What is the wind speed of the vertical mill nozzle ring

Vertical raw mill pradeep kumar PPT Free Download

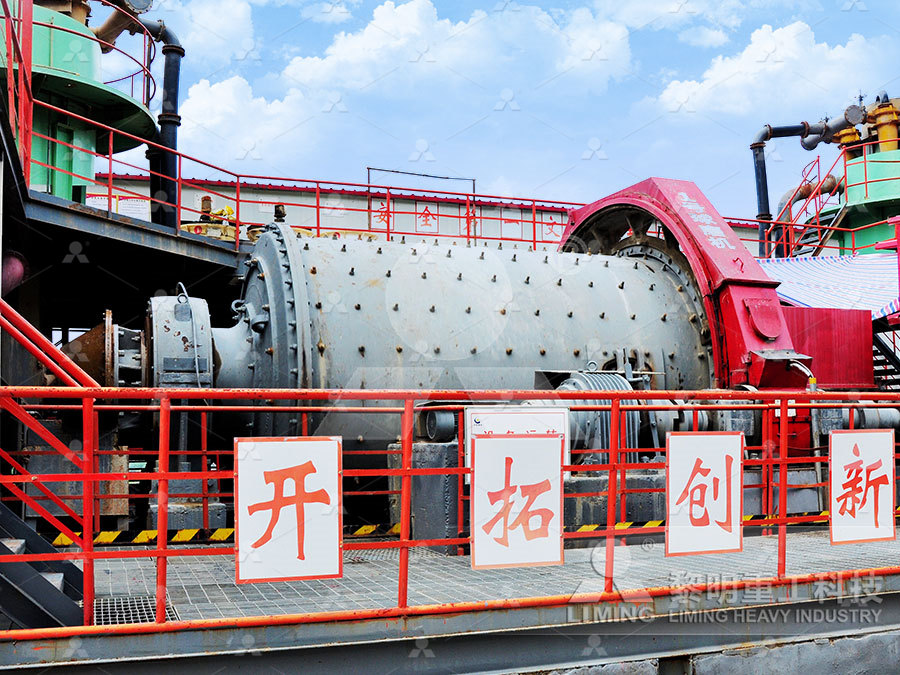

2013年5月15日 In the test production grinding to find the right pressure and wind pressure can form a reasonable good internal circulation, so that the material layer disc proper, stable, high grinding efficiency In the production Vertical Roller Mills Pressure Profile Draw Up Curve Influenced by: •Mill Inlet Pressure •Nozzle Ring Coverage •Classifier Speed •Dam Ring Height •Mill Load •Material Blockage in Hot Gas Optimization of VRM Operation RUCEMRU1) The document contains calculations of nozzle ring areas and velocities for a raw mill 2) It lists the dimensions (A, B, C) and calculated areas of 16 nozzle rings between each pair of 4 rollers in the raw mill 3) It provides site A Raw Mill Nozzle Ring Area Velocity Calculation: 1/2 Important internals are the nozzle ring, which controls material fall through its area and velocity, and the dam ring, whose optimum height is 254% of the table diameter An example heat balance is provided for a 200 tonne per hour mill Vertical Mill Calculations PDF Mill (Grinding) Nozzle

PROCESS TRAINING for operators of Vertical RAW Mills

The amount of rejected material (spillage material) mainly depends on the grain size of the feed material (mass of particles) and the speed of the air in the nozzle ring The feed grain size [mm] can be adjusted by the crusher and should be The grinding pressure has components from the roller weight and hydraulic system Key internals are the nozzle ring, which controls material fall through, and the dam ring, typically 254% of the table diameter An example heat balance Vertical Mill Calculations PDF Mill (Grinding) Nozzle Vertical roller mills are adopted in 20 cement plants (44 mills) in Japan In the vertical roller mill which is widely used in the raw material grinding process, raw materials input grinding table Vertical roller mill for raw Application p rocess materialsAs a countermeasure for uneven velocity gas flowing into the separator, UBE installed a nozzle ring of ideal form to achieve optimized gas speed To correct the uneven velocity gas flowing VERTICAL ROLLER MILLS AMCL

.jpg)

Vertical roller mill Wikipedia

Vertical roller mill is a type of grinder used to grind materials into extremely fine powder for use in mineral dressing processes, paints, pyrotechnics, cements and ceramics It is an energy The MPS mill also grinds, dries, calcines, and classifies gypsum without any problem, all in a single machine, for any fineness requested and considering individual requirements The MPS vertical roller mill built to last, reliable and Coal mill, gypsum mill, clay mill, etc Pfeiffer MPS millsNozzle ring Segmented grinding track and carrier Grinding track support Tensioning rods with hydraulic cylinder Bevel spur gea ing KV Figure 2 First Generation MPS Mill with spring grinding force loading system The standard mill capacity for twenty (20) different mill sizes ranges from 10 tph to 190 tph (Figure 3) o RPI MPS Mill Standard CapacityCoal Pulverizer Design Upgrades to Meet the Demands of Low 2017年8月1日 There are two kinds of wind turbines according to the axis of rotation to the ground, horizontal axis wind turbines (HAWT) and vertical axis wind turbines (VAWT)Review Paper: Overview of the Vertical Axis Wind

64: The Physics of a Wind Turbine Engineering

But for wind speed \( \gt 25 \mathrm{~m} / \mathrm{s}\) it is no longer safe to let the rotor turn – so the blades are set to a neutral position in which they generate no torque and a special electromagnetic brake is engaged to completely Verticalaxis wind turbines come in one of two basic types: the Darrieus wind turbine, which looks like an eggbeater, and the Savonius turbine, (BWEA) rated power is 85 kW aerodynamic power, which is rated at a wind speed of 16 m/s After converting to electrical power, the output is 70 kW DC or 65 kW gridquality ACVerticalAxis Wind Turbine (VAWT): Working, Types, Advantages due to its vertical design, less wind speed is readily available to harness, Graphical representation in figures 3 and 4 illustrates the rise in wind velocity with nozzle system The effective utilization of kinetic energy of air is occurred at 450 of Design and Performance of a Ducted Wind Mill”, College of Aeronautics, Report 102 Increasing The Theoretical Power Coefficient of A Vertical Axis Wind What is Vertical Axis Wind Turbine or VAWT? The Vertical Axis Wind Turbine is a type of wind turbine and it is most frequently used for residential purposes to provide a renewable energy source to the home This turbine includes the rotor shaft and two or three blades where the rotor shaft moves vertically So, this turbine movement is related to the spinning of coins on the edgeWhat is Vertical Axis Wind Turbine : Working Its Applications

(PDF) VERTICAL AXIS WIND TURBINE ResearchGate

2022年4月6日 The vertical axis wind turbine is renowned for its simple design, low maintenance and low cost over the Horizontal axis wind turbine [1] [2] [3] But as the solidity (ratio of blade area to swept 2015年12月3日 Rolling of steel in Hot Strip Mill satyendra; December 3, 2015; 2 Comments ; AGC, edger, finishing mill, hot strip mill, Laminar cooling, rolling speed, scale breaker, slab roughing mill, tension,; Rolling of steel in Hot Strip Mill Hot strip mills in these days are either conventional hot strip mills or strip mills for rolling thin slabsRolling of steel in Hot Strip Mill – IspatGuru2022年12月1日 Renewable technologies are the focus of today’s energetic scenario In this context, vertical axis wind turbines (VAWT) Due to the contraction ratio of 16:1 in the nozzle, the wind velocity in the settling chamber is assumed negligible For Performance assessment of vertical axis wind turbines (VAWT) Vertical Roller Mills Pressure Profile Draw Up Curve Influenced by: •Mill Inlet Pressure •Nozzle Ring Coverage •Classifier Speed •Dam Ring Height •Mill Load •Material Blockage in Hot Gas Channel •Size and Condition of Filter / Cyclone •Air Flow NegativeOptimization of VRM Operation RUCEMRU

Piping Design Considerations for Vertical Columns

Operator Access – Proper headroom clearance should be available for safe operator access to the column; Maintenance Access– Proper maintenance access clearance should be available for the safe movement of maintenance ring rolled by SFGM (2) With the same feed amount, the outer radius of the ring rolled by SFGM is always larger than that of the rings rolled by SFUGM (3) During the rolling process of the ring rolled by SFGM, severe eccentricity will exist at the ring’s center, which is not obvious in the rolling process of the ring rolled by SFUGMAnalysis of guide modes in vertical hot ring rolling and their 2023年8月22日 Vertical axis wind turbines present many advantages compared with horizontal axis ones despite their low performance Thus, mechanisms, which aim to improve VAWT performance, are still in continuous development and investigation The present paper aims to contribute to this improvement by proposing a mechanism for an HDarrieus wind turbine and Numerical and experimental investigations of a vertical wind 2014年6月1日 This paper introduces the wind power generator using horizontal axis wind turbine with convergent nozzle This paper brings a detailed theoretical and practical study of air concentrating nozzle and the optimum nozzle dimensions have been analyzed in detail Commercial CFD software which is used for the nozzle with different tapering angle has also [PDF] Wind power generator using horizontal axis wind turbine

An investigation of performance characteristics and energetic

2020年8月12日 This study shows the performance of a currently running vertical roller coal mill (VRM) in an existing coalfired power plant In a power plant, the coal mill is the critical equipment, whose 2023年6月1日 This study aims to improve the output and production efficiency of a large vertical mill by optimizing its operational parameters This paper takes a large vertical mill in LGM as the object, a numerical calculation method of particle–fluid coupling system in large vertical mill based on CFDDPM theory, and a multiobjective optimization method of operating parameters of Operation parameters multiobjective optimization method of 2015年7月21日 As a result, a shrouded wind turbine equipped with a flanged diffuser has been developed, and demonstrated power augmentation for a given turbine diameter and wind speed by a factor of about 4–5 Increasing Efficiency of a Wind Turbine Using a Convergent Nozzle 2023年9月9日 Definition and overview of Vertical Axis Wind Turbines (VAWTs) The overview and definition of VAWTs can help us understand how these turbines function A verticalaxis wind turbine (VAWT) is a type of wind turbine where the main rotor shaft is set vertically Unlike horizontalaxis wind turbines (HAWTs), VAWTs can operate regardless of wind The Ultimate Guide To Vertical Axis Wind Turbines Green Life Zen

Sprayer Nozzle Guide: 21 Common Questions Answered

Then input this flow rate along with your speed and nozzle spacing into this formula: *Spacing is measured in inches Example: 5940 x 020 gallons per minute / 4 mph x 15 inches = 198 Gallons per acre output from your sprayer You can also find your gallonper The objective of the current review is to present the development of a large vertical axis wind turbine (VAWT) since its naissance to its current applications The turbines are critically reviewed in terms of performance, blade configuration, tower design, and mode of failure The early VAWTs mostly failed due to metal fatigue since the composites were not developed Revisiting those Review on the Evolution of Darrieus Vertical Axis Wind Turbine 2022年1月19日 If the nozzle ring is worn or partially worn, the airflow will become chaotic, the stable rotational upward airflow will not be formed, and the wind speed will also be reduced, the material cannot be taken away in time, and return to the grinding disc or fall into the scraping cavity at the bottom of the nozzle ring, increasing the circulation and affecting the output 6 reasons and solutions about the capacity reduction of vertical 2021年7月4日 This article presents theoretical and experimental studies of an improved vertical axis wind power device that generates electricity in areas with an average wind speed of 3545 m/s(PDF) Study Of Effective Omnidirectional Vertical Axis

.jpg)

Effects of Blade Parameters on the Flow Field and Classification

2020年11月4日 Region Air inlet Separator outlet Separator inlet Top of wind ring Bottom of wind ring Pressure (Pa) − 1926 − 6500 − 5020 − 2447 − 2277 194 e + 年6月1日 This paper introduces the wind power generator using horizontal axis wind turbine with convergent nozzle This paper brings a detailed theoretical and practical study of air concentrating nozzle Wind power generator using horizontal axis wind turbineThe document discusses the layout, calculations, components, and heat balance of a vertical roller mill (VRM) There are two basic layouts product collection in cyclones or a filter Key calculations include power consumption, grinding pressure, and heat balance Important internals are the nozzle ring, which controls material fall through its area and velocity, and the dam ring, Vertical Mill Calculations PDF Mill (Grinding) NozzleThis is the methodology to conversion of electricity through wind energy using convergent nozzle in low wind speed area By the help of this process of conversion we convert low wind speed in sufficient power conversion with the use of nozzle Then this maximizes the wind speed, that maximum wind speed rotate fan blade at useful speed levelPower Generation through the Wind Energy Using Convergent Nozzle

.jpg)

What bearings are used in wind turbines ACORN® Insight

2020年3月23日 Slewing ring bearings are generally used in the pitch and yaw locations of a wind turbine, to enable the blades to rotate smoothly These bearings can support extremely heavy loads at slow speeds They allow the transmission of both axial and radial forces, as well as accommodating tilting momentsPROCESS TRAINING for operators of Vertical RAW Mills Heating of mill and grinding plant In fact there are three processes going on in the MPS mill namely grinding, drying and clas sifying, The speed of the air in the nozzle ring [m/s] depends on the air flow [m3/h] PROCESS TRAINING for operators of Vertical RAW Mills2020年6月29日 6 TYPES OF COAL PULVERIZER • Tube or ball mills: Lowspeed machines that grind the coal with steel balls in a rotating horizontal cylinder If the diameter of the cylinder is greater than the length of the cylinder, the mill is called a ball mill If the length of the cylinder is greater than the diameter of the cylinder, it is called a tube millclassifications and working of mills in a power plant PPTBackground technology: our domestic mediumspeed pulverizer generally uses the swivel nozzle ring as the coal pulverizer nozzle at presentThis swivel nozzle gyration ring puts together on to use through flange bolt with the coal pulverizer mill sees that figure one, this kind swivel nozzle ring structure have following 2 major defects: 1, receive its structure influence, between swivel Integrated rotating nozzle ring of mediumspeed coal mill

.jpg)

Coal Pulverizer Design Upgrades to Meet the Demands of Low

Nozzle ring Segmented grinding track and carrier Grinding track support Tensioning rods with hydraulic cylinder Bevel spur gea ing KV Figure 2 First Generation MPS Mill with spring grinding force loading system The standard mill capacity for twenty (20) different mill sizes ranges from 10 tph to 190 tph (Figure 3) o RPI MPS Mill Standard Capacity2017年8月1日 There are two kinds of wind turbines according to the axis of rotation to the ground, horizontal axis wind turbines (HAWT) and vertical axis wind turbines (VAWT)Review Paper: Overview of the Vertical Axis Wind But for wind speed \( \gt 25 \mathrm{~m} / \mathrm{s}\) it is no longer safe to let the rotor turn – so the blades are set to a neutral position in which they generate no torque and a special electromagnetic brake is engaged to completely 64: The Physics of a Wind Turbine Engineering Verticalaxis wind turbines come in one of two basic types: the Darrieus wind turbine, which looks like an eggbeater, and the Savonius turbine, (BWEA) rated power is 85 kW aerodynamic power, which is rated at a wind speed of 16 m/s After converting to electrical power, the output is 70 kW DC or 65 kW gridquality ACVerticalAxis Wind Turbine (VAWT): Working, Types, Advantages

.jpg)

Increasing The Theoretical Power Coefficient of A Vertical Axis Wind

due to its vertical design, less wind speed is readily available to harness, Graphical representation in figures 3 and 4 illustrates the rise in wind velocity with nozzle system The effective utilization of kinetic energy of air is occurred at 450 of Design and Performance of a Ducted Wind Mill”, College of Aeronautics, Report 102 What is Vertical Axis Wind Turbine or VAWT? The Vertical Axis Wind Turbine is a type of wind turbine and it is most frequently used for residential purposes to provide a renewable energy source to the home This turbine includes the rotor shaft and two or three blades where the rotor shaft moves vertically So, this turbine movement is related to the spinning of coins on the edgeWhat is Vertical Axis Wind Turbine : Working Its Applications2022年4月6日 The vertical axis wind turbine is renowned for its simple design, low maintenance and low cost over the Horizontal axis wind turbine [1] [2] [3] But as the solidity (ratio of blade area to swept (PDF) VERTICAL AXIS WIND TURBINE ResearchGate2015年12月3日 Rolling of steel in Hot Strip Mill satyendra; December 3, 2015; 2 Comments ; AGC, edger, finishing mill, hot strip mill, Laminar cooling, rolling speed, scale breaker, slab roughing mill, tension,; Rolling of steel in Hot Strip Mill Hot strip mills in these days are either conventional hot strip mills or strip mills for rolling thin slabsRolling of steel in Hot Strip Mill – IspatGuru

Performance assessment of vertical axis wind turbines (VAWT)

2022年12月1日 Renewable technologies are the focus of today’s energetic scenario In this context, vertical axis wind turbines (VAWT) Due to the contraction ratio of 16:1 in the nozzle, the wind velocity in the settling chamber is assumed negligible For Vertical Roller Mills Pressure Profile Draw Up Curve Influenced by: •Mill Inlet Pressure •Nozzle Ring Coverage •Classifier Speed •Dam Ring Height •Mill Load •Material Blockage in Hot Gas Channel •Size and Condition of Filter / Cyclone •Air Flow NegativeOptimization of VRM Operation RUCEMRU