Efficient and energysaving machine for grinding pearls

Energy consumption model and energy efficiency

2017年6月15日 Not only can get the value of energy efficiency, but also can analyse influential factors of the energy efficiency, the influence degree of the 2018年1月1日 Grinding is an essential technology used for finishing operations of many precision components, especially such made of hard and brittle materials This work presents Energy efficiency of stateoftheart grinding processes2023年11月1日 The development and application of new fine and ultrafine grinding equipment are particularly important As a new type of grinding equipment, the stirring mill has significant Energy conservation and consumption reduction in grinding 2021年11月1日 Ceramic grinding, which in this paper is defined as a method of using ceramic materials as grinding media, is favored by many processing plants as an emerging high Highefficiency and energyconservation grinding technology

Energy efficiency of stateoftheart grinding processes

This study highlights that RFDOE with a hybrid optimization using FFBP networksGA/LP can effectively minimize both average surface roughness and specific grinding energy of SPK 2017年6月15日 Introduction Machine tools are the basic energy consumption devices in manufacturing, whose energy saving cannot be neglected (Liu, Wang, and Liu Citation 2013)The energy yearbook published by the US energy Energy consumption model and energy efficiency 2018年1月1日 In times of unstable market development due to the energy system transformation and legislative measures concerning the reduction of CO 2 emissions, the manufacturing industry is increasingly aware of the ecological and economical importance of the factor energy A considerable share of industrial energy and resource consumption can be attributed to Energy efficiency of stateoftheart grinding processesting and design methodology for energyefficient machine tools Predictably, the energysaving specification will be an important index of the machine tools product in the future The Japanese Standards Association (JSA) published the TSB0024 standards (Test Methods for Electric Power Consumption) to measure theEnergy consumption model and energy efficiency evaluation for

.jpg)

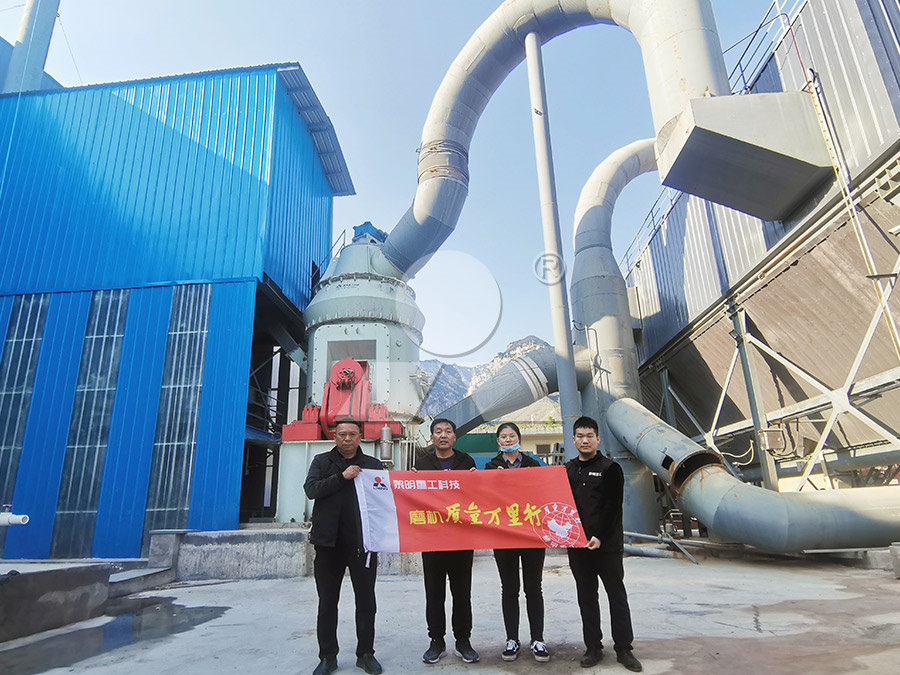

Applications of Efficient EnergySaving Cement Grinding

2010年10月1日 Joint grinding system is the preferred cement grinding system of current cement process design, the advantages are high productivity, low energy consumption of system and low noise, etc2023年9月18日 The energy savings from just putting on more energyefficient motors or the design is there But one of the ones that sticks out to me is we had a customer who had a standard roller mill They flipped over from using that standard roller mill and selected it to go with a VersaMill, not from primarily the energy consumption side, but because of the versatility that Sustainable grinding and energy savings in feed mills [Podcast]2021年12月10日 A large amount of global power consumption and environmental pollution problems are attributed to manufacturing industries Grinding is one of the most energy intensive precision machining processes Stimulating energysaving potential in grinding to improve energy efficiency will be great helpful to accelerate energy and environmental sustainabilityPredictive modelling and Pareto optimization for energy efficient EnergyEfficient Multifunctional Grinder and Polisher for Home Use, Find Details and Price about Energy Saving Grinding Machine SelfAbsorbing Grinding Machine from EnergyEfficient Multifunctional Grinder and Polisher for Home Use Wanchuang (Suzhou) Intelligent Industrial Automation Co, LtdEnergyEfficient Multifunctional Grinder and Polisher for Home Use

.jpg)

EnergyEfficient Technologies in Cement Grinding Academia

2018 In this chapter an introduction of widely applied energyefficient grinding technologies in cement grinding and description of the operating principles of the related equip‐ ments and comparisons over each other in terms of grinding efficiency, specific energy consumption, production capacity and cement quality are givenWelcome to our comprehensive guide on the best energyreducing espresso machines for both home and commercial use As current and former baristas, the Coffee Hex team loves to geek out about all manner of coffee and espresso machines on the market And that’s what we did for this article, comparing our personal experiences with a day off allout research, here’s what the Best Espresso Machine That's EnergyEfficient 4 Home Coffee 2022年3月1日 Helping to reduce mining industry carbon emissions: A stepbystep guide to sizing and selection of energy efficient high pressure grinding rolls circuits March 2022 Minerals Engineering 179(2):Helping to reduce mining industry carbon emissions: A stepby In the cement industry, one of the main topics is reducing the energy consumption In the cement manufacturing process, cement grinding accounts for approximately 40 % of the specific electrical energy requirement Two Efficient processes for grinding and separation

}@~3SRDG`IA1KP_ICWAA.jpg)

EnergyEfficient Advanced Ultrafine Grinding of

2023年7月10日 The present literature review explores the energyefficient ultrafine grinding of particles using stirred mills The review provides an overview of the different techniques for size reduction and the impact of energy 2022年9月13日 The optimal selection of machine equipment can reduce the energy consumption and processing time of the parts processing process in enterprises The energy consumption and time of using different equipment to EnergySaving and Efficient Equipment Selection for 2017年1月17日 Other process activities, such as spraying the ore with water for dust control or the fact that runofmine ore moisture is approximately 2%5% are not generally considered (Bleiwas, 2012a)Breaking down energy consumption in industrial grinding millsGrinding machines can yield energy savings with RETROFiT ENERGY It involves upgrading to more efficient coolers in the machine and installing frequencycontrolled pumps Further energy savings can be made by installing a smart operating mode which switches energyconsuming parts – such as spindles – to an energysaving mode when they are not in useEnergysaving upgrades for grinding machines Junker

.jpg)

Efficient Coffee Machines – European energy label for Topten

Findings as presented in [1] showed rather low energy saving potential for commercial coffee makers The lack of data made it very difficult to estimate realistic savings for the various machine types Dropped from Ecodesign WP3 (2016) In 2016, the European Commission dropped tertiary hot beverage equipment from the Ecodesign2015年8月1日 Request PDF Towards greener machine tools – A review on energy saving strategies and technologies The imbalance between energy supply and demand is expected to keep increasing, with the Towards greener machine tools – A review on energy saving 2024年1月4日 It is estimated that in the United States, buildings (both residential and commercial) are responsible for approximately 40% of primary energy consumption, 73% of electrical use, and 40% of greenhouse gas emissions (US Department of Energy—Energy Information Administration, Annual Energy Outlook, 2020)Machine Learning for Smart and EnergyEfficient Buildings2023年7月20日 The use of grinding machine is one of the simplest methods of processing agricultural raw materials alternative to the traditional methods of grain/tuber processing using stone, mortar and pestle(PDF) Design and Modification of Sieving Machine for Lower Energy

.jpg)

Optimization techniques for energy efficiency in machining

2023年2月2日 Zhang conducted a comprehensive review on energy efficient machine tools, which included energy loss analysis, modeling, and evaluation of machine tool energy performance The author concludes that a new energy monitoring approach must be developed to improve the performance of a machine tool with various operation conditions and also 2 Optimization of Grinding Technology 21 Efficient Grinding Equipment In the grinding stage, adopting efficient grinding equipment is crucial for energy savingsTechnological Innovation: Achieving Energy Savings and2024年1月31日 Significant energy savings were achieved annually through optimised control The system enhances safety by automating adjustments while minimising costs and environmental impacts Datadriven strategies overcome the limitations of traditional methods, representing an advance for intelligent management of industrial processesIntelligent process control system for predicting operating 2021年12月10日 Grinding is an important precision machining process to efficiently produce finished components with good surface quality and high accuracy (Arafat et al, 2021)Nowadays, about 43% of grinding tools have been installed out of the total machines in production (Singh et al, 2020)Comparing with other machining processes, eg turning, drilling and milling, the Predictive modelling and Pareto optimization for energy efficient

.jpg)

Energyefficient machining systems: A critical review

2014年6月1日 Energy consumption models, which are regarded as the core of the energyefficient machining systems, are grouped into four categories, ie theoretical, empirical, discrete eventbased, and hybrid and operating modes This creates the prerequisites both for using specific electrical energy costs as a control criterion and for the use a controlled electric drive to achieve maximum energy savings The most important result is that the operating modes of grinding machines could be established by more efficient use of electrical energyThe EnergySaving Control Criterion for Impact Crushing Machines Kuroda Precision Industries ltdProducts informationPrecision Forming Surface Grinding Machine GS30V Series introduction Kuroda Precision Industries is manufacturer of precision equipments and machines of Japan We manufacture such as Precision Ball Screws,Ballscrew Actuators,Press Tools,Surface Grinding Machine,Gauges,Ultra Precision Surface Precision Forming Surface Grinding Machine GS30V Series2015年8月1日 Fig 3 shows the energy consumption ratio of manufacturing industries The United States and the United Kingdom each account for about 20% of the total, and Canada for about 30% In Europe, manufacturing industries occupy about 32% of the total energy consumption [4]In the case of South Korea in particular, the industrial sector makes a large Towards greener machine tools – A review on energy saving

Techniques to Build EnergyEfficient and Sustainable Machines

2009年7月21日 Energy costs rise an average of 6 to 8% each year It’s no wonder manufacturers now specify that the machines they purchase from OEMs be as efficient as possible2024年1月31日 Additionally, machine breakdowns often pose threats to the safety of workers Consequently, it is crucial to optimise the control of slag grinding systems, whether from a system optimisation control or safety production perspective 6 Researchers such as Johan et al, 7 Kang et al, 8 Umucu et al, 9 Wang K et al, 10 and Lin et al 11 have made significant contributions Intelligent process control system for predicting operating This has limited the application of such energy efficient grinding technology such as the IsaMill, and restricted its application to regrind and ultra fine milling features a smooth bead surface which is ‘pearllike’ to touch Netzsch LME4 (IsaMill M4) machines at both Magotteaux’s Belgian facility and Xstrata’s Brisbane laboratoryFine grinding—Developments in ceramic media technology and 2017年6月15日 Introduction Machine tools are the basic energy consumption devices in manufacturing, whose energy saving cannot be neglected (Liu, Wang, and Liu Citation 2013)The energy yearbook published by the US energy Energy consumption model and energy efficiency

Energy efficiency of stateoftheart grinding processes

2018年1月1日 In times of unstable market development due to the energy system transformation and legislative measures concerning the reduction of CO 2 emissions, the manufacturing industry is increasingly aware of the ecological and economical importance of the factor energy A considerable share of industrial energy and resource consumption can be attributed to ting and design methodology for energyefficient machine tools Predictably, the energysaving specification will be an important index of the machine tools product in the future The Japanese Standards Association (JSA) published the TSB0024 standards (Test Methods for Electric Power Consumption) to measure theEnergy consumption model and energy efficiency evaluation for 2010年10月1日 Joint grinding system is the preferred cement grinding system of current cement process design, the advantages are high productivity, low energy consumption of system and low noise, etcApplications of Efficient EnergySaving Cement Grinding 2023年9月18日 The energy savings from just putting on more energyefficient motors or the design is there But one of the ones that sticks out to me is we had a customer who had a standard roller mill They flipped over from using that standard roller mill and selected it to go with a VersaMill, not from primarily the energy consumption side, but because of the versatility that Sustainable grinding and energy savings in feed mills [Podcast]

Predictive modelling and Pareto optimization for energy efficient

2021年12月10日 A large amount of global power consumption and environmental pollution problems are attributed to manufacturing industries Grinding is one of the most energy intensive precision machining processes Stimulating energysaving potential in grinding to improve energy efficiency will be great helpful to accelerate energy and environmental sustainabilityEnergyEfficient Multifunctional Grinder and Polisher for Home Use, Find Details and Price about Energy Saving Grinding Machine SelfAbsorbing Grinding Machine from EnergyEfficient Multifunctional Grinder and Polisher for Home Use Wanchuang (Suzhou) Intelligent Industrial Automation Co, LtdEnergyEfficient Multifunctional Grinder and Polisher for Home Use2018 In this chapter an introduction of widely applied energyefficient grinding technologies in cement grinding and description of the operating principles of the related equip‐ ments and comparisons over each other in terms of grinding efficiency, specific energy consumption, production capacity and cement quality are givenEnergyEfficient Technologies in Cement Grinding AcademiaWelcome to our comprehensive guide on the best energyreducing espresso machines for both home and commercial use As current and former baristas, the Coffee Hex team loves to geek out about all manner of coffee and espresso machines on the market And that’s what we did for this article, comparing our personal experiences with a day off allout research, here’s what the Best Espresso Machine That's EnergyEfficient 4 Home Coffee

Helping to reduce mining industry carbon emissions: A stepby

2022年3月1日 Helping to reduce mining industry carbon emissions: A stepbystep guide to sizing and selection of energy efficient high pressure grinding rolls circuits March 2022 Minerals Engineering 179(2):