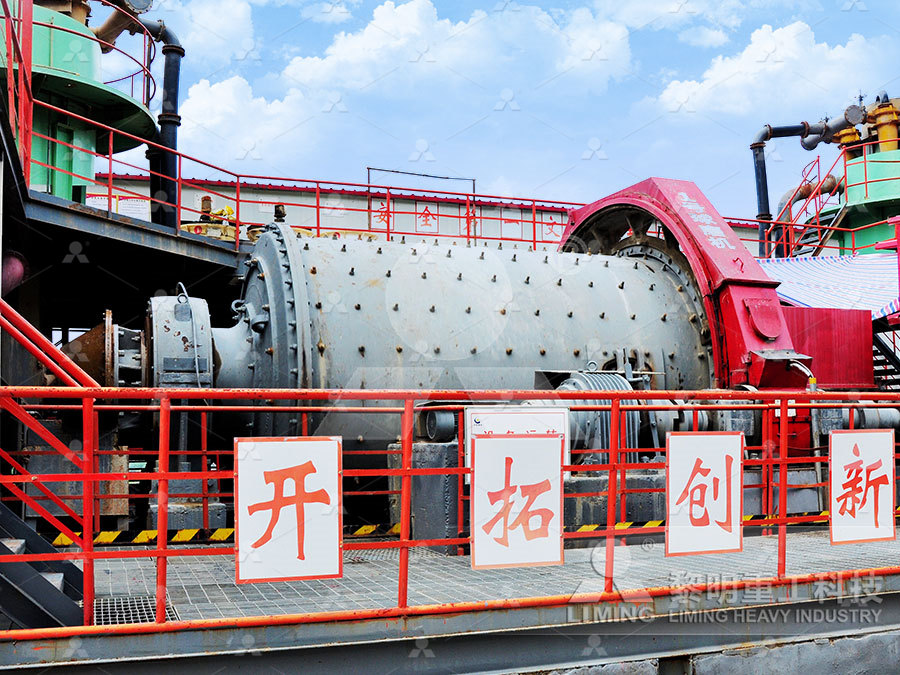

Silica ash densification equipment

.jpg)

CNU Silica fume storage and densification integrated

The silica fume storage bin and the densification bin are integrally designed, independent densification of the densification bin is achieved, the silica fume densification effect isCMT can design and customized the silica fume densification system according to your dust removel system The silicon powder densification system adopts Silica Fume Densifier System/ Silicon Powder We have also invested in pneumatic and mechanical densification equipment, offering various specifications such as original ash, semidensified (200400kg/m³), and fully densified (over Silica Fume2022年5月7日 Standard practices utilize bucket elevators, cam line belt feeders, or pneumatic lines to transport between the silo and bulk tanker Being less prone to agglomerate, nearly Transportation, Storage, and Transfer of Dry Densified Silica Fume

What is densified silica fume? HSA Microsilica

Densified silica fume is produced by treating undensified silica fume to increase the bulk density up to a maximum of about 400 to 720kg/m This increase in bulk density is usually accomplished by tumbling the silicafume particles in a silo, 2023年10月19日 In this study, a rapid wetgrinding dispersion technique was designed to achieve the dispersion of densified silica fume (DSF) within 5 min, and the results were better Potential industrial approach for efficient dispersion of silica fume 2020年9月3日 Silica fume (SF) is a key ingredient in the production of ultrahigh performance fiberreinforced concrete (UHPFRC) The use of undensified SF may have an advantage in Performance Comparison between Densified and Undensified The silicon powder densification system adopts compressed air to densify the silicon powder Without changing the properties of silicon powder, the silicon particles collide with each other and the surface tension changesSGS Silicon Powder Densification Equipment,

.jpg)

Performance Comparison between Densified and

2020年9月3日 Silica fume (SF) is a key ingredient in the production of ultrahigh performance fiberreinforced concrete (UHPFRC) The use of undensified SF may have an advantage in the dispersion efficiency inside cementbased materials, 2023年12月1日 The combustion success parameter in obtaining amorphous silica in Rice Husk Ash (RHA) is a critical aspect of the extraction process It involves various factors and Silica extraction from rice husk: Comprehensive review and 2018年11月1日 Therefore it is decided to study the fly ashmicro silica based geopolymer mortar under elevated temperature and thermal cycle in this present paper Meanwhile, the densification of the matrix creates stress when water is evaporating from composites leading to the strength loss 322Thermal and structural micro analysis of micro silica blended fly ash 2017年12月9日 As the temperature drops in the smokestack, the SiO 2 condenses into small droplets of silica These small spherical particles have an average diameter of 01–02 μm However, while they are in the molten state, a common occurrence is that some of these primary particles come into contact and fuse into primary agglomerates, typically with a Silica Fume SpringerLink

Effect of sintering temperature on phaseformation behavior

2010年1月1日 Silica ceramics were prepared using three types of raw materials derived from rice husk Cleaned husk and acidleached husk were burned at 700 C to get brown ash (BA) and white ash, respectively2020年6月4日 Silica xerogel produced from rice husk ash (RHA) taken from South East Sulawesi Indonesia has been successfully sintered by using a microwave oven 245 GHz as well as a millimeter waves (MMW Characteristics of Solid State Sintered Silica Ceramic Derived from Microstructure examination of mixes prepared with volcanic ash, silica fume and Portland cement revealed the coexistance of calcium silicate hydrate (CSH) and calcium–aluminosilicatehydrate (CASH) gels, along with other hydration products that led to a reduction in porosity and densification of the cement matrixUse of silica fume and natural volcanic ash as a replacement to Mesoporous silicate particles, called MCM41 were produced from rice husk ash generated by a biomass fired power plant More than 95 % of amorphous silica was extracted from rice husk ash by acid The SEM image of silica extracted from rice husk ash (x200)

The role of bauxite and flyash on the water stability and

2020年6月28日 According to the literature studies, little inclusion of supplementary materials (SMs) like fly ash, silica fume and slag prolong significantly improve the physical, mechanical and microstructural 2019年2月21日 Permanent density increase of silica glass was used to calibrate pressure generation delivered by cupped sintered diamond anvils (‘dimple anvils’) within the ParisEdinburgh press between Permanent densification of silica glass for pressure calibration 2020年11月30日 This is because the induce hydration ability of nanosilica for fly ash is limited, for fly ash proportion surpass 30%, 3% nanosilica are not enough to induce its hydration [22] Besides, influence of fly ash fineness on pozzolanic activity is investigated and the results were illustrated in Fig 11 Synergistic effects of nanosilica and fly ash on properties of 2020年12月8日 Thus, silica fume has a specific surface and an amorphous silica content, according to XRD, higher than that of quartz powder, which directly affects the chemical and physical reactivity of these Influence of quartz powder and silica fume on the performance

.jpg)

LowCarbon Concrete Based on Binary Biomass

2020年3月27日 The civil construction industry consumes huge amounts of raw materials and energy, especially infrastructure Thus, the use of ecofriendly materials is indispensable to promote sustainable development In this Silica Fume Supplier, Microsilica, Fly Ash Manufacturers/ Suppliers Shanghai Topken Silica Industrial Equipment Components; Instruments Meters; Light We mainly invest a lot in Ferro Silicon and Silicon Metal production line for manufacturing Silica Fume and its densification line Topken has six Silica Fume bases in different Silica Fume Manufacturer, Microsilica, Fly Ash Supplier Shanghai 2022年2月21日 Thermal degradation of potassiumactivated ternary slagfly ashsilica fume binders Author links open overlay The underlying mechanism may be related to the further densification and strengthening of KASH in The financial support from The University of Hong Kong through the URC Small Equipment Grant and Seed Fund for Thermal degradation of potassiumactivated ternary slagfly ashsilica 2024年4月24日 According to the results of macroscopic, fine, and microscopic multiscale tests, the addition of 15 wt% fly ash, 10 wt% silica ash, 02 vol% basalt fiber, and 01 vol% polypropylene fiber to the steamed concrete is the best to improve the performance of the steamed concreteOptimization Design of Mix Proportion for Fly Ash–Silica Fume

Effects of silica fume and fly ash on the properties of high

2005年6月2日 This paper presents the results of experimental work on the mechanical properties of selfcompacting highperformance concrete (SCHPC) containing fly ash (FA) and silica fume (SF)2019年12月31日 Rice hull ash consisting of 61% silica and 36% carbon was dispersed in sodium hydroxide to dis solve the silica and produce a sodium silicate solution The latter was titrated to pH 7 with 1M Extraction of Silica Nanoparticles from Rice Husk Ash (RHA) and We have also invested in pneumatic and mechanical densification equipment, offering various specifications such as original ash, semidensified (200400kg/m³), and fully densified (over 400kg/m³) The density can be adjusted according to customer needsSilica FumeThe silica (wet impure silica) obtained above is filtered Box 1 General Material Balance Husk: 100kg Ash content: 1914kg Total silica in ash:1818kg Extractable silica:1182kg (65%conversion) Residue ash:732kg Residue quality: good for bricks Results: product: silica purity: >980%, w/w surface area: >1500 m2/g byproduct: sodium sulSilica from Ash Indian Academy of Sciences

.jpg)

Effect of sintering temperature on phaseformation behavior and

Phase Transitions Vol 82, No 12, December 2009, 879–888 Effect of sintering temperature on phaseformation behavior and mechanical properties of silica ceramics prepared from rice husk ash JP Nayak and J Bera* Department of Ceramic Engineering, National Institute of Technology, Rourkela , Orissa, India (Received 9 August 2009; final version received 9 2017年10月30日 PDF As a byproduct of the combustion of rice husk to generate energy, rice husk ash (RHA) is formed by silica and carbon, apart from small amounts of Find, read and cite all the research (PDF) Characterization of Silica Produced from Rice 2016年7月1日 Fly ash can be used for soil amendment (Ukwattage et al, 2013) and nutrients (Kováčik et al, 2011) It can also be used to make a lowcost adsorbent for waste removal (Rubel et al, 2005, Yildiz, 2004) Besides, it can act as silica and alumina sources for zeolite production (Chang and Shih, 2000, Izidoro et al, 2012) (Fig 1 b)Fly ashbased geopolymer: clean production, properties and applications2012年3月1日 L A Bui et al, Effect of silica forms in rice husk ash on the properties of concrete 257 creasin g sharply, which was different from the control con creteEffect of silica forms in rice husk ash on the ResearchGate

Extraction Of Silica From Rice Husk Via Acid Leaching Treatment

2019年5月2日 The ash mainly consists of silica (SiO 2) and some alkali metal impurities The chemical composition of rice husk is similar to that of many common organic fibres and it contains of cellulose 40% to 50%, lignin 25% to 30%, ash 15% to 20% and moisture 8% 15% (Govinda, 2007) Problem Statement The problems statements are:2021年6月1日 Alkalisilica reaction (ASR) mitigation mechanisms of fly ash in concrete are still being debated and remain an interesting research topic This study provides new insights into the role of aluminum oxide (Al 2 O 3) in fly ash particles on ASR mitigationA comprehensive test program was conducted and included expansion measurements, dissolution model New insights into the role of fly ash in mitigating alkalisilica 2023年10月1日 11 Sol–Gel Synthesis The physics and chemistry involved in the synthesis of silica gels were detailed in books [1, 2] and many reviews on aerogels with particular focus on silica aerogels have already been published [3,4,5,6,7,8,9,10,11,12,13,14,15]Schematically, a nanostructured solid network is formed in a liquid reaction medium as a result of a Silica Aerogels SpringerLink2011年5月17日 In this paper, we present and discuss experimental results from a microwave sintering of a silicaglass ceramic, produced from a silica xerogel extracted from a sago waste ash As a radiation source for the microwave heating a submillimeter wave gyrotron (Gyrotron FU CW I) with an output frequency of 300 GHz has been used The powders of silica xerogel have Rapid Sintering of Silica Xerogel Ceramic Derived from Sago Waste Ash

.jpg)

Wheat Straw ash and its use as a silica source Request PDF

2012年1月17日 Request PDF Wheat Straw ash and its use as a silica source The overall aim of this project was to study the reutilisation of the major ash components, predominantly silica and potassium, in 2015年7月5日 Fig 2 (a) shows the effect of pH on the specific surface area of silica gels prepared in the presence of Na + (Method I) and in the absence of Na + (Method II) In the presence of Na +, the surface area of silica gels tended to decrease with the increase in pHOn the other hand, in the absence of Na +, it tended to increase when increasing pH, peaking at Synthesis of mesoporous silica with controlled pore structure 2022年7月1日 The result indicates that the percentage of silica was increased from 5710% to 990% when the leaching time increased from 30 to 90 min Result of XRD analysis indicates that the extracted silica has an amorphous phase structure whilst the peak angle and intensity of the highest silica’s percentage were recorded at Bragg angle of 2154° and intensity of 18833 cps Extraction of Silica from Sugarcane Bagasse via Acid Springer2018年11月1日 Therefore it is decided to study the fly ashmicro silica based geopolymer mortar under elevated temperature and thermal cycle in this present paper Meanwhile, the densification of the matrix creates stress when water is evaporating from composites leading to the strength loss 322Thermal and structural micro analysis of micro silica blended fly ash

]@S0{UDKK%G24F3JGHC.jpg)

Silica Fume SpringerLink

2017年12月9日 As the temperature drops in the smokestack, the SiO 2 condenses into small droplets of silica These small spherical particles have an average diameter of 01–02 μm However, while they are in the molten state, a common occurrence is that some of these primary particles come into contact and fuse into primary agglomerates, typically with a 2010年1月1日 Silica ceramics were prepared using three types of raw materials derived from rice husk Cleaned husk and acidleached husk were burned at 700 C to get brown ash (BA) and white ash, respectivelyEffect of sintering temperature on phaseformation behavior 2020年6月4日 Silica xerogel produced from rice husk ash (RHA) taken from South East Sulawesi Indonesia has been successfully sintered by using a microwave oven 245 GHz as well as a millimeter waves (MMW Characteristics of Solid State Sintered Silica Ceramic Derived from Microstructure examination of mixes prepared with volcanic ash, silica fume and Portland cement revealed the coexistance of calcium silicate hydrate (CSH) and calcium–aluminosilicatehydrate (CASH) gels, along with other hydration products that led to a reduction in porosity and densification of the cement matrixUse of silica fume and natural volcanic ash as a replacement to

The SEM image of silica extracted from rice husk ash (x200)

Mesoporous silicate particles, called MCM41 were produced from rice husk ash generated by a biomass fired power plant More than 95 % of amorphous silica was extracted from rice husk ash by acid 2020年6月28日 According to the literature studies, little inclusion of supplementary materials (SMs) like fly ash, silica fume and slag prolong significantly improve the physical, mechanical and microstructural The role of bauxite and flyash on the water stability and 2019年2月21日 Permanent density increase of silica glass was used to calibrate pressure generation delivered by cupped sintered diamond anvils (‘dimple anvils’) within the ParisEdinburgh press between Permanent densification of silica glass for pressure calibration 2020年11月30日 This is because the induce hydration ability of nanosilica for fly ash is limited, for fly ash proportion surpass 30%, 3% nanosilica are not enough to induce its hydration [22] Besides, influence of fly ash fineness on pozzolanic activity is investigated and the results were illustrated in Fig 11 Synergistic effects of nanosilica and fly ash on properties of

Influence of quartz powder and silica fume on the performance

2020年12月8日 Thus, silica fume has a specific surface and an amorphous silica content, according to XRD, higher than that of quartz powder, which directly affects the chemical and physical reactivity of these