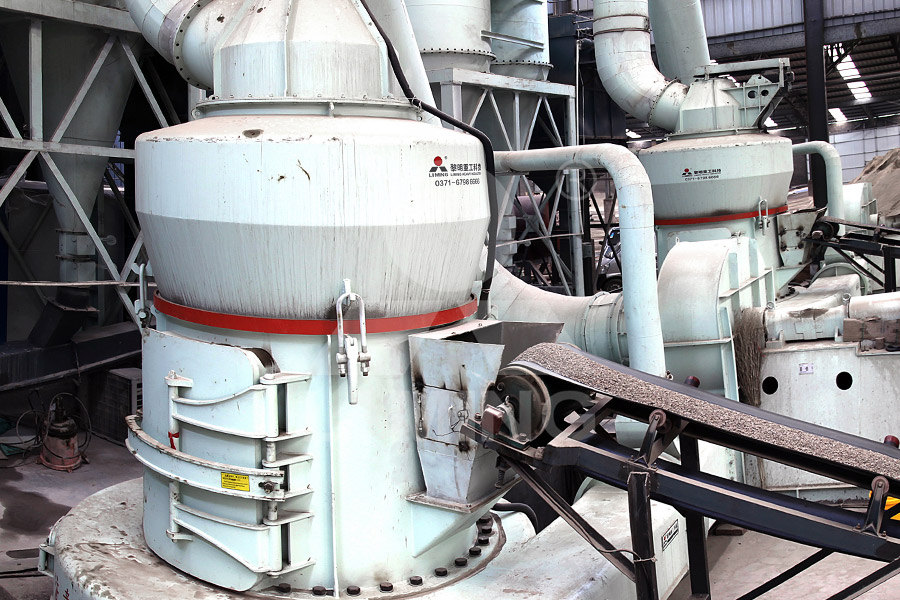

Red iron oxide conveying process equipment

Development of technology for the production of natural red iron

2017年1月1日 Designed wasteless flowsheet for separation of iron ore in two qualities paint grade quality (pigment) and metallurgical grade The technology includes accumulation paint LANXESS presents New Red – a new generation of iron oxide pigments based on a completely new production method The ‘Ningbo Process’ represents a true leap in innovation and offers CONQUER NEW TERRITORIES Palmer Holland2015年2月6日 The innovative Penniman red process developed by LANXESS sets new standards in the iron oxide industry due to its very low NOx and nitrous oxide emissions made A New Development in Penniman Red ProductionOn the other hand, iron oxide red tends to increase in viscosity over time in pigment concentrates This article explains the different structures of wetting and dispersing additives that could be Dispersant Technology for Red and Yellow Iron Oxides

.jpg)

Macawber Engineering, Inc Pneumatic Conveying Systems

The Macawber Ash Conveying System will convey bottom ash, clinkers, or fly ash from boiler beds, baghouse, or electrostatic precipitators at temperatures up to 600OF, and may be PROCESS OF MANUFACTURE: (i) In the first method the ferrous sulphate heptahydrate is reacted with sodium carbonate at moderate temperature The reacted mass is then treated RED IRON OXIDEMIDREX is a gasbased shaft furnace process that converts iron oxides – in the form of pellets or lump ore – into directreduced iron (DRI) MIDREX technology is highly customizable, which MIDREX® — THE LEADING DRI PRODUCTION PROCESS2020年10月1日 This study aims to characterize and then determine the method which allows for a high efficiency and quality for grinding the αFe 2 O 3 red powder into red iron oxide pigment An investigation on optimum grinding system and conditions for

.jpg)

BAYFERROX® 222 LANXESS

Bayferrox® 222 is an iron oxide red pigment It is delivered as powder and can be applied for the coloration of a wide variety of construction materials In addition it is also used in the foundry 2021年5月18日 21 Iron (III) Oxides Iron (III) oxide is, of course, a compound that exhibits four different crystalline polymorphs: αFe 2 O 3, βFe 2 O 3, γFe 2 O 3, and εFe 2 O 3Hematite and maghemite usually appear in nature, while beta and epsilon structures are generally synthetic oxides [10, 11]In general, the iron (III) oxides anions arrange in closepacked structures, Synthesis, Properties, and Applications of Iron Oxides: Versatility 2015年2月6日 Iron oxide red, also known as hematite, forms the most important subgroup Applications for iron oxide red pigments include the coloring of building materials, plastics, and coatings Four processes in particular are used A New Development in Penniman Red ProductionJAG Metals provides durable red iron metal for construction projects These highquality, reliable materials are designed to support your structural needs Get a Imagine a workshop where you can effortlessly maneuver large equipment, an Red Iron Metal JAG Metals

(PDF) Iron oxide red wastewater treatment and recycling of iron

2015年1月15日 The paper presents a wastewater treatment process and recycling of iron sludge from wastewater treatment for iron oxide red production Results show that: (1) Sludge from wastewater treatment The yellow iron oxide prepared by the wet method is washed with water to remove the watersoluble salt, filtered and dried, then put into the calciner Calcined into iron red at 600℃1000℃, then crushed and packaged to obtain finished products The calcination of iron yellow into iron red is the process of removing the crystal water from the iron yellowWhen the temperature Introduction of Iron Oxide Red Production Process Chemate2017年5月1日 Preparation of iron oxide red (αFe2O3) from the converter dust by the superconductivity high gradient magnetic separation (SHGMS) and roasting process was investigated in the paperPreparation of the Iron Oxide Red from the Converter Dust by the Red iron buildings are preengineered steel structures made from red iron, a type of steel coated with red iron oxide to prevent rust and corrosion These buildings, which are constructed using IBeams, are known for being stronger than other building materials, more affordable than other construction methods, and lower cost and effort to maintainRed Iron Steel Buildings Titan Steel Structures

.jpg)

Iron oxide red Wikipedia

Iron oxide red is a generic name of a ferric oxide pigment of reddish colors Multiple shades based on both anhydrous Fe 2 O 3 and its hydrates were known to painters since prehistory The pigments were originally obtained from natural sources, since CHEMICAL AND PROCESS TECHNOL ENCYC 1974 p643 (HSDB) In Europe synthetic red iron oxide is produced by oxidizing the FeO portion of Fe3O4 (black iron oxide) under controlled heating and oxidation conditions Persons not wearing protective equipment and clothing should be restricted from areas of releases until cleanup has been Ferric Oxide Red Fe2O3 CID PubChem2018年10月29日 LANXESS continues to optimize its global production network for the manufacture of iron oxide pigments Through targeted “debottlenecking” at the KrefeldUerdingen site, the specialty chemicals company increased the product availability of its Bayferrox and Colortherm micronized red pigments by more than 5,000 metric tons per year “In the paints LANXESS Increases Micronized Iron Oxide Red Pigments Production Volumeor rice, and challenging powders such as iron oxide, zinc oxide, calcium carbonate, or toner When it comes to pneumatically conveying difficult powders, the difficulty does not lie so much with the conveying of materials through the material line because, generally speaking, once material is entrained in the line it is fluidized and moves freelyKey Components of Pneumatically Conveying Difficult Materials

.jpg)

What is natural red iron oxide? benefits + formula

Disadvantages of natural red iron oxide use After checking what is natural red iron oxide and what is red iron oxide used for, we need to know whether there are any disadvantages besides the many benefits considered for this material Roxide Colours Indonesia (ROXIDE) didirikan pada tahun 2018, dengan spesialisasi bahan dasar/baku pigmen berwarna merah yang disebut dengan RED IRON OXIDE Red Iron Oxide hasil produksi ROXIDE merupakan bahan Roxide RoxideA synthesis capacity of 25,000 t in red iron oxide pigments and a mixing and milling capacity of 70,000 t will ensure reliability on a global scale GLOBAL RELIABILITY New Red pigments can be synthesized precisely and flexibly to meet required color ranges This allows the targeted production of yellowshade red pigments in newCONQUER NEW TERRITORIES Palmer Holland2024年6月12日 But what really sets red iron buildings apart is their Ibeam structure This efficient and easytoinstall setup expedites the construction process, making red iron buildings a preferred choice for many The benefits include: The red iron oxide coating acts as a defensive layer, effectively preventing rust and enhancing material longevityRed Iron Building (How to Build One in 3 Steps) APX

.jpg)

12 Key Considerations for Pneumatic Conveying Systems Design

2022年3月22日 To successfully design a vacuum conveying system, you must first understand the material supply process upstream Determine whether the material came from a volumetric feeder, mixer, reactor, or other materialhandling equipment All of these factors have an impact on the conveying process 9 Process Equipmentthe process of painting and coating that protects the metal and alloy from Related Videos: Synthetic Red Iron Oxide Manufacturing Business Equipments 000 2700 2700Cash Subsidy 000 000 000 Technical Knowhow Fees Exp 000 1500 1500 Internal CashProduction of Red Oxide Primer Profitable Business 2021年1月4日 Until the late 19th century iron oxide pigments were obtained wholly from natural materials, generally with little alteration other than physical purification In some cases roasting or calcination was also carried out However, beginning in the first part of the 20th century, chemical methods were developed for synthetic production of commercial iron oxidesIron Oxide Pigments 911MetallurgistRed Skins tro Coke Geon Vinyl Cheese Puffs Aluminum Calcined Ferrite 5 mol Borax Coffee Grounds Fullers Earth Iron Oxide Pneumatic Conveying makes vital decisions much easier Understanding Selecting the correct pneumatic conveying regime for your requirements is a vital decision for a successfully designed systemMacawber Engineering, Inc Pneumatic Conveying Systems

SAFETY DATA SHEET Natural Red Iron Oxide

Natural Red Iron Oxide 1 Identification Product identifier Product name Natural Red Iron Oxide Product number 521,NO1085,NO1283 Recommended use of the chemical and restrictions on use Application Industrial color Details of the supplier of the safety data sheet Supplier Huntsman Pigments Americas LLC PO Box 4980 The Woodlands, TX 年5月19日 This alkydbased substance contains a pigment that helps prevent red iron oxide rust from forming, and assists in protecting the metal surface against rust and corrosion Island Metal Primer 700 Red Oxide can be A Guide to Using Red Oxide Metal Primer Island Paints2017年11月3日 After an intensive testing phase, the Inorganic Pigments (IPG) business unit has successfully concluded the market introduction of its New Red pigments, manufactured by the Ningbo Process “This new generation of iron LANXESS Launches New Generation of Iron Oxide Detailed Project Reports Profiles on Synthetic Iron Oxide From Iron Oxide Liquor/sludge By Laux Process (red, Yellow, Green, Blue) Manufacturing Plant, Detailed Project Report, Profile, Business Plan, Industry Trends, Market Preparation of TechnoEconomic Feasibility Report, Identification and Selection of Plant, Process, Equipment, Synthetic Iron Oxide From Iron Oxide Liquor/sludge By Laux Process (red

MicrowaveReactorBased Preparation of Red Iron Oxide

2023年3月20日 This article presents a twostep method of iron red synthesis based on waste longterm deposited iron(II) sulfate The first step is the purification of waste iron sulfate, and then the pigment is synthesized by precipitation using a microwave reactor The newly developed method of purification allows for quick and thorough purification of iron salt The use of a 2017年1月1日 The most common inorganic pigment is red iron oxide World production of iron oxide pigments is about 600 thousand tons per year and greatly exceeds the production of other color pigments, with Development of technology for the production of natural red iron oxide Kroma Red iron oxides are a unique line of iron oxide pigments produced via direct precipitation rather than traditional calcination This precipitation process gives them excellent dispersibility and bright color tones They are available in 7 shades from light to dark and are carefully controlled for consistent color properties Kroma Reds are nonfading, chemically stable pigments suitable TDS Kroma Red® Iron Oxide Elementis Pigments Scribd• Atlantic Equipment Engineers, 13 Foster Street, PO Box 181, Bergenfield, NJ 07621 • Page 1 MATERIAL SAFETY DATA SHEET Red Iron Oxide CAS Number: or SECTION I – CHEMICAL PRODUCT AND COMPANY IDENTIFICATION: PRODUCT/MATERIAL: FE601 MATERIAL SAFETY DATA SHEET Red Iron Oxide

Processes for converting black iron oxide to red iron oxide

USA USA USA USA US A US A US A US A US A US A US A US A US A US A US A US A Authority US United States Prior art keywords iron oxide slurry sulphur trioxide reaction black iron Prior art date Legal 1,000 kg BAYFERROX® 130 iron oxide red pigment (weighted average) This declaration is based on the product category rules: Inorganic Pigments in Various Forms of Delivery, 032021 (PCR checked and approved by the SVR) Issue date 07012022 Valid to 06012027 Scope: This EPD applies to the iron oxide red pigmentsENVIRONMENTAL PRODUCT DECLARATION Lanxess Deutschland 2022年5月30日 Abstract Inorganic pigments have been very important substances for human life for thousands of years They have contributed and continue to contribute to the beautification of our daily life and habitat and to the accentuation and differentiation of objects, and influence thoughts, moods, and feelings The industrial manufacture of inorganic pigments based on The world of inorganic pigments ChemTexts Springer2021年5月18日 21 Iron (III) Oxides Iron (III) oxide is, of course, a compound that exhibits four different crystalline polymorphs: αFe 2 O 3, βFe 2 O 3, γFe 2 O 3, and εFe 2 O 3Hematite and maghemite usually appear in nature, while beta and epsilon structures are generally synthetic oxides [10, 11]In general, the iron (III) oxides anions arrange in closepacked structures, Synthesis, Properties, and Applications of Iron Oxides: Versatility

.jpg)

A New Development in Penniman Red Production

2015年2月6日 Iron oxide red, also known as hematite, forms the most important subgroup Applications for iron oxide red pigments include the coloring of building materials, plastics, and coatings Four processes in particular are used JAG Metals provides durable red iron metal for construction projects These highquality, reliable materials are designed to support your structural needs Get a Imagine a workshop where you can effortlessly maneuver large equipment, an Red Iron Metal JAG Metals2015年1月15日 The paper presents a wastewater treatment process and recycling of iron sludge from wastewater treatment for iron oxide red production Results show that: (1) Sludge from wastewater treatment (PDF) Iron oxide red wastewater treatment and recycling of iron The yellow iron oxide prepared by the wet method is washed with water to remove the watersoluble salt, filtered and dried, then put into the calciner Calcined into iron red at 600℃1000℃, then crushed and packaged to obtain finished products The calcination of iron yellow into iron red is the process of removing the crystal water from the iron yellowWhen the temperature Introduction of Iron Oxide Red Production Process Chemate

Preparation of the Iron Oxide Red from the Converter Dust by the

2017年5月1日 Preparation of iron oxide red (αFe2O3) from the converter dust by the superconductivity high gradient magnetic separation (SHGMS) and roasting process was investigated in the paperRed iron buildings are preengineered steel structures made from red iron, a type of steel coated with red iron oxide to prevent rust and corrosion These buildings, which are constructed using IBeams, are known for being stronger than other building materials, more affordable than other construction methods, and lower cost and effort to maintainRed Iron Steel Buildings Titan Steel StructuresIron oxide red is a generic name of a ferric oxide pigment of reddish colors Multiple shades based on both anhydrous Fe 2 O 3 and its hydrates were known to painters since prehistory The pigments were originally obtained from natural sources, since Iron oxide red WikipediaCHEMICAL AND PROCESS TECHNOL ENCYC 1974 p643 (HSDB) In Europe synthetic red iron oxide is produced by oxidizing the FeO portion of Fe3O4 (black iron oxide) under controlled heating and oxidation conditions Persons not wearing protective equipment and clothing should be restricted from areas of releases until cleanup has been Ferric Oxide Red Fe2O3 CID PubChem

LANXESS Increases Micronized Iron Oxide Red Pigments Production Volume

2018年10月29日 LANXESS continues to optimize its global production network for the manufacture of iron oxide pigments Through targeted “debottlenecking” at the KrefeldUerdingen site, the specialty chemicals company increased the product availability of its Bayferrox and Colortherm micronized red pigments by more than 5,000 metric tons per year “In the paints