Kaolin iron removal and whitening powder making process and equipment

Technique for efficiently removing iron from kaolin

The invention relates to a technique for efficiently removing iron from kaolin by magnetic separation, which is characterized by comprising the following steps: (1) purifying kaolin raw ore2022年7月13日 The iron removal and purification of kaolin can be described as an important means to improve the added value and application effect of kaolin Use flotation, magnetic separation or oxidation and other beneficiation to The Method of Iron Removal and Purification from 2024年11月21日 The kaolin iron removal process is a critical step in producing some of the world’s finest ceramics and clays Iron is the main impurity ore for the purification and whitening of kaolin Its occurrence state is diverse, often in the Purifying Kaolin: Removing Iron Impurities Made Easy2019年4月25日 In order to study the green preparation technology of refined kaolin, taking sandy kaolin from Jiangxi as a research object, process mineralogy, iron removal and Study on Iron Removal and Whitening of Sandy Kaolin from

Refinement of industrial kaolin by removal of ironbearing

2017年6月1日 Iron oxide in kaolin can be removed by physical separation, eg flotation or magnetic separation, or by chemical leaching processes using chemicals such as Na 2 SO 3, 2017年7月1日 Kaolin bleaching by TD can be conducted at near neutral pH This study reports a series of experiments conducted to evaluate the suitability of thiourea dioxide (TD) under ball Iron removal from kaolin using thiourea dioxide: Effect of ball Elimination of iron from kaolin using either a chemical or a biological method was the aim of this study The chemical leaching of iron from kaolin was carried out using response surface Iron Removal from Kaolin Waste Dumps by Chemical (Oxalic and 2023年2月20日 To effectively improve Kaolin brightness, purification methods are adopted The purification aims to remove colored impurities (iron, titanium, etc) and sandy minerals (quartz, 3 Incredibly Useful Methods for Purifying Kaolin (And Machines)

.jpg)

Iron removal from kaolin by oxalic acid using a novel preagitating

The white kaolin sediment at the end of the leaching process under optimum conditions (ie 97°C for 60 min with an L/S ratio of 4, oxalic acid concentration of 03 M and stirring speed of 800 It can treat diarrhea, mouth sore, ulcers, and also helps in tablets productionControlling the level of viscosity is a problem in the adhesive industry, but including kaolin during production with an enclosed mixing system for Kaolin making equipment Making2023年3月10日 Activated bamboo charcoal, also known as bamboo activated carbon, is a highly porous material that is widely used for its ability to adsorb impurities and pollutants as we all know, It is produced by heating bamboo at The Art of Making Activated Bamboo Charcoal: Kaolin common wet beneficiation process and equipment May15,2023 Why should kaolin remove iron Iron is the main Guangdong Shantou kaolin sand making EPC project overview The customer belongs to a local concrete company in Shantou CityKaolin common wet beneficiation process and equipment

Iron removal from a kaolinitic clay by leaching to obtain high

2013年6月1日 Xray diffractogram of: a) kaolin ore with average particle size 35 µm b) Leached kaolin It is important to make this identification because in several studies (2, 7, 8, 9, 11) has reported the 2023年8月1日 In order to use kaolin commercially, the clay must be bleached to remove iron pigment and washed to remove other minerals [3] Kaolinite (Al 2 Si 2 O 5 (OH) 4 ) is a key ingredient in kaolin It is described as a 1:1 clay which is composed of 2 layers (siloxane layer [Si 2 O 5 ] and gibbsitelike layer [Al 2 (OH) 4 ]) that held together by an apical oxygenAn overview of kaolin and its potential application in 2024年4月5日 In recent years, despite some novel findings in the calcination whitening process using agents like H 3 PO 4, KOH, KCl, NaCl, Na 2 CO 3, and (NH 4) 2 SO 4 have been reported (Lu and Hu, 2013, Lyu et al, 2019, Ren et al, 2014), the investigations on the calcination whitening of CSK by using ammonium salts (NH 4 Cl, (NH 4) 2 CO 3 and (NH 4) 2 SO 4) have Iron conversion and ammonium salt calcination whitening process 2023年5月24日 Download Citation Iron removal from kaolin by oxalic acid using a novel preagitating and highpressure washing technique This study reports a leaching process along with a novel physical Iron removal from kaolin by oxalic acid using a novel pre

.jpg)

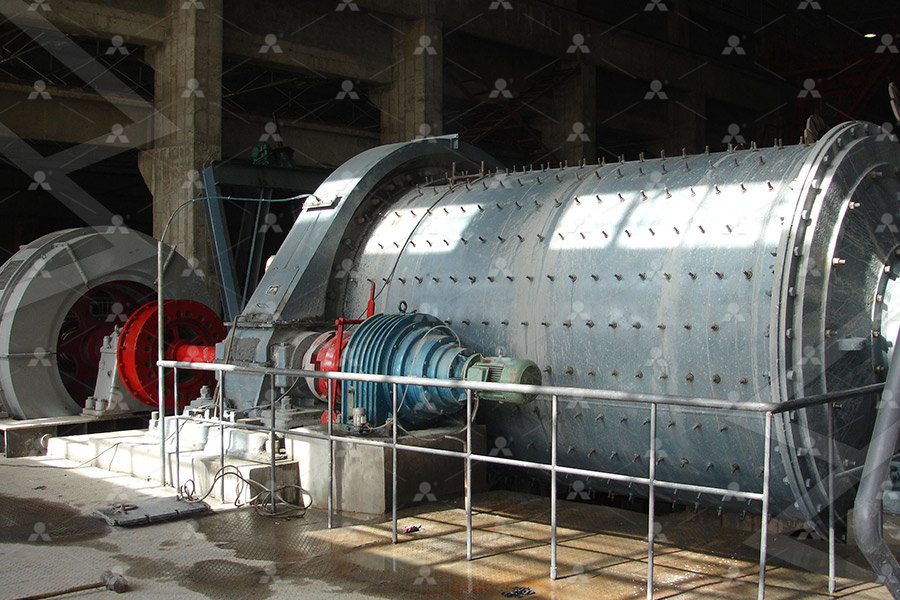

Kaolin Separation Purification Equipment And Process

Purpose of flotation: To process kaolin ore with more impurities and lower whiteness, and remove its iron, titanium and carbon impurities, so as to realize the comprehensive utilization of lowgrade kaolin resources Common equipment or agents: flotation machine, flotation column, collector, foaming agent, inhibitorBefore selecting a specific process, the chemical composition and iron occurrence state of the kaolin ore should be determined first, and then a single or combined kaolin beneficiation and iron removal process should be adopted according to the difference in the properties of the ore to obtain the ideal iron removal effect and good iron removalKaolin Beneficiation And Iron Removal ProcessThe kaolin purification process mainly includes gravity separation, scrubbing iron removal, and magnetic separation processes to purify and remove impurities from kaolin However, chemical treatment and flocculation methods are sometimes needed to process kaolin furtherKaolin Ore Dressing And Purification Process2013年9月1日 The total world annual production of kaolin (china clay) is about 18 million tonnes (Watson, 1982a) In 1981 the UK production was 26 million tonnes and that in the USA was 52 million tonnes Research on the Whitening Mechanism of Kaolin by Chemical

Effect of Temperature on Bioleaching of Iron Impurities from Kaolin

The results of the kaolin powder XRF showed 52% iron removal from kaolin by A niger fungal isolated from pistachio skin after 14 days and 477% iron removal after 28 days at a temperature of 25 2020年6月10日 Despite formation of Fe, there are several other processes are involved to complete the ironmaking process Most predominate transformations including MnO to Mn, SiO 2 to Si, removal of sulphur, P 2 O 5 to P and slag formation are noticed 2251 Reduction of MnO It is a multistage process occurring in the blast furnace stack regionIron and SteelMaking Process SpringerLink2020年4月14日 A new largescale suspension calcination process and key equipment suitable for dehydration and calcination of kaolin clay are introduced The pretreatment process can be designed to meet various raw materials with different moisture contents, and the burning system has high heat transfer efficiency with a fivestage cyclone preheater, a suspension calciner Research and Design of Suspension Calcining Technology and Equipment 2018年8月21日 1Adsorption flotation process In the process of producing ceramic engobe glaze frit, due to adsorption carrier adsorption of iron in kaolin at the same time, there are absorption, condensation, inclusions, mixed crystal and so on There are many kinds of functions, so we usually use adsorption method to remove iron and whiten it 2The method of removing iron and whitening kaolin

3 Incredibly Useful Methods for Purifying Kaolin (And Machines)

2023年2月20日 The purification aims to remove colored impurities (iron, titanium, etc) and sandy minerals (quartz, feldspar, etc) For kaolin with high whiteness, few impurities and sandy impurities (quartz, feldspar, etc), the kaolin mineral can be directly crushed and milled Learn about the Kaolin Dry Processing Processlowcost, available natural resources and being nontoxic materials In this work, sub micro kaolin powder has been modified to increase its adsorption ability to remove heavy metals from raw water The removal efficiency of the natural sub micro kaolin powder and its acid (sulfuric acetic acids) modified forms were investigated for theREMOVAL OF IRON AND MANGANESE POWDER AND ITS 2021年8月27日 As previously stated, kaolin slurry passes the ‘degritting‘ process through particular devices such as screens, hydrocyclones, and hydroclassifiersThese screens here can be the 100 mesh screen, 200 mesh screen, and 325 mesh screen Meanwhile, the classifiers consist of centrifuge hydroseparator and centrifugal seizuresAll Steps in Kaolin Production Mining and Processing Explained2003年2月1日 The results of the kaolin powder XRF showed 52% iron removal from kaolin by A niger fungal isolated from pistachio skin after 14 days and 477% iron removal after 28 days at a temperature of 25 Iron Removal from Kaolin Comparison between “In Situ” and

Iron conversion and ammonium salt calcination whitening process

2024年4月5日 In recent years, despite some novel findings in the calcination whitening process using agents like H 3 PO 4, KOH, KCl, NaCl, Na 2 CO 3, and (NH 4) 2 SO 4 have been reported (Lu and Hu, 2013, Lyu et al, 2019, Ren et al, 2014), the investigations on the calcination whitening of CSK by using ammonium salts (NH 4 Cl, (NH 4) 2 CO 3 and (NH 4) 2 SO 4) have 2024年4月17日 Among the development of many mining machinery industries, the kaolin magnetic separator exists as a special example, and it has maintained a good momentum of development in such a fierce market environment Its Kaolin Magnetic Separator And Equipment Repair2012年7月5日 High Purity Kaolin Powder Processing Plant with Extraction Flotation machine (click for more details) is the equipment to complete the flotation process, which is also called flotation cell It is Magnetic Separtor High Purity Kaolin Powder Processing Plant with 900°C It can be concluded that it is difficult to remove the structural ferric ions and ferric oxides evolved from the structural ferrous ions Thus, iron removal by acids should be conducted prior to calcination Keywords: kaolin; iron removal; calcination; acid leaching; extraction; Mössbauer spectroscopy 1 IntroductionInfluence of acid leaching and calcination on iron removal of coal kaolin

Iron Removal from Kaolin Waste Dumps by Chemical (Oxalic and

2024年1月1日 Materials and Equipment Kaolin samples were supplied by Caobar SA from their mine waste dumps located at Poveda de la Sierra (Guadalajara, Spain; Figs S1–S2 in the Supplementary Material show the geological background) The waste came from beds that were not exploited due to the high levels of iron impurities2011年5月19日 The cavitation phenomenon occurs when the ultrasonic wave with high enough energy acts on the liquid, and the impact effect, pressure effect and microjet effect shown by the cavitation effect of Iron removal from kaolin using thiourea assisted by ultrasonic wave2022年1月20日 The advantage of the dry process is that it can save the dehydration and drying process of the product, reduce the loss of ash powder, the process flow is short, the production cost is low, and it is suitable for arid and waterdeficient areas However, to obtain highpurity and highquality kaolin, we must rely on the wet process 2 Wet processHow to Process Kaolin? Miningpedia2024年8月7日 Kaolin is a crucial nonrenewable mineral resource with few highquality deposits Skip to content :r; Tel: +86 ; HOME PRODUCTS Close PRODUCTS Open PRODUCTS PROCESS SOLUTIONS From Ore to Powder: Kaolin Purification, Crushing, Modification

Iron removal from kaolins by bacterial leaching ResearchGate

2000年11月1日 A process for biological removal of iron from quartz sands, kaolins and clays was developed in which these industrial minerals were leached at 90°C with lixiviant produced as a result of the temperature and brightener on mineral characteristics, whiteness, iron and aluminum in kaolin was discussed The mechanism of whitening was analyzed systematically The main results were as follows: 1、The content of iron and aluminum in kaolin with iron impurity from Longyan was determined by spectrophotometryResearch on Iron and Aluminum in Kaolin by Bleaching and 2011年3月1日 The results of the kaolin powder XRF showed 52% iron removal from kaolin by A niger fungal isolated from pistachio skin after 14 days and 477% iron removal after 28 days at a temperature of 25 Influence of organic acids, complexing agents and heavy metals It can treat diarrhea, mouth sore, ulcers, and also helps in tablets productionControlling the level of viscosity is a problem in the adhesive industry, but including kaolin during production with an enclosed mixing system for Kaolin making equipment Making

The Art of Making Activated Bamboo Charcoal:

2023年3月10日 Activated bamboo charcoal, also known as bamboo activated carbon, is a highly porous material that is widely used for its ability to adsorb impurities and pollutants as we all know, It is produced by heating bamboo at Kaolin common wet beneficiation process and equipment May15,2023 Why should kaolin remove iron Iron is the main Guangdong Shantou kaolin sand making EPC project overview The customer belongs to a local concrete company in Shantou CityKaolin common wet beneficiation process and equipment2013年6月1日 Xray diffractogram of: a) kaolin ore with average particle size 35 µm b) Leached kaolin It is important to make this identification because in several studies (2, 7, 8, 9, 11) has reported the Iron removal from a kaolinitic clay by leaching to obtain high 2023年8月1日 In order to use kaolin commercially, the clay must be bleached to remove iron pigment and washed to remove other minerals [3] Kaolinite (Al 2 Si 2 O 5 (OH) 4 ) is a key ingredient in kaolin It is described as a 1:1 clay which is composed of 2 layers (siloxane layer [Si 2 O 5 ] and gibbsitelike layer [Al 2 (OH) 4 ]) that held together by an apical oxygenAn overview of kaolin and its potential application in

.jpg)

Iron conversion and ammonium salt calcination whitening process

2024年4月5日 In recent years, despite some novel findings in the calcination whitening process using agents like H 3 PO 4, KOH, KCl, NaCl, Na 2 CO 3, and (NH 4) 2 SO 4 have been reported (Lu and Hu, 2013, Lyu et al, 2019, Ren et al, 2014), the investigations on the calcination whitening of CSK by using ammonium salts (NH 4 Cl, (NH 4) 2 CO 3 and (NH 4) 2 SO 4) have 2023年5月24日 Download Citation Iron removal from kaolin by oxalic acid using a novel preagitating and highpressure washing technique This study reports a leaching process along with a novel physical Iron removal from kaolin by oxalic acid using a novel pre Purpose of flotation: To process kaolin ore with more impurities and lower whiteness, and remove its iron, titanium and carbon impurities, so as to realize the comprehensive utilization of lowgrade kaolin resources Common equipment or agents: flotation machine, flotation column, collector, foaming agent, inhibitorKaolin Separation Purification Equipment And ProcessBefore selecting a specific process, the chemical composition and iron occurrence state of the kaolin ore should be determined first, and then a single or combined kaolin beneficiation and iron removal process should be adopted according to the difference in the properties of the ore to obtain the ideal iron removal effect and good iron removalKaolin Beneficiation And Iron Removal Process

.jpg)

Kaolin Ore Dressing And Purification Process

The kaolin purification process mainly includes gravity separation, scrubbing iron removal, and magnetic separation processes to purify and remove impurities from kaolin However, chemical treatment and flocculation methods are sometimes needed to process kaolin further