heavy calcium heavy calcium powder ore grinding machine

.jpg)

Heavy calcium + superfine processing equipment ALPA Powder

2021年8月27日 Heavy calcium ultrafine processing equipment is divided into grinding equipment and grading equipment The grinding equipment includes Raymond mill, vibration The grinding mill is the core of the entire production line The choice of grinding mill machine is related to the quality of the final ground calcium carbonate powder, so how to choose the right calcium carbonate grinding equipment has How to Choose a Calcium Carbonate Grinding Mill2022年5月5日 Calcium carbonate grinding mill is an efficient industrial powder grinder machine It can grind 100+ kinds of ores into a fine powder (1503000 mesh) +17Calcium Carbonate Grinding Mill Powder Modify2023年6月25日 Crushing: The calcium carbonate stones just mined from the quarry are relatively large, and they need to be crushed by a jaw crusher and a hammer crusher in turn to the feed fineness (10mm20mm) that can enter the Guide to Calcium Carbonate Grinding: Mills, Tips, and

How to choose a suitable calcium carbonate grinding mill?

2024年9月14日 Calcium carbonate grinding mills are machines They grind calcium carbonate (CaCO3) into fine powder for various uses Skip to content : [ protected] Tel: +86 ; It can meet various customers’ needs 2024年7月12日 Due to the relatively high impurities, the whiteness of heavy calcium carbonate is generally 89% to 93%, and very few products can reach 95%; The purity of light calcium carbonate products is relatively high, so the whiteness is generally 92% to 95%, and some products can reach 96% to 97% 7 Specific surface area The specific surface area of Heavy calcium and light calcium, 10 essential differencesAt present, the production methods of heavy calcium carbonate mainly include dry method and wet method The dry method generally produces heavy calcium with less than 2500 mesh If the heavy calcium with more than 2500 mesh is produced, wet grinding is mainly used, and dry grinding is the first step of wet grinding Wet grinding heavy calcium has the characteristics of News Apply The Heavy Calcium Grinding Mill Machine To The Note: This specification is just referencing, any changes are subject to the products Shanghai clirik machinery co, LTD Should you have any questions on our powder grinder; micro powder grinder; industrial powder grinder; fine powder grinder; powder grinder series; powder grinder machineease do not hesitate to contact us Phone: ;86Heavy calcium carbonate micro powder grinderHeavy calcium

Calcium carbonate millGrinding mill machine, mineral mill,

The bulk material of calcium carbonate is crushed by the crusher to the feed fineness (15mm50mm) that can enter the mill The crushed calcium carbonate small pieces of material are sent to the silo through the elevator, and then sent to the grinding chamber of the mill by the vibrating feeder for quantitative grinding2024年7月10日 Heavy calcium carbonate grinding technology and Organic coating modification is a method of coating and modifying heavy calcium carbonate powder with organic substances such as stearic acid Our experts will contact you within 6 hours to discuss your needs for machine and processes Fill out this field Please enter a valid Heavy calcium carbonate grinding, surface modification Heavy calcium carbonate, light calcium carbonate is based on the production method of calcium carbonate divided, can be distinguished from the following three aspects: LUMSeries Ultra Fine Vertical Grinding Mill 1 The shape of the particles are different Heavy calcium carbonate particles irregular shape, is polydisperse powderThe difference between heavy calcium carbonate and light calcium 2021年7月20日 CLIRIK HGM series ring roller mill for calcium carbonate powder making CLIRIK HGM series ring roller mill (characterized by large pulverization ratio and low energy consumption per unit product): The ring roller mill mainly performs ultrafine processing of heavy calcium, and mainly produces 2002500 purpose productsCalcium carbonate grinding millCLIRIK Machinery

Production and modification process of heavy calcium carbonate

2021年8月24日 Among them, the use of 25006500 mesh heavy calcium powder in highend papermaking has also increased Production of heavy calcium carbonate The raw materials are carbonate minerals such as shells, calcite, marble, limestone, chalk and dolomite Common heavy calcium processing methods include dry, wet, and drywet process combination methodsEPIC Powder Machinery is a highquality calcium carbonate production line manufacturer in China with more than 20 years of experience Skip to content Providing with green, highvalue calcium carbonate ultrafine grinding, classifying and powder coating processes Get Started Our Services Quality is fundamental Creating trustworthy productsCalcium Carbonate Powder Production Line ManufacturerHeavy calcium powder is not equal to talc powder Both heavy calcium powder and talc powder have similar uses But, they are completely different And, there are some differences in their properties and uses Heavy calcium powder Heavy calcium powder is the short form of heavy calcium carbonate It has a molecular formula of CaCO3Differences in uses and properties between heavy calcium powder 2023年10月16日 The characteristics of heavy calcium powder are: irregular The processing of heavy calcium is mainly achieved through mechanical crushing and grinding; The production of light calcium is made through chemical Our experts will contact you within 6 hours to discuss your needs for machine and processes Fill out this fieldLearn the 17 differences between light calcium and heavy calcium!

.jpg)

Quality requirements and grinding process control of heavy calcium

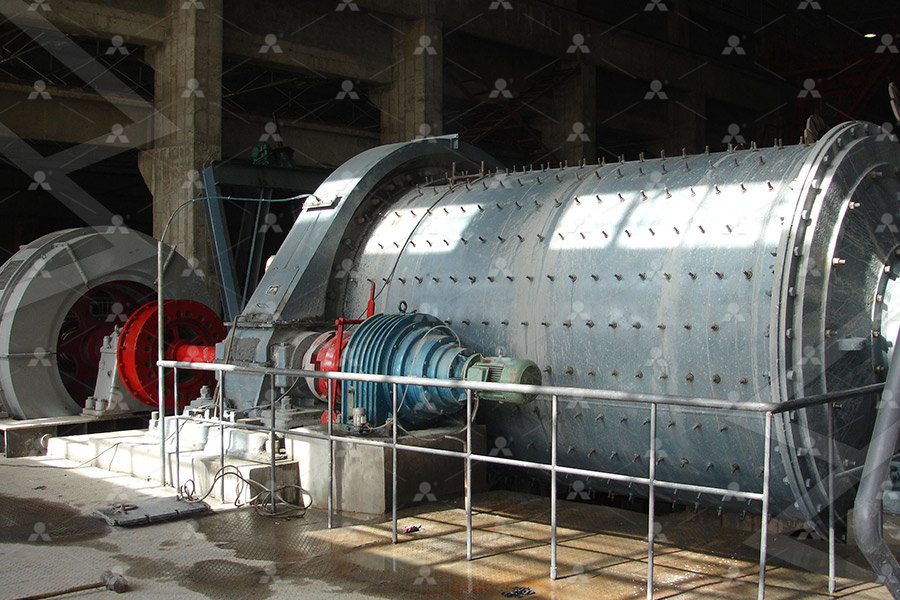

Such quality problems may cause abnormal operation of the wet end system of the paper machine Normally, calcium carbonate with a content of 2μm and 65% (solid content: 17%) 18%) 15min settling velocity is ≤ 1mm 2 Heavy calcium carbonate grinding process and process parameter control2022年2月21日 Heavy calcium carbonate is made of calcite, chalk, marble and other ores as raw materials, and is produced by mechanical pulverization It is a commonly used powdery inorganic filler with high chemical purity, high inertness, not easy to chemical reaction, good thermal stability, no decomposition below 400 ℃, high whiteness, low oil absorption rate, low How to do the grinding of heavy calcium industry?Heavy calcium carbonate and light calcium carbonate are different in particle size, crystal shape, and interface properties The characteristics are also very different Calcium carbonate is usually used as a filler, artificial floor tiles, rubber, plastics, paper making, coatings, paints, inks, cables, construction supplies, food, medicine Calcium carbonate mill grinding plant2024年8月23日 The ball mill with classifier process is a process solution strongly recommended by the world’s advanced powder technology companies and widely adopted by famous European and American powder companies It can be used to produce heavy calcium carbonate products with particle sizes of d97=5μm, 10μm, 16μm, 45μm, etcHeavy calcium carbonate dry production process and equipment EPIC Powder

.jpg)

Calcium Carbonate Rock MadeinChina

High Purity Heavy Calcium Carbonate Powder CaCO3 for Coating, Feed Grade US$ 180260 / Ton 10 Tons Calcium Carbonate Powder Superfine Grinding Machine Ring Roller Mill US$ 3000090000 / Piece 1 Piece Marble Limestone Ore Calcium Carbonate Gypsum Stone Crusher Machine US$ 1200 / Piece 1 Piece In the quicklime grinding plant case, the customer using our HGM grinding mill as a stone dust making machine to process quicklime (calcium oxide) and calcium carbonate into a fine, 325 mesh powder 2024 1029SBM Ultrafine Powder Technology Industrial Calcium hydroxide / calcium oxide powder making machine widely applied in mineral grinding processing of metallurgy, construction material, chemical industry and mine fields, and is widely used to grind minerals with Mohs Calcium hydroxide / calcium oxide powder making Whether soft rock, hard rock, nonmetallic minerals, or coal, FTM Machinery can provide costeffective grinding solutions Our powder milling machines are particularly suitable for producing clean coal powder, limestone powder, gypsum powder, quartz powder, calcium carbonate powder, marble powder, barite powder, mica powder, and bentonite Powder Grinding Mills Engineered by FTM Fote Machinery

FYEFEPS2HDZ49G5Z0[B.jpg)

Calcium Carbonate Grinding Production Line TAYMACHINERY

The calcium carbonate grinding production line is an efficient, stable, and reliable production line with wide application prospects By using advanced equipment and technology, this production line is able to produce highquality calcium carbonate powder to meet the needs of different industries At the same time, the production line also has the advantages of energy 2021年1月26日 According to its original average particle size (d), heavy calcium carbonate is divided into: coarsely ground calcium carbonate (> 3μm), finely ground calcium carbonate (1~3pm), superfine calcium carbonate (05~1μm) powder of heavy calcium carbonate Body characteristics: a Irregular particle shape; bThe difference between heavy calcium carbonate and light calcium Looking for a highquality machine to improve your Calcium carbonate powder production machinery business? EPIC is here to support you Machines Menu Toggle Ultrafine powder grinding Menu Toggle Ball Mill; Raymond Mill; Roller Mill; Table Roller Mill; Ultrafine Air Classifier Menu Toggle Horizontal Air Heavy calcium powder is not Machines EPIC Calcium carbonate powder production machineryIn the calcium carbonate superfine powder vertical mill, the contact point between the grinding roller shell and the grinding disc liner adopts electronic limit technology and mechanical limit protection technology, which can avoid the destructive effects caused by machine vibration (such as the direct crushing of the grinding roller and the grinding disc) ( Such as the grinding roller Calcium Carbonate Ultrafine Powder Vertical Mill

News Calcium powder processing machinery and equipment

Heavy calcium carbonate is a calcium carbonate powder material produced by mechanical crushing method using calcite, chalk, marble and other ores as raw materials It has the characteristics of wide source of raw materials, high whiteness, low oil absorption value, good applicability and low pricCalcium Carbonate Modified Line Highspeed rotor pulverizer is used as the modified main machine to heat the air intake to keep the modified main machine at a suitable modification temperature, and the superfine heavy calcium (D97 10um) is coated with stearic acid, and the processing capacity is from 500 to 6000Kg /h, the coverage rate is above 98%Industrial Powder Grinding Machine Manufacturers, FactoryThe grinding mill is the core of the entire production line The choice of grinding mill machine is related to the quality of the final ground calcium carbonate powder, so how to choose the right calcium carbonate grinding equipment has How to Choose a Calcium Carbonate Grinding Mill2022年5月5日 Calcium carbonate grinding mill is an efficient industrial powder grinder machine It can grind 100+ kinds of ores into a fine powder (1503000 mesh) +17Calcium Carbonate Grinding Mill Powder Modify

Guide to Calcium Carbonate Grinding: Mills, Tips, and

2023年6月25日 Crushing: The calcium carbonate stones just mined from the quarry are relatively large, and they need to be crushed by a jaw crusher and a hammer crusher in turn to the feed fineness (10mm20mm) that can enter the 2024年9月14日 Calcium carbonate grinding mills are machines They grind calcium carbonate (CaCO3) into fine powder for various uses Skip to content : [ protected] Tel: +86 ; It can meet various customers’ needs How to choose a suitable calcium carbonate grinding mill?2024年7月12日 Due to the relatively high impurities, the whiteness of heavy calcium carbonate is generally 89% to 93%, and very few products can reach 95%; The purity of light calcium carbonate products is relatively high, so the whiteness is generally 92% to 95%, and some products can reach 96% to 97% 7 Specific surface area The specific surface area of Heavy calcium and light calcium, 10 essential differencesAt present, the production methods of heavy calcium carbonate mainly include dry method and wet method The dry method generally produces heavy calcium with less than 2500 mesh If the heavy calcium with more than 2500 mesh is produced, wet grinding is mainly used, and dry grinding is the first step of wet grinding Wet grinding heavy calcium has the characteristics of News Apply The Heavy Calcium Grinding Mill Machine To The

Heavy calcium carbonate micro powder grinderHeavy calcium

Note: This specification is just referencing, any changes are subject to the products Shanghai clirik machinery co, LTD Should you have any questions on our powder grinder; micro powder grinder; industrial powder grinder; fine powder grinder; powder grinder series; powder grinder machineease do not hesitate to contact us Phone: ;86The bulk material of calcium carbonate is crushed by the crusher to the feed fineness (15mm50mm) that can enter the mill The crushed calcium carbonate small pieces of material are sent to the silo through the elevator, and then sent to the grinding chamber of the mill by the vibrating feeder for quantitative grindingCalcium carbonate millGrinding mill machine, mineral mill, 2024年7月10日 Heavy calcium carbonate grinding technology and Organic coating modification is a method of coating and modifying heavy calcium carbonate powder with organic substances such as stearic acid Our experts will contact you within 6 hours to discuss your needs for machine and processes Fill out this field Please enter a valid Heavy calcium carbonate grinding, surface modification