Vertical mill process operation management

PROCESS OPTIMISATION FOR LOESCHE GRINDING PLANTS

The core elements of these plants are the Loesche vertical mills for drygrinding the abovementioned grinding stock Loesche has developed and built the largest and most efficient Vertical roller mills are adopted in 20 cement plants (44 mills) in Japan In the vertical roller mill which is widely used in the raw material grinding process, raw materials input grinding table Vertical roller mill for raw Application p rocess materialsmonitoring of the mill process allows for Loesche is launching its new LMMaster for advanced vertical roller mill (VRM) control This automation solution stabilises the VRM to allow FOR VERTICAL ROLLER MILLS Loesche2016年9月1日 VRM data from a steady plant process operation, such as raw material output, material moisture, kiln hot gas, mill fan flow, grinding pressure, and separator speed, was used Operational parameters affecting the vertical roller mill

Analysis of vertical roller mill performance with changes in material

2022年5月31日 The vertical roller mill (VRM) is commonly used for secondary and tertiary crushing processes in numerous industries In this study, the discrete element method (DEM) The todate biggest mill size modular vertical roller mill 6700 C6 shows satisfactory results for cement and composite cement grinding This mill, installed in Northern Africa, is inGrinding Process Optimization Featuring Case Studies and 2017年4月1日 In this study, pilot scale tests were performed with a mobile verticalrollermill grinding plant to investigate the relationships between operational parameters The Operational parameters affecting the vertical roller mill 2023年12月1日 This paper addresses the issue of vibrations in rolling mills during operation and employs a virtual commissioning technique based on digital twins to optimize process Virtual commissioning and process parameter optimization of

.jpg)

Operation parameters multiobjective optimization method of

This paper aims to provide an aerodynamic optimization procedure to improve the aerodynamic performance of singlelayer spherical domes, by coupling the kriging surrogate model with 2024年4月4日 The operations management process is about making a company’s daily actions as sharp and effective as possible The process involves smart use of resources and data to reach goals while keeping costs down Operations Management: Processes Best PracticesVertical mill is a equipment that grinds materials by relative rolling of a grinding roller on grinding disc In the vertical grinding operation process, to form a stable material layer, it is required that the grinding material has a suitable Important Operation Tips For Cement Vertical Mill2020年3月1日 Finally, the health management system, including the functions of condition monitoring, fault diagnosis, and trend prediction for large vertical mill is implemented using Microsoft Visual Studio C A health management system for large vertical mill

Vertical Roller Mill Summary

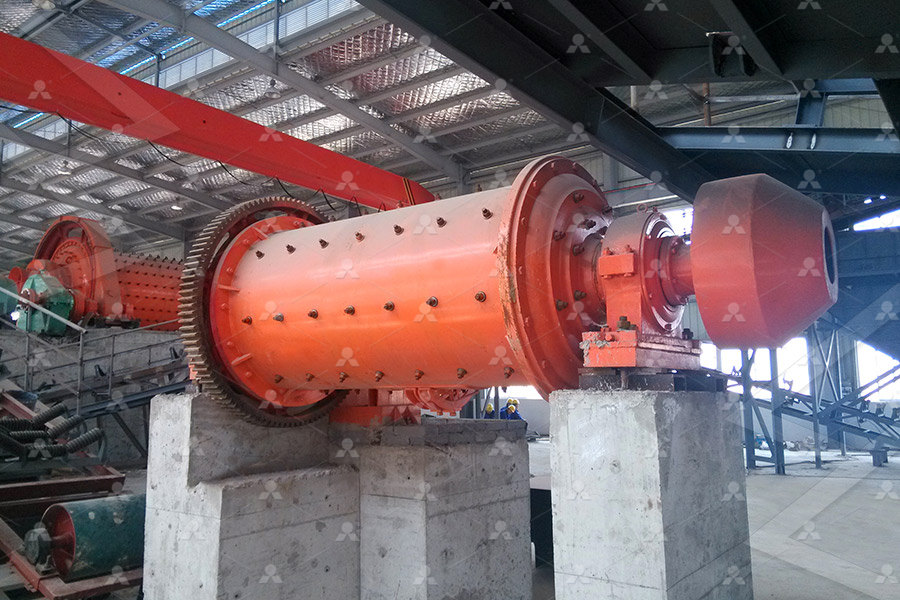

Vertical Roller Mill Summary Free download as PDF File (pdf), Text File (txt) or view presentation slides online Ball mill vs vertical mill Operations Structure of a vertical mill Working Process Components Dam Ring Armour Ring Louver Ring Grinding Table Rollers Separators Maintenance Performance ImprovementGlobally, cement plants are striving to improve their energy efficiency Therefore, it is critical for cement plant operations to increase the monitoring and control of a vertical raw mill energy process This technology has attracted the interest of the cement industry with its proven benefitAssessment of the thermodynamics efficiency of a cement vertical Fig 2 Modular Vertical Roller Mill 5000 R4 Installed in Canada Fig 3 Modular Vertical Roller Mill 5000 R4 Installed in Canada V Operational Experience with Modular Vertical Roller MillsGrinding Process Optimization Featuring Case Studies and 2022年3月28日 The VXPmill is an established vertical ceramic media regrind mill used in energy efficient gold, copper, lead and zinc plants worldwide All slurrycontacting components of the VXP are polyurethanelined and the grinding discs are solid polyurethane, making the VXP the only vertical stirred mill providing ironfree grinding worldwideFLSmidth VXPmill Operation

.jpg)

Review on vertical roller mill in cement industry its

2021年1月1日 Vertical roller mill has proved to be a popular choice for finished cement grinding over all other machineries due to advantages like low power consumption, higher capacity, process simplifications and compactness but it is also very sensitive to vibrations and can deteriorate productivity if process optimization is varied slightlyInternational Journal of Advances in Engineering and Management (IJAEM) Volume 4, Issue 10 Oct 2022, pp: 10671100 ijaem ISSN: 23955252 DOI: 1035629/1100 Impact Factor value 7429 ISO 9001: 2008 Certified Journal Page 1067 Optimization of vertical milling process ANOVA and ANN techniqueparameters of EN24 by usingOPTIMIZATION OF VERTICAL MILLING PROCESS PARAMETERS Complex operation: The VRM has a complex operation process and requires skilled operators to maintain its optimal performance Risk of vibration: The VRM is susceptible to vibration during operation, which can result in unstable production and lower cement quality Applications of Vertical Roller MillVertical Roller Mill in Cement Plant ball mills supplier2020年3月13日 Generally, the sensors are installed in the important positions of vertical mill, and the common health management system first collects various data of the equipment with a certain frequency, 4 and then according to expert A health management system for large vertical mill

.jpg)

quadropol® thyssenkrupp Polysius Grinding

In recent years, thyssenkrupp Polysius has successfully continued step by step the development process for the quadropol® vertical roller mill concept This compact and modular concept includes the latest market requirements 2024年3月17日 Milling is a popular machining process Milling is a machining operation in which a revolving cutter removes material from a workpiece in a controlled manner This method of subtractive manufacturing seeks to give the 16 Types of Milling Operations Explained [with PDF]• Mill motor speed • Mill air flow/mill differential pressure • Temperature after the mill • Pressure before the mill • Grinding stock feed • Classifier speed • Mill fan speed • Water spraying • Hot gas • Fresh air Manipulated variables Disturbance variable Process measured value RelauchLMmaster 6 250814 11:47PROCESS OPTIMISATION FOR LOESCHE GRINDING PLANTS2023年12月1日 The vibration of the rolling mill has been a persistent issue affecting its safe and stable operation To address the vibration problem in the F2 stand of a continuous rolling mill, this paper establishes a digital twin model of the rolling mill Based on the digital twin model, a rolling mill virtual commissioning framework has been proposed to enhance the accuracy of realtime Virtual commissioning and process parameter optimization of

Operational parameters affecting the vertical roller mill

2016年9月1日 The vertical roller mill (VRM) is a comminution device in which crushing, grinding and classification processes are combine together into a single unit operationMagotteaux: The global leader in wear parts for Vertical Mill grinding circuits Magotteaux has established itself as a global leader in wear parts for vertical mill grinding circuits by consistently delivering innovative solutions that address the complex requirements of multiple industries Our commitment to innovation, quality, and customer satisfaction has earned us the trust and Vertical Mill Mining MagotteauxExcellent Visibility and Ease of Use: Due to the vertical spindle orientation, operators have a clear view of the cutting process, making it ideal for less complex operations and setups This ease of use also translates to shorter learning curves for new operators Precise Drilling and Tapping: Vertical mills excel at performing accurate drilling and tapping tasksMaximize Efficiency: Horizontal Mill vs Vertical MillVertical turning, also known as vertical turning lathe (VTL) or vertical boring mill (VBM), holds a significant advantage in various machining applications, particularly when dealing with large and heavy workpieces It offers a set of benefits that make it a deservedly popular choice in industries such as automotive, aerospace, and energyA Comprehensive Guide to Vertical Turning – TMC Technologies

.jpg)

What Is Operations Management? Benefits, Functions, and Types

2024年2月24日 The operations management office has five major decisionmaking spheres They include policymaking in the physical production process They also make short, medium, and longterm decisions on their organization’s output capacity Operations management also makes logistical decisions on inventory and the workforceprocess of the VRM is very wellpredictable with the population balance model Keywords: vertical roller mill, modeling, simulation, cement grinding, residence time distribution 1 Introduction Grinding operation is one of the important parts of the cement production processes AlmostModeling and simulation of vertical roller mill using population 2020年8月12日 As one of the three major forces of coal mills, the grinding force exerts a significant impact on the working process of coal mills and parameters like mill current and outlet temperatureAn investigation of performance characteristics and 2021年1月29日 Unground material would stay over the classifier, and they have to be kept inside the mill to meet the desired size One of the critical factors through the process is controlling the mill body Increase productivity of vertical roller mill using seven

Vertical (Dis‑)Integration and Firm Performance: A Management

2020年2月10日 Vertical disintegration in manufacturing industries has been an increasing trend since the 1990s in many countries According to a prevailing management paradigm of focusing on core competencies 1 To know about process management and its importance in business 2 To increase awareness about various concepts of process management 3 Enhance understanding of the learner about different tools and types of process management 1 Introduction: A key aspect of operations management is process managementProcess Management: Types of Process and its implication in operation 2023年12月4日 21 Vertical Roller Mill The VRM shall have three or four rollers and a table The rollers were pressed against the ore and table using hydraulic cylinders during operationNumerical Investigation of Vertical Roller Mill Operation Using The power ingesting of a grinding process is 5060% in the cement production power consumption The Vertical Roller Mill (VRM) reduces the power consumption for cement grinding approximately 3040% associated with other grinding mills The process variables in cement grinding process using VRM are strongly nonlinear and having large time delay characteristics PROCESS CONTROL FOR CEMENT GRINDING IN VERTICAL ROLLER MILL

Production and Operations Management MBA MCQ

Production and Operations Management Downsized Outsourced Internationalization vertical integration entrepreneurial ship View answer Correct answer: (B) Outsourced 283 Repetitive processing results in output that is: Highly What type of process would a paper mill be most likely to use? Continuous flow Project Job shop Flow The Raymond® Vertical Mill is well adapted to the grinding of nonmetallic minerals and manufactured materials in the extreme fineness range Typicalmaterialsprocessed include graphite, limestone, cocoa powder, marble, kaolin,sugar, talc, certain synthetic resins, organic and inorganic colors, phosphate,chemicals, glass, enamel, food products, pharmaceuticals and a Raymond® Vertical Mill Coperion2022年5月31日 Mineral crushing is the main source of energy consumption in mineral processing According to statistics, this consumption accounts for about 35–50% of the total cost of the mine (Curry et al, 2014), or even higherIt may also account for 18% of the global electrical energy consumption (NapierMunn, 2015)More efficient crushing equipment needs to be Analysis of vertical roller mill performance with changes in 2024年4月4日 The operations management process is about making a company’s daily actions as sharp and effective as possible The process involves smart use of resources and data to reach goals while keeping costs down Operations Management: Processes Best Practices

.jpg)

Important Operation Tips For Cement Vertical Mill

Vertical mill is a equipment that grinds materials by relative rolling of a grinding roller on grinding disc In the vertical grinding operation process, to form a stable material layer, it is required that the grinding material has a suitable 2020年3月1日 Finally, the health management system, including the functions of condition monitoring, fault diagnosis, and trend prediction for large vertical mill is implemented using Microsoft Visual Studio C A health management system for large vertical millVertical Roller Mill Summary Free download as PDF File (pdf), Text File (txt) or view presentation slides online Ball mill vs vertical mill Operations Structure of a vertical mill Working Process Components Dam Ring Armour Ring Louver Ring Grinding Table Rollers Separators Maintenance Performance ImprovementVertical Roller Mill SummaryGlobally, cement plants are striving to improve their energy efficiency Therefore, it is critical for cement plant operations to increase the monitoring and control of a vertical raw mill energy process This technology has attracted the interest of the cement industry with its proven benefitAssessment of the thermodynamics efficiency of a cement vertical

Grinding Process Optimization Featuring Case Studies and

Fig 2 Modular Vertical Roller Mill 5000 R4 Installed in Canada Fig 3 Modular Vertical Roller Mill 5000 R4 Installed in Canada V Operational Experience with Modular Vertical Roller Mills2022年3月28日 The VXPmill is an established vertical ceramic media regrind mill used in energy efficient gold, copper, lead and zinc plants worldwide All slurrycontacting components of the VXP are polyurethanelined and the grinding discs are solid polyurethane, making the VXP the only vertical stirred mill providing ironfree grinding worldwideFLSmidth VXPmill Operation2021年1月1日 Vertical roller mill has proved to be a popular choice for finished cement grinding over all other machineries due to advantages like low power consumption, higher capacity, process simplifications and compactness but it is also very sensitive to vibrations and can deteriorate productivity if process optimization is varied slightlyReview on vertical roller mill in cement industry its International Journal of Advances in Engineering and Management (IJAEM) Volume 4, Issue 10 Oct 2022, pp: 10671100 ijaem ISSN: 23955252 DOI: 1035629/1100 Impact Factor value 7429 ISO 9001: 2008 Certified Journal Page 1067 Optimization of vertical milling process ANOVA and ANN techniqueparameters of EN24 by usingOPTIMIZATION OF VERTICAL MILLING PROCESS PARAMETERS

.jpg)

Vertical Roller Mill in Cement Plant ball mills supplier

Complex operation: The VRM has a complex operation process and requires skilled operators to maintain its optimal performance Risk of vibration: The VRM is susceptible to vibration during operation, which can result in unstable production and lower cement quality Applications of Vertical Roller Mill