How to process porcelain powder

.jpg)

How porcelain is made material, making, used,

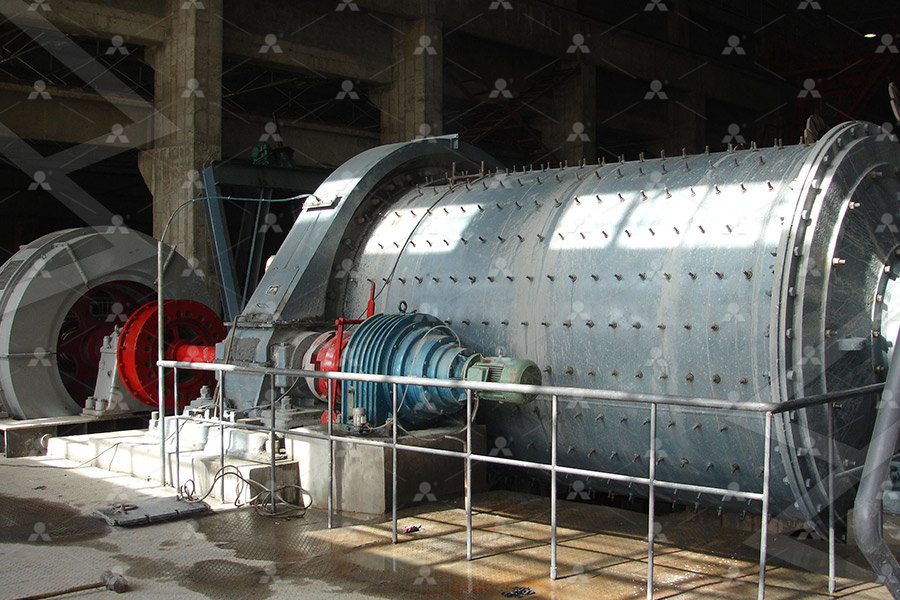

To make porcelain, the raw materials—such as clay, felspar, and silica—are first crushed using jaw crushers, hammer mills, and ball mills2005年1月21日 Composed primarily of clay, feldspar, and quartz, porcelains are heattreated to form a mixture of glass and crystalline phases This review (PDF) Porcelain—Raw Materials, Processing, Phase 2015年9月11日 EMA 5646 Ceramic Processing Zhe Cheng (2015) 2 Powder Preparation Powder Preparation by Mechanical Methods Comminution Using mechanical force, which EMA5646 Ceramic Processing 2 Powder PreparationGranulation is a process involving particle size enlargement and is a complex process controlled by various mechanisms such us: wetting, nucleation, agglomeration and consolidation, Case Study 2: Ceramic Powder Processing

.jpg)

Porcelain—Raw Materials, Processing, Phase Evolution,

2005年1月21日 Composed primarily of clay, feldspar, and quartz, porcelains are heattreated to form a mixture of glass and crystalline phases This review focuses on raw materials, processing, heat treatment, and mechanical behaviorThe manufacturing process used for porcelain is similar to that used for earthenware and stoneware, the two other main types of pottery, although it can be more challenging to produce It has usually been regarded as the most Porcelain WikipediaTo do this, the mass must first be pulverized, which then passes through magnetic sieves or magnetic tapes that extract the oxide from the powder This diagram shows the preparation of Processing Raw materials Holst Porzellan/Germany Porcelain for 1991年1月1日 Prefiring is an essential step in powder processing, being used to ensure good sintering during the firing operation Second milling needs to be more effective than first milling Ceramics Process Engineering ScienceDirect

.jpg)

Cleaner production of porcelain tile powders Granule and green

2012年1月1日 In this study, a recently proposed new ceramic powder preparation process, the droplet–powder granulation process (DPGP), was analysed and the granules and resulting This article explains how ceramic powders are made It begins by briefly describing the raw materials used in structural clay products, whitewares, refractories, and advanced ceramics It Processing and Characterization of Ceramic Powders2024年1月17日 It has been used in various forms for centuries, from creating dishes and figurines to intricate decorative pieces However, one of the main challenges with porcelain is its fragility – it can easily break or chip if How to Glue Porcelain Together 10 Easy Methods 2023年5月15日 Grinding wood chips into powder is an easy process that requires minimal tools and effort With the right technique, you can create a powder that is suitable for your needs Whether to get a finer texture, make it How to Grind Wood Chips Into Powder 5 Easy Steps

Porcelain Definition, History, Types, Facts Britannica

porcelain, vitrified pottery with a white, finegrained body that is usually translucent, as distinguished from earthenware, which is porous, opaque, and coarserThe distinction between porcelain and stoneware, the other class of 2024年7月18日 Before you begin laying porcelain tiles, it’s crucial to mix the mortar or thinset to the right consistency Follow the manufacturer’s instructions for the proper ratio of water to mortar powder Use a mixing paddle attached to a drill to achieve a smooth, lumpfree consistencyHow To Install Porcelain Tiles Tile Factory Direct2023年4月25日 Porcelain Porcelain is smooth and has a high heat tolerance but is more elastic (it does not mold as easily), which makes it a bit more difficult for beginners to work with There are many options when it comes to selecting your pottery clay, but don’t worry For more detailed information, check out Choosing Your Pottery ClayHow to Make Pottery – 8 Step Pottery Making ProcessPorcelain (/ ˈ p ɔːr s (ə) l ɪ n /) is a ceramic material made by heating raw materials, generally including kaolinite, in a kiln to temperatures between 1,200 and 1,400 °C (2,200 and 2,600 °F) The greater strength and translucence of porcelain, relative to other types of pottery, arise mainly from vitrification and the formation of the mineral mullite within the body at these high Porcelain Wikipedia

.jpg)

Molding Your Way to Masterful Ceramics: A StepbyStep Guide

2023年8月18日 The mold is not just a vessel; it plays an active part in the process by absorbing moisture and helping the clay set in the desired shape The drying process can’t be rushed, and ensuring the slip has the right consistency is crucial for the best results Gather Materials The Importance of Preparation2024年11月8日 35) Porcelain and China marking and Symbols Porcelain marks are the fingerprints of antique china Serving as both evidence of its origin, age, and often times, quality, the makers mark on a porcelain item is the first place many collectors look before making a purchase Click picture for lesson detailsCeramic, Porcelain, Sculpture, Pottery Repair and Restoration How Fill an electrostatic or a corona gun with the required porcelain particle powder coat Attach the gun to an air compressor and using compressed air, blow the powder coating onto the cast iron object The powder will become electrostatically charged inside of the gun and will literally stick to the surface of the cast ironHow to Enamel Cast Iron ehowSifting – dry powder can be applied directly onto the metal or over a flux layer Wet process – finely ground powder is mixed in water and can be applied to the metal using a paintbrush Painting Enamel – special painting enamel powder is mixed with a painting medium (often pine oil) and painted onto the surface of a flux or coloured layer (usually white) while being fired in How To Enamel Jewellery The Enamelling Process The Bench

Dental Porcelain an overview ScienceDirect Topics

The firing process also involves physical changes as partial melting occurs The control of porosity in this process is very important to both appearance and mechanical properties Because dental porcelain usually needs to be used in thin sections, strength is of great significance, but the brittleness of ceramics in general is a disadvantage 2023年8月26日 When gearing up to mix clay powder, the first thing I always do is make sure I have all my materials ready It’s a bit like cooking; having everything on hand makes the process smoother Clay Powder Starting with the clay powder, I prefer to use a highquality one The quality of the clay powder can really make a difference in the end productUnlock the Secrets of Mixing Clay Powder with Ease – Artabys2024年10月21日 Cold porcelain is not actually made from porcelain, but it's cheap and easy to prepare If you want to learn how to make cold porcelain, read this wikiHow to get started Mix together 1 cup (125 grams) cornstarch and 1 3 Ways to Make Cold Porcelain wikiHow2021年2月18日 Cold Porcelain Clay: Cold porcelain clay was very commonly made in India by mixing corn starch and white glue in a proportion of 1:1/2 and just kneaded into a dough In Dubai and the Middle East we used to get a powder specially sold for making cold porcelain flowers known as "ceramic powder" and the cold porcelain flowers known as ceramic flowersThe Best Cold Porcelain Clay Recipe Sweet Everlasting Blooms

Sintering of ceramics SubsTech

2023年12月13日 Dr Dmitri Kopeliovich Sintering (Firing) of ceramic materials is the method involving consolidation of ceramic powder particles by heating the “green” compact part to a high temperature below the melting point, when the material of the separate particles difuse to the neghbouring powder particles The driving force of sintering process is reduction of surface 2015年12月10日 Standard and custom hooks for powder coating linescustom racking equipment Pretreatment Systems Chemicals for Powder Coating An essential step in the powder coating process if you want to deliver the highest quality finished product Pretreatment Chemicals for Powder Coating; Pretreatment Equipment Ultrasonic Pretreatment SystemsCeramic Coating Metal Instructions and ExplanationInvest in highquality porcelain paints that are specifically formulated for this medium These paints are designed to adhere to porcelain surfaces and withstand firing temperatures without fading or discoloration Avoid using acrylic or oil paints, as they won't bond properly with the porcelain and may not survive the firing processA Guide To China Paint Materials, Techniques and Firing2023年12月13日 Dr Dmitri Kopeliovich Sintering (Firing) of ceramic materials is the method involving consolidation of ceramic powder particles by heating the “green” compact part to a high temperature below the melting point, when the material of the separate particles difuse to the neghbouring powder particles The driving force of sintering process is reduction of surface Sintering of ceramics SubsTech

How To Make Pottery At Home: Materials, Equipment, Steps

Learn how to make pottery at home in this guide outlining the materials, equipment, and tools to get started2024年9月20日 The exception to this would be using stains to tint porcelain for neriage work Use in concentrations of 10–15% in clay, using more or less depending on the intensity needed Add the pigment to the slip and sieve through a 120x mesh screen to ensure adequate dispersionCeramic Pigments What They Are and How to Use ThemOne of the key phases in the manufacture of porcelain is the in situ formation of mullite(2) Mullite is an aluminosilicate material and depending on stoichiometry, has the formula 3Al 2 O 3 2SiO 2 and 2Al 2 O 3 SiO 2It is a very rare mineral What Is Porcelain And How Is It Made African 2011年9月6日 The porcelain reenameling process is not cheap, because it is timeconsuming and requires craftsmanship, materials and the tools and equipment John explains that porcelain = glass To reporcelain a piece, he Real porcelain enamel coating to restore your

.jpg)

How To Clean Porcelain Figurines Cleanestor

The Importance Of Gentle Handling During The Cleaning Process When cleaning porcelain figurines, gentle handling is paramount to their preservation Here are some crucial points to keep in mind: Always hold the figurines by 2022年7月28日 In the United States, kaolin is most abundant in Georgia, including in the city of Sandersville, which is the world’s kaolin capital Extracting kaolin clay from the earth requires mining Then, manufacturers process extracted kaolin minerals and prepare them into powder forms for commercial use What Is Kaolin Clay and Its Properties?Kaolin Properties Applications of Kaolin Active MineralswikiHow Quick Video on How to Make Cold Porcelain To quickly make cold porcelain, combine 1 cup (125 grams) of cornstarch, 1 cup (240 mL) of white glue, 2 Tbsp (30 mL) of baby oil, and 2 Tbsp (30 mL) of lemon juice Microwave it at 15second intervals, stirring between each one Knead the dough for 10 to 15 minutes until it cools Wrap it tightly and let it rest for 24 hoursVideo: How to Make Cold Porcelain wikiHow2024年7月19日 Learn effective methods to safely remove paint from porcelain surfaces, ensuring a clean finish without damaging the underlying material 0 Additional tips and tricks to make the process easier Read on to learn more about removing paint from porcelain Apply Bon Ami cleaner powder with a damp washcloth and scrubHow to Remove Paint from Porcelain

.jpg)

How to Clean Porcelain Kitchen Sink: Easy Steps Expert Tips

2023年9月17日 Once you’ve finished scrubbing away any visible dirt and grime from all parts of your porcelain kitchen sink including around faucets edges etc, rinse thoroughly with warm water to remove any remaining residue from cleaning products used earlier in this processHow Porcelain Is Made ? : Porcelain, sometimes called "china" is a kaolin white clay fired at 1300°C Fine and translucent the quality of the porcelain is known all around the world Two famous places in the world make high quality of this tresor : Limoges in France, and JHow Porcelain Is Made ? : 5 Steps InstructablesEnamel (glass) is crushed to a powder somewhat finer than granulated sugar and somewhat coarser than flour This powder is applied, by one of several methods, to the metal or glass surface Next the article is heated to 1100 to 1500 degrees F, either in a preheated furnace, a hand held torch, or for enamels fused to glass, in a kilnEnameling Help and Information – Thompson Enamel2020年8月7日 Cold porcelain is a nonedible airdrying modeling material Although various brands are available commercially premixed or in dry form, variants of cold porcelain are fairly easy to make at home Made with cornstarch/cornflower and polyvinyl acetate glue (also known as PVA or white glue), cold porcelain is usually mixed roughly one to one (1 cup cornstarch to Cold Porcelain and How to Use It for Modelling The Spruce Crafts

How to Glue Porcelain Together 10 Easy Methods

2024年1月17日 It has been used in various forms for centuries, from creating dishes and figurines to intricate decorative pieces However, one of the main challenges with porcelain is its fragility – it can easily break or chip if 2023年5月15日 Grinding wood chips into powder is an easy process that requires minimal tools and effort With the right technique, you can create a powder that is suitable for your needs Whether to get a finer texture, make it How to Grind Wood Chips Into Powder 5 Easy Steps porcelain, vitrified pottery with a white, finegrained body that is usually translucent, as distinguished from earthenware, which is porous, opaque, and coarserThe distinction between porcelain and stoneware, the other class of Porcelain Definition, History, Types, Facts Britannica2024年7月18日 Before you begin laying porcelain tiles, it’s crucial to mix the mortar or thinset to the right consistency Follow the manufacturer’s instructions for the proper ratio of water to mortar powder Use a mixing paddle attached to a drill to achieve a smooth, lumpfree consistencyHow To Install Porcelain Tiles Tile Factory Direct

How to Make Pottery – 8 Step Pottery Making Process

2023年4月25日 Porcelain Porcelain is smooth and has a high heat tolerance but is more elastic (it does not mold as easily), which makes it a bit more difficult for beginners to work with There are many options when it comes to selecting your pottery clay, but don’t worry For more detailed information, check out Choosing Your Pottery ClayPorcelain (/ ˈ p ɔːr s (ə) l ɪ n /) is a ceramic material made by heating raw materials, generally including kaolinite, in a kiln to temperatures between 1,200 and 1,400 °C (2,200 and 2,600 °F) The greater strength and translucence of porcelain, relative to other types of pottery, arise mainly from vitrification and the formation of the mineral mullite within the body at these high Porcelain Wikipedia2023年8月18日 The mold is not just a vessel; it plays an active part in the process by absorbing moisture and helping the clay set in the desired shape The drying process can’t be rushed, and ensuring the slip has the right consistency is crucial for the best results Gather Materials The Importance of PreparationMolding Your Way to Masterful Ceramics: A StepbyStep Guide2024年11月8日 35) Porcelain and China marking and Symbols Porcelain marks are the fingerprints of antique china Serving as both evidence of its origin, age, and often times, quality, the makers mark on a porcelain item is the first place many collectors look before making a purchase Click picture for lesson detailsCeramic, Porcelain, Sculpture, Pottery Repair and Restoration How

36.jpg)

How to Enamel Cast Iron ehow

Fill an electrostatic or a corona gun with the required porcelain particle powder coat Attach the gun to an air compressor and using compressed air, blow the powder coating onto the cast iron object The powder will become electrostatically charged inside of the gun and will literally stick to the surface of the cast ironSifting – dry powder can be applied directly onto the metal or over a flux layer Wet process – finely ground powder is mixed in water and can be applied to the metal using a paintbrush Painting Enamel – special painting enamel powder is mixed with a painting medium (often pine oil) and painted onto the surface of a flux or coloured layer (usually white) while being fired in How To Enamel Jewellery The Enamelling Process The Bench