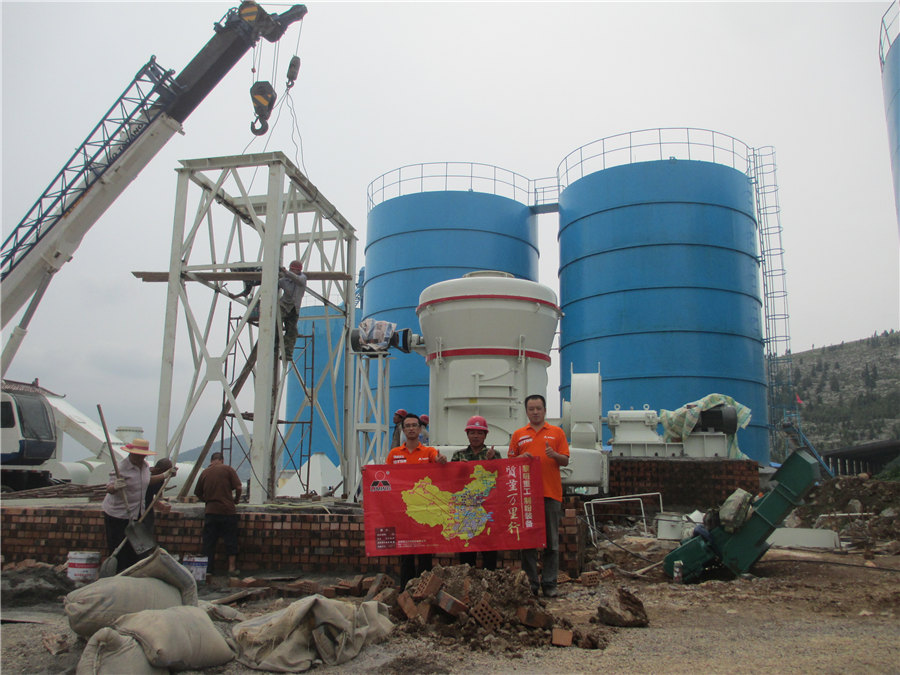

Iron oxide green T type mill

Preparation of iron oxide nanoparticles by mechanical milling

2011年1月1日 The aim of this study is to prepare iron oxide nanoparticles through dry milling using a planetary mill and to characterize the mill particles2011年1月1日 Hematite powder (Fe 2 O 3) was ground in a planetary mill and the milling time and mill rotational speed were varied at three levels The ground products were then Preparation of iron oxide nanoparticles by mechanical milling本文首先根据合成途径、纳米铁的类型介绍了利用植物和微生物对纳米零价铁(nZVI)及纳米铁氧化物(IONPs)进行绿色合成的方法,同时论述了制备的纳米铁所表现的特征(如形貌、尺寸 纳米铁的绿色合成及其在环境中的应用研究进展 cip2023年5月4日 Different models of isotherm and kinetic adsorption of Cd 2+ and Ni 2+ on green iron oxide nanoparticles were applied to obtain and find the most suitable model to explain the Green synthesis and characterization of iron oxide nanoparticles

Green Synthesis: An Ecofriendly Route for the Synthesis of Iron

2021年5月31日 PDF Green approach has received major attention for the synthesis of metal oxide nanoparticles One such metal oxide nanoparticles are iron oxide Find, read and cite 2021年5月17日 This article presents results of experiments using the TG/DTA thermal analysis method aimed at verifying the possibility of recovering iron from the mill scale by a reduction Recovery of Iron from Mill Scale by Reduction with Carbon 2024年2月17日 In this study, which covers various processes in several stages, the solution of iron in MS, which is the Iron and Steel Industry (ISI) waste, as FeCl 3 (MSFeCl 3) in the Green industry work: production of FeCl3 from iron and steel This review provides an overview of various reports of green synthesised zero valent metallic iron (ZVMI) and iron oxide (Fe2O3/Fe3O4) nanoparticles (NPs) and highlights their substantial Green Synthesis of Iron Nanoparticles and Their Environmental

.jpg)

An Overview Analysis of Current Research Status in Iron Oxides

2024年5月17日 Using biomass as a renewable carbon source for iron ore reduction in blast furnaces significantly cuts CO 2 emissions compared to conventional coal and coke2021年1月1日 Mill Scale is a byproduct of the rolling mill in steel hot rolling processes It contains both iron in elemental form and three types of iron oxides: wustite (FeO), hematite (αFe 2 O 3), and magnetite (Fe 3 O 4)It usually contains around 70% iron with traces of nonferrous metals and alkaline compounds [1]Mill Scale is treated as a waste byproduct by the steel Overview on production of reduced iron powder from mill scale HEADTOHEAD: Blast Furnace Vs Electric Arc Furnace Comparing Greenhouse Gas Emissions Intensity for Steelmaking The difference in inputs and processes between the BFBOF (extractive) and EAF (circular) How to Make Steel: Blast Furnace Vs Electric Arc Furnace2570985: Iron hydroxide oxide yellow (no separate registration needed for hydroxides)2157218: Iron oxide 3 Although EINECS number 305 438 9 (Slimes and sludges, steel rolling) could also be used for mill scale, this won’t certainly be used to register mill scale in the end So 3054389 won’t be used for registrationPosition paper on Iron Oxide and Mill Scales Eurofer

.jpg)

Synthesis of Iron Oxide Pigments from Iron Waste (Mill Scale)

Synthesis of Iron Oxide Pigments 315 22 Methods to Synthesis of Iron Oxide Pigments The synthesis of a welldefined color pigment is done according to several processes Thus, we proceed as follows (Table 1): Table 1 Reaction equations for the production of different iron oxide pigments Color Reac on Process Red 6 FeSO 4x H 2O+ ½O 2 Fe 2O Iron oxide pigment The brown color indicates that iron is at the oxidation state +3 Green and reddish brown stains on a limestone core sample, respectively corresponding to oxides/hydroxides of Fe 2+ and Fe 3+ Iron oxides feature as ferrous or ferric or bothThey adopt octahedral or tetrahedral coordination geometryOnly a few oxides are significant at the earth's Iron oxide Wikipedia2023年11月8日 The rise of antimicrobial resistance caused by inappropriate use of these agents in various settings has become a global health threat Nanotechnology offers the potential for the synthesis of nanoparticles (NPs) with antimicrobial activity, such as iron oxide nanoparticles (IONPs) The use of IONPs is a promising way to overcome antimicrobial resistance or Iron Oxide Nanoparticles: Green Synthesis and Their MDPIThe amount of mill scale generated in a rolling mill depends on the type of the reheating furnace and on the practice of rolling adopted in the mill It is generally in the range of 1 % to 3 % of the weight of the steel rolled Mill scale mill scale is a layered and brittle material, composed of iron oxides with wustite as a predominant phaseMill Scale IspatGuru

Synthesis, Properties, and Applications of Iron Oxides: Versatility

2021年5月18日 21 Iron (III) Oxides Iron (III) oxide is, of course, a compound that exhibits four different crystalline polymorphs: αFe 2 O 3, βFe 2 O 3, γFe 2 O 3, and εFe 2 O 3Hematite and maghemite usually appear in nature, while beta and epsilon structures are generally synthetic oxides [10, 11]In general, the iron (III) oxides anions arrange in closepacked structures, 2023年7月7日 Moreover, the MIC of the Green synthesized Iron Oxide NPs showed outstanding results against various bacterial strains The synthesized NPs have shown better Photothermal, photo(PDF) Synthesis, characterization, and applications of iron oxide 2023年3月23日 life by 2030, it is crucial to s tart investing in green steel technologies during the 2020s 9 B y using shaft furnaces, iron oxide can be directly reduced by methane (C H 4 )derived syngas, a Green steel: design and cost analysis of hydrogenbased direct iron 2023年6月28日 Green synthesis has emerged as a promising and ecofriendly approach for the synthesis of nanoparticles, including iron and iron oxide nanoparticlesGreen Engineering of Iron and Iron Oxides by Different Plant

[PDF] Iron Oxide Nanoparticles Derived from Mill Scale Waste as

2017年10月1日 In this work, iron oxide were derived from millscale has been used as a potential scavenging agent in wastewater treatment due to its high adsorption capacity and its shorter sedimentation time during wastewater treatment Iron oxide obtained from the magnetic separation technique was subjected to high energy ball milling (HEBM) at different milling time 2022年6月10日 Recovery of Zinc and Iron from Steel Mill Dust—An Overview of ash and iron oxide scale, can be directly used in the sintering A hydrocyc l one is a type of we t par t icle siz e cl assi Recovery of Zinc and Iron from Steel Mill Dust—An 2022年8月23日 Chemical analysis has shown that Mill scale contains 7236% total iron in the form of iron oxides ( FeO (312%), Fe 3 O 4 (3352%), Fe 2 O 3 (346%) Thermal analysis by DSC shows exothermic peak which corresponds to dehydration and deoiling of Mill scale and endothermic peak indicating a possible recrystallization of iron oxides (FeO) which is stable Synthesis of Iron Oxide Pigments from Iron Waste (Mill Scale)2022年1月1日 Mill scale is one of solid waste materials in steel This work treat the valorization of Mill scale and transformed it into an iron oxide pigments with a high value (nontoxic chemically stable Synthesis of Iron Oxide Pigments from Iron Waste (Mill Scale)

Recovery of Iron from Mill Scale by Reduction with Carbon

Minerals 2021, 11, 529 4 of 12 After thermal analysis, the samples were subjected to further chemical composition analyses Total iron content was determined by Atomic Absorption Spectrometry (ASA)2024年8月5日 The transition to green steel production is pivotal for reducing global carbon emissions This study presents a comprehensive technoeconomic analysis of various green steel production methods, including hydrogen reduction and three different electrolysis techniques: aqueous hydroxide electrolysis (AHE), molten salt electrolysis, and molten oxide electrolysis Economics of Electrowinning Iron from Ore for Green Steel 1997年1月1日 The advantages of lime over bentonite as a binder for pelletising iron ores, especially of the magnetite type, are indicated and laboratory studies on pellet production with lime describedThe role of calcium hydroxide in the production of iron oxide ( mill 2023年1月1日 Moreover, the MIC of the Green synthesized Iron Oxide NPs showed outstanding results against various bacterial strains The synthesized NPs have shown better Photothermal, photo(PDF) Synthesis, characterization, and applications of iron oxide

Recycling of steel plant mill scale via iron ore ResearchGate

2009年8月1日 Mill scale is an iron oxide waste generated during steelmaking, casting and rolling Total generation of mill scale at JSWSL is around 150 t/day and contains 60–70%FeO and 30–35%Fe2O32021年1月1日 The word “iron” was originated from the word “iren” in AngloSaxon [1]Some linguistics speculated that the word “iron” was derived from Etruscan aisar, meaning the “gods” [2]The symbol “Fe” was taken from the Latin word ferrum meaning “holy metal,” which was used to prepare the crusades in earlier days People have been using iron for more than 5000 years Green synthesis of iron oxide nanoparticles using plant extracts and 2022年1月13日 Irondoped copper chromate with (FexCu1–xCr2O4) as a black ceramic decoration pigment is successfully synthesized using a solidstate synthesis method with a pure oxide precursorEffect of Annealing Temperature of BrownishRed 2013年2月23日 Recrystallization of iron oxides is essentially a physical process in which smaller particles consolidate into larger ones with the loss of surface energy During the recrystallization of iron oxides, continued growth of iron Introduction to Iron ore Pellets and Pelletizing

.jpg)

Green Synthesis of Iron Oxide Nanoparticle Using Coffee Seed

2021年12月15日 Green Synthesis of Iron Oxide Nanoparticle Using Coffee Seed Extract and Its Antibacterial Activity Based on a report by Pavani et al, 20 the E g range for γ typeFe 2 O 3 is 20 to 22 eV Green rust (SO 2−4) synthesized under anaerobic conditions in the absence of dissolved oxygen Green rust is a generic name for various green crystalline chemical compounds containing iron(II) and iron(III) cations, the hydroxide (OH −) anion, and another anion such as carbonate (CO 2− 3), chloride (Cl −), or sulfate (SO 2− 4), in a layered double hydroxide (LDH) structureGreen rust WikipediaThis work refers to the study of the conditions of mill scale reduction, a byproduct of iron and stee l formed during the hot rolling of steels, with a reducing gas (car bon monoxide) in order to produce iron powder having characteristics required by powder metallurgy The reduction was carried out at various temperatures ( 7501050°C) during different times ranging between 40 Elaboration of iron powder from mill scale Semantic Scholar2021年5月17日 The mill scale is a waste from the iron and steel industry Due to the high content of iron in the form of oxides, it is an attractive material for the recovery of metallic iron by reduction The product of mill scale reduction is an iron with a very extended surface and a high affinity for oxygen The smaller iron particles are, the easier it is for spontaneous rapid Recovery of Iron from Mill Scale by Reduction with Carbon

(PDF) Production of Reduced Iron from Mill Scale Waste Using

2023年1月1日 Mill scale (MS) has a potential to use as an iron source because of its high iron content MS mainly consists of a mixture of iron oxides, metallic iron and other base metal oxides2020年9月17日 This work aims at conversion of mill scale to produce valueadded pigment grade red iron oxide by multistep process, such as milling, acid treatment, mixing with redox reagents and calcinationSynthesis and Characterization of Pigment Grade Red Iron Oxide Iron Oxide has shown excellent photothermal activities due to: Good biocompatible nature, and better optical and physical properties[3942] From the literature study it is cleared that Iron Oxide nanoparticles have good photothermal activity in light, which could be due to their better super magnetic activity, NIR absorption and itself a photothermal agentSynthesis, characterization, and applications of iron oxide 2021年1月1日 Mill Scale is a byproduct of the rolling mill in steel hot rolling processes It contains both iron in elemental form and three types of iron oxides: wustite (FeO), hematite (αFe 2 O 3), and magnetite (Fe 3 O 4)It usually contains around 70% iron with traces of nonferrous metals and alkaline compounds [1]Mill Scale is treated as a waste byproduct by the steel Overview on production of reduced iron powder from mill scale

How to Make Steel: Blast Furnace Vs Electric Arc Furnace

HEADTOHEAD: Blast Furnace Vs Electric Arc Furnace Comparing Greenhouse Gas Emissions Intensity for Steelmaking The difference in inputs and processes between the BFBOF (extractive) and EAF (circular) 2570985: Iron hydroxide oxide yellow (no separate registration needed for hydroxides)2157218: Iron oxide 3 Although EINECS number 305 438 9 (Slimes and sludges, steel rolling) could also be used for mill scale, this won’t certainly be used to register mill scale in the end So 3054389 won’t be used for registrationPosition paper on Iron Oxide and Mill Scales EuroferSynthesis of Iron Oxide Pigments 315 22 Methods to Synthesis of Iron Oxide Pigments The synthesis of a welldefined color pigment is done according to several processes Thus, we proceed as follows (Table 1): Table 1 Reaction equations for the production of different iron oxide pigments Color Reac on Process Red 6 FeSO 4x H 2O+ ½O 2 Fe 2O Synthesis of Iron Oxide Pigments from Iron Waste (Mill Scale)Iron oxide pigment The brown color indicates that iron is at the oxidation state +3 Green and reddish brown stains on a limestone core sample, respectively corresponding to oxides/hydroxides of Fe 2+ and Fe 3+ Iron oxides feature as ferrous or ferric or bothThey adopt octahedral or tetrahedral coordination geometryOnly a few oxides are significant at the earth's Iron oxide Wikipedia

.jpg)

Iron Oxide Nanoparticles: Green Synthesis and Their MDPI

2023年11月8日 The rise of antimicrobial resistance caused by inappropriate use of these agents in various settings has become a global health threat Nanotechnology offers the potential for the synthesis of nanoparticles (NPs) with antimicrobial activity, such as iron oxide nanoparticles (IONPs) The use of IONPs is a promising way to overcome antimicrobial resistance or The amount of mill scale generated in a rolling mill depends on the type of the reheating furnace and on the practice of rolling adopted in the mill It is generally in the range of 1 % to 3 % of the weight of the steel rolled Mill scale mill scale is a layered and brittle material, composed of iron oxides with wustite as a predominant phaseMill Scale IspatGuru2021年5月18日 21 Iron (III) Oxides Iron (III) oxide is, of course, a compound that exhibits four different crystalline polymorphs: αFe 2 O 3, βFe 2 O 3, γFe 2 O 3, and εFe 2 O 3Hematite and maghemite usually appear in nature, while beta and epsilon structures are generally synthetic oxides [10, 11]In general, the iron (III) oxides anions arrange in closepacked structures, Synthesis, Properties, and Applications of Iron Oxides: Versatility 2023年7月7日 Moreover, the MIC of the Green synthesized Iron Oxide NPs showed outstanding results against various bacterial strains The synthesized NPs have shown better Photothermal, photo(PDF) Synthesis, characterization, and applications of iron oxide

.jpg)

Green steel: design and cost analysis of hydrogenbased direct iron

2023年3月23日 life by 2030, it is crucial to s tart investing in green steel technologies during the 2020s 9 B y using shaft furnaces, iron oxide can be directly reduced by methane (C H 4 )derived syngas, a