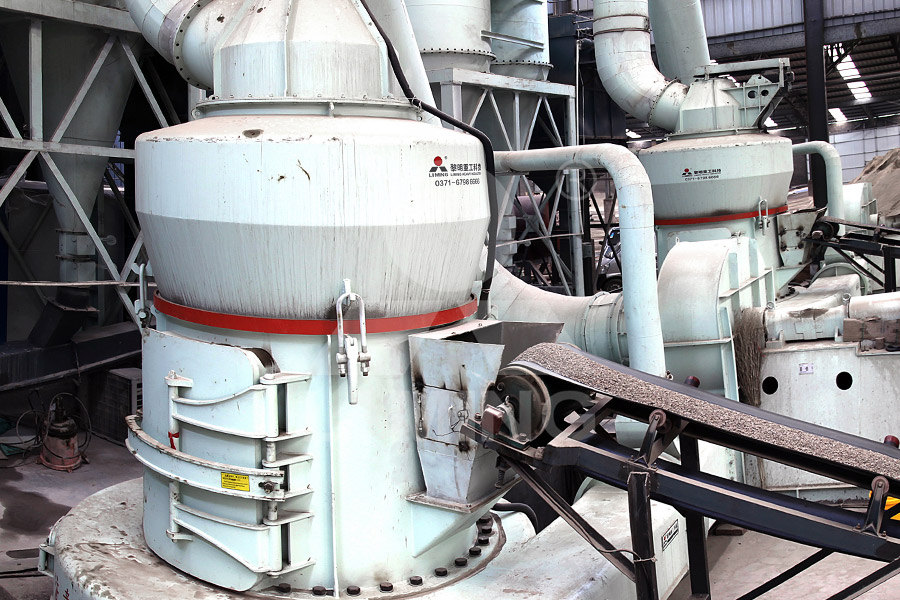

Raymond mill traditional fine crushing equipment can effectively save 50

.jpg)

Raymond Ultrafine Mill Qlar

The Raymond Ultrafine Mill System is designed to produce extremely fine powders for use in various applications including coatings, fillers, and pigments The mill system will generate The Raymond® Ultrafine Mill System is designed to produce extremely fine powders for use in various applications including coatings, fillers, and pigments The mill system will generate Raymond® Ultrafine Mill CoperionThe Raymond® Ultrafine Mill System is designed to produce extremely fine powders for use in various applications including coatings, fillers, and pigments The mill system will generate Ultrafine mill Schenck Process Holding GmbH Raymond / Optimized internal design greatly improves its production efficiency and can save 20% of the time compared with the traditional grinding mill to complete the same processing capacity At the Raymond Mill Makes Coarse Powder Processing More Efficient

.jpg)

Crushing and Grinding Process JXSC Machine

2019年10月8日 The crushing and grinding operations are an important part of the processing of mineral resources, and it is also operation with high investment and high energy consumption In the case of metal mines, equipment The Raymond Vertical Mill is designed to pulverize materials into the extreme fineness range, with particle sizes as small as 510 microns It uses a principle of integral air classification to efficiently produce finely ground materials The mill Raymond Vertical Mill Technical Datasheet PDF Mill 2024年5月30日 Quartz Crushing Jaw crushers are the ideal choice for primary crushing of quartz ore, effectively breaking down the highhardness mineral Subsequently, cone crushers (or impact crushers) further reduce the quartz to Quartz Processing Mastering the Art of Stone to PowderThis grinding mill integrates crushing, drying, grinding, separating and transport The structure is simple while the layout is compact Its occupational area is about 50% of that of the ballmilling system The LM grinding mill can also be arranged outdoors, which greatly reduces the investment costLM Vertical Grinding MillSBM Industrial Technology Group

.jpg)

China RM Series Raymond Mill Factory, Manufacturer JINGHUA

It has both the wide feed particle size requirements of the Raymond mill and the ultrafine crushing function of the ultrafine mill Crushing, grinding, and ultrafine are all done in one step, and the fineness can reach d90:10um 5 Convenient operationRaymond Roller Mill Brochure Free download as PDF File (pdf), Text File (txt) or read online for free The document discusses Raymond roller mills which are used to grind materials Key details include that Raymond has over 125 years of experience building these mills, they can grind a wide variety of materials from 1050mm in size down to fine particles, and each system is Raymond Roller Mill Brochure PDF Mill (Grinding) GearLUM Ultrafine Vertical Grinding Mill In contrast to typical grinding mills, this specific mill cuts down energy consumption by 30% to 50% SCM Ultrafine Grinding Mill The multihead cagetype powder selector can be tailored to meet user demands for output, fineness, and sieving efficiencyCrusherJaw crusherImpact crusherCone crusherGrinding millRaymond 2022年3月9日 Advantages of Raymond mill 1 High fineness of finished products: The finished powder after Raymond mill treatment has uniform fineness, and the sieving rate can reach 99% 2 Strong wear resistance: The important parts of the machine are made of highquality castings and profiles, and the craftsmanship is fine, which ensures the durability of the entire grinding How to set the mesh of Raymond mill?

500TPH Limestone Crushing Plant JXSC Machine

2022年3月9日 This setup is a 500tph complete limestone crushing plant, the max input size is 1020mm, output sizes are 05mm, 519mm, 1925mm,2550mm It is configured with hopper, vibrating feeder DN6015, primary jaw crusher PE1200*1500, 2 sets impact crusher PF1520,4 sets vibrating screen 2YD3072, and 12 pcs belt conveyors Flowchart Explanation 1 The At the meeting, CLIRIK highlighted two ultrafine Raymond mills that are widely acclaimed in the field of calcium carbonate powder processing: HGM ring roller micro powder grinding Raymond mill and CLUM ultrafine vertical roller Raymond mill, helping to Ultra Fine Raymond Mill Is The Future Of Calcium Carbonate Save 30%50% energy As China's largest crushing plant,mill equipments and beneficiation plants production base, kefid has exported large quantities and highend mobile crushing plant and milling equipments to Russia, Kazakhstan, Indonesia Raymond Mill LUM SERIES ULTRAFINE GRINDING MILL2012年2月6日 The new Raymond ultra fine mill system is designed to produce fine powders used in fillers, coatings, and pigments Capable of generating products as fine as 50% passing 2 microns or as coarse as 50% passing 10 Raymond Ultra Fine Mill Powder Bulk Solids

Raymond Mill Raymond Mill For Sale AGICO

Compared with the traditional oldstyle Raymond mill, it reduces the falling speed of the material through the grinding zone, prolongs the crushing and pulverizing time, and has the Raymond mill The machine has a wide range of feed Low Construction Cost: Compared with the vertical mill and ball mill system, the land area can be reduced by 50%, and the construction cost can be reduced by about 70% Due to the combination of crushing, drying, grinding, grading, and transportation, the system is simple and can be arranged in the open ai and low investment and construction costCRLM1300 Vertical MillVertical Roller Mill Raymond Mill2022年10月4日 The semidry production process can save 35–50% of land resources (flat type is 35%, slope type is 50%) and raw materials compared with the traditional production process In the process of producing, the waste mud and impurities can be used for rehabilitation and restoration of ecological balanceProduction of Manufactured Sand SpringerLink2021年10月13日 Coal Gangue Pulverizer Raymond Mill Finished product fineness: 80325 mesh Production capacity: 15100t/h It is suitable for the processing of more than 300 kinds of highfine powder materials in nonflammable and explosive mineral, chemical, construction and other industries with Mohs hardness not greater than 7 and humidity below 6%How To Effectively Use Coal Gangue?

Limestone crushing and grinding production line SBM Ultrafine

2022年4月20日 Medium and fine crushing: The coarsely crushed limestone is then subjected to medium and fine crushing We can choose impact crusher for equipment Some stones use cone crusher for secondary crushing, but the hardness of limestone is not high Considering the problem of investment cost, we choose impact crusher Crusher is more costeffectiveFTM Machinery sand making equipment can offer numerous advantages for your various applications: The machine has the functions of fine crushing and coarse grinding Compared with traditional sand making machines, it can save energy by 50%, and the sandforming rate is 20% higher Maximum feed size: Hard material 45 mm, Sand Making Machine: HighQuality Sand Production Fote 2024年10月22日 b) Fine Crusher The fine crusher uses 50% less energy than traditional machines and provides better sand output Its investment and longterm maintenance costs are 35%–50% lower than traditional methods It has a simple structure and streamlined process, making maintenance easier It is perfect for small to medium sand production linesA Comprehensive Guide to Sand Making Plants and MachinesMining tertiary crusher is an efficient, energysaving crushing equipment that can save energy 50% than traditional crushers The tertiary stone crusher is also be called fine crusher As the name suggests, it is a crusher for fine crushing and always used after coarse crushers like concrete jaw crushers and secondary crushers like impact crushers and cone crushersSecondary Tertiary Crusher Saves Energy 20% Than Common

Limestone Aggregate Crushing JXSC Machine

1 Firststage Crushing The Limestone raw material is transported to the jaw crusher by the vibrating feeder for coarse crushing 2 Secondstage Crushing Screening After coarse crushing, the Limestone enters the impact crusher for operation, there is no sewage discharge, which can effectively reduce pollution and improve the level of environmental protection Advantages of Equipment 2 Save Electrical Energy长久 The newly invented beneficiation equipment saves more than 30% of electricity than the traditional equipment When the equipment is idling, it is only 10%introduction of new type iron ore grinding and dry separation2024年7月31日 Raymond mill is mainly used as a piece of common mining equipment, which is mainly suitable for grinding various minerals, chemicals, construction, and other industries of more than 300 kinds of materials with Raymond Mill For Making Fine Charcoal Powder2013年7月15日 Energy Efficient Ball Mill Circuit – Equipment Sizing Their results showed that fine screening can provide sharp classification An average classification efficiency of 50% can be (PDF) Energy Efficient Ball Mill Circuit – Equipment Sizing

Dry Permanent Magnetic Separator: Present Status and Future

2022年9月30日 preselection of products after the highpressure roller mill fine crushing, but due to equipment space limitati ons, the improvement in magnetic tumbling is limited, and the tailing rate is low 2023年3月3日 It can independently complete the screening system of limestone coarse crushing or fine crushing, which realizes the installation form of integrated unit equipment and is more flexible and adaptable The limestone can be directly crushed on site, which eliminates the intermediate link of recrushing limestone away from the site, and greatly reduces the 5 Limestone crushers make benefits to limestone plantAnd YS can provide you with six crushers for your choice Such as hammer mill, mobile wood crusher, mobile disc type tree stump shredder, double shafts shredder, charcoal wheel grinder and Raymond mill You can choose them according to your needs And we can also customize crushers according to your actual production conditionCharcoal Grinder Machine 6 Types of Crushers CharacteristiicThe cement roller press is a kind of important cement equipment applied in cement grinding units we usually adopt the cement roller press to replace the fine crushing and coarse grinding role of the ball mill This increases the output of the ball mill system by 3050%, and 2035% of the extruded materials are smaller than 008mm, Cement Roller Press Roller Press In Cement Plant Roller Press

Can Raymond Mill Be Used As A Vertical Mill? How to

2021年2月18日 Among them, Raymond mill adopts integral transmission (by bevel gear), which makes a limited area and a more reasonable layout; while the vertical mill occupies about 50% of ball mill, and can be arranged in the open air, which greatly reduces investment costsCXM Ultrafine roller mill JHM ball mill The height above ground is by 50% compare with traditional grinding machine reduce the workshop height, compare with traditional Raymond mill, reducing the material failing speed through the grinding area, prolonged the grinding time, RM new Raymond mill2019年10月8日 The crushing and grinding operations are an important part of the processing of mineral resources, and it is also operation with high investment and high energy consumption In the case of metal mines, equipment Crushing and Grinding Process JXSC MachineThe Raymond Vertical Mill is designed to pulverize materials into the extreme fineness range, with particle sizes as small as 510 microns It uses a principle of integral air classification to efficiently produce finely ground materials The mill Raymond Vertical Mill Technical Datasheet PDF Mill

Quartz Processing Mastering the Art of Stone to Powder

2024年5月30日 Quartz Crushing Jaw crushers are the ideal choice for primary crushing of quartz ore, effectively breaking down the highhardness mineral Subsequently, cone crushers (or impact crushers) further reduce the quartz to This grinding mill integrates crushing, drying, grinding, separating and transport The structure is simple while the layout is compact Its occupational area is about 50% of that of the ballmilling system The LM grinding mill can also be arranged outdoors, which greatly reduces the investment costLM Vertical Grinding MillSBM Industrial Technology GroupIt has both the wide feed particle size requirements of the Raymond mill and the ultrafine crushing function of the ultrafine mill Crushing, grinding, and ultrafine are all done in one step, and the fineness can reach d90:10um 5 Convenient operationChina RM Series Raymond Mill Factory, Manufacturer JINGHUARaymond Roller Mill Brochure Free download as PDF File (pdf), Text File (txt) or read online for free The document discusses Raymond roller mills which are used to grind materials Key details include that Raymond has over 125 years of experience building these mills, they can grind a wide variety of materials from 1050mm in size down to fine particles, and each system is Raymond Roller Mill Brochure PDF Mill (Grinding) Gear

CrusherJaw crusherImpact crusherCone crusherGrinding millRaymond

LUM Ultrafine Vertical Grinding Mill In contrast to typical grinding mills, this specific mill cuts down energy consumption by 30% to 50% SCM Ultrafine Grinding Mill The multihead cagetype powder selector can be tailored to meet user demands for output, fineness, and sieving efficiency2022年3月9日 Advantages of Raymond mill 1 High fineness of finished products: The finished powder after Raymond mill treatment has uniform fineness, and the sieving rate can reach 99% 2 Strong wear resistance: The important parts of the machine are made of highquality castings and profiles, and the craftsmanship is fine, which ensures the durability of the entire grinding How to set the mesh of Raymond mill?2022年3月9日 This setup is a 500tph complete limestone crushing plant, the max input size is 1020mm, output sizes are 05mm, 519mm, 1925mm,2550mm It is configured with hopper, vibrating feeder DN6015, primary jaw crusher PE1200*1500, 2 sets impact crusher PF1520,4 sets vibrating screen 2YD3072, and 12 pcs belt conveyors Flowchart Explanation 1 The 500TPH Limestone Crushing Plant JXSC MachineAt the meeting, CLIRIK highlighted two ultrafine Raymond mills that are widely acclaimed in the field of calcium carbonate powder processing: HGM ring roller micro powder grinding Raymond mill and CLUM ultrafine vertical roller Raymond mill, helping to Ultra Fine Raymond Mill Is The Future Of Calcium Carbonate