What is the crushing value of heavy calcium powder

Heavy calcium carbonate dry production process and

2024年8月23日 Among them, the dry process is generally used to produce heavy calcium carbonate products with d97≥35μm The main crushing equipment includes Raymond mill, impact mill, dry stirred mill, air flow mill, 2024年7月10日 Heavy calcium carbonate is a calcium carbonate powder material produced by mechanical crushing using calcite, chalk, marble and other minerals as raw materials It has Heavy calcium carbonate grinding, surface modification 2020年12月10日 Heavy calcium carbonate (commonly known as ground calcium carbonate) can be made by directly crushing natural calcite, limestone, chalk and shell by mechanical method (Raymond mill or other highpressure 【Technical analysis】How to choose “industrialHeavy calcium carbonate is a calcium carbonate powder material produced by mechanical crushing method using calcite, chalk, marble and other ores as raw materials It has the characteristics of wide source of raw materials, high News Calcium powder processing machinery and

The difference between heavy calcium and light calcium in

2024年8月13日 Light calcium carbonate is produced chemically, while heavy calcium carbonate is made by mechanical crushing and grinding Their densities are similar—24–26 g/cm³ for According to different production methods, calcium carbonate can be divided into heavy calcium carbonate, light calcium carbonate, colloidal calcium carbonate and crystalline calcium carbonate Among them, heavy calcium is refined by Calcium Carbonate Powder Processing2023年10月16日 The characteristics of heavy calcium powder are: irregular particle shape, and the particles have certain edges and corners, and the surface is rough; the particle size difference is large, the particle size distribution is Learn the 17 differences between light calcium and 2021年12月20日 Heavy machinery is primarily used during the dry processing phase, when calcium carbonate manufacturing processes focus on reduction through milling, crushing, and screening, whereas air classification is generally Calcium Carbonate Manufacturing Process and

.jpg)

The difference between heavy calcium carbonate and light calcium

2021年3月11日 The heavy calcium carbonate adopts the crushing method, and the white stone containing more than 90% CaCO 3 is crushed, classified and separated with a Raymond mill Production and processing equipment for ultrafine heavy calcium powder mainly include crushing, grinding, classification, and drying equipment Here is a detailed introduction to the main Production and processing equipment for ultrafine heavy calcium 2021年8月13日 Generally speaking, the larger the crushing ratio, the stronger the processing capacity of the crusher +29 The value of the width of the discharge port and heavy hammer crushers that are relatively large in the market The heavy hammer crusher is particularly special The heavy hammer crusher has the What is the crushing ratio of the crusher?2023年12月11日 Heavy Calcium Carbonate Definition and Properties: Heavy calcium carbonate, or ground calcium carbonate (GCC), is a fine powder derived from natural limestone or marble deposits It has a higher density than light The Difference Between Heavy Calcium Carbonate

Heavy calcium carbonate dry production process and

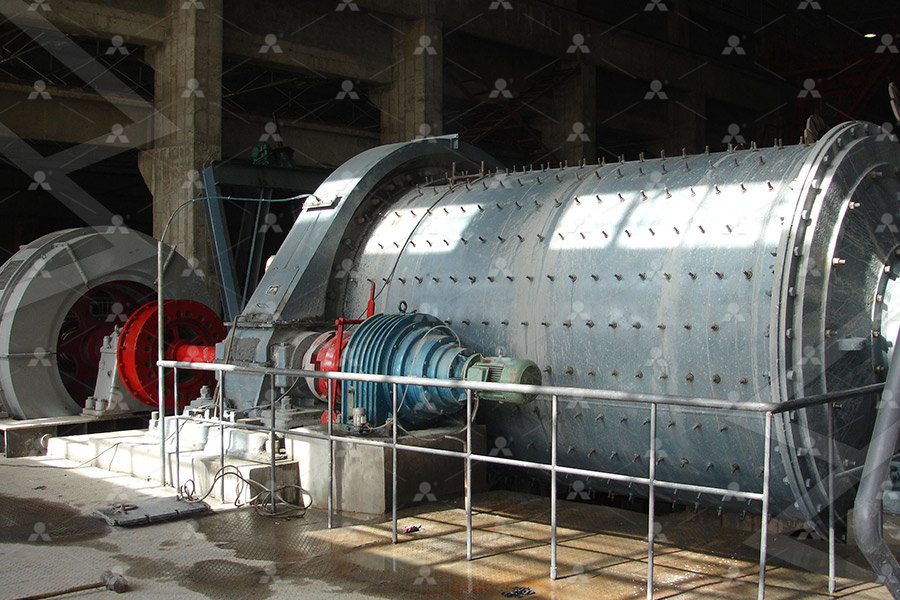

2024年8月23日 The ball mill with classifier process is a process solution strongly recommended by the world’s advanced powder technology companies and widely adopted by famous European and American powder companies It can be 2023年4月27日 3 Heavy calcium is made from natural ore crushing Light calcium is produced artificially It has a large amount of application in coatings 4 Heavy calcium is stable, but relatively light calcium is easy to settle 5 Light calcium is better at settling But the oil absorption is greater than heavy calcium The price is generally more The difference between calcium carbonate heavy and calcium 2023年12月7日 In the case of synthetic calcium carbonate, the next step is to dissolve the calcium oxide in water to form a solution of calcium hydroxide This is done by adding the calcium oxide to water and stirring until it dissolves 3 Carbonation The final step is to carbonate the calcium hydroxide solution with carbon dioxideWhat is the steps in the Calcium Carbonate Liming Heavy 2023年9月28日 To reduce the heavy reliance on limestone in cement manufacturing, dolomite powder is an excellent alternative which is a byproduct from rock crushing plant on GGBS based GPC, was studied(PDF) Dolomite Powder in Concrete: A Review of ResearchGate

.jpg)

Uses of Heavy Calcium Carbonate in Various Industries

2024年9月12日 Coalfired power plants use heavy calcium carbonate powder in flue gas desulfurization Flue gas desulfurization synthesizes calcium sulfite with heavy calcium carbonate and sulfur dioxide produced during coal combustion and then oxidizes it into gypsum (calcium sulfate) in contact with air, which can effectively reduce the emission of sulfur dioxide 2023年10月23日 Ahmadian F, et al (2017) The effect of consumption of garlic tablet on proteins oxidation biomarkers in postmenopausal osteoporotic women: A randomized clinical trial https://ncbimnih 11 Proven Health Benefits of Garlic2021年3月8日 Bio sorbent such as banana peel, pumpkin, papaya seed, crab shell, and eggshell uses effectively to remove contamination from the wastewater This experiment is designed to evaluate the factors Evaluating the effectiveness of eggshells to remove heavy Aggregate Crushing Value Test Result For accurate test results conduct the test at least 3 times and take an average of 3 values Aggregate Crushing Value Test Lab Report Aggregate Crushing Value Limits for Road Pavement The below table shows the aggregate crushing value limits for different types of roadsAggregate Crushing Value Test – Procedure, Result Calcualtion

UltraFine grinding processing method and flow of heavy calcium powder

The ultrafine grinding of heavy calcium powder is essential to improve its application range and performance 1 Introduction Heavy calcium powder, also known as calcium carbonate, is a commonly used filling material in the industries of plastics, rubber, paper, paint, and pharmaceuticals The particle size of heavy calcium powder directly At present, the production methods of heavy calcium carbonate mainly include dry method and wet method The dry method generally produces heavy calcium with less than 2500 mesh If the heavy calcium with more than 2500 mesh is produced, wet grinding is mainly used, and dry grinding is the first step of wet grinding Wet grinding heavy calcium has the characteristics of News Apply The Heavy Calcium Grinding Mill Machine To The 2023年6月13日 Calcium is an essential mineral that is the key to healthy bones and teeth How much calcium you need per day depends on your age and sex assigned at birthCalcium: What It Does and How Much You Need2021年9月22日 The influence of intact rock properties on powder factor selection and the influence of powder factor selection on postblast conditions have also been discussedA Review on the Prediction and Assessment of Powder Factor in

Calcium Carbonate Grinding Mill Powder Modify SBM Ultrafine Powder

2022年5月5日 According to different production methods, calcium carbonate can be divided into heavy calcium carbonate, light calcium carbonate, colloidal calcium carbonate, and crystalline calcium carbonate Heavy calcium carbonate is made by mechanical methods (using a fine powder mill or other industrial grinding mills) to directly crush natural calcite, limestone, chalk, calcium carbonate powder contain water contact angle,activity index,oil absorption value Oil absorption value is seldom evaluated the modified calcium carbonate powderDry surface modification of heavy calcium carbonate powder Characteristics and application of heavy calcium carbonate Heavy calcium carbonate, referred to as heavy calcium, is a white powder made from highquality calcite Its main component is CaCO3, which is insoluble in water and ethanol It has the characteristics of high whiteness, good purity, soft color and stable chemical compositionThe Difference between Heavy and Light Calcium Carbonate2022年2月21日 Heavy calcium carbonate is made of calcite, chalk, marble and other ores as raw materials, and is produced by mechanical pulverization It is a commonly used powdery inorganic filler with high chemical purity, high inertness, not easy to chemical reaction, good thermal stability, no decomposition below 400 ℃, high whiteness, low oil absorption rate, low How to do the grinding of heavy calcium industry?

.jpg)

Production and modification process of heavy calcium carbonate

2021年8月24日 Modification of heavy calcium carbonate The minerals of heavy calcium carbonate dissociate during the crushing process, and unsaturated particles Ca 2+ and CO 3 2 will be exposed Unsaturated particles will hydrate with surface water, making the surface of heavy calcium carbonate particles hydrophilic and oleophobic2024年4月18日 Best powder calcium: NOW Supplements Calcium Carbonate Powder heavy metals, and mold Dosage: which is 10% of the daily value for added sugar; Product details7 Best Calcium Supplements for 2024 Medical News Today2021年3月11日 Heavy calcium carbonate and light calcium carbonate are classified according to different methods of calcium carbonate production They can be distinguished from the following aspects: 1 Powder characteristics The particles of heavy calcium carbonate are irregular in shape and are polydisperseThe difference between heavy calcium carbonate and light calcium 2024年7月12日 5 Oil absorption value Due to its large particles, smooth surface and small specific surface area, heavy calcium has a low oil absorption value, generally 4060mL/100g; Light calcium has fine particles, rough surface and Heavy calcium and light calcium, 10 essential

What is the difference between heavy and light calcium carbonate?

2024年10月25日 Heavy calcium carbonate and light calcium carbonate have different applications due to their different physical propertiesease check the belows information: Heavy calcium carbonate is commonly used as a filler in the manufacturing of paper, plastic, rubber, and paint It can also be used as a dietary supplement to provide calcium to the body2021年7月26日 Agrofood from fields of industries and communities produce a substantial amount of pollution every day, so it is becoming urgent to manage this problem 1As the restriction connected to Simple recycling of biowaste eggshells to various calcium phosphates The most obvious difference between heavy calcium and light calcium lies in the different bulk density of the products Generally, the bulk density of heavy calcium products is larger, ranging from 08 to 13g/cm3, while that of light calcium products What are the differences between light calcium carbonate and heavy 2023年5月29日 Ways to Use Eggshell Powder While you can just add eggshells to your compost, making eggshell powder is a great way to enhance their utility They’re great in the garden, but they’re also wonderful as a health supplement, and they also can be used for crafting, pets, and more! Eggshell Calcium Powder for HumansHow to Make Eggshell Powder ( 10+ Ways to Use It)

Five surface modification methods of heavy calcium carbonate to

2024年2月6日 The main purposes of surface modification of heavy calcium carbonate are: 1 Reduce the surface energy of heavy calcium carbonate and prevent agglomeration; 2 Improve the dispersion of heavy calcium carbonate in the matrix; 3 Enhance the interface affinity between the surface of heavy calcium carbonate and the matrix; 42023年7月13日 Eggshells are a cheap, natural source of calcium This article looks at the risks and benefits of eggshell supplementsThe Benefits and Risks of Eating Eggshells Healthline2021年9月14日 Laser diffraction technology is one of several methods currently employed to determine particle size distributions But laser diffraction is the only technology applicable for powders, suspensions (PDF) Measuring the Particle Size Distribution of Calcium 2023年3月21日 Application of ultrafine vertical mill in the processing and production of ultrafine heavy calcium Considering the diversified needs of heavy calcium powder products, the “CLUM ultrafine vertical mill + secondary (or tertiary)” classification process is often used in the design of vertical grinding powder engineering systems There are two reasons:The advantages of ultrafine vertical mill in the processing and

What is the crushing ratio of the crusher?

2021年8月13日 Generally speaking, the larger the crushing ratio, the stronger the processing capacity of the crusher +29 The value of the width of the discharge port and heavy hammer crushers that are relatively large in the market The heavy hammer crusher is particularly special The heavy hammer crusher has the 2023年12月11日 Heavy Calcium Carbonate Definition and Properties: Heavy calcium carbonate, or ground calcium carbonate (GCC), is a fine powder derived from natural limestone or marble deposits It has a higher density than light The Difference Between Heavy Calcium Carbonate 2024年8月23日 The ball mill with classifier process is a process solution strongly recommended by the world’s advanced powder technology companies and widely adopted by famous European and American powder companies It can be Heavy calcium carbonate dry production process and 2023年4月27日 3 Heavy calcium is made from natural ore crushing Light calcium is produced artificially It has a large amount of application in coatings 4 Heavy calcium is stable, but relatively light calcium is easy to settle 5 Light calcium is better at settling But the oil absorption is greater than heavy calcium The price is generally more The difference between calcium carbonate heavy and calcium

What is the steps in the Calcium Carbonate Liming Heavy

2023年12月7日 In the case of synthetic calcium carbonate, the next step is to dissolve the calcium oxide in water to form a solution of calcium hydroxide This is done by adding the calcium oxide to water and stirring until it dissolves 3 Carbonation The final step is to carbonate the calcium hydroxide solution with carbon dioxide2023年9月28日 To reduce the heavy reliance on limestone in cement manufacturing, dolomite powder is an excellent alternative which is a byproduct from rock crushing plant on GGBS based GPC, was studied(PDF) Dolomite Powder in Concrete: A Review of ResearchGate2024年9月12日 Coalfired power plants use heavy calcium carbonate powder in flue gas desulfurization Flue gas desulfurization synthesizes calcium sulfite with heavy calcium carbonate and sulfur dioxide produced during coal combustion and then oxidizes it into gypsum (calcium sulfate) in contact with air, which can effectively reduce the emission of sulfur dioxide Uses of Heavy Calcium Carbonate in Various Industries2023年10月23日 Ahmadian F, et al (2017) The effect of consumption of garlic tablet on proteins oxidation biomarkers in postmenopausal osteoporotic women: A randomized clinical trial https://ncbimnih 11 Proven Health Benefits of Garlic

.jpg)

Evaluating the effectiveness of eggshells to remove heavy

2021年3月8日 Bio sorbent such as banana peel, pumpkin, papaya seed, crab shell, and eggshell uses effectively to remove contamination from the wastewater This experiment is designed to evaluate the factors Aggregate Crushing Value Test Result For accurate test results conduct the test at least 3 times and take an average of 3 values Aggregate Crushing Value Test Lab Report Aggregate Crushing Value Limits for Road Pavement The below table shows the aggregate crushing value limits for different types of roadsAggregate Crushing Value Test – Procedure, Result Calcualtion