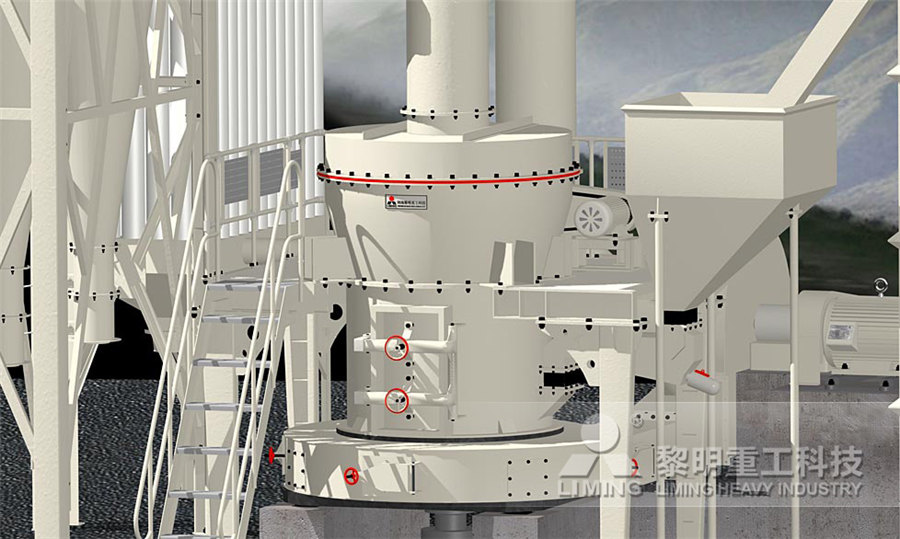

Vertical micro powder grinding model

Modeling of Vertical Micro Grinding Request PDF ResearchGate

2014年8月1日 A new analytical model has been proposed to calculate cutting forces of microgrinding process based on the process configuration, work piece material properties, and In this paper, through the industry vertical mill grinding GGBS carried out a detailed analysis of particle size, on this basis, using the attached to the sample preparation method, obtainedThe Vertical Mill Slag MicroPowders' Particle Size Distribution and balance model was developed to analyze the response in product size resulting from changing operating conditions The model prediction was compared with the results obtained in the PREDICTING THE PRODUCT PARTICLE SIZE DISTRIBUTION FROM 2014年4月1日 Therefore, a new analytical model has been proposed to evaluate cutting forces of microgrinding process based on the process configuration, Modeling and simulation of cutting forces generated

CFB石灰石脱硫剂制备——磨机公众号12.8 推送案例(8)53.jpg)

A multiscale model revealed in the grinding process and its

2023年12月21日 This research presents a multiscale model to capture the interaction state of the grainworkpiece by determining the transient stage of each individual grain based on the 2020年11月1日 In the literature [5], a detailed analysis of the particle size has been carried out through the industry vertical mill grinding GGBS (ground granulated blastfurnace slag) On Analysis and multiobjective optimization of slag powder processA new analytical model has been proposed to calculate cutting forces of microgrinding process based on the process configuration, work piece material properties, and microgrinding tool Modeling of Vertical Micro Grinding Experimental investigation in a microgrinding configuration has been pursued to validate the proposed predictive model The estimated cutting force showed a good correlation with the Modeling and simulation of cutting forces generated during

Mechanical behavior and modeling of grinding force: A

2023年9月29日 The modeling of grinding force is a complex process, the factors affecting the grinding force are the physical properties of the material, the critical depth of cut for the plastic 2020年3月15日 The DEM model was also used to compare the performance of twoimpeller designs and to provide insights on possible powder compaction causes at the bottom of the Investigating grinding media dynamics inside a vertical stirred mill Model and technical data of powder grinder;industrial powder the lifetime of its wearing parts can reach to more than one year, about 25 times as long as that of vertical shaft impact manufacture and sales of crushing machinery, mining Industrial Powder Grinder, Stone Powder Grinder, The particle size of the finished fine powder is arbitrarily adjusted between 3253000 mesh, and the output can reach 0445 tons per hour >>Equipment composition The HGM grinding mill production line usually consists of HGM Ultrafine Grinding Mill Vertical Roller Grinding

Stone powder making machinemicro powder millStone powder

Model: HGM80: HGM90: HGM100: HGM100A: HGM125: Ring Diameter(mm) 800: 930: 1035: 1035: 1300: transportation, hydraulic engineering and so on Specially we independently developed HGM micro powder grinding mill, which are not only renowned in domestic market, but also have been sold Ultrafine Vertical Mill; Clay powder grinder, clay micro 2021年9月30日 It is a highly efficient industrial micro powder grinding mill +17 [ protected] language >Shibang Industry Technology Group, Shanghai Ultrafine Powder Tech Co CLUM vertical mill (1503000 meshes), and wet stirring mill (3256000 meshes) They can grind nonmetallic ores, and the fineness can be adjusted freely Chalk Micro Powder Mill SBM Ultrafine Powder Technology2021年7月28日 CLUM Vertical Roller Mill Model of grinding mill: HGM100L High Pressure Grinding mill, and ThreeRing Micro Powder grinding mill Raymond mill is the most famous but traditional grinding mill machine It can be used for grinding Dolomite Grinding Mill SBM Ultrafine Powder TechnologyLUM series ultrafine vertical roller mill and MW series micro powder mill focus on ultrafine grinding within the range of 4003250 mesh, the fineness is adjustable and controllable They are widely used for grinding calcium carbonate, limestone, calcite, marble, dolomite, barite, talc, bentonite, quartz, gypsum, etcUltrafine Grinding Mill for Minerals Liming Heavy Industry

.jpg)

SBM micro powder technology leads the market, HGM ultrafine

2024年2月23日 HGM ultrafine grinding mill adopts micropowder technology and has the characteristics of high output, fine fineness, chemicals, building materials, medicine and other industries This model has compact structure, simple operation and convenient Clum ultrafine vertical mill Fineness: 1503000mesh Yield: 120t/h see More High Crushing ratio High Energy Utilization Primary processing D97 ≤ 10 μ M fine powder, and 3 µ m fine powder accounts for about 40%, with a large specific surface area; It not only has the advantages of high efficiency and low consumption of highspeed impact crusher, but also has the fineness close to that of air millHCH Ultrafine Grinding Mill, Micro powder grinding mill, Ultra 2024年4月2日 HGM micro powder grinding mill is a widely used ultrafine grinding mill for various minerals powder processing, including bauxite +17 [ protected] Clum ultrafine vertical mill Fineness: 1503000mesh Yield: 120t/h see More >> GET IN TOUCH Tel: +86 WhatsApp: +86 Click to chat (Web)How does HGM micro powder grinding mill process bauxite?2022年1月13日 HGM micro powder mill HGM micro powder mill is an industrial grinding equipment specialized in processing and manufacturing fine powder and ultrafine powder The product fineness can be adjusted between 3002500 mesh according to the needs, and the product fineness can reach D97≤5um at one timeThe difference between CLUM ultrafine vertical mill and HGM micro

Slag grinding mill micro powder production line

2022年5月12日 Mode 2: Drying and grinding are carried out at the same time, the material is ground with a vertical micropowder mill, One of the main equipment of the slag powder production line is the grinding mill >> Vertical Advantages of Ultrafine Vertical Mill(Upgrade product of HGM Micro powder mill): 1High grinding efficiency: save 20~30% power consumption compared with the ball mill 2Strong drying capacity: dry and grind raw materials with moisture content as much as 15% 3 Mutifunction: crushing, drying, grinding, separating and conveyingUltrafine Vertical MillThe project owner has rich and high quality limestone resources, which can be great material of calcium oxide producing The calcium oxide micro powder of the project majority applied in paint filter, environmental emulsion paint, waterproof putty and sewage treatment fields The factory of customer was equipped with 1 set of Vertical MillVMX Superfine Vertical Mill Grinding Mill Fertilizer production Model: HGM80: HGM90: HGM100: HGM100A: HGM125: Ring Diameter(mm) 800: 930: 1035: 1035: 1300: transportation, hydraulic engineering and so on Specially we independently developed HGM micro powder grinding mill, which are not only renowned in domestic market, but also have been sold Ultrafine Vertical Mill; Clay powder grinder, clay micro Dry grinder, dry grinding millDry grinder, dry grinding millPowder

Phosphate Mineral Powder Grinding Mill SBM Ultrafine Powder

2021年11月3日 At present, for the field of nonmetallic ore, there are ultrafine grinding mills, micropulverizers, superfine vertical roller mills, wet mills, and other industrial ore Phosphate Mineral Powder Grinding Mill >> There are many models of phosphate rock powder mills CLUM vertical roller mills, HGM ultrafine grinding mills 2022年6月17日 With the development of the solid waste slag industry, the special dry vertical mill for the equipment of the slag micro powder industry is a new type of powder mill to increase production and reduce consumption It has high grinding efficiency, fast powder separation efficiency and fine classification accuracy It is favored by the industry and is a new type of Slag Powder Vertical Roller Grinding Mill2024年2月22日 The steel slag powder produced by the HLMX steel slag powder vertical mill model can be directly ground to a steel slag 700 specific particle size without the need for regrinding by a ball mill, saving equipment space and energy consumption, and greatly reducing investment costsCan vertical mill produce ultrafine steel slag powder?CLUM series of ultrafine gypsum powder vertical grinding mills are a new type of ultrafine industrial ore grinding equipment that integrates The company's main products are HGM series micro pulverizer, superfine micro pulverizer, micro pulverizer, Model: CLUM Payment methods: Accepted Delivery Terms: FOB, CFR, CIF, EXW, CPT CLUM Ultrafine Vertical Grinding Mill

Xzm 221 Micro Powder Grinding Mill with Large Capacity

MKLVM airflow vortex micro powder machinestainless steel water cooling This micro powder grinding machine with the Model\Parameter MKLVM5 MKLVM15 MKLVM30 MKL suppliers, manufacturers, factory, buy, price, bulk, cheap, in stock, Pulverizer for plastic, Vertical Shaft Nonsieving Micropowder Machine, size reduction, super fine 2020年7月1日 the industry vertical mill grinding GGBS (ground granulated blastfurnace slag) On this basis, qualitative analysis has been carried on by using image method and samAnalysis and multiobjective optimization of slag powder 2024年8月29日 Is excellent ore mill supplier Our main products include ultrafine powder grinding mill, vertical roller mill, roller grinding mill, stone powder production equipment, Welcome to consult Chinese website; Contact us; Focus on the field of micro powder grinding equipmentGrinding Mill mofen Shibang Industry Technology Group, Shanghai Ultrafine Powder Tech Co, Ltd has ultrafine mill, ultrafine vertical mill, Raymond mill, coarse mill The product processing range covers 03mm coarse powder, 20400 mesh fine powder and 4003250 mesh ultrafine powder more >>Grinding Mill Industrial Grinding Mill, Vertical Mill, Raymond

.jpg)

Ring Roller Grinding Mill

Ring Roller Grinding Mill Benefits 1 High powder fineness process, the powder fineness can be adjusted between 3002500 mesh; 2 High capacity, there are 5 models dolomite powder making machine in Shanghai Clirik, the highest capacity can up to 45 t/h; 3 Environment friend, Clirik HGM dolomite powder making machine id environment friendly, it was popularity by our The vertical roller mill integrates crushing, grinding, powder concentration, drying and conveying It can be widely used in cement, power, metallurgy, chemical industry, and nonmetallic mineral HGM Micropowder Grinding MillYGM Grinding Mill Powder Grinding Mill Fine Grinding Mill2021年9月14日 About CLIRIK Shanghai CLIRIK Machinery Co,Ltd has been committed to the field of ultrafine powder grinding and modification machines for 20 years CLIRIK has a firstclass manufacturing base with standardized and intelligent production lines CLIRIK's professional RD, sales, installation and aftersales teams have provided doortodoor services to more than 100 6 types of powder surface modification methodsIntroduce of YGM9517 powder grinder; YGM9517 powder grinder series: The finished size:30425mesh The capacity:2156t/h Working Principle of YGM9517 powder grinder;YGM9517 powder grinder series: Big materials are crushed by jaw crusher to the required particle sizes, and carried by bucket elevator to the storage hopper, and are fed evenly and continuously by YGM9517 Raymond Powder GrinderYGM9517 Raymond Powder Grinder

JoyalThreering Micro Powder Mill,Threering Micro Powder

ZYM Ultrafine Powder Mill Grinding The JOYAL Threering Micro Powder Mill(ultrafine mill) is for superfine grinding materials with hardness less than 6 in Moh’s scale and humidity less than 6 percent such as kaolin, limestone, calcite, marble,talcum, barite, gypsum, dolomite, bentonite mud,mica, pyrophyllite, sepiolite, diatomite, graphite, alunite, fluorite, potassium feldspar Barite powder ultrafine vertical roller mill are suitable for huge capacity producing, widely used in grinding non flammable and nonexplosive materials under 6(the Moh’s hardness), such as barite, vermiculite ,calcium carbonate,quartz, feldspar, calcite, talcum, fluorite, iron ore, copper ore quartz, especially for slag, cement clinker, zircon sand, fly ash and carborundum, coal, etcBarite powder ultrafine vertical roller mill Clirik Barite grinding High quality High Efficiency Vertical Roller Slag Grinding Mill For Mining Limestone Pulverized from China, HVM type slag vertical mill is a common equipment for processing slag micro powder It integrates fine crushing, drying, grinding, Model HVM2500 HVM2800 HVM3400 HVM3700 HVM4200 HVM4500 HVM4800 HVM5100 HVM5600Slag Grinding Mill, High Efficiency Vertical Roller Slag Grinding The RM 200 is a commonly used model, suitable for dry and wet grinding Disc Mills Disc mills are used for fine grinding of mediumhard to hard materials The vibrating disc mill is used for the fast and dust and lossfree comminution of minerals, organic and ceramic materials, Grinding Mills for reliable size reduction tasks RETSCH

Industrial Powder Grinder, Stone Powder Grinder,

Model and technical data of powder grinder;industrial powder the lifetime of its wearing parts can reach to more than one year, about 25 times as long as that of vertical shaft impact manufacture and sales of crushing machinery, mining The particle size of the finished fine powder is arbitrarily adjusted between 3253000 mesh, and the output can reach 0445 tons per hour >>Equipment composition The HGM grinding mill production line usually consists of HGM Ultrafine Grinding Mill Vertical Roller Grinding Model: HGM80: HGM90: HGM100: HGM100A: HGM125: Ring Diameter(mm) 800: 930: 1035: 1035: 1300: transportation, hydraulic engineering and so on Specially we independently developed HGM micro powder grinding mill, which are not only renowned in domestic market, but also have been sold Ultrafine Vertical Mill; Clay powder grinder, clay micro Stone powder making machinemicro powder millStone powder 2021年9月30日 It is a highly efficient industrial micro powder grinding mill +17 [ protected] language >Shibang Industry Technology Group, Shanghai Ultrafine Powder Tech Co CLUM vertical mill (1503000 meshes), and wet stirring mill (3256000 meshes) They can grind nonmetallic ores, and the fineness can be adjusted freely Chalk Micro Powder Mill SBM Ultrafine Powder Technology

Dolomite Grinding Mill SBM Ultrafine Powder Technology

2021年7月28日 CLUM Vertical Roller Mill Model of grinding mill: HGM100L High Pressure Grinding mill, and ThreeRing Micro Powder grinding mill Raymond mill is the most famous but traditional grinding mill machine It can be used for grinding LUM series ultrafine vertical roller mill and MW series micro powder mill focus on ultrafine grinding within the range of 4003250 mesh, the fineness is adjustable and controllable They are widely used for grinding calcium carbonate, limestone, calcite, marble, dolomite, barite, talc, bentonite, quartz, gypsum, etcUltrafine Grinding Mill for Minerals Liming Heavy Industry2024年2月23日 HGM ultrafine grinding mill adopts micropowder technology and has the characteristics of high output, fine fineness, chemicals, building materials, medicine and other industries This model has compact structure, simple operation and convenient Clum ultrafine vertical mill Fineness: 1503000mesh Yield: 120t/h see More SBM micro powder technology leads the market, HGM ultrafine High Crushing ratio High Energy Utilization Primary processing D97 ≤ 10 μ M fine powder, and 3 µ m fine powder accounts for about 40%, with a large specific surface area; It not only has the advantages of high efficiency and low consumption of highspeed impact crusher, but also has the fineness close to that of air millHCH Ultrafine Grinding Mill, Micro powder grinding mill, Ultra

.jpg)

How does HGM micro powder grinding mill process bauxite?

2024年4月2日 HGM micro powder grinding mill is a widely used ultrafine grinding mill for various minerals powder processing, including bauxite +17 [ protected] Clum ultrafine vertical mill Fineness: 1503000mesh Yield: 120t/h see More >> GET IN TOUCH Tel: +86 WhatsApp: +86 Click to chat (Web)2022年1月13日 HGM micro powder mill HGM micro powder mill is an industrial grinding equipment specialized in processing and manufacturing fine powder and ultrafine powder The product fineness can be adjusted between 3002500 mesh according to the needs, and the product fineness can reach D97≤5um at one timeThe difference between CLUM ultrafine vertical mill and HGM micro