, transmission shaft and hollow shaft by motor Through the continuous turnover movement of the cylinder, the grinding medium insi de the cylinder is driven to crush 2024年10月25日 Gear transmission systems in ball mills play a crucial role in industrial production Their performance directly affects the working efficiency and lifespan of the equipment This article aims to conduct an indepth study on the vibration and sound characteristics of ball mill gear transmission systemsAnalysis of Vibration and Sound Characteristics of Ball Mill Gear 2019年5月21日 Planetary Mill with Friction Wheels Transmission Aided by an Additional Degree of Processing in planetary ball mills is well suited to a large number of applications because they are (PDF) Planetary Mill with Friction Wheels Transmission Aided by 2024年2月25日 The helical gear transmission system of ball mills plays a crucial role in industrial production, and their performance directly affects the efficiency and lifespan of equipment ZHY Gear aims to conduct indepth research on the vibration and sound characteristics of the helical gear transmission system of ball millsBall mill helical gear transmission system

Mill gearboxes GearTec AG (Englisch)

Due to our longstanding activity in this transmission sector, we have readymade solutions for various mill sizes Phone: 0391 0 : infoatgeartecag Keywords Deutsch; English; Spanish; Ball mill: 4,250: Planetary gearbox: MP425C66: 66,800: A3600 A4000: Gearboxes for SAG mills Mill size / type Nominal power in kW 2019年8月14日 Common Types of Ball mill back to top The common industrial ball mills mainly include cement ball mill, tubular ball mill, ultrafine laminating mill, cone ball mill, ceramic ball mill, intermittent ball mill, overflow ball mill, grid ball mill, wind discharge ball mill, double bin ball mill, energy saving ball mill 1The Ultimate Guide to Ball Mills Miningpedia2021年6月3日 Abstract The stirred ball mill (SBM) method is a common method applied in largescale sludge disintegration Many reports focus on the disintegration results of sludge or the influence of parameters on the anaerobic process of treated sludge, but there have been few studies on the mechanism of sludge disintegration by SBM This study focused on the Mechanism Investigation of Excess Sludge Disintegration by Stirred Ball Ball Mill is made up of feeding part, discharging part, gyre part, transmission part, (decelerator, small transmission gear, generator, electrical control) and so on The hollow axis adopts the cast steel and the lining can replace , the rotating Ball Mill Manufacturer China Henan Zhengzhou

A Review of the Grinding Media in Ball Mills for Mineral

2023年10月27日 The ball mill is a rotating cylindrical vessel with grinding media inside, which is responsible for breaking the ore particles Grinding media play an important role in the comminution of mineral ores in these mills This work reviews the application of balls in mineral processing as a function of the materials used to manufacture them and the mass loss, as 2024年9月19日 4 Vibrations in ball mill gear transmission systems often originate from the gear mesh process Key contributors to these vibrations include: Gear Mesh Frequency: The frequency of vibrations generated during gear mesh is directly related to the number of teeth on the gears and their rotational speedsBall Mill Gear Transmission System Vibration and Acoustic 2024年8月5日 The comprehensive production process of the mill head inlet and discharge for ball and SAG mills, meticulously designed and manufactured by ABS Bearings and Power Transmission Manufacture of the Loesche 3,2+2 Cement Mill vertical gearbox transmission set and supervision of assembly on location View More Projects Newsletter Be Mill head manufacturing process for ball and SAG millsLattice ball mill is composed of feeding part, discharging part, rotating part, transmission part (reducer, small transmission gear, motor, electric control) and other main parts The hollow shaft is made of cast steel, and the inner lining is removable The large rotary gear is processed by casting gear hobbingLattice Ball MillHenan Hongke Heavy Machinery Co, Ltd

.jpg)

Milling Ball Mill

HIGH EFFICIENCY – Due to the relatively slow rotational speed but large mass of media, more of the energy goes into milling and less wasted as heat; NARROW PARTICLE DISTRIBUTION – Solids milled in tumble mills are normally so fine and consistent in size that it’s rare to require classification; REPEATABLE RESULTS – Mill operating parameters including rotational 2022年1月1日 The ball mill is used for the conversion of the raw stone material into the powder form by using steel balls inside The ball mill is a cylindrical form of container that is driven by a toothed circular gear by couple of gears present in the gear box The gear box is a setup intended for making the power transmission from the electric motor to Design and simulation of gear box for stone crushing ball millBall mills are available with a grinding drum made of porcelain (100250 litres) or steel, with a lining of steatite or aluminium oxide (4012,000 litres) The ball mills are also equipped with a fully integrated or remotecontrol system KERA experts can Ball mills KERA2024年5月27日 Ball mills’ efficiency and performance can be optimised through proper design, maintenance, and advanced technologies like MechProTech’s TITAN Ball Mill and TITAN Automatic Ball Charger Investing in cuttingedge Ball Mills in the Mineral Processing Industry

Global optimization of reliability design for large ball mill gear

2013年11月1日 Many factors affect the reliability of ball mill gear transmission, such as the normal module, the Helix angle, and so on The computations for gear transmission reliability are tedious and the formula is not precise; as such, to reduce the values for calculation accuracy, the Kriging model is considered the real calculation functionTransmission device: The ball mill is a heavyduty, lowspeed and constantspeed machine Generally, the transmission device is divided into two forms: edge drive and center drive, including motor, reducer, drive shaft, edge drive gears and V Ball Mill SBM Ultrafine Powder Technology2023年7月18日 When maintaining the ball mill, the following tools and equipment may be helpful: 1 Wrench: used to disassemble and install fastening bolts, nuts, and other components 2 Lubricating oil gun: used to add lubricating oil to bearings, gears, transmission devices, and other parts 3 Lubricating oil: selecting appropriate lubricating oil is crucial for ball mill Ball Mill Maintenance Process and Methods MiningpediaBall Mill Drives We can provide all elements of a mill drive system as a fully optimised solution to suit your process exactly, or individual mill drive gearboxes, Pinions are designed to give the highest torque transmission capability and are available as integral or bored designs;Ball Mill Drives Crushing Grinding Drives David Brown

.jpg)

Grinding in Ball Mills: Modeling and Process Control

2012年6月1日 PDF The paper presents an overview of the current methodology and practice in modeling and control of the grinding process in industrial ball mills Find, read and cite all the research you 2019年10月19日 Ball mills are extensively used in the size reduction process of different ores and minerals The fill level inside a ball mill is a crucial parameter which needs to be monitored regularly for optimal operation of the ball mill In this paper, a vibration monitoringbased method is proposed and tested for estimating the fill level inside a laboratoryscale ball mill A vibration Monitoring the fill level of a ball mill using vibration sensing and 2022年3月23日 Gearboxes are frequently used in the mining industry, especially for power transmission between the electric drive and the ball mill; besides the extreme complexity of a ball mill gear transmission system, the fault diagnosis by vibration analysis can be easily distorted by the presence of impulsive noises due to the ball pulses on the mill shell Although several Modeling Impulsive Ball Mill Forces Effects on the DynamicIt meshes with the pinion and drives the entire ball mill cylinder to rotate for a long time through the transmission shaft, which withstands large torque and axial force Therefore, we have higher quality requirements for the girth gear castings AGICO is an experienced ball mill and ball mill spare part manufacturer5 Mustknow Ball Mill Parts And Functions

.jpg)

Ball Mill Adalah? Prinsip Kerja, Bagian, Komponen Dan Fungsinya

2022年10月5日 Ball Mill menjadi salah satu mesin yang sangat penting dalam proses produksi di suatu industri seperti dalam pembuatan cat, keramik, semen, kembang api, batu bara, pigmen feldspar dan serbuk material 3d printing, dll Transmission