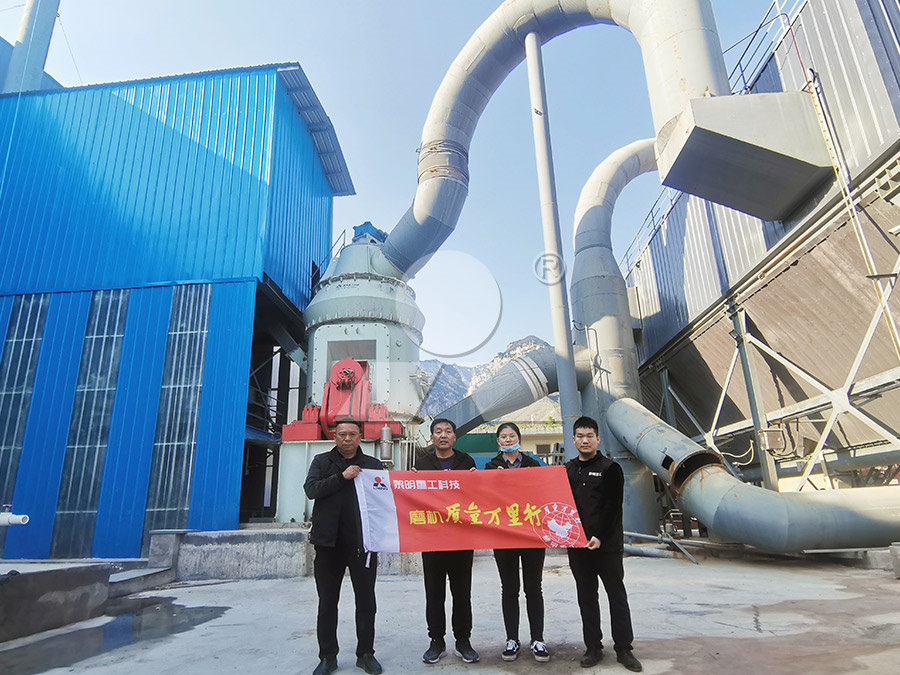

A full set of equipment for producing light calcium carbonate

Understanding Light Calcium Carbonate (PCC): Production,

2023年11月28日 Light calcium carbonate, also known as precipitated calcium carbonate (PCC), stands at the forefront of industrial innovation due to its unique properties and diverse applications This article delves into the intricacies of PCC production, its distinctive Nanosized calcium carbonate with high purity was successfully prepared Fluid hydrodynamics in an integrated airlift loop reactor is investigated Operating parameters for preparing calcium An integrated airlift loop reactor for continuous production of 2022年3月1日 In this work, we coupled the treatment of flue gas and carbide slag to propose a facile CO 2 mineralization route to prepare light calcium carbonate And the route feasibility CO2 mineralization of carbide slag for the production of light 2017年1月1日 Calcium carbonate (CaCO3) is the most widely used filler material in paper, paint, plastic, food, ceramic, cosmetic, medicine and other Precipitated Calcium carbonate production, synthesis

.jpg)

CO2 mineralization of carbide slag for the production of light calcium

2022年3月1日 In the experimental part, through range analysis, the significance level of the influence on Ca leaching rate was as follows: molar ratio > liquidtoCS ratio > reaction time > reaction temperature In mineralization experiment, a light calcium carbonate of less than 10 μm was obtained at a CO 2 concentration of 12%2022年9月29日 Method 2 Mass of the reaction vessel Measure 040 g of calcium carbonate into a weighing boat; Add 50 cm 3 of dilute hydrochloric acid to a conical flask; Place the conical flask of hydrochloric acid AND the weighing Rate of Reaction Calcium Carbonate Hydrochloric The calcium carbonate plant includes a complete set of calcium carbonate manufacturing equipment For example, there are crusher, vibrating feeder, elevator bucket or belt conveyor, calcium carbonate grinding mill, air classifier, silos, dust collector, calcium carbonate coating machine, packing machines and so onCustomize Suitable Calcium Carbonate Plant DASWELL2021年1月26日 The hybrid calcium carbonate (HCC) was prepared by the insitu calcium carbonate (CaC03) formation on the preflocculated mixture of grounded calcium carbonate (GCC) and calcium oxide particles in Application of In Situ Calcium Carbonate Process for Producing

Rates of reaction AQA Practical measure the production of a

Support a gas syringe with a stand, boss and clamp Using a measuring cylinder, add 50 cm 3 of dilute hydrochloric acid to a conical flask; Add 04 g of calcium carbonate to the flask 2016年4月23日 The formation of mineral scale is a complex problem during the oilfield operations Scale inhibitors are widely used to prevent salt precipitation within reservoirs, in downhole equipment, and in production facilities The scale inhibitors not only must have high effectiveness to prevent scale formation, but also have good adsorption–desorption Laboratory investigation of a new scale inhibitor for preventing 2016年4月23日 Laboratory investigation of a new scale inhibitor for preventing calcium carbonate precipitation in oil reservoirs and production equipment April 2016 Petroleum Science 13(2)Laboratory investigation of a new scale inhibitor for preventing 2017年3月9日 The current high global demand for highquality paper, paint, adhesive/sealant, and plastic, filler industries cannot survive without unique and highquality precipitated calcium carbonate (PCC) They are used as fillers, additives, and reinforcements PCC is a key constituent of the modern paper and plastic industry This article reports the effect of various Synthesis of precipitated calcium carbonate: a review

.jpg)

Calcium Carbonate Powder Production Line – Powder Equipment

Tailored turnkey solution EPIC Powder specializes in designing and engineering calcium carbonate processing lines We also provide a complete set of equipment to meet customers’ needs in calcium carbonate powder fineness, production capacity, ground calcium carbonate applications, etc Controlled calcium carbonate particle size2023年12月11日 It has a smaller particle size and lower density compared to heavy calcium carbonate The average particle size of light calcium carbonate typically ranges from 05 to 2 microns Light Calcium Carbonate Production Process: Light calcium carbonate is manufactured by reacting calcium hydroxide (lime) with carbon dioxide gas under controlled The Difference Between Heavy Calcium Carbonate and Light Calcium 2014年12月1日 Precipitated calcium carbonate (PCC) is widely used as a filler and a pigment in various applications, eg in paper, plastics and pharmaceutics (Roskill Information Services, 2012, Stratton, 2012)The main PCC production method is the socalled carbonation process, in which limestone (CaCO 3) is first calcined in a lime kiln to calcium oxide, slaked with water to Cradletogate life cycle assessment of precipitated calcium carbonate 2013年4月19日 Request PDF Functionalized Calcium Carbonate as a Novel Pharmaceutical Excipient for the Preparation of Orally Dispersible Tablets Purpose: To overcome the limitation of insufficient hardness Functionalized Calcium Carbonate as a Novel ResearchGate

.jpg)

Development of a process for producing high‐purity calcium carbonate

2005年7月1日 A new type of process for producing highpurity calcium carbonate from waste cement powder was developed The process consists of two main reactions; extraction of calcium in the form of calcium A highquality calcium carbonate was prepared with individual carbonation efficiencies of 9631 % and 9822 % Moreover, the PG was applied to fix carbon dioxide with ultrasonic enhancement, and calcium carbonate nanoparticles were obtained, reaching a carbon dioxide capture efficiency of over 95 % [8]An integrated airlift loop reactor for continuous production of calcium 2022年2月1日 Carbonation [4], complicated decomposition [5], and pyrolysis [6] are the most common techniques used to produce calcium carbonate Although well developed, the conventional production methods CO2 mineralization of carbide slag for the production of light calcium 2023年10月28日 Ammonium acetate's significance underscores its dual role in both the leaching and carbonation processes This process yielded calcium carbonate with particle sizes smaller than 100 nm, with a purity of 98% and a single vaterite phase The calcium carbide residue demonstrated an impressive CO 2 uptake rate of 235%Optimization of calcium carbide residue utilization for producing

Development of a process for producing high‐purity calcium carbonate

2005年6月14日 A new type of process for producing highpurity calcium carbonate from waste cement powder was developed The process consists of two main reactions; extraction of calcium in the form of calcium ions from waste cement powder in a water slurry by pressurized CO 2 (typically at several MPa), and precipitation of calcium carbonate (CaCO 3) from the extracted Calcium carbonate nanocomposites Y Lin, CM Chan, in Advances in Polymer Nanocomposites, 2012 31 Introduction: applications of calcium carbonate nanoparticles Calcium carbonate particles have been used in the plastics industry for many years The original purpose of adding ground calcium carbonate (GCC) particles as filler material for plastics was to Calcium Carbonate an overview ScienceDirect Topics2014 A fundamental study of scale formation of calcium carbonate (CaCO3) for producing oil wells has been carried out This article presents the study of the prediction of salt deposition in two different synthetic formation waters and investigates the effects of temperature and pressure on calcium carbonate precipitationLaboratory investigation of a new scale inhibitor for preventing 2017年11月1日 Tests were also performed at calcium chloride (CaCl2) concentrations of 01 and 03 M, resulting in specimens with average calcium carbonate (CaCO3) content ranging from 15 to 25% for the 50/70 (PDF) Methods for Calcium Carbonate Content Measurement

Typical processes and equipment for ultrafine

2023年10月10日 Calcium carbonate dry ultrafine grinding equipment and process Calcium carbonate dry ultrafine grinding equipment mainly includes Raymond mill, vertical mill, ball mill, jet mill, stirring mill, vibration mill and 2016年12月31日 Calcium carbonate is a chemical compound with the formula CaCO3 formed by three main elements: carbon, oxygen, and calcium It is a common substance found in rocks in all parts of the world (most (PDF) Calcium Carbonate ResearchGate2022年1月1日 The crab shell (Portunus Pelagicus) wastes are constituted of major calcium carbonate (account for 70 wt %) and have the potential to reuse as a starting biomaterial for precipitated calcium REUSE OF WASTE CRAB SHELLS FOR SYNTHESIS OF 2017年7月9日 Recently, a precipitated calcium carbonate (PCC) production technology utilizing steel converter (basic oxygen furnace) slag as a calcium source, referred to as Slag2PCC, has been developed and demonstrated successfully by researchers at Aalto university together with their collaborators (Said et al, 2013, 2016; Mattila et al, 2014)Frontiers Calcium Carbonate Precipitation for CO2 Storage and

Development of Flexible Calcium Carbonate for Papermaking Filler

2020年5月29日 Flexible calcium carbonate (FCC) was developed as a functional papermaking filler for high loaded paper, which was a fiberlike shaped calcium carbonate produced from the in situ carbonation 2005, Environmental Progress A new type of process for producing highpurity calcium carbonate from waste cement powder was developed The process consists of two main reactions; extraction of calcium in the form of calcium ions from waste cement powder in a water slurry by pressurized CO2 (typically at several MPa), and precipitation of calcium carbonate (CaCO3) Development of a process for producing highpurity calcium carbonate 2011) Calcium carbonate is found in the form of white crystals The main factor influencing the formation of carbonate deposits is that the formation water must be supersaturated with calcium, carbonate, or bicarbonate ions (Kumar et al 2010; Bezerra et al 2013; Mavredaki and Neville 2014) More, inorganic calcium carbonate precipLaboratory investigation of a new scale inhibitor for preventing 2022年10月13日 Use of Ground Calcium Carbonate for Selfcompacting Concrete This study aims to utilize fly ash and waste PET bottles for producing more Doi: 1028991/CEJ014 Full Use of Ground Calcium Carbonate for Selfcompacting Concrete

Process efficiency and optimisation of precipitated calcium carbonate

PDF On Jun 26, 2012, HannuPetteri Mattila and others published Process efficiency and optimisation of precipitated calcium carbonate (PCC) production from steel converter slag Find, read and 2016年2月21日 One challenge of the concept presented in Figure 1 is that the produced calcium carbonate is precipitated in a solution of ammonia and ammonium chloride, which raises concern that chloride may be embedded in the product and hinders its commercial use However, the maximum chloride content that can be allowed in a PCC product is not clear as there does not Performance of Separation Processes for Precipitated Calcium Carbonate 2022年3月1日 In the experimental part, through range analysis, the significance level of the influence on Ca leaching rate was as follows: molar ratio > liquidtoCS ratio > reaction time > reaction temperature In mineralization experiment, a light calcium carbonate of less than 10 μm was obtained at a CO 2 concentration of 12%CO2 mineralization of carbide slag for the production of light calcium 2022年9月29日 Method 2 Mass of the reaction vessel Measure 040 g of calcium carbonate into a weighing boat; Add 50 cm 3 of dilute hydrochloric acid to a conical flask; Place the conical flask of hydrochloric acid AND the weighing Rate of Reaction Calcium Carbonate Hydrochloric

Customize Suitable Calcium Carbonate Plant DASWELL

The calcium carbonate plant includes a complete set of calcium carbonate manufacturing equipment For example, there are crusher, vibrating feeder, elevator bucket or belt conveyor, calcium carbonate grinding mill, air classifier, silos, dust collector, calcium carbonate coating machine, packing machines and so on2021年1月26日 The hybrid calcium carbonate (HCC) was prepared by the insitu calcium carbonate (CaC03) formation on the preflocculated mixture of grounded calcium carbonate (GCC) and calcium oxide particles in Application of In Situ Calcium Carbonate Process for Producing Support a gas syringe with a stand, boss and clamp Using a measuring cylinder, add 50 cm 3 of dilute hydrochloric acid to a conical flask; Add 04 g of calcium carbonate to the flask Rates of reaction AQA Practical measure the production of a 2016年4月23日 The formation of mineral scale is a complex problem during the oilfield operations Scale inhibitors are widely used to prevent salt precipitation within reservoirs, in downhole equipment, and in production facilities The scale inhibitors not only must have high effectiveness to prevent scale formation, but also have good adsorption–desorption Laboratory investigation of a new scale inhibitor for preventing

Laboratory investigation of a new scale inhibitor for preventing

2016年4月23日 Laboratory investigation of a new scale inhibitor for preventing calcium carbonate precipitation in oil reservoirs and production equipment April 2016 Petroleum Science 13(2)2017年3月9日 The current high global demand for highquality paper, paint, adhesive/sealant, and plastic, filler industries cannot survive without unique and highquality precipitated calcium carbonate (PCC) They are used as fillers, additives, and reinforcements PCC is a key constituent of the modern paper and plastic industry This article reports the effect of various Synthesis of precipitated calcium carbonate: a reviewTailored turnkey solution EPIC Powder specializes in designing and engineering calcium carbonate processing lines We also provide a complete set of equipment to meet customers’ needs in calcium carbonate powder fineness, production capacity, ground calcium carbonate applications, etc Controlled calcium carbonate particle sizeCalcium Carbonate Powder Production Line – Powder Equipment2023年12月11日 It has a smaller particle size and lower density compared to heavy calcium carbonate The average particle size of light calcium carbonate typically ranges from 05 to 2 microns Light Calcium Carbonate Production Process: Light calcium carbonate is manufactured by reacting calcium hydroxide (lime) with carbon dioxide gas under controlled The Difference Between Heavy Calcium Carbonate and Light Calcium