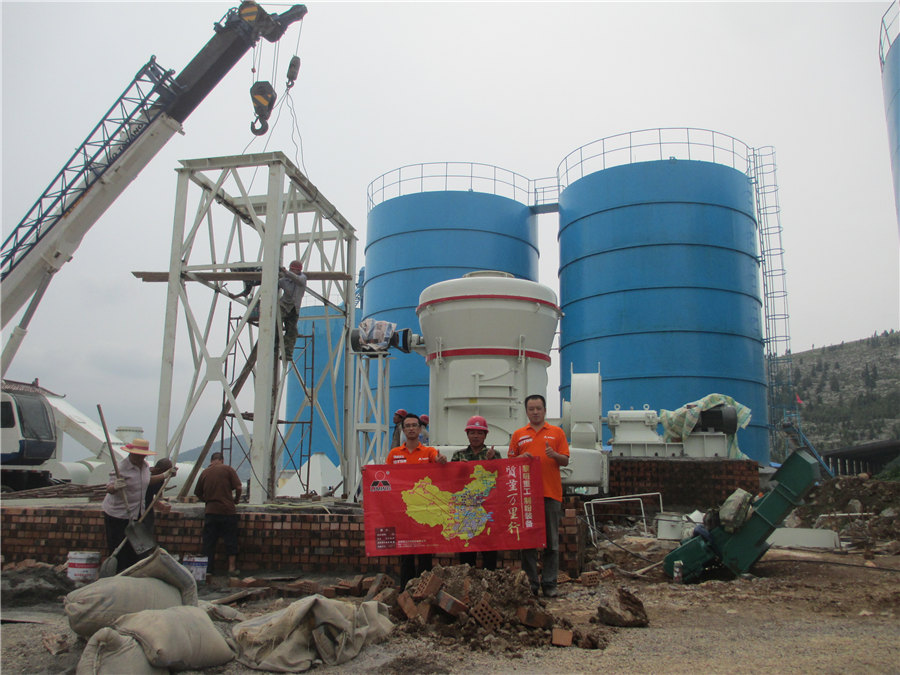

Gypsum ore powder processing Raymond mill process flow chart

.jpg)

Infrastructure and Construction Materials Guide —

Gypsum processing can be divided into three basic steps: (1) rock preparation, (2) calcining, and (3) formulating and manufacturing This is illustrated graphically with the flow chart in Figure 1 The specifics of each step will vary with the A flow diagram for a typical gypsum process producing both crude and finished gypsum products is shown in Figure 11161 In this process gypsum is crushed, dried, ground, and calcined 1116 Gypsum Manufacturing US EPAThe Raymond mill, also called Raymond roller mill, combines grinding, classifying, and if necessary, drying, in one machine to produce precisely sized powders to meet exact production specifications It is an efficient fine grinding Raymond MillThe grinding process of gypsum generally selects Raymond mill for processing operations Raymond Mill is good at high fineness grinding of nonflammable and explosive materials with Gypsum powder production line Baichy Heavy Industry

sbm/sbm raymond mill process flow diagrammd at main

Contribute to dihog/sbm development by creating an account on GitHubContribute to sili2023/sbm development by creating an account on GitHubsbm/sbm raymond mill for gypsum ore production lemd at main 1 Product Parameter Of Gypsum Powder Raymond Mill; 2 Product Introduction of Gypsum Powder Raymond Mill; 3 Working Principle Of Gypsum Powder Raymond Mill; 4 Product Advantages Of Gypsum Powder Raymon Mill 41 Gypsum Powder Raymond MillYGM Industrial Raymond Mill Discharge fineness: 80600 mesh Feed size: 35 mm Output: 0435 t/h Materials: Calcite, limestone, wollastonite, gypsum, potassium feldspar, kaolin, bentonite, barite, phosphate rock, manganese ore, YGM Industrial Raymond Mill SBM Ultrafine Powder

What is the process flow of 1250 mesh gypsum

2020年7月8日 Many gypsum powder customers commented and commented: "Clirik is an equipment factory favored and loved by customers They produce a variety of mills, such as Raymond mill, vertical mill, ultrafine mill, ultrafine 2021年8月4日 CLIRIK gypsum grinding mills are specialized in the production process of 303000 mesh gypsum powder The gypsum powder production process is obtained by grinding natural dihydrate gypsum ore (green gypsum) or industrial byproduct gypsum (desulfurized gypsum, phosphogypsum, etc) through a special mill and heating and calcining at a certain CLIRIK gypsum grinding mill for gypsum powder production process2023年11月13日 1 Crusher: Gypsum ore is initially crushed into smaller pieces in a crusher to reduce its size for further processing 2 Grinding Mill: After crushing, the gypsum ore is often ground into a fine powder using a grinding mill The grinding process further reduces the size of the gypsum particles 3 Rotary Kiln or Fluidized Bed Calciner: The calcination process, where Gypsum Manufacturing Process Gypsum Processing EquipmentTable 11161 (cont) c Typical pollution control devices generally have a negligible effect on CO 2 emissions d Factors for these operations are in Sections 1119 and 132 e References 34,8,1112 Equation is for the emission rate upstream of any process cyclones and applies only to concurrent rotary ore dryers with flow rates of 75 cubic meters per second (m3/s) or1116 Gypsum Manufacturing US EPA

.jpg)

Hematite Ore Beneficiation Flow Chart

Hematite Ore Beneficiation Flow Chart The early hematite beneficiation is mainly gravity separation with machines of jigger, centrifugal separator, spiral chute, spiral washer, shaking table can be involved and later floatation separation has been used in the hematite iron ore upgrading with floatation separator and magnetic separator involved However, these single separation 2023年2月15日 It is commonly crushed by a jaw crusher and hammer crusher, then ground by a Raymond mill and superfine mill Talc powder processing: 1 Coarse crushing: First, the talc ore is evenly sent to a jaw crusher through a vibrating feeder for coarse crushing; 2 Drying: Then the crushed ore is sent to a dryer through a bucket elevator for dying;How to Process Talc (the Softest Mineral)? FTM MachineryThe Manufacturing Process Although there are three ways of manufacturing dry laundry detergent, only two are commonly used today In the blender process favored by smaller companies, the ingredients are mixed in large vats before being packaged i will prepare washing powder and many more interested this line,how to make washing powder 10 flow chart of manufacturing process wheel washing powderGypsum powder is a product made by processing natural gypsum ore or industrial byproduct gypsum into fine powder through a series of physical and chemical treatment processes, such as crushing, grinding, calcination, etc Gypsum powder has a wide range of uses and can be used in many fields such as building materials, chemicals, medicine, agriculture, etc Usually, the Gypsum Powder Production Line Hongji Mining Machinery

.jpg)

Gypsum Plaster Manufacturing Process Gongyi

The gypsum ores are crushed into small granules of the size less than 30mm, conveyed to mills to complete selecting and separating, and then the qualified powder are delivered into fluidized bed boiler for calcinations while the rest Flow chart of low grade iron ore processing plant can be divided into three steps: crushing, grinding and dressing Low Grade Iron Ore Crushing Flow Chart Iron ore processing plant in China generally use the thick broken, broken and fine Flow Chart Of Low Grade Iron Ore Processing PlantThis gold mining and processing flow chart is the ore by Hubei mining crusher preliminary broken in, to a reasonable size broken through after lifting machine, feeder evenly into the ball, for ore crushing, grinding by ball mill After the ore Gold Mining And Processing Flow Chart2021年6月16日 This article will introduce to you 400 mesh alumina powder Raymond vertical mill Home; ABOUT US; Raymond Mill; CASE; NEWS; NEWS Position:Home>NEWS 400 Mesh Alumina Powder Processing Machine CLIRIK Raymond Miller Date: such as the fine powder processing of raw material ore, gypsum ore, coal and other materials 400 Mesh Alumina Powder Processing Machine CLIRIK Raymond

Gypsum Mining Processing Equipment Flow Chart JXSC

50TPH Diamond Extraction Process Flow Chart 60TPH Alluvial Diamond Extraction Process in Venezuela 75TPH Diamond Dense Medium Separation Process in CongoChrome Processing Plant12TPH Chromite Ore Beneficiation Process Flow 15TPH Chrome Ore Beneficiation Process in Ukraine 24TPH Chrome Ore Processing Plant in South AfricaFlow chart of low grade iron ore processing plant can be divided into three steps: crushing, grinding and dressing Low Grade Iron Ore Crushing Flow Chart Iron ore processing plant in China generally use the thick broken, broken and fine broken three sections of crushing flowsheets crushing oreFlow Chart Of Low Grade Iron Ore Processing Plant PagesRaymond mill, also known as Raymond grinding mill, Raymond roller mill, and Raymond grinder, is suitable for grinding nonflammable and nonexplosive materials The finished powder size can be adjusted between 30 and 425 mesh(0613 mm0044 mm)Gypsum Powder Processing Plant Raymond Mill PriceDownload scientific diagram 1 Steelmaking process flow chart for a typical steel mill [5] from publication: Grain refinement of high alloy stainless steels in sand and directionally solidified 1 Steelmaking process flow chart for a typical steel mill [5]

.jpg)

Flow Chart Of Coal Processing Plant Pages

Coal processing has two forms, here descripe flow chart of coal processing plant: Industrial process is the coal after the coal crusher, with the belt conveyor to quantitative feeder, to pressure the ball machine feeding by quantitative feeder uniform, sometimes need to improve the coal briquette strength, therefore, quantitative feeder and intermediate pressure ball machine can 2024年9月28日 Gypsum Powder Manufacturing Process Using HGM Micro Powder Grinding Mill ; EXPOMINA PERÚ 2024Set Off Again With a Full Harvest ; CLIRIK Ball Mill For Copper Ore Processing Plant CLIRIK CLRM Series Raymond Mill Enhances Limestone Production Efficiency in Kyrgyzstan Gypsum Powder Manufacturing Process Using HGM Micro Powder Grinding MillCoal processing has two forms, here descripe flow chart of coal processing plant: Industrial process is the coal after the coal crusher, with the belt conveyor to quantitative feeder, to pressure the ball machine feeding by quantitative Flow Chart Of Coal Processing PlantGypsum Powder Plant: Gypsum Grinding Mill Machine,Gypsum Mining Grinder Service; About us; Contact; Gypsum Powder Production Line introduce production line processing equipment Zenith Gypsum Powder Line excels in the performance of its facilities Gypsum Powder Production Line Flow Chart Relevant facilities PEW Jaw Gypsum Powder Making Production Line Manufacturer

.jpg)

Handbook on Gypsum and Gypsum Based Products (Mining, Processing

The major contents of the book are Mining, Processing, Transportation, Handling Storage, Gypsum Board, Plaster of Paris for gypsum, Plant Layout, Process Flow Chart and Diagram, Plant Machinery Suppliers and Photographs of Machineries This book is onestop guide to one of the fastest growing sector of the Gypsum and GypsumMills Powder Engineering RM Raymond Mill Manufacturer Widely applied to various nonflammable and explosive ores with Mohs hardness below 7 and moisture below 6%, such as calcium carbonate, graphite, bentonite, wollastonite, coal dust, granulating slag, coal ash, alumina, zircon sand, quartz sand, gypsum, talc, calcite, limestone, barite, dolomite, granite, RM Raymond Mill – Jinghua Powder EngineeringRaymond grinding mill is widely used to grind the calcite, limestone, talc, quartz, gypsum, feldspar, marble, wollastonite, bentonite, manganese ore, phosphate ore, ilmenite, mica, kaolin, rare earth, dolomite, barite, graphite and other nonflammable and nonexplosive materials with hardness below 7 on Mohs scale and humidity below 6%Raymond Roller Mill For Getting Coarse Powder DASWELL2013年7月22日 Gypsum Powder Processing Flow Chart: kefid Gypsum Powder Production Line Capacity List Capacity/T Ton/hour Gold Ore Refining Process Flow Chart; Gypsum Powder Production Line T/H,Gypsum Grinding Mill flow chart of gypsum powder production line Mining Quarry

What is Raymond Mill? How Does It Work? alwepo

2024年9月4日 Risks Associated with Using Raymond Mill While Raymond Mill is a valuable tool for material grinding, it is essential to be aware of potential risks that come with its operation These risks include: 1 Dust and Particle Hazards During the grinding process in a Raymond Mill, there is a notable risk of dust and fine particles being generatedChina Gypsum Grinder Mill wholesale Factory Direct Sale Copper Ore Stone Gypsum Marble Grinder Mill Raymond Grinding Mill Machine Heavy Spar Grinding Mill US$ 11500 / Piece 1 Piece Feldspar Chalk Silica Sand Powder Grinder Mill Raymond Mill for Gypsum Powder Price US$ 25800 / Piece 1 Piece (MOQ) Shanghai Zenith Mineral Co, Gypsum Grinder Mill MadeinChinaThe gypsum powder ultrafine grinding mill can grind gypsum ore into gypsum powder, which is widely used in industry, construction, medicine, and other fields +17 [ it is especially important to use a piece of stable equipment in the process of processing the gypsum powder Principle of Gypsum Powder Ultrafine Grinding MillGypsum Powder Ultrafine Grinding Mill2015年8月26日 Returning to the overall process; that is the process for the sulfide ores and the oxide ore as I said are treated differently Direct from the pit the oxide ore is piled onto large lined leach pads and the sulfuric acid The top photo shows one of these leach pads with the new thick black plastic liner visible on the right of the padCopper Mining Extraction Process Flow Chart

Gypsum Powder Raymond Mill

1 Product Parameter Of Gypsum Powder Raymond Mill; 2 Product Introduction of Gypsum Powder Raymond Mill; 3 Working Principle Of Gypsum Powder Raymond Mill; 4 Product Advantages Of Gypsum Powder Raymon Mill 41 YGM Industrial Raymond Mill Discharge fineness: 80600 mesh Feed size: 35 mm Output: 0435 t/h Materials: Calcite, limestone, wollastonite, gypsum, potassium feldspar, kaolin, bentonite, barite, phosphate rock, manganese ore, YGM Industrial Raymond Mill SBM Ultrafine Powder 2020年7月8日 Many gypsum powder customers commented and commented: "Clirik is an equipment factory favored and loved by customers They produce a variety of mills, such as Raymond mill, vertical mill, ultrafine mill, ultrafine What is the process flow of 1250 mesh gypsum 2021年8月4日 CLIRIK gypsum grinding mills are specialized in the production process of 303000 mesh gypsum powder The gypsum powder production process is obtained by grinding natural dihydrate gypsum ore (green gypsum) or industrial byproduct gypsum (desulfurized gypsum, phosphogypsum, etc) through a special mill and heating and calcining at a certain CLIRIK gypsum grinding mill for gypsum powder production process

.jpg)

Gypsum Manufacturing Process Gypsum Processing Equipment

2023年11月13日 1 Crusher: Gypsum ore is initially crushed into smaller pieces in a crusher to reduce its size for further processing 2 Grinding Mill: After crushing, the gypsum ore is often ground into a fine powder using a grinding mill The grinding process further reduces the size of the gypsum particles 3 Rotary Kiln or Fluidized Bed Calciner: The calcination process, where Table 11161 (cont) c Typical pollution control devices generally have a negligible effect on CO 2 emissions d Factors for these operations are in Sections 1119 and 132 e References 34,8,1112 Equation is for the emission rate upstream of any process cyclones and applies only to concurrent rotary ore dryers with flow rates of 75 cubic meters per second (m3/s) or1116 Gypsum Manufacturing US EPAHematite Ore Beneficiation Flow Chart The early hematite beneficiation is mainly gravity separation with machines of jigger, centrifugal separator, spiral chute, spiral washer, shaking table can be involved and later floatation separation has been used in the hematite iron ore upgrading with floatation separator and magnetic separator involved However, these single separation Hematite Ore Beneficiation Flow Chart2023年2月15日 It is commonly crushed by a jaw crusher and hammer crusher, then ground by a Raymond mill and superfine mill Talc powder processing: 1 Coarse crushing: First, the talc ore is evenly sent to a jaw crusher through a vibrating feeder for coarse crushing; 2 Drying: Then the crushed ore is sent to a dryer through a bucket elevator for dying;How to Process Talc (the Softest Mineral)? FTM Machinery

flow chart of manufacturing process wheel washing powder

The Manufacturing Process Although there are three ways of manufacturing dry laundry detergent, only two are commonly used today In the blender process favored by smaller companies, the ingredients are mixed in large vats before being packaged i will prepare washing powder and many more interested this line,how to make washing powder 10 Gypsum powder is a product made by processing natural gypsum ore or industrial byproduct gypsum into fine powder through a series of physical and chemical treatment processes, such as crushing, grinding, calcination, etc Gypsum powder has a wide range of uses and can be used in many fields such as building materials, chemicals, medicine, agriculture, etc Usually, the Gypsum Powder Production Line Hongji Mining Machinery