Grinding production line CH430

Sandvik CH430 Cone Crusher Suitable For Secondary

Sandvik CH430 Cone crusher incorporates our sophisticated Hydrocone technique which enables you to run your crusher at maximum performance levels under changing feed conditions without overloading the crusherThis document provides technical specifications for the Sandvik CH430 cone crusher including its dimensions, weights, recommended motor specifications, capacities, and crushing chamber optionsTechnical Data CH430 PDF Nature ScribdDiscover Sandvik's stationary crushers, designed for maximum productivity and reliability in crushing applications Ideal for mining and aggregate industriesStationary crushers Stationary crushing and screening CH430 Nominal capacities MTPH Chamber EC C MC M MF F EF CSS 95–110 75–90 – – – – – SH 160 130 105 80 70 45 34 TS 185 145 115 90 75 50 38 Max motor power (kW) 132 132 CONE CRUSHER CH SERIES CH430 Sandvik Mining and Rock

.jpg)

Premier Equipment CH430 Cone Crusher

Sandvik CH430 is an advanced design with a small footprint and high capacity in relation to its size This cone crusher has a hydraulically supported main shaft that is supported at both 2020年4月27日 CH430 (H3800) PREMIUM CRUSHING CHAMBER SOLUTIONS Our unique profiles and wearresistant alloys help to achieve optimal crushing performance, ensuring Crushing Chamber Application Guide C51086:01ENG IssuuProduction time, energy costs and wear and tear from recirculation all afect your bottom line To illustrate the benefits of optimising your setup, we compare sandvik’s CH540 and CH430 MASTER YOUR OUTPUT CRUSHER SELECTION QUICK GUIDEConsulte especificaciones técnicas detalladas y fichas técnicas para Sandvik CH430 del año 2017 2024 Obtenga una visión más profunda para Sandvik CH430 con las fichas técnicas Sandvik CH430 Ficha tecnica Especificaciones (20172024)

QH331HS HYDROCONE PIONEERING SOLUTIONS FOR YOU

– The CH430 cone has choice of six concaves and three eccentric bushes providing a range of throws from 16mm to 36mm – The concave and bush settings give unrivalled flexibility Sandvik QS332 is a compact, robust mobile secondary cone crushing solution designed for versatility and ease of operation Fitted with Sandvik CS430 "S" type gyratory cone crusher, it Sandvik CS430 Cone Crusher For Secondary Crushing Applications MIAMISBURG, Ohio, February 10, 2020 – As products grow thinner and lighter to meet the needs of the electronics, medical and micromechanics industries, UNITED GRINDING and EWAG have developed the LASER LINE ULTRA for EWAG LASER LINE ULTRA Simplifies Micro Cutting 2024年11月7日 Die UNITED GRINDING Group ist einer der führenden Hersteller von Präzisionsmaschinen für das Schleifen, das Erodieren, das Lasern und das MessenUNITED GRINDING: Hersteller von

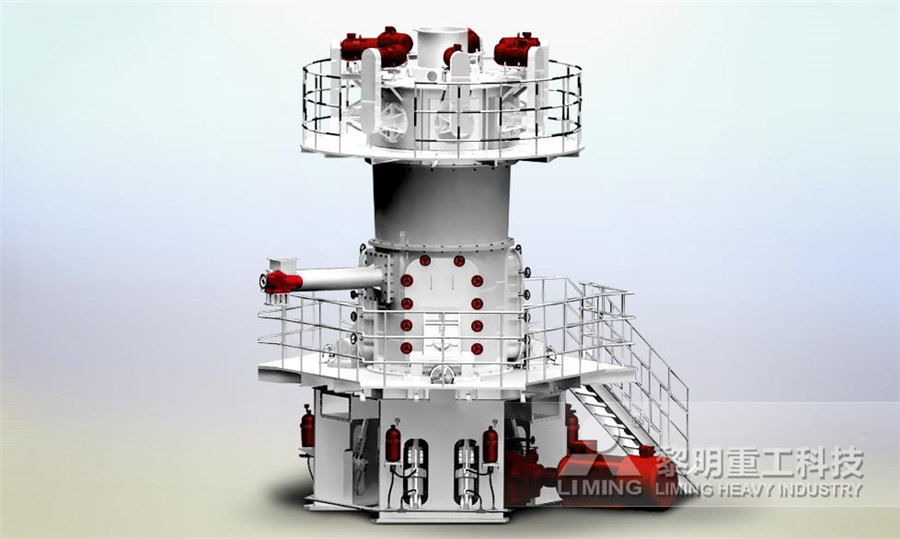

active lime production line CHAENG

CHAENG can undertake the 2001500t/d active lime production line EPC, including the the reach report, civil engineering, designing, equipment, installation and debugging Active lime production line; Cement Grinding Plant; Cement Production Line; Stone Crushing Plant; Contact us Tel:+79300 t/d Cement Production Line 300t/d cement production line designed by Great Wall machinery, fully learns from the lessons and experiences of more than 20 years of NSP production line design, advanced vertical roller mill grinding system and DCS automatic control system; 3000 t/d Cement Production Line Xinxiang Great Wall Machinery provides turnkey basis service Production LineProduct Name: GGBS Production Line / Slag Mill Capacity: 3,6000 – 1,000,000 T/Y Grinding Systems: VRM system, Ball mill open circuit system, Ball mill closed circuit system, Roller press final grinding systemGGBS Production Line Slag Mill for Slag Powder Grinding AGICOThe slag grinding production line is a production system specially used to process slag and make slag powder Slag, as a byproduct in the industrial production process, can be converted into valuable resources through grinding processing and used in cement mixtures, highperformance concrete admixtures, etcSlag Grinding Production Line TAYMACHINERY

News overview UNITED GRINDING

2024年11月7日 The employees of the United Grinding Group – over 2500 strong characters with their own history – make us successful Our brands and companies make us what we are: one of the leading manufacturers of precision machines for grinding, eroding, laser machining, combination machining and measuring2023年12月6日 Recently, the HGM100 ultrafine mill production line of a customer in Binzhou, Shandong, China has been installed and officially put into production +17 [ protected] language Advantages of HGM series ultrafine grinding production lineLimestone ultrafine grinding production line customer site Work across multiple application centers to optimize all processes through the production line (eg grain technology and milling solutions) and develop endtoend solutions 7 Application Center Service Workshop Nutrition Application Center Changzhou Wuxi, China Grinding Application Center Uzwil, Switzerland Grinding Application CenterGrinding Portfolio Next Generation Size Reduction Bühler Groupmaintain( grinding head) It need to change the grinding head each month: Cover Area: It based on the groups of grinding head, eg14 groups of grinding heads, the lenght of the line is 40*8 m: Production: It based on the line speed and thickness of plate, the usually production is 700 kg/ month: Speed: It could control between 1 m10m/ min 304/430 Stainless Steel Plate/ Sheet/ Coil Surface No 8/ Super 8K

Barite Grinding Production Line TAYMACHINERY

The barite grinding production line is a production line specially used to process barite raw ore into fine barite powder; it has the advantages of simple configuration, stable operation, high output, low energy consumption, and the fineness of the finished product meets the requirements Barite is a pure natural stone with high practical value in mining, machinery, metallurgy, UNITED GRINDING Group Our ultimate goal in everything we do is to make a contribution to the success of our customers Under the "UNITED GRINDING Digital Solutions™" brand we supply products and services for Industry 40 applications UNITED GRINDING Digital Solutions™ services streamline and simplify processes, help preSolutions for precision machining UNITED GRINDINGThe compact 5 axis grinding center is ideal for grinding complex geometries, offer the prerequisite for delivering an optimal and costeffective solution for your production tasks Surface grinding machines; Cylindrical grinding MFP 30 UNITED GRINDING2023年5月25日 Grinding is an essential process in the manufacturing industry It involves the removal of material from a workpiece to create a desired shape or surface finish While traditional grinding techniques require manual labor and can be timeconsuming, the use of grinding automation systems has revolutionized the production lineREVOLUTIONIZE YOUR PRODUCTION LINE WITH GRINDING

.jpg)

PROFIMAT RT UNITED GRINDING

Whether precision, profile, internal or external cylindrical grinding – the PROFIMAT MC is a highly efficient grinding centre for any application This extremely compact travelingcolumn machine offers everything that modern production solutions require, with a machine width of just 2000 mm Work across multiple application centers to optimize all processes through the production line (eg grain technology and milling solutions) and develop endtoend solutions 7 Application Center Service Workshop Nutrition Application Center Changzhou Wuxi, China Grinding Application Center Uzwil, Switzerland Grinding Application CenterGrinding Portfolio Next Generation Size Reduction床身採用米漢納鑄鐵,熱處理及精密研磨 ( 硬度 HS 70 ˚ ) 。 可調整車身,橫送台單方給油或同時給油之分油器。 自動兼手動之強制給油泵,潤滑範圍包括橫送台,車床滑動面。 有安全裝置的起動停止把手。 能瞬間停機的剎車裝置。CH430 金竑精密股份有限公司UNITED GRINDING Group is one of the world’s leading manufacturers of grinding, eroding, laser, and measuring machines as well as machine tools for additive manufacturing With roughly 2500 employees at more than 20 manufacturing, service, and sales locations, the Group is organized in a customeroriented and efficient wayOur products UNITED GRINDING

Rebar Threading Equipment And Grinding Production Line

Rebar Threading Equipment And Grinding Production Line is engineered for outstanding efficiency and quality in steel bar processing This advanced system processes one steel bar with two thread ends in just 12 seconds, enabling you to complete up to 4,000 thread ends in an 8hour shift or handle over 100 tons of steel bar thread rolling each day2023年12月26日 As we all know, the dryprocess cement production line is commonly used in the cement industry The new type of dryprocess cement production process includes four main sections: Prehomogenization of raw materials, homogenization of raw materials, clinker firing, cement grinding, etc Raw material conveying system The raw material, including limestone, 6 Cement Equipment For Dryprocess Cement Production Line2024年11月7日 The cover of this Motion, with its focus on recruiting, employer branding, and young professionals, shows how the training team at STUDER is preparing for the international professional championship WorldSkills 2024 in Lyon, France The motif was created during training at STUDER in Thun, Switzerland, on some of the country’s most modern training grinding UNITED GRINDING2020年7月7日 By integrating a wide range of technologies into the MFP 51, MÄGERLE has enabled maximum flexibility to achieve high productivity on surface and profile grinding machines In addition to the full range of surface and profile grinding operations, the MFP 51 also offers the option of drilling, milling and measuring in a single clamping, always with full fiveaxis Highmix/lowvolume production on 5/6 axis grinding centers

grinding UNITED GRINDING

2024年11月7日 Die UNITED GRINDING Group ist einer der führenden Hersteller von Präzisionsmaschinen für das Schleifen, das Erodieren, das Lasern und das MessenUNITED GRINDING Group is one of the world’s leading manufacturers of COMPACT LINE HELICHECK 3D HELICHECK ADVANCED HELICHECK NANO HELICHECK PLUS The S30 is a cylindrical grinding machine for mediumsized workpieces in individual and small batch production It has distances between centres of 650mm (256") / 1000mm (40") and S30 UNITED GRINDINGThe calcium carbonate grinding production line is an efficient, stable, and reliable production line with wide application prospects By using advanced equipment and technology, this production line is able to produce highquality calcium carbonate powder to meet the needs of different industries At the same time, the production line also has the advantages of energy Calcium Carbonate Grinding Production Line TAYMACHINERY2024年3月12日 Grinding machines use rotating, abrasive wheels that take light cuts — not so much for high material removal, but to create a better surface finish than can be achieved by milling or turning operations Grinding is commonly one of the last machining operations performed to complete a partGrinding for Precision Machining Production Machining

.jpg)

Mining production line process flow CM Mining Machinery

In mine crushing treatment, choosing a complete set of crushing and grinding production line is the top priority, so choosing highefficiency, energysaving and environmentally friendly mine crushing equipment is the preferred standard for mining in the future Dahua Heavy Industry provides you with the following referenceWith its grinding range of 300 x 600 mm the J600 realizes its full potential particularly when grinding demanding applications in tool and die making The J600 offers a unique ease of use The double sliding door to the work area and additional maintenance doors guarantee optimal handling and cleaning of the machineJ600 UNITED GRINDINGCHAENG (Great Wall Machinery) can undertake 20 tons 15 million tons of Blast furnace slag/Steel slag/Nickel slag/Manganese slag powder production EPC projects Up to now, CHAENG has constructed more than 100 slag grinding production lines at home and abroadSlag CHAENGUNITED GRINDING Group is one of the world’s leading manufacturers of grinding, eroding, offer the prerequisite for delivering an optimal and costeffective solution for your production tasks Surface grinding machines; Cylindrical grinding COMPACT LINE HELICHECK 3D HELICHECK ADVANCED HELICHECK NANO HELICHECK PLUS HELICHECK PLUS LONGPROFIMAT MC UNITED GRINDING

.jpg)

EWAG LASER LINE ULTRA Simplifies Micro Cutting

MIAMISBURG, Ohio, February 10, 2020 – As products grow thinner and lighter to meet the needs of the electronics, medical and micromechanics industries, UNITED GRINDING and EWAG have developed the LASER LINE ULTRA for 2024年11月7日 Die UNITED GRINDING Group ist einer der führenden Hersteller von Präzisionsmaschinen für das Schleifen, das Erodieren, das Lasern und das MessenUNITED GRINDING: Hersteller von CHAENG can undertake the 2001500t/d active lime production line EPC, including the the reach report, civil engineering, designing, equipment, installation and debugging Active lime production line; Cement Grinding Plant; Cement Production Line; Stone Crushing Plant; Contact us Tel:+79active lime production line CHAENG300 t/d Cement Production Line 300t/d cement production line designed by Great Wall machinery, fully learns from the lessons and experiences of more than 20 years of NSP production line design, advanced vertical roller mill grinding system and DCS automatic control system; 3000 t/d Cement Production Line Xinxiang Great Wall Machinery provides turnkey basis service Production Line

.jpg)

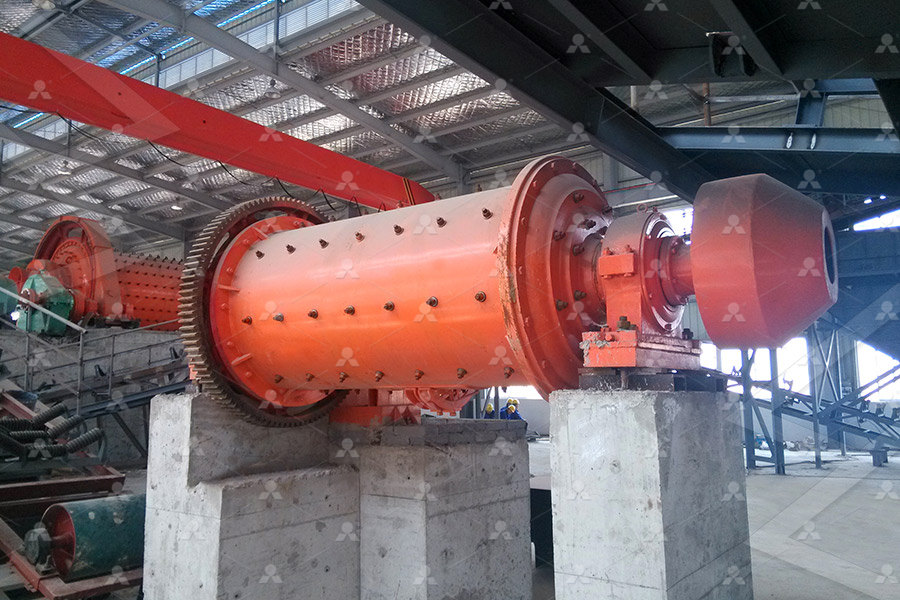

GGBS Production Line Slag Mill for Slag Powder Grinding AGICO

Product Name: GGBS Production Line / Slag Mill Capacity: 3,6000 – 1,000,000 T/Y Grinding Systems: VRM system, Ball mill open circuit system, Ball mill closed circuit system, Roller press final grinding systemThe slag grinding production line is a production system specially used to process slag and make slag powder Slag, as a byproduct in the industrial production process, can be converted into valuable resources through grinding processing and used in cement mixtures, highperformance concrete admixtures, etcSlag Grinding Production Line TAYMACHINERY2024年11月7日 The employees of the United Grinding Group – over 2500 strong characters with their own history – make us successful Our brands and companies make us what we are: one of the leading manufacturers of precision machines for grinding, eroding, laser machining, combination machining and measuringNews overview UNITED GRINDING2023年12月6日 Recently, the HGM100 ultrafine mill production line of a customer in Binzhou, Shandong, China has been installed and officially put into production +17 [ protected] language Advantages of HGM series ultrafine grinding production lineLimestone ultrafine grinding production line customer site

.jpg)

Grinding Portfolio Next Generation Size Reduction Bühler Group

Work across multiple application centers to optimize all processes through the production line (eg grain technology and milling solutions) and develop endtoend solutions 7 Application Center Service Workshop Nutrition Application Center Changzhou Wuxi, China Grinding Application Center Uzwil, Switzerland Grinding Application Centermaintain( grinding head) It need to change the grinding head each month: Cover Area: It based on the groups of grinding head, eg14 groups of grinding heads, the lenght of the line is 40*8 m: Production: It based on the line speed and thickness of plate, the usually production is 700 kg/ month: Speed: It could control between 1 m10m/ min 304/430 Stainless Steel Plate/ Sheet/ Coil Surface No 8/ Super 8K