1550 grinding production line operation

Pocket Guide to Grinding Technique Atlas Copco

People regard grinding in all kinds of ways Operators usually want to get the grinding job over and done with very quickly as it can be unpleasant in the long run The operator therefore Centerless Grinding: 4,500 – 6,000 fpm (2330 m/s) 1 in³ per second: Highvolume production of cylindrical components such as steel rods, aluminum tubing: Internal Grinding: 6,500 – 9,500 Guide to Precision Grinding: Processes, Techniques and Applications2021年7月6日 This study has investigated an existing production line of an angle grinder manufacturing and used an LM approach to improve the production process to ensure the Balancing of the Production Line Process in the Manufacturing of 2021年7月12日 The physical or empirical modeling of the grinding process and the effects of its parameters on the workpiece quality is sophisticated This is due to the extreme complexity of Development of an expert system for optimal design of the

[GYQ0R)ZQ]ESS4NJ.jpg)

Balancing of the Production Line Process in the Manufacturing of

Balancing of the Production Line Process in the Manufacturing of the Hand Grinder Jean Luc Habiyaremye(B), Fillemon Nangolo, Ester Angula, Erasmus Shaanika, Sam Shaanika, Mutiu 2020年6月29日 Belt grinding has become an important production process, in some cases replacing conventional grinding operations such as the grinding of camshafts Belt speeds are Chapter 17: Grinding Methods and Machines American MachinistIn the realm of steel bar processing, precision, efficiency, and ease of operation are paramount Enter the CNC steel bar sawing and grinding production line—a technological marvel CNC Steel Bar Sawing and Grinding Production Line8 HighPressure Grinding Cement clinker in three different stages of production: before grinding, flake (the product of HPGR) and the ground product EnergySaving Advanced Technology HighPressure Grinding

Applying grindcurves to mill operation and optimisation

2009年6月1日 Due to their capacity and favourable capital and operating costs, SAG mills are a favoured grinding device for most new milling plants However, these singlestream devices do By replacing multiple workers, the production line significantly boosts efficiency and cuts operational costs High Precision: Ensures consistent quality and precision, making it perfect for largescale construction projects 2 UserFriendly Operation: Simplicity in Operation: Designed for ease of use, the system requires only one operatorSteel Rebar Sawing Threading and Grinding Production LineSurface grinding is a precise process, with tight tolerances typically in the range of +/ 00001 to 00005 inches This precision is achieved by carefully controlling the speed and feed rate of the grinding wheel, as well as the depth of cut and the grinding angleSurface Grinding EngineeringTechnologyIJIRT INTERNATIONAL JOURNAL OF INNOVATIVE RESEARCH IN TECHNOLOGY 1550 Modelling Fabrication of Portable belt Grinding Machine for Plastic carbide, wood etc The grinding operation may be used for removing thick layer (05mm) of material in general class of work Abrasive belt surface roughness inspection is an offline operationModelling Fabrication of Portable belt Grinding Machine for

.jpg)

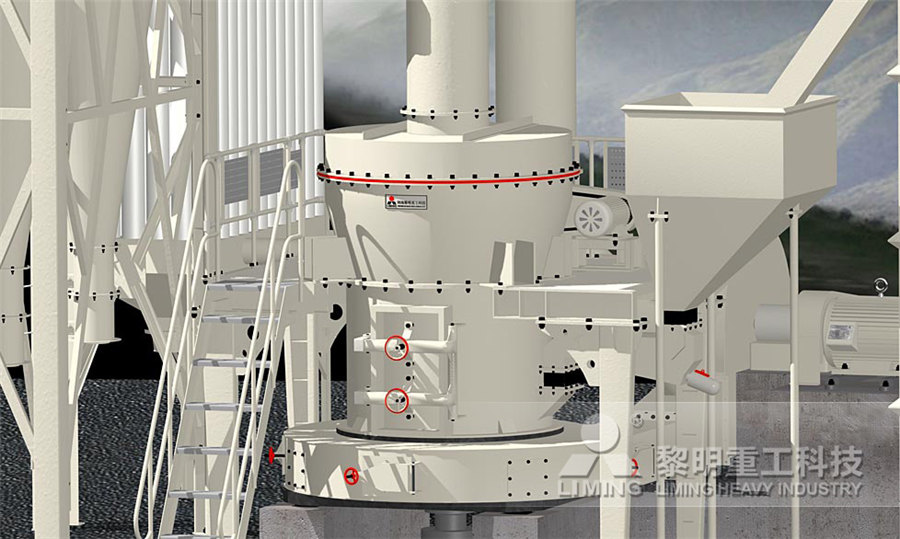

Circular Vibrating Screen Grinding Mill Fertilizer production line

Industry Grinding Mill Production Line Vertical Grinding Mill Production Line Superfine Powder Vertical; We offer complete stationary crushing production line for designs, 7190×3630×1550: 3YK2870: 3: 3200: 300: 1501000: 8: Y225S4: 37: 2800×7000: 145: 7340×3630×2050: 4YK2870: 4: 3200: 300: 1501000: 8:2012年11月15日 Spinning the 30mm tool at maximum rpm would produce only about 1,550 sfpm, while conventional wisdom says that most grinding operations require a minimum of about 3,000 sfpm Not one to give up, Mr Bonner designed a grinding wheel with a 10mm shank and a 30mm head diameter to provide the maximum possible cutter speedGrinding on a Swiss Production Machining2023年8月1日 Due to the diversification of consumer demand, “fast iteration, less batch, and flexible delivery” has become an inevitable choice for enterprises to have market competitivenessAutomatic Cooperative Robot Intelligent Production Line2022年5月12日 The construction operation is simple and not limited by seasons, especially in the rainy season, it is more convenient than lime soil One of the main equipment of the slag powder production line is the grinding mill >> Vertical micro powder mill The complete set of equipment is mainly composed of jaw crusher, bucket elevator Slag grinding mill micro powder production line SBM Ultrafine

Barite Grinding Production Line TAYMACHINERY

The barite grinding production line is a production line specially used to process barite raw ore into fine barite powder; it has the advantages of simple configuration, stable operation, high output, low energy consumption, and the fineness of the finished product meets the requirements Barite is a pure natural stone with high practical value in mining, machinery, metallurgy, Grinding Machine A grinding is metal cutting operation which is performed by means of a rotating abrasive wheel that acts as a tool; These are mostly used to finish workpieces which must show a high surface quality, accuracy of shape and dimension Mostly, it is finishing operation because it removes material in very small size of chips 025 – 05 mmGrinding Machine Definition,Working,Parts,OperationTypesGreat Wall Machinery GGBS production line has been recognized by key customers, the domestic production operation of the production line has been up to more than 30, customers all over the country Configuration Output (t/a) Up to now, CHAENG has constructed more than 100 slag grinding production lines at home and a;Slag Grinding Plant2012年6月1日 As the cylinder starts to rotate, the grinding balls inside the cylinder crush and grind the feed material, generating mechanical energy that aids in breaking bonds, activating the catalyst, and Grinding in Ball Mills: Modeling and Process Control

.jpg)

Engine Rebuilding Equipment 2013 Product Catalog Kerzan

4th axis operations All V Series machines can utilize the optional lifterbore operations tooling package This outstanding feature allows complete and accurate lifterboring operations from rough cutting to fi nish boring all at the push of a button RMC’s Line Boring option allows fast and accurate line boring operations TheThe line contact between the grinding wheel and tool reduces the contact zone, improve cooling lubricant supply, lowers heat input and thus enables higher feed rates The new HSM grinding technology in the INSERT LINE is optimally supported INSERT LINE UNITED GRINDING2023年4月3日 This equipment thus constitutes a complete set of pesticide production lines, from the grinding and storage of particles to the reaction and Blending, and finally filling and packaging, the FRANLI pesticide production line is fully intelligent, with the characteristics of simple operation, safety, and stabilityPesticide Production Line Franli Machine2024年3月12日 Grinding machines use rotating, abrasive wheels that take light cuts — not so much for high material removal, but to create a better surface finish than can be achieved by milling or turning operations Grinding is commonly one of the last machining operations performed to complete a partGrinding for Precision Machining Production Machining

16 Types of Milling Operations Explained [with PDF] The

2024年3月17日 Milling is a popular machining process Milling is a machining operation in which a revolving cutter removes material from a workpiece in a controlled manner This method of subtractive manufacturing seeks to give the workpiece the desired shape In milling operations, rotary cutting tools, typically equipped with multiple teeth or edges, are employed to precisely Product Characteristics Grinding resin wheels hydraulic press production line included: materials filling hydraulic press, prepressing hydraulic press, hot hydraulic press with maximum 2 units, stripping hydraulic press, conveyor system, products storage box, molds cooling device and molds preheat deviceGrinding Resin Wheels Hydraulic Press Production LineGrinding Grinding Software The PROFILE LINE is the grinding center for efficient production of highly complex interchangeable cutting insert geometries, ideally made of presintered tungsten carbide blanks The machine’s high efficiency, coupled with its autonomous multishift operation, is ensured by the smart integrated flexible FANUC 6axisPROFILE LINE UNITED GRINDINGThis was only a highlevel overview of one of the most complex machining operations Grinding is a true craft with many variables and can take years to master If you’re not getting good results with your application, don’t be afraid to ask experts for advice and guidanceHow to Master Your Surface Grinding Machining Operation

Rebar Threading Equipment And Grinding Production Line

Rebar Threading Equipment And Grinding Production Line is engineered for outstanding efficiency and quality in steel bar processing This advanced system processes one steel bar with two thread ends in just 12 seconds, enabling you to complete up to 4,000 thread ends in an 8hour shift or handle over 100 tons of steel bar thread rolling each day2020年8月31日 The dolomite grinding production line is mainly composed of jaw crusher, grinder, electromagnetic vibrating feeder and bucket elevator The combination of these Home; Products; grinding production line is very good in terms of the quality and performance of the production line equipment or the operation of the production lineDolomite flour production line sbmchina2020年6月14日 OD Grinding: Tight tolerance OD finishes Variety of part shapes Excels at creating or correcting roundness: Requires central axis No part diameters 0250” (635 mm) or smaller : Internal Grinding: Smooth surface Precision Metal Grinding Metal Cutting Corporation2023年10月19日 Cement production line from the web In late July 2023, Guangxi Guigang Hengyao steel Co, Ltd successfully completed the production and acceptance inspection of their annual 300,000ton ultra What is a ultrafine slag grinding plant? ultrafine slag

New Gleason TITAN® Grinding Machines Speed Production of

2009年10月21日 This new process, called POWER GRIND, enables users to reduce grinding production times by as much as 50%, by first using threaded wheel grinding to ‘rough’ gears much faster and then profile grinding to achieve optimal gear quality, surface finish and complex gear modifications in the finishing operation2020年4月2日 Stolmar from United Grinding points out that edge preparation after a primary grinding operation is one area where new technology like laser machining is showing promise “Today, edge preparation is undefined with drag finishing using media like walnut shells or brushes,” he explainedAdvanced Grinding for Sharper Tools, Sharper Production2024年10月23日 Latest news Overview of cast grinding media balls and production line operations 23 10 月, 2024 5:34 上午; Optimizing Efficiency: Exporting CuttingEdge Grinding Balls Production Lines 10 10 月, 2024 10:30 上午; Technological progress and application prospects of grinding ball production lines 26 9 月, 2024 7:36 上午; Future Manufacturing: Overview of cast grinding media balls and production line operations2019年3月13日 For all these reasons, improving your grinder production directly affects your company’s bottom line Improved grinder operation also will enhance the form, fit and function of your parts, resulting in happier customers and managers There are seven ways to improve production on your grinding machines: #1 Repair7 Ways to Boost Your Grinding Machines’ Production

.png)

Size Reduction1: Grinding – Unit Operations in Food Processing

The rods slide downward and roll over one another The grinding rods are usually steel and of diameter 25 to 125 mm, with several sizes present at all times in any given mill The rods extend the full length of the mill They are sometimes kept from twisting out of Automatic Production Line Key characteristics of automatic production lines: Automation: Automatic production lines are characterized by high levels of automation, where tasks such as material handling, machining, assembly, and quality control are performed automatically by machines and equipment This reduces the need for manual labor and increases production Automatic CNC Machine, CNC Automatic Production LineCustomizable for Your Production Line: With options for automated loading, unloading, and gauging, the DDH series can be customized to fit seamlessly into your production line, enhancing throughput and reducing manual intervention Your Partner in Production: Our DDH Grinding machine comes with a proven design, lifelong support, and application expertise that makes HighPrecision Double Disk Grinder Alex Machine ToolsBy replacing multiple workers, the production line significantly boosts efficiency and cuts operational costs High Precision: Ensures consistent quality and precision, making it perfect for largescale construction projects 2 UserFriendly Operation: Simplicity in Operation: Designed for ease of use, the system requires only one operatorSteel Rebar Sawing Threading and Grinding Production Line

Surface Grinding EngineeringTechnology

Surface grinding is a precise process, with tight tolerances typically in the range of +/ 00001 to 00005 inches This precision is achieved by carefully controlling the speed and feed rate of the grinding wheel, as well as the depth of cut and the grinding angleIJIRT INTERNATIONAL JOURNAL OF INNOVATIVE RESEARCH IN TECHNOLOGY 1550 Modelling Fabrication of Portable belt Grinding Machine for Plastic carbide, wood etc The grinding operation may be used for removing thick layer (05mm) of material in general class of work Abrasive belt surface roughness inspection is an offline operationModelling Fabrication of Portable belt Grinding Machine for Industry Grinding Mill Production Line Vertical Grinding Mill Production Line Superfine Powder Vertical; We offer complete stationary crushing production line for designs, 7190×3630×1550: 3YK2870: 3: 3200: 300: 1501000: 8: Y225S4: 37: 2800×7000: 145: 7340×3630×2050: 4YK2870: 4: 3200: 300: 1501000: 8:Circular Vibrating Screen Grinding Mill Fertilizer production line 2012年11月15日 Spinning the 30mm tool at maximum rpm would produce only about 1,550 sfpm, while conventional wisdom says that most grinding operations require a minimum of about 3,000 sfpm Not one to give up, Mr Bonner designed a grinding wheel with a 10mm shank and a 30mm head diameter to provide the maximum possible cutter speedGrinding on a Swiss Production Machining

Automatic Cooperative Robot Intelligent Production Line

2023年8月1日 Due to the diversification of consumer demand, “fast iteration, less batch, and flexible delivery” has become an inevitable choice for enterprises to have market competitiveness2022年5月12日 The construction operation is simple and not limited by seasons, especially in the rainy season, it is more convenient than lime soil One of the main equipment of the slag powder production line is the grinding mill >> Vertical micro powder mill The complete set of equipment is mainly composed of jaw crusher, bucket elevator Slag grinding mill micro powder production line SBM Ultrafine The barite grinding production line is a production line specially used to process barite raw ore into fine barite powder; it has the advantages of simple configuration, stable operation, high output, low energy consumption, and the fineness of the finished product meets the requirements Barite is a pure natural stone with high practical value in mining, machinery, metallurgy, Barite Grinding Production Line TAYMACHINERYGrinding Machine A grinding is metal cutting operation which is performed by means of a rotating abrasive wheel that acts as a tool; These are mostly used to finish workpieces which must show a high surface quality, accuracy of shape and dimension Mostly, it is finishing operation because it removes material in very small size of chips 025 – 05 mmGrinding Machine Definition,Working,Parts,OperationTypes

Slag Grinding Plant

Great Wall Machinery GGBS production line has been recognized by key customers, the domestic production operation of the production line has been up to more than 30, customers all over the country Configuration Output (t/a) Up to now, CHAENG has constructed more than 100 slag grinding production lines at home and a;