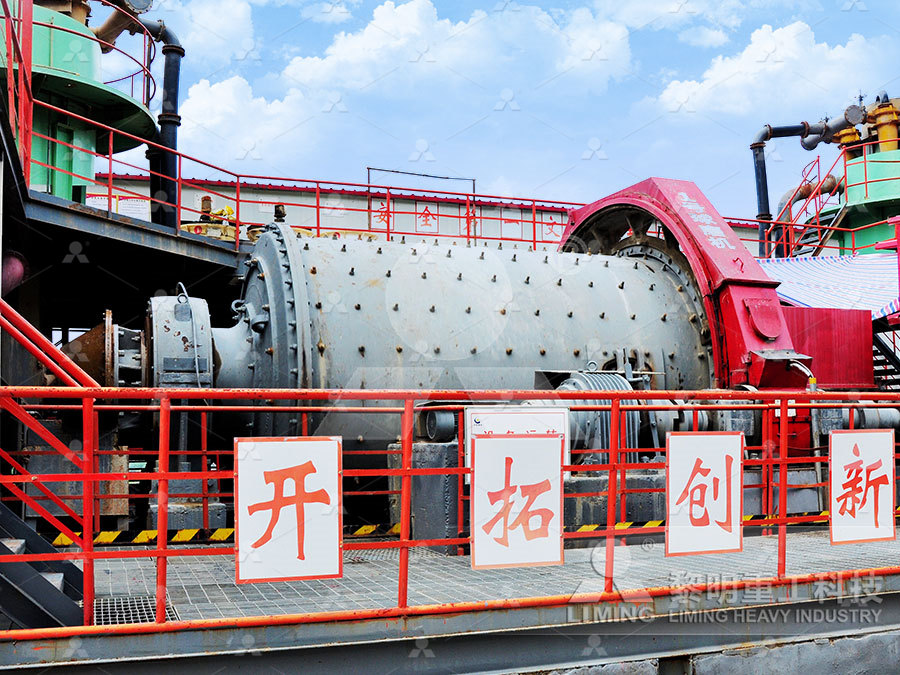

Ceramic highyield ore grinding machine

.jpg)

Energy conservation and consumption reduction in grinding

2023年11月1日 In response to the high consumptions of energy and media during grinding operations, An ingenious technique incorporating ceramic media and a new type of stirring mill 2024年1月31日 The results indicate that employing binary media effectively improves the grinding efficiency for +03 mm coarse particles while maintaining the energysaving advantages of ceramic ball milling Simultaneously, the Enhancing the Grinding Efficiency of a Magnetite 2022年1月1日 The results suggested that the highefficiency liberation of ore was obtained using the ceramicmedium stirred mill grinding technology, thus the efficient separation of iron and Highefficiency and energyconservation grinding technology 2023年11月7日 Due to their excellent wear resistance, high hardness, and lowdensity characteristics, ceramic balls, a revolutionary form of grinding media, can significantly reduce the consumption of grinding power and grinding media Effect on Fine Particles Output Characteristics of

Towards understanding the machining process in grinding of

2024年9月1日 These papers mainly recapitulate the development of machining techniques for ceramic matrix composites, including both conventional methods such as drilling, milling, and 2007年2月7日 High speed grinding with diamond wheels has been used in the machining of advanced structural ceramics to increase productivity It has been suggested that grinding Ceramic Response to High Speed Grinding: Machining Science and 2019年4月15日 In this chapter, we demonstrated that highspeed grinding was capable to machine difficulttomachine materials or structures including advanced ceramics, thin film HighSpeed Grinding of Advanced Ceramics and Combination 2023年11月24日 Laserassisted machining (LAM) can achieve highprecision machining of zirconia ceramics, which is prone to thermal stress, thermal damage, porosity, and material Research advances on primary machining technologies of zirconia

.jpg)

Simulation experimental investigations into material removal

2023年10月14日 To investigate the machining mechanism of silicon carbide (SiC) ceramic materials, this study utilized sintered diamond tools to perform drilling and grinding simulations 2023年6月6日 Welcome to the intriguing world of CNC grinding in the machine tool industry, where precision, speed, and efficiency amalgamate to craft perfection in metalworking CNC grinding, renowned for its ability to yield high CNC Grinding 101: Everything You Need to Know AT AGICO gold ore ball mills have been greatly improved on output They can realize highyield and ultrafine grinding The gold ore processed by our ball mill has high gold content and high purity AGICO ball mill is dedicated to creating more Gold Ball Mill Ball Mill For Gold Mining AGICO They are usually applied in the grinding process of copper, gold, iron ore and polymetallic Steel ball grinding media are used in tower mills, Isa mill, rotary mills, semiautogenous grinding (SAG) mill Plastic Grinding Media Plastic Ball Mill Grinding Media Options Ceramic Balls for

Study of the machining quality of CMC ceramic composite during high

2021年5月1日 Dependence of machined surface roughness on cutting speed during grinding (solid line) and trend line (dashed line) According to the results of the experiment with the use of diamond grinding 2024年6月11日 9 Orbis Machinery Ceramic Ball Mill Overview Orbis Machinery offers robust ceramic ball mills known for their high efficiency and reliability These mills are suitable for various industrial applications Key Features Capacity: Available in different sizes to meet various production needs10 Best Ceramic Ball Mills for 2024 Zoneding Machine2012年6月1日 As the cylinder starts to rotate, the grinding balls inside the cylinder crush and grind the feed material, generating mechanical energy that aids in breaking bonds, activating the catalyst, and Grinding in Ball Mills: Modeling and Process ControlAdditionally, it can be highly polished making it useful for precision sealing applications like pumps and pistons Alumina is an excellent high temperature ceramic material due to its high temperature stability It is the most commonly used type of advanced ceramic and is available in purities ranging from 95 – 999%Alumina – CeramAlox™ Precision Ceramics

Ceramic Grinding Kinetics of Fine Magnetite Ores in the Batch

2023年9月10日 Aiming to reveal the kinetic characteristics of ceramic ball grinding of fine magnetite comprehensively, two types of ceramic balls ground with the same filling rate and total weight as steel balls were researched The results show that the breakage rate of ceramic ball grinding is only half of that of steel ball grinding with the same media filling rate With the same Between Ceramic Grinding Rollers and Traditional Grinding Rollers Ceramic Composite High Chrome Grinding Roller Yield:12,572 Tons Service Life:33 Times Over Hardfacing Grinding Rollers Customer Name Ore Hardness:Mohs Hardness 65~80 Grinding Roller Yield:Approx 81,360 tons Service Life:2030 Times Over Hardfacing Grinding Ceramic Grinding Roller Qiming Castingdiamond grinding wheel suffers from loading and dulling, which results in decrement in material removal rate A novel grinding system is proposed in this research to improve the efficiency of the superfine grinding of ceramic ball This grinding system consists of the eccentric grinding machine with magnetic fluid support and the electrolytic High Efficiency Ultraprecision Grinding of Ceramic BallsPrecision Ceramics Grinding » INCREASE EFFICIENCY with precision grinding » Remove LARGE OR SMALL AMOUNTS of material fast » Grind to TIGHT TOLERANCES and surface finish specs » Expert help to OPTIMIZE YOUR GRINDING PROCESSES LEARN MORE DCM Rotary Surface Grinders » 1848" ELECTROMAGNETIC/VACUUM CHUCKS » 1050HP Ceramic Grinding DCM Tech

Modeling and prediction of surface roughness in ceramic grinding

2010年12月1日 The experiments have been carried out on a horizontal surface grinding machine The diamondgrinding wheels of ASD 240 R100 B2 have been used in the present experimental study Silicon carbide with a modulus of elasticity of 410 GPa was ground at a speed of 2200 m/min without cutting fluidPhone: 5865415300 : sales@totalgrindingsolutions Total Grinding Solutions Inc 13265 East 8 Mile Road Warren, Michigan, USA 48089Ceramic Milling Machines Total Grinding SolutionsPrecision Ceramics has extensive experience with hightolerance technical ceramic milling, grinding and polishing of unfired (‘green’) and fired ceramics Our stateoftheart equipment allows us to offer a variety of technical ceramic services including: CNC Milling Grinding; Brazing Joining; Glazing; Lapping Polishing; MetalizingCeramics Machining GrindingCeramic grinding is an essential process in achieving tight tolerances in otherwise impossibletocut materials Machining them requires superior tooling—such as special diamond tooling—that can create unique properties and high accuracy in the final components, which must meet complex and heavyduty demandsCeramic Grinding Machining Pillar Page Quartzite Processing

Ceramic CNC Machining: Enhancing Performance and

2023年2月28日 Surface grinding of ceramics requires a high level of precision, as any imperfections in the surface can affect the performance of the ceramic component Manufacturers often use the process to create flat and parallel surfaces on ceramic components, and they also use it to remove any surface defects or damageindicated that the best set of input parameters for surface grinding of sintered Al 2 O 3 ceramics is 2000 rpm spindle speed 03 m depth of cut and 5,000 mm/min Xstage movement ( Key Words – High Alumina Ceramics, CNC Grinding machine, surface finish) 1 IntroductionSurface Finish Studies of ADENSE Alumina Ceramic Material Using 3 Machines for use with porcelain jars, capacities range from a min of 15 l to a max of 15 l Suitable for carrying out grinding tests or simple wet process mixing tests on ceramic glazes and colouring agents, paints and other products Ore mill, Ore grinding mill All industrial manufacturers2004年12月30日 Such applications require high accuracy, surface finish and dimensional tolerance that can be achieved by finishing operations like grinding High grinding speeds yield smaller values of maximum Ceramic Response to High Speed Grinding Request PDF

.jpg)

A HighSpeed Precision Bearing Internal Grinding

2021年4月14日 PDF In order to meet the requirement of grade P2 bearing grinding, we designed a highspeed internal grinding machine used for bearing raceway and Find, read and cite all the research you Grinders with horizontal spindles: In these grinding operations, the flat edge of the grinding wheel contacts the workpiece, leading to highprecision results Grinders with vertical spindles: In contrast with horizontal spindle grinders, vertical Ceramic Machining Kadco Ceramics2014年1月20日 High pressure grinding rolls in AG/SAG mill circuits the next step in the evolution of grinding plants for the new millennium SAG 2001, Conference, Vancouver, BC 2001 Vol(PDF) Effects of High Pressure ORE Grinding on the Xkj New Type of HighYield and LowPower Consumption Ceramic Ball Mill, Find Details and Price about Milling Machine Grinding Machine from Xkj New Type of HighYield and LowPower Consumption Ceramic Ball Mill Henan Xingyang Mining Machinery ManufactoryXkj New Type of HighYield and LowPower Consumption Ceramic

Simulation experimental investigations into material removal

2023年10月14日 To investigate the machining mechanism of silicon carbide (SiC) ceramic materials, this study utilized sintered diamond tools to perform drilling and grinding simulations on the material and developed a drilling model for SiC ceramic materials By analyzing parameters such as surface morphology, stress, and cutting force, the material removal mechanism of SiC SAMA Maschinenbau GmbH is the leading manufacturer of fine ceramic plant and machinery on the international market For the technical ceramic industry SAMA offers shaping machinery for extrusion, isostatic pressing, high pressure and taped casting, surface treatment such as fettling and glazing machines and finally automation for ceramic factoriesMachines and systems for the production of kitchenware SACMICeramic dispersions take on a wide 500gal multishaft mixing system with independently controlled highspeed disperser and anchor agitator range of rheologies during processMixing strategies for ceramic powders differ from one application to another Specialty Equipment and Techniques for Dispersing Ceramic Powders #dispersing #mixingmilling grinding pulveriing Specialty Equipment and Techniques 2024年9月1日 It is worth mentioning that in recent years, several review articles on the machining of ceramic matrix composites have been published [32, [44], [45], [46], [47]]These papers mainly recapitulate the development of machining techniques for ceramic matrix composites, including both conventional methods such as drilling, milling, and grinding as well Towards understanding the machining process in grinding of ceramic

How to Choose Ceramic Forming Machine for Ceramic

Yutai ceramic machine manufacturer, specializing in the production of ceramic machines for more than 20 years, providing professional ceramic factory solutions to more than 100 countries Welcome to contact us to learn more about technical support Conclusion Ceramic forming machinery is the core equipment for the production of ceramic productsThe new energysaving structure of motor builtin wet gold grinding machine, vacuum casting roller, large diameter grinding pot design, make the new rolled gold machine has stable structure, safe use, long service life, high efficiency and energy saving, high yield characteristics, widely used for grinding various ferrous metals, nonferrous metals, nonmetallic minerals, and dilute Grinding gold machine Yantai Jinpeng Mining equipment, ore 2023年6月6日 Welcome to the intriguing world of CNC grinding in the machine tool industry, where precision, speed, and efficiency amalgamate to craft perfection in metalworking CNC grinding, renowned for its ability to yield high CNC Grinding 101: Everything You Need to Know AT AGICO gold ore ball mills have been greatly improved on output They can realize highyield and ultrafine grinding The gold ore processed by our ball mill has high gold content and high purity AGICO ball mill is dedicated to creating more Gold Ball Mill Ball Mill For Gold Mining AGICO

Ball Mill Grinding Media Options Ceramic Balls for

They are usually applied in the grinding process of copper, gold, iron ore and polymetallic Steel ball grinding media are used in tower mills, Isa mill, rotary mills, semiautogenous grinding (SAG) mill Plastic Grinding Media Plastic 2021年5月1日 Dependence of machined surface roughness on cutting speed during grinding (solid line) and trend line (dashed line) According to the results of the experiment with the use of diamond grinding Study of the machining quality of CMC ceramic composite during high 2024年6月11日 9 Orbis Machinery Ceramic Ball Mill Overview Orbis Machinery offers robust ceramic ball mills known for their high efficiency and reliability These mills are suitable for various industrial applications Key Features Capacity: Available in different sizes to meet various production needs10 Best Ceramic Ball Mills for 2024 Zoneding Machine2012年6月1日 As the cylinder starts to rotate, the grinding balls inside the cylinder crush and grind the feed material, generating mechanical energy that aids in breaking bonds, activating the catalyst, and Grinding in Ball Mills: Modeling and Process Control

Alumina – CeramAlox™ Precision Ceramics

Additionally, it can be highly polished making it useful for precision sealing applications like pumps and pistons Alumina is an excellent high temperature ceramic material due to its high temperature stability It is the most commonly used type of advanced ceramic and is available in purities ranging from 95 – 999%2023年9月10日 Aiming to reveal the kinetic characteristics of ceramic ball grinding of fine magnetite comprehensively, two types of ceramic balls ground with the same filling rate and total weight as steel balls were researched The results show that the breakage rate of ceramic ball grinding is only half of that of steel ball grinding with the same media filling rate With the same Ceramic Grinding Kinetics of Fine Magnetite Ores in the BatchBetween Ceramic Grinding Rollers and Traditional Grinding Rollers Ceramic Composite High Chrome Grinding Roller Yield:12,572 Tons Service Life:33 Times Over Hardfacing Grinding Rollers Customer Name Ore Hardness:Mohs Hardness 65~80 Grinding Roller Yield:Approx 81,360 tons Service Life:2030 Times Over Hardfacing Grinding Ceramic Grinding Roller Qiming Casting