Ore powder processing

82: Mining and Ore Processing Geosciences LibreTexts

When ore is first processed (typically close to the mine) it is crushed to gravelsized chunks and then ground to a fine powder and the ore minerals are physically separated from the rest of the rock to make a concentrate2022年4月1日 Run of mine ore undergoes an initial process of crushing, milling and classification to generate particles of a sufficient size and mineral liberation This is done to Review on advances in mineral processing technologies suitable 2021年3月15日 This part describes the history, goals of pelletization, and provides a framework so that the chemical factors leading into an effective pelletizing process can be understood Iron Ore Pelletization: Part I Fundamentals: Mineral Processing Iron ore powder agglomeration is the basis for blast furnace ironmaking and is the processing work in between ore crushing, ore grinding separation, and steelmaking Its purpose is to Agglomeration of Iron Ores SpringerLink

.jpg)

Comprehensive Study on Mineral Processing Methods

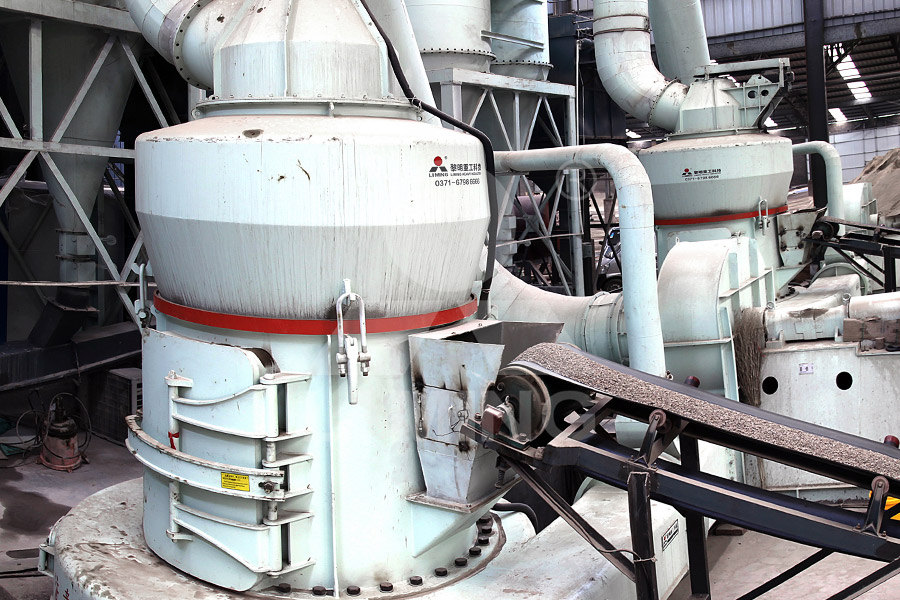

2024年2月26日 At present, the domestic and foreign research on the ore process mineralogy is mainly through chemical phase analysis, Xray diffraction analysis, chemical multielement analysis, scanning electron microscopy, 2022年10月20日 Making iron and steel from iron ore requires a long process of mining, crushing, separating, concentrating, mixing, agglomeration (sintering and pelletizing), and Iron Ore Processing, General SpringerLinkThere are four main processes used in powder production: solidstate reduction, atomization, electrolysis, and chemical In solidstate reduction, selected ore is crushed, typically mixed with carbon, and passed through a continuous furnaceMaking Metal Powder MPIF2021年9月6日 We describe a micronsized ore powder production by propulsion and rapid unloading of highpressure gas The research consists of three parts Firstly, we obtain the Micronsized ore powder production by propulsion and rapid

.jpg)

(PDF) Overview of Mineral Processing Methods

2015年8月3日 This study investigates the potential application of microwave imaging (MWI) in ore sorting systems for mineral processing Modern sensorbased ore sorting employs various sensing methods, such as 2023年10月17日 Factors for choosing a suitable ore powder grinding mill 1 Raw material characteristics: Different raw materials have different hardness, humidity and grinding and crushing properties, and the corresponding ore How to choose a suitable ore powder grinding mill?PDF On Jul 11, 2018, Sandra Lúcia de Moraes and others published Iron Ore Pelletizing Process: An Overview Find, read and cite all the research you need on ResearchGateIron Ore Pelletizing Process: An OverviewThe continuous advancements in ore powder production process equipment are transforming the mineral processing industry With the ability to produce highquality powders efficiently and sustainably, these technologies are not only meeting the demands of various applications but also contributing to the environmental stewardship of the industryAdvancements in ore powder production process equipment:

Iron Ore Processing: From Extraction to Manufacturing

2024年4月26日 Crushing is the initial stage in the iron ore processing journey, where large chunks of ore are broken down into smaller fragments The primary objective of crushing is to reduce the ore size for subsequent processing and improve the liberation of valuable minerals from the gangue a Jaw Crushers: Jaw crushers are commonly used for primary Chromium processing, preparation of the ore for use in various products Chromium (Cr) is a brilliant, hard, refractory metal that melts at 1,857 °C (3,375 °F) The Cr 2 O 3 is blended with finely divided aluminum powder, charged to a refractorylined container, and ignited The combustion quickly generates temperatures in excess of 2,000 Chromium processing Extraction, Uses Applications BritannicaThis tier triples ingot yield for SilkTouch'ed ores, or doubles the yield for standard raw ores It starts by processing raw ores in the Purification Chamber This machine is the first introduced in the ore processing pipeline that uses an additional input component as a part of processing its ore In this case, the chamber uses OxygenOre Processing Official Mekanism Wiki aidancbrady2017年5月10日 In the industrial process fine iron ores should be wet agglomerated and sintered or pelletized to be used as feed in the blast furnace For instance, their surface wettability will contribute to the initial distribution of liquid through the powder and it will define the rate of granule growth and the moisture capacity required to produce agglomeratesWettability in water/iron ore powder systems: To the universality

.jpg)

Comex Group – Sorting technologies and powder processing

Powder processing Comex offers innovative grinding systems that guarantee high grinding capacity and significantly lower energy consumption compared to traditional methods See more Particle analysis At Comex, we offer advanced particle characterization systems from the grinding processIron processing Ores, Smelting, Refining: Iron ores occur in igneous, metamorphic (transformed), or sedimentary rocks in a variety of geologic environments Most are sedimentary, but many have been changed by weathering, and so their precise origin is difficult to determine The most widely distributed ironbearing minerals are oxides, and iron ores consist mainly of Iron processing Ores, Smelting, Refining Britannica2023年11月9日 Rare earth ore processing cases The following takes the most common bastnaesite and beach mineral sand as examples to provide a reference for your rare earth processing Case 1 American bastnaesite processing Unlocking Potential: Rare Earth Elements Processing Once the gold ore is extracted, it undergoes further processing to separate the valuable gold from the impurities This typically involves crushing the ore into smaller fragments and then grinding it into a fine powder The powdered ore is Gold Refinery Process: From Raw Material to Pure Gold

.jpg)

Agglomeration of Iron Ores SpringerLink

Powdery iron ore includes the concentrate and natural rich ore produced by fine grinding separation Iron ore powder agglomeration is the basis for blast furnace ironmaking and is the processing work in between ore crushing, ore grinding separation, and steelmaking Its purpose is to provide highquality furnace burden for steelmaking2024年8月15日 A mineral processing plant is a place dedicated to processing ores, converting raw ores extracted from mines into highgrade mineral products or metals through a series of physical and chemical methods Dry grinding reduces the Mineral Processing Plants: What You Need to KnowCopper From Beginning to End Copper is a major metal and an essential element used by man It is found in ore deposits around the world It is also the oldest metal known to man and was first discovered and used about 10,000 years agoFrom Ore to Finished Product CopperCopper Ore Processing Plant in South Africa: Chemical Separation A copper mine in South Africa adopts the process of leaching — extraction — electrodeposition The plant's copper ore contains oxide ores such as malachite and malachite, and sulphide ores such as chalcocite and bornite Ore processing flow: 1 Crush the ores to 6 mmCopper Ore Processing Plant Fote Machinery

.jpg)

Gold processing Mining, Concentrating, Refining Britannica

2024年11月14日 Gold processing Mining, Concentrating, Refining: The nature of the ore deposit determines the mining and mineral processing techniques applied Oxide ore deposits are frequently of such low grade (eg, 3 to 10 parts per million) that extensive mineral processing cannot economically be justified In this case they are merely shattered by explosives and then 2023年2月15日 Fluorite ore processing plant 1 Africa 100TPD fluorite ore processing plant In a fluorite beneficiation plant in Africa, fluorite and quartz are the main minerals, and there is a small amount of pyrite, sericite, chlorite, calcite, barite, clay minerals and various sulfides4 Steps to Process Complex Lowgrade Fluorite Ore2023年3月13日 The beneficiation methods of oxidized copper ore mainly include gravity separatio, magnetic separation (see details on copper ore processing plant), flotation and chemical beneficiation Azurite: a kind of copper oxide How to Process Copper Ore: Beneficiation Methods and EquipmentWhen iron ore is extracted from a mine, it must undergo several processing stages Six steps to process iron ore 1 Screening We recommend that you begin by screening the iron ore to separate fine particles below the crusher’s CSS before the crushing stageThe six main steps of iron ore processing Multotec

Niobium processing History, Ores, Mining,

niobium processing, preparation of niobium ore for use in various products Niobium (Nb) has a bodycentred cubic (bcc) crystal structure and a melting point of 2,468 °C (4,474 °F) Of the refractory metals, it has the lowest density and 2015年12月26日 In mineral processing or metallurgy, the first stage of comminution is crushing Depending of the type of rock (geometallurgy) to be crushed, there are 2 largely different techniques at your disposition for Crushing in Mineral Processing 911Metallurgist2023年2月15日 Talc powder processing: 1 Coarse crushing: First, the talc ore is evenly sent to a jaw crusher through a vibrating feeder for coarse crushing; 2 Drying: Then the crushed ore is sent to a dryer through a bucket elevator for How to Process Talc (the Softest Mineral)? FTM 2019年8月28日 The article studies the mineralogical features of phosphate ores In the conditions of declining industrial reserves of apatitecontaining ores, issues of a more comprehensive and indepth study of the mineral and material composition, as well as the improvement of existing technologies for the processing of this type of raw material, become Mineralogical and Technological Aspects of Phosphate Ore Processing

.jpg)

Microwave Treatment of Minerals and Ores: Heating Behaviors

2024年2月21日 The application of microwave technology in mineral metallurgy is a transformative approach to ore processing that offers new ideas about the current progressive depletion of resources and the environmental impact of mineral processing This review delves into the principles, applications, and future directions of microwave treatment in mineral and 2024年5月30日 Quartz Crushing Jaw crushers are the ideal choice for primary crushing of quartz ore, effectively breaking down the highhardness mineral Subsequently, cone crushers (or impact crushers) further reduce the quartz to below 25 mm Quartz Grinding The finely crushed quartz particles are conveyed by bucket elevators to storage bins, then fed into quartz ball Quartz Processing Mastering the Art of Stone to Powder2021年3月15日 Iron ore concentration typically involves comminution, Mineral Processing and Extractive Metallurgy Review An International Journal Volume 43, 2022 Issue 4 Submit an article Journal homepage 1,222 Views 20 CrossRef citations to date Iron Ore Pelletization: Part I Fundamentals: Mineral Processing 2024年10月30日 Ore is a deposit in Earth’s crust of one or more valuable mineralsThe most valuable ore deposits contain metals crucial to industry and trade, like copper, gold, and iron Copper ore is mined for a variety of industrial uses Copper, an excellent conductor of electricity, is used as electrical wire Copper is also used in constructionOre Education National Geographic Society

Iron Ore Pelletizing Process: An Overview IntechOpen

The iron ore production has significantly expanded in recent years, owing to increasing steel demands in developing countries However, the content of iron in ore deposits has deteriorated and lowgrade iron ore has been processed The fines resulting from the concentration process must be agglomerated for use in iron and steelmaking This chapter shows the status of the 2021年7月19日 Today’s steelmaking from iron ore is globally a main source for CO 2emissions causing global warmingIn Sweden more than 10% of all CO 2 emissions originate from the reduction process of iron ore to iron When an environmentally friendly chemical reduction is found in an orebased laser additive manufacturing process, CO 2 emissions will be avoided, From mine to part: directed energy deposition of iron ore2015年8月3日 This study investigates the potential application of microwave imaging (MWI) in ore sorting systems for mineral processing Modern sensorbased ore sorting employs various sensing methods, such as (PDF) Overview of Mineral Processing Methods2023年10月17日 Factors for choosing a suitable ore powder grinding mill 1 Raw material characteristics: Different raw materials have different hardness, humidity and grinding and crushing properties, and the corresponding ore How to choose a suitable ore powder grinding mill?

Iron Ore Pelletizing Process: An Overview

PDF On Jul 11, 2018, Sandra Lúcia de Moraes and others published Iron Ore Pelletizing Process: An Overview Find, read and cite all the research you need on ResearchGateThe continuous advancements in ore powder production process equipment are transforming the mineral processing industry With the ability to produce highquality powders efficiently and sustainably, these technologies are not only meeting the demands of various applications but also contributing to the environmental stewardship of the industryAdvancements in ore powder production process equipment: 2024年4月26日 Crushing is the initial stage in the iron ore processing journey, where large chunks of ore are broken down into smaller fragments The primary objective of crushing is to reduce the ore size for subsequent processing and improve the liberation of valuable minerals from the gangue a Jaw Crushers: Jaw crushers are commonly used for primary Iron Ore Processing: From Extraction to ManufacturingChromium processing, preparation of the ore for use in various products Chromium (Cr) is a brilliant, hard, refractory metal that melts at 1,857 °C (3,375 °F) The Cr 2 O 3 is blended with finely divided aluminum powder, charged to a refractorylined container, and ignited The combustion quickly generates temperatures in excess of 2,000 Chromium processing Extraction, Uses Applications Britannica

.jpg)

Ore Processing Official Mekanism Wiki aidancbrady

This tier triples ingot yield for SilkTouch'ed ores, or doubles the yield for standard raw ores It starts by processing raw ores in the Purification Chamber This machine is the first introduced in the ore processing pipeline that uses an additional input component as a part of processing its ore In this case, the chamber uses Oxygen2017年5月10日 In the industrial process fine iron ores should be wet agglomerated and sintered or pelletized to be used as feed in the blast furnace For instance, their surface wettability will contribute to the initial distribution of liquid through the powder and it will define the rate of granule growth and the moisture capacity required to produce agglomeratesWettability in water/iron ore powder systems: To the universality Powder processing Comex offers innovative grinding systems that guarantee high grinding capacity and significantly lower energy consumption compared to traditional methods See more Particle analysis At Comex, we offer advanced particle characterization systems from the grinding ex Group – Sorting technologies and powder processingIron processing Ores, Smelting, Refining: Iron ores occur in igneous, metamorphic (transformed), or sedimentary rocks in a variety of geologic environments Most are sedimentary, but many have been changed by weathering, and so their precise origin is difficult to determine The most widely distributed ironbearing minerals are oxides, and iron ores consist mainly of Iron processing Ores, Smelting, Refining Britannica