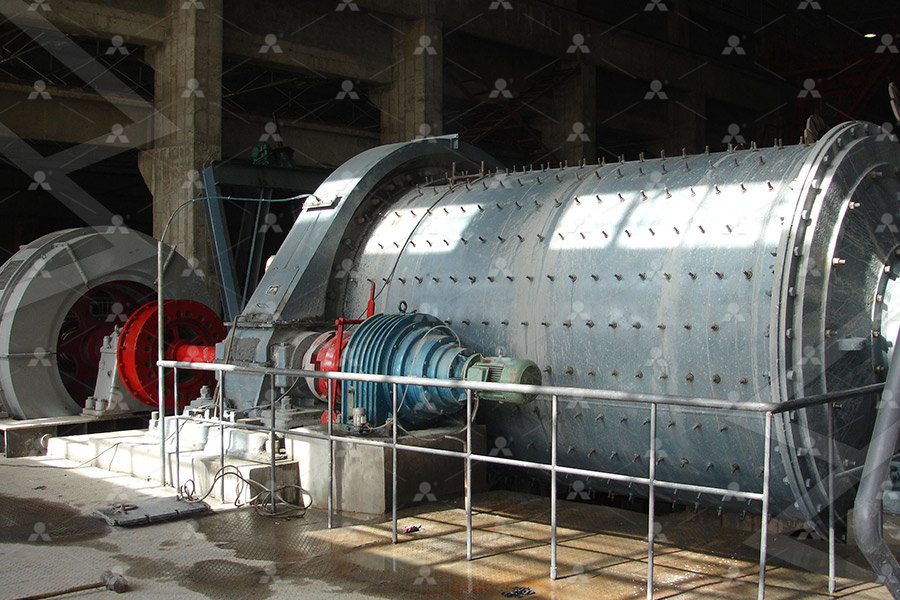

Asphalt coke petroleum coke mill ore mill

.jpg)

Colloidal Fuel Dispersions using Coal, Petroleum Coke and Asphaltite

New mixing technologies have led to the development of colloidal fuel dispersions using coal, petroleum coke, and asphaltite These nonsettling liquid fuels have the handling characteristicsSpecial mill for petroleum coke and asphalt rock In response to the national "energy saving, consumption reduction" environmental protection policy innovation, giant powder equipment Special mill for petroleum coke and asphalt rockReported in this paper are the findings of a lab oratory investigation to evaluate the effect of us ing petroleum coke with different percentages and degrees of fineness as an additive to paraffinic Effect of Petroleum Coke on Certain ParaffinicWaxy Asphalt Thermally cracking, or pyrolysis, of chemical bonds within petroleum, coal and biomass is convenient route to produce additional liquids for use in chemicals and fuels, and/or to Coking and Visbreaking

Asphalt SpringerLink

2023年5月16日 Petroleum asphalt is the sticky, black, and highly viscous liquid or semisolid residue during the refining of petroleum by steaming and other processes Tar is a byproduct 2022年6月17日 In the course of this work, petroleum coke was obtained from raw materials of various types: vacuum residue, asphalt, HTC and HCG Increasing the coking pressure in the Parameters influence establishment of the petroleum coke genesis 2019年5月8日 In the present work, we determine the influence of the coking pressure on the physicochemical properties of petroleum coke produced from heavy oil tar and asphalt The Influence of Pressure in the Coking of Heavy Oil Tar and Asphalt 2012年10月14日 New mixing technologies have led to the development of colloidal fuel dispersions using coal, petroleum coke, and asphaltite These nonsettling liquid fuels have the handling characteristicsColloidal Fuel Dispersions using Coal, Petroleum Coke

Comparisons of Dry Grinding Kinetics of Lignite, Bituminous Coal,

2013年5月15日 In this paper, anthracite and coking coals of low ash are ground together in a Hardgrove mill, and resistance to be broken is compared based on the classical breakage modelNew developments of Anode Coke Grinding using a vertical Mill Technology, TMS 2015 3 Stefan A Gosau, Andreas Wolf; “The Vertical Ball Mill for the Grinding of Calcined Petroleum Coke to improve the Quality of the Anodes in the Aluminium Industry”; TMS 2011, Claudius Peters Projects GmbH, Buxtehude, Germany 4Changing the Fineness of Calcined Petroleum Coke with Ball Race Petroleum coke is a product of crude oil that is distilled to separate light and heavy oils, and the heavy oils are then thermally cracked From the appearance point of view, the coke has an irregular shape and different size black lumps uses of petroleum coke petroleum coke grinding 2024年8月23日 Calcined petroleum coke is a purified form of petroleum coke, obtained through a calcination process that removes volatile components, such as sulfur and residual hydrocarbons, present in raw coke This process is Petroleum Coke: What it is, Function and Industrial

.jpg)

What grinding equipment is needed for petroleum coke

2022年3月29日 Petroleum coke can be used in ceramics, glass, carbon products, steelmaking and other industries after being processed and ground into powder by industrial grinding mill +17 [ protected]HCMilling(Guilin Hongcheng) provides exclusive Petroleum Coke Vertical Roller Mill equipment with customers for grinding Petroleum Coke powder It is a kind of advanced pulverizing equipment integrated with drying, pulverizing, powder selecting and conveying Its fineness can achieve 200325 mesh (7544μm) The production capacity is 5200T/HPetroleum Coke HLM Vertical Roller MillCoke is a grey, hard, and porous coalbased fuel with a high carbon content It is made by heating coal or petroleum in the absence of air Coke is an important industrial product, used mainly in iron ore smelting, but also as a fuel in stoves and forges Coke (fuel) Coke (fuel) WikiMili, The Best Wikipedia ReaderTAPPI PEERS Conference Proceedings, Savannah, 14 – 18 October 2012 Colloidal Fuel Dispersions using Coal, Petroleum Coke and Asphaltite Alonso Alvaradoa, María I Briceñoa, Christopher Dietelb Colloidal Fuel Dispersions using Coal, Petroleum Coke and

.jpg)

Thermal Analysis Study on the Carbothermic Reduction of Chromite Ore

2015年7月1日 The reduction of chromite ore by petroleum coke with or without the addition of mill scale is investigated by Thermogravimetric Analysis (TGA) under nonisothermal conditions (from room 2007年2月14日 By MA, Cui et al [14] produced TiC nanoparticles (2282 nm) from elemental Ti and petroleum coke after 105 h of milling in a highenergy ball mill (QMISP Planetary Mill) at 150 rpmSynthesis of nanometersized TiC and SiC from petroleum coke Infect only a few investigators worked on the kinetics of mill scale reduction [24][25][26][27][28][29][30]In previous studies on the use of the catalyst for iron ore or mill scale reduction Selfreducing bag of mill scale and petroleum coke2019年2月16日 Stefan A Gosau, Andreas Wolf; “The Vertical Ball Mill for the Grinding of Calcined Petroleum Coke to improve the Quality of the Anodes in the Aluminium Industry”; TMS 2011, Claudius Peters Projects GmbH, Buxtehude, Germany Google Scholar NN; Presentation documents, Claudius Peters Technologies GmbH, Buxtehude, Germany, 2001Changing the Fineness of Calcined Petroleum Coke with Ball

News Advantages of petroleum coke environmental

How is the price of oil coke powder? Guilin Hongcheng environmental protection vertical mill plant learned that petroleum coke is the decompression slag oil of oil, through the coking unit, in 500550℃ cracking coking and generated black 2024年11月21日 Petroleum Coke: 8600: Shree Dwarkadhish Enterprise: INR: Petroleum Coke : 25: TRIBHUWAN PRASAD SINGH CO INR: 6% Sulphur Content CarbonRich Petroleum Coke For Industrial: 25000: Ghosh Co: INR: Solid Industrial Grade 80% Ash Content Crystals Petroleum Coke: 32: VIMLA FUELS METALS PRIVATE LIMITED: INR: Carbon Rich Petroleum Coke Manufacturers, PET Coke Suppliers ExportersThe petroleum coke grinding production line typically includes the following components: 1 **Feeder**: The coke feeder is responsible for delivering the coke to the grinding unit 2 **Grinder**: The heart of the production line is the grinder, which can be a ball mill, vertical roller mill, or other types of mills depending on the required Petroleum coke grinding production line and application Raw coke Coke is a grey, hard, and porous coalbased fuel with a high carbon content It is made by heating coal or petroleum in the absence of air Coke is an important industrial product, used mainly in iron ore smelting, but also as a fuel in stoves and forges The unqualified term "coke" usually refers to the product derived from lowash and lowsulphur bituminous coal by a Coke (fuel) Wikipedia

Coke briquette making and the binders MAXTON

2024年7月10日 What is coke fine Coke fine refers to the smallsized particles or fine granules of coke, a carbonrich material derived from coal or petroleum These fine particles are typically produced as a byproduct during the crushing, screening, and handling of larger coke pieces Coke fine sources types of them At present, coke fines primarily come from the following two Petroleum coke is a carbonaceous solid residue that is obtained as a byproduct during the refinement of crude oil The increasing demand for energy and the depletion of traditional fossil fuel resources have led to a growing interest in the utilization of Petroleum Coke Crusher CM Mining Machinery2020年4月9日 1 In view of the characteristics of light petroleum coke and light weight, it is not easy to form a powder abrasive layer, MTW European type grinding mill optimizes the structure of the main machine grinding device and blade, and adopts the structure design of cage turbine classifier, which improves the capacity and does not have large particles appears, and can What kind of mill is used for grinding petroleum coke?2002年1月1日 The design for a Loesche roller mill for drying and grinding petroleum coke has now been adequately tried and tested through years of operating experience Discover the world's researchDrying and grinding petroleum coke in a roller mill at the Usje

.jpg)

Petroleum coke mill SANDMINE

2018年1月24日 From the appearance of petroleum coke, coke is a black block (or particle Provide you massive, authoritative, realtime information Petroleum coke mill Petroleum coke is a product transformed by the process of spreading light and heavy oil Metal Ore Crushing for Dressing Solution Mineral Grinding for Powder 1 Raw material preparation: select highquality petroleum coke as raw material Petroleum coke is usually a byproduct of the oil refining process and is a solid material obtained by calcination 2 Crushing: The raw material lump Petroleum Coke Ultrafine Pulverizer2020年5月22日 With the vigorous development of ore powder market, invite new and old customers and friends to visit the grinding mill manufacturer to know the details of professional petroleum coke grinding mill equipment Tel:+86 Raymond Mill For Grinding 300 Mesh Petroleum Petroleum Coke is a fuel item distilled from Heavy Oil Residue As the AWESOME Sink does not accept fluids, converting Heavy Oil Residue into Coke is one way to sink it, solving the fluid deadlock problem in the early petrochemical setup It was formerly used in the production of Aluminum Scrap without alternate recipes It can be burned in the Coal Generator, which Petroleum Coke Official Satisfactory Wiki

Petroleum coke Wikipedia

Petroleum coke Petroleum coke, abbreviated coke, pet coke or petcoke, is a final carbonrich solid material that derives from oil refining, and is one type of the group of fuels referred to as cokesPetcoke is the coke that, in particular, derives from a final cracking process—a thermobased chemical engineering process that splits long chain hydrocarbons of petroleum into Revised: Mill scale is one of the byproducts which produced during the processing of 11 Mar 2021 Accepted: 28 Apr 2021 ore substitution by mill scale at 3%, the rate of production increases from 2194 to 2550 Keywords mill scale; sintering process; iron ore Abstract steelIt is richEffect of Partial Replacement of Iron Ore by Mill Scale on the 2013年5月15日 However, petroleum coke was given finer than other fuel in respect to finer size fraction mill revolution, called the ore grindability of the c ycle, is then calculated and is used to es parisons of Dry Grinding Kinetics of Lignite, Bituminous 2024年2月27日 Petroleum coke grinding machines encompass a variety of specialized equipment tailored to meet the unique requirements of petroleum coke processing CLUM Series Mill: EcoFriendly and EnergySaving, Leading UltraFine Powder Production to New Height ;Petroleum Coke Grinding Machines

.jpg)

Petroleum Coke Ring Roller Mill Producer

Four Output: shot coke 3t/h4t/h ; sponge coke 4t/h5t/h 5 Provide completed grinding machine (together with crusher, conveyor tools and grinding machine) FLMa thousand grinding machine is suitable for petroleum coke, together with crusher, conveyor gear (including auger and powder pneumatic conveying),grinding machine2012年4月1日 Button and Lundh, [6] using an ore blend containing 30 wt pct magnetite in pot tests, found that compared to a 100 wt pct hematite ore blend, the maximum sintering temperature at a given coke rate Recycling of steel plant mill scale via iron ore sintering plantPetroleum coke is a solid byproduct of petroleum refining and is used in the production of carbon electrodes for the aluminum industry, graphite electrodes for steel making, as fuel in power generation, and as fuel for cement kilns In the United States, more than 15 million tonnes (168 × 10 6 tons) of petroleum coke are used by major utilities, as shown for 2000 in Table 57Petroleum Coke an overview ScienceDirect TopicsNew developments of Anode Coke Grinding using a vertical Mill Technology, TMS 2015 3 Stefan A Gosau, Andreas Wolf; “The Vertical Ball Mill for the Grinding of Calcined Petroleum Coke to improve the Quality of the Anodes in the Aluminium Industry”; TMS 2011, Claudius Peters Projects GmbH, Buxtehude, Germany 4Changing the Fineness of Calcined Petroleum Coke with Ball Race

.jpg)

uses of petroleum coke petroleum coke grinding

Petroleum coke is a product of crude oil that is distilled to separate light and heavy oils, and the heavy oils are then thermally cracked From the appearance point of view, the coke has an irregular shape and different size black lumps 2024年8月23日 Calcined petroleum coke is a purified form of petroleum coke, obtained through a calcination process that removes volatile components, such as sulfur and residual hydrocarbons, present in raw coke This process is Petroleum Coke: What it is, Function and Industrial 2022年3月29日 Petroleum coke can be used in ceramics, glass, carbon products, steelmaking and other industries after being processed and ground into powder by industrial grinding mill +17 [ protected]What grinding equipment is needed for petroleum coke HCMilling(Guilin Hongcheng) provides exclusive Petroleum Coke Vertical Roller Mill equipment with customers for grinding Petroleum Coke powder It is a kind of advanced pulverizing equipment integrated with drying, pulverizing, powder selecting and conveying Its fineness can achieve 200325 mesh (7544μm) The production capacity is 5200T/HPetroleum Coke HLM Vertical Roller Mill

.jpg)

Coke (fuel) WikiMili, The Best Wikipedia Reader

Coke is a grey, hard, and porous coalbased fuel with a high carbon content It is made by heating coal or petroleum in the absence of air Coke is an important industrial product, used mainly in iron ore smelting, but also as a fuel in stoves and forges Coke (fuel) TAPPI PEERS Conference Proceedings, Savannah, 14 – 18 October 2012 Colloidal Fuel Dispersions using Coal, Petroleum Coke and Asphaltite Alonso Alvaradoa, María I Briceñoa, Christopher Dietelb Colloidal Fuel Dispersions using Coal, Petroleum Coke and 2015年7月1日 The reduction of chromite ore by petroleum coke with or without the addition of mill scale is investigated by Thermogravimetric Analysis (TGA) under nonisothermal conditions (from room Thermal Analysis Study on the Carbothermic Reduction of Chromite Ore 2007年2月14日 By MA, Cui et al [14] produced TiC nanoparticles (2282 nm) from elemental Ti and petroleum coke after 105 h of milling in a highenergy ball mill (QMISP Planetary Mill) at 150 rpmSynthesis of nanometersized TiC and SiC from petroleum coke

Selfreducing bag of mill scale and petroleum coke

Infect only a few investigators worked on the kinetics of mill scale reduction [24][25][26][27][28][29][30]In previous studies on the use of the catalyst for iron ore or mill scale reduction