50 kg ball mill technical parameters

Ball Mill Design/Power Calculation 911Metallurgist

2015年6月19日 The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, Ball mill is the key equipment for grinding materials after crushing and screening It is also commonly used in grinding equipment I It is mainly used in refractory, fertilizer, cement and BALL MILL FOR ALL YOUR NEEDS FTM MachineryThe mill balls calculated parameters 8 1 FIELD OF APPLICATION This standard applies to steel grinding balls produced by rolling, forging, STEEL MILLING BALLS FOR BALL MILLS Energosteel Grinding technical warranty parameters Tests are carried out both on a production scale and a pilot scale Spread over approx 3000 m 2, the application testing centre provides ample space for ALPINE AGITATED BALL MILL ANRCL

.jpg)

TECHNICAL SPECIFICATION OF WET BALL MILL EQUIPMENT

The Wet Ball Mill system consists of Wet Ball Mill, Wet Ball Mill Lubrication system, Mill circuit tank with an agitator, Mill circuit Pump, Mill Hydro cyclone, 3way distributor and accessories This standard is applied to milling balls with diameter of 15120 mm made of low alloy carbon steelor alloy carbon steel using methods of cogging, beating out and pressing and used forSTEEL MILLING BALLS FOR BALL MILLS SpecificationsBall Milling Mid Size Balls Molycop manufactures balls for grinding operations (using high carbon alloy steel bars as the raw material) through special bar heating, forging and heat treatment MCGBLMIDTS20 Version 20 Ball Milling TechnicalPBM 14 planetary ball mill is designed for fine grinding of materials of different hardness in batch mode The grinding can be performed dry or wet The mill is produced by VIBROTECHNIK Planetary ball mills VIBROTECHNIK

.jpg)

Influences of operating parameters on dry ball mill performance

This experimental study is aimed to examine the influence of various operating parameters such as mill speed (% of Nc), ball filling ratio (J), ball size distribution (%), powder filling ratio (fc), Technical Parameter Table(I) of Vertical Planetary Ball Mill (Square Type) Type No Remarks: XQM1: 1L: 50250ml: 4pcs: Matched with vacuum mill pots from 50ml to 250ml: XQM2: 2L: 50500ml: 4pcs: Matched with vacuum mill pots Vertical Planetary Ball Mill (Square Type) from China During the operation of the planetary ball mill, it generates an extremely high level of impact energy between the grinding balls and the grinding jars, allowing it to complete the sample grinding in a very short duration The fundamental Planetary Ball Mill TorontechTechnical Parameter Table Parameters of Cryogenic Planetary Ball Mill Model No Power (KW) Voltage Revolution Speed (rpm) Rotation Speed (rpm) Total Timing (min) Alternating Run Time of Forward Reversal Rotation(min) KC6 6L 115L 4pcs Can be Cryogenic Planetary Ball Mill Korea Process Technology

Calibration of DEM Parameters to Simulate a Planetary Ball Mill

2022年1月1日 Planetary ball mill is a powerful tool, which has been used for milling various materials for size reduction The discrete element method (DEM) was used to simulate the dynamics of particle LAARMANN’s Planetary Ball Mill has, unlike other similar Reproducible results due to progr grinding parameters; CE – certified; Watch Video Buy Product Buy Components Dimenstions closed W x D x H: ca 1090 x 660 x 1400 mm: Effective sun wheel diameter: 360 mm: Sun wheel speed: 50 – 400 min1: Electrical requirements: 200240 LM PBM4000 Planetary Ball Mill Laarmann Group BVparameters such as mill speed, ball filling ratio, ball size distribution, powder filling ratio, grinding aid 50, d 80) and surface area (m2/kg) As a result of this study, optimum grinding test conditions determined to be 70% of Nc, J=035 for ball Influences of operating parameters on dry ball mill performanceLABINDIA Planetary Ball Mill BM1150+ (Two Grinding Stations) is suitable for grinding (Dry / Wet) and mixing some soft, hard, brittle and fibrous samples, which are used wherever the highest degree of fineness as customer required, as well as the grinding result is reproduciblePlanetary Ball Mill BM1150+ (Two Grinding Stations) Labindia

.jpg)

MZ Vibration Mill Impact Mill ALPA Powder Tech

Compared with ball mill, higher grinding efficiency, Medium and small Amplitude Vibration Mill Technical Parameter Parameter: MZ10: MZ30: MZ50: MZ100: MZ200: MZ300: MZ500: Chamber Volume(L) 10: 30: 50: 100: 200: 300: 500: Produce Size (μm) 10150: 10150: 10150: 10150: 10150: 10150: 10150: Production Capacity (kg/h) 15: 520: 10 The effects of various technical parameters, such as ball size and density of ball material, 3 kg/m3) Alumina (35 X 103 ) Glass (25 X 103 ) *Steel shot selected by an inclined plate 8 4 2 1* 10 5 in a tumbling ball mill and about 50 times greater than that in a stirred ball mill2)The Mechanism and Grinding Limit of Planetary Ball Millingt J Technical Parameter Table Parameters of Cryogenic Planetary Ball Mill; Model No Power (KW) Voltage Revolution Speed (rpm) Rotation Speed (rpm) Total Timing (min) Can be matched with 50250ml vacuum mill jar: KC4: 4L: 2501000ML: 4pcs: Can be matched with 501000ml vacuum mill jar: KC6: 6L: 115L:KCSeries Cryogenic Planetary Ball Mill 한국코프로텍 (주)A batch ball mill is a machine to grinds the crushed materials, which is widely used in the manufacturing industries, such as cement, silicate, new building material, refractory material, fertilizer, ferrous metal, nonferrous metal, and Batch Small Ball Mill JXSC Machine

Effect of Ball Mill Parameters’ Variation on the Particles of a

Effect of Ball Mill Parameters’ Variation on the Particles of a Mechanical Activation‑Assisted Leaching: A Hydrometallurgical Mechanics Oluwasegun Samuel Odebiyi1,2 Hao Du1,2 Kayode Hassan Lasisi2,3 Biao Liu1 Shaona Wang1 Charlse Chukwuemeka Nwakanma4 Mary Otuosorochukwu Nnyia2,5Ball Mill Design Parameters For grate discharge mills, the charge should occupy about 50% of the mill volume Dry Ball Mill = kg / kWh = 0023A i 05; Replacement Ball Size Rowland and Kjos proposed the use of their equation for the determination of the AMIT 135: Lesson 7 Ball Mills Circuits – Mining Mill Operator Vertical planetary ball mill is a necessary device of hightech materials mixing, 50500ml: 4pcs: Matched with vacuum mill pots from 50ml to 250ml: XQM4: 4L: Technical Parameter Table(II) of Vertical Planetary Ball Mill (Square Type) Model: Power (KW) Voltage: Revolutionvertical lab planetary ball mill, lab ball mill, lab grinder• Technical features of Tencan Ball Mill: Low center of gravity, stable performance, compact structure, Application Technical parameter Technical Features of Horizontal Planetary Ball Mill; Drive Mode 50100ML: 4pcs: Can be matched with 50ml vacuum mill KM Mini Vertical Planetary Ball Mill 코프로몰

.jpg)

Vertical Planetary Ball Mill (Semicircle Type) BIOBASE

Application: Planetary Ball Mill has four ball grinding tanks installed on one turntable When the turntable rotates, the tank axis makes planetary movements, the balls and samples inside the tanks are impacted strongly in high speed movement, and samples are eventually ground into powder Various kinds of different materials can be ground by the mill with dry or wet method Planetary ball mills are used for grinding with highest fineness high pulverization energy short grinding times reproducible results Learn Comfortable parameter setting via display and ergonomic 1button operation ; Planetary Ball Mill PM 100 Technical Data Applications: pulverizing, mixing, homogenizing, colloidal milling, Planetary Ball Mill PM 100 RETSCH highest finenessKM Mini Vertical Planetary Ball Mill Overview Vertical planetary ball mill is a necessary device of hightech materials mixing, Application Technical parameter Technical Features of Horizontal Planetary Ball Mill; Drive Mode Gear drive and belt drive; 50100ML: 4pcs: Can be matched with 50ml vacuum mill jar: Mill Jar and Mill Ball KM Mini Vertical Planetary Ball Mill 한국코프로텍 (주) Rotor Mills Cutting Mills Knife Mills Mortar Grinders Disc Mills Mixer Mills Planetary Ball Mills Mixer Mills Selection guide / technical data 10 RETSCH Mixer Mills are used for the pulverization of hard, mediumhard, soft, brittle, elastic and fibrous materials The sample feed size depends on the mill and can be as large as 8 mmMixer Mills / CryoMill Retsch GmbH PDF Catalogs Technical

Grinding in Ball Mills: Modeling and Process Control

2012年6月1日 PDF The paper presents an overview of the current methodology and practice in modeling and control of the grinding process in industrial ball mills Find, read and cite all the research you for each value of ball filling ratio was 95 kg for 25%, 114 kg for 30%, 133 kg for 35%, and 152 kg for 40% by volume feed masses And, the weight of the materials for each value of charged volumeEffect of ball mill grinding parameters of hydrated lime fine 58 rpm for as and 385 min for rt The new working conditions identified for the ball mill considered enabled to rise output from 109 kg/h to 156 kg/h, with a 43% increase in productivity A control experiment carried out in the optimized conditions to corroborate the results obtained, confirmed calculated expectations of response variablesOptimization of processing parameters of a ball mill refiner for 2019年1月19日 Stirred ball mills are generally used for fine and ultrafine grinding of ceramic materials, in food and chemical industry, but this equipment is still an uptodate and relatively new one and SCALE UP FOR ULTRAFINE GRINDING IN STIRRED BALL MILL

KFDSeries FullDirectional Planetary Ball Mill

Available Size of Mill Jar for Fulldirectional Planetary Ball Mill; Mode Specification Available size of Mill Jars Quantity Remarks; KFD2: 2L: 50500ML: 4pcs: Can be matched with 50ml250ML vacuum mill jar: KFD4: 4L: 2501000ML: 4pcs: Can be matched with 50ml1000ML vacuum mill jar: KFD6: 6L: 115L: 4pcs: Can be matched with 501000ML 2011年4月1日 Stirred ball mills are frequently used for ultrafine and nanogrinding in food, pharmaceutical and chemical industry, but only few investigations have been published on empirical or scaleup Empirical and scaleup modeling in stirred ball mills10mm – 1 micron, or for colloidal grinding 01 micron Code LAG480 Weight (kg) 86 Tariff 90 Planetary Ball Mills are used wherever the highest degree of fineness is required Apart from the classical mixing and size reduction processes, the mills also meet all the technical requirements for colloidal grinding and have the energy []Planetary Ball Mill (LAG480) Material Testing Laboratory Model PMG ball mill has adopted special intergrate diaphragm and discharge grate to adjust material levels of every chamber so as to increase air ventilation and improve conditions inside mill; 50 TR15128 570 740 Zd80 56 92 φ24×8 2091 ≤25 14~18 395 φ32×13m cement mill(side drive)technical parameterBall millPMG series high efficient ball mill China Pengfei

.jpg)

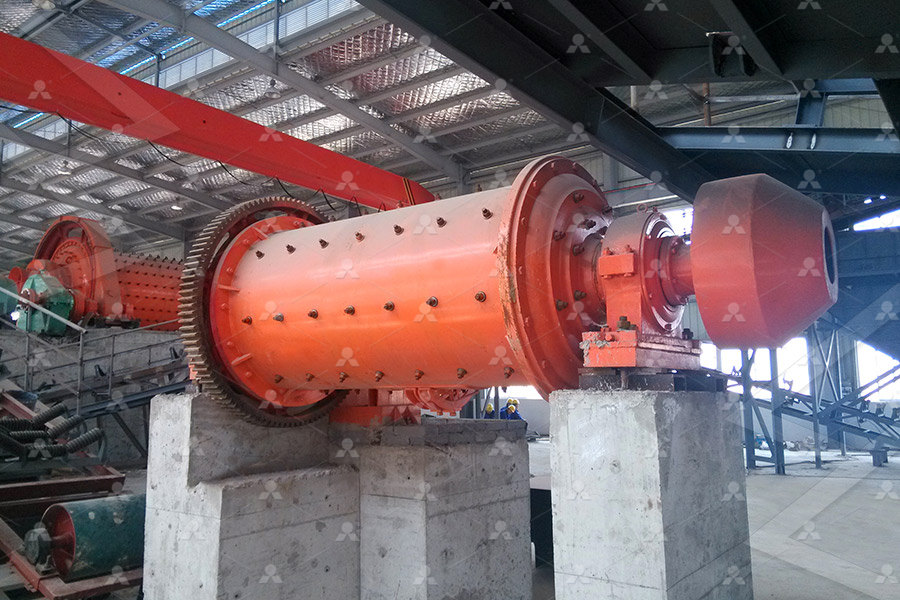

Ball Mill Ball Mill Manufacturer SINOMALY

This ball mill is widely used in production lines for powders such as cement, silicates, Technical Parameters Size (Φ x L) RPM (r/min) Material Feed Size (mm) Capacity (T/hr) Ball Load (T) Motor Power (kW) kg: 20gZ25, Medium alloy steel: Slide shoe bearing at inlet end (equipped with temperature sensor pt100)This paper covers theoretical and experimental explorations for the sake of determining the optimal ball charge in mills In the first part of the paper, on the basis of the theoretical analysis of the energygeometric correlations, which are being established during the grain comminution by ball impact, as well as on the basis of the experiment carried out on grinding quartz and THE OPTIMAL BALL DIAMETER IN A MILL AcademiaTechnical Parameter Table(I) of Vertical Planetary Ball Mill (Square Type) Type No Remarks: XQM1: 1L: 50250ml: 4pcs: Matched with vacuum mill pots from 50ml to 250ml: XQM2: 2L: 50500ml: 4pcs: Matched with vacuum mill pots Vertical Planetary Ball Mill (Square Type) from China During the operation of the planetary ball mill, it generates an extremely high level of impact energy between the grinding balls and the grinding jars, allowing it to complete the sample grinding in a very short duration The fundamental Planetary Ball Mill Torontech

Cryogenic Planetary Ball Mill Korea Process Technology

Technical Parameter Table Parameters of Cryogenic Planetary Ball Mill Model No Power (KW) Voltage Revolution Speed (rpm) Rotation Speed (rpm) Total Timing (min) Alternating Run Time of Forward Reversal Rotation(min) KC6 6L 115L 4pcs Can be 2022年1月1日 Planetary ball mill is a powerful tool, which has been used for milling various materials for size reduction The discrete element method (DEM) was used to simulate the dynamics of particle Calibration of DEM Parameters to Simulate a Planetary Ball MillLAARMANN’s Planetary Ball Mill has, unlike other similar Reproducible results due to progr grinding parameters; CE – certified; Watch Video Buy Product Buy Components Dimenstions closed W x D x H: ca 1090 x 660 x 1400 mm: Effective sun wheel diameter: 360 mm: Sun wheel speed: 50 – 400 min1: Electrical requirements: 200240 LM PBM4000 Planetary Ball Mill Laarmann Group BVparameters such as mill speed, ball filling ratio, ball size distribution, powder filling ratio, grinding aid 50, d 80) and surface area (m2/kg) As a result of this study, optimum grinding test conditions determined to be 70% of Nc, J=035 for ball Influences of operating parameters on dry ball mill performance

Planetary Ball Mill BM1150+ (Two Grinding Stations) Labindia

LABINDIA Planetary Ball Mill BM1150+ (Two Grinding Stations) is suitable for grinding (Dry / Wet) and mixing some soft, hard, brittle and fibrous samples, which are used wherever the highest degree of fineness as customer required, as well as the grinding result is pared with ball mill, higher grinding efficiency, Medium and small Amplitude Vibration Mill Technical Parameter Parameter: MZ10: MZ30: MZ50: MZ100: MZ200: MZ300: MZ500: Chamber Volume(L) 10: 30: 50: 100: 200: 300: 500: Produce Size (μm) 10150: 10150: 10150: 10150: 10150: 10150: 10150: Production Capacity (kg/h) 15: 520: 10 MZ Vibration Mill Impact Mill ALPA Powder TechThe effects of various technical parameters, such as ball size and density of ball material, 3 kg/m3) Alumina (35 X 103 ) Glass (25 X 103 ) *Steel shot selected by an inclined plate 8 4 2 1* 10 5 in a tumbling ball mill and about 50 times greater than that in a stirred ball mill2)The Mechanism and Grinding Limit of Planetary Ball Millingt J Technical Parameter Table Parameters of Cryogenic Planetary Ball Mill; Model No Power (KW) Voltage Revolution Speed (rpm) Rotation Speed (rpm) Total Timing (min) Can be matched with 50250ml vacuum mill jar: KC4: 4L: 2501000ML: 4pcs: Can be matched with 501000ml vacuum mill jar: KC6: 6L: 115L:KCSeries Cryogenic Planetary Ball Mill 한국코프로텍 (주)