What are the regulations for coke grinding time

Impact of Feed Properties and Operating Parameters on Delayed

Petroleum Coke General Properties: Volatile Combustible Matter (VCM) • VCM is unconverted pitch – Target 12% Max, fuel coke 9% to 10% – 14% VCM is very high; Coke will be soft • Increases green coke hydrogen content • Rules of thumb for control in fuel coke – Increase Coke plant operators have to comply with ever more challenging regulations in terms of emission control and environmental protection Therefore, Paul Wurth pursues a policy of continuous COKEMAKING TECHNOLOGY Paul Wurth2002年5月1日 For a coke with a stabilization of a 25m drop, the CRI and CSR estimated values are 24% and 70%, respectively, for a conventional coke oven of 450mm width operating with Coal for metallurgical coke production: predictions of coke quality Prepared wet coal is finely crushed before charging to the oven Flashdried coal may be transported directly to the ovens by the hot gases used for moisture removal Wall AP 42 122 Coke Production

Delayed Coking Operational Optimization Refining Community

• Usually set by refinery operational capabilities and requirements • Can use shorter cycles, eg 12 hours, for revamp designs to allow for processing more feed capacitymining and processing This effects the requirements for the coal handling system of the coke oven plant The main equipment for this process is the crusher station Normally it is equipped Effects and impacts of components of coal handling system on conventional batteries are not built within the same time frame, these predicted closures could have a severe effect on overseas consumers of Chinese coke Increasingly stringent Coke production and the impact of environmental legislation ICSCWhen demand for coke is low, coking times can be extended to 24 hours for blast furnace coke and to 48 hours for foundry coke Coking temperatures generally range from 900° to 1100°C 122 Coke Production US Environmental Protection Agency

Coke Plant Technologies ThyssenKrupp

complete cement plants and grinding systems of the Polysius brand, as well as machines, plants and systems for mining, extraction, preparation, processing or transshipment of commodities2019年1月1日 It is well known that the three factors which control coke strength are (1) selection of coals for coal blend, (2) adopted cokemaking technology, and (3) operating parameters Industrial perspective of the cokemaking technologies2010年5月1日 The ball size of 254 cm shows slight changes in particle median diameter over time, while 30 cm ball size requires more grinding time to reduce metallurgical coke particles View Show abstractGranulation of Coke Breeze Fine for Using in the 2024年3月8日 Understanding OSHA dust regulations is crucial for workplace safety Learn how to comply and protect your employees Using water sprays during activities such as cutting or grinding reduces dust formation and the OSHA Dust Regulations: What You Need to Know?

CCOHS: Combustible Dust Canadian Centre for

2024年5月10日 For example, the Hazardous Products Regulation (for Workplace Hazardous Materials Information System (WHMIS) 2015) defines combustible dust as " a mixture or substance that is in the form of finely Federal Regulation of Coke Ovens Under the National Emission Standards for Hazardous Air Pollutants Program years, since the time of the adoption of the standards in 1989 Sources: 54 Fed Reg 38,044 (Sep 14, 1989) 40 CFR 6113061139 (current regulations)1 Regulation of benzene (1989) Analysis: Federal Regulation of Coke J Control Theory Appl 2013 11 (3) 454–462 DOI 101007/s1176801312103 Intelligent optimal control system for ball mill grinding process Dayong ZHAO 1†, Tianyou CHAI,2 1State Key Laboratory of Synthetical Automation for Process Industries, Northeastern University, Shenyang Liaoning , China;Intelligent optimal control system for ball mill grinding processFederal Regulation of Coke Ovens Under the National Emission Standards for Hazardous Air Pollutants Program years, since the time of the adoption of the standards in 1989 Sources: 54 Fed Reg 38,044 (Sep 14, 1989) 40 CFR 6113061139 (current regulations)1 Regulation of benzene (1989) PACokeOvens

Regulatory Exclusions and Alternative Standards for the Recycling

2024年10月11日 Hazardous wastes do not cease to be dangerous simply because they are being reused, recycled, or reclaimed Many hazardous waste recycling operations may pose serious health and environmental hazards and should be subject to regulation under Subtitle C of the Resource Conservation and Recovery Act (RCRA) Reuse, recycling, and reclamation Chronic Pain: Over time, if Coke Jaw continues, it can result in chronic jaw pain and muscle fatigue, which can significantly affect a person's overall quality of life Dental Complications: Longterm teeth grinding related to Coke Jaw can lead to severe dental problems, including extensive tooth damage and temporomandibular joint (TMJ) disordersWhat Is Coke Jaw? A Side Effect of Cocaine Use Avenues RecoveryENVIRONMENTAL REGULATIONS FOR WORKPLACES [Updated to 7 March 2003] GoN R2281, G 10988 from time to time modify the Schedule to these Regulations as he deems necessary (3) machines, rough grinding, medium buffing and polishing 200ENVIRONMENTAL REGULATIONS FOR WORKPLACES SAFLIIWhat are Coke Drums Used for? Coke drums are used in the oil refining process known as coking The primary function of a coke drum is to convert heavy oil residues into lighter, more valuable hydrocarbon fractions and petroleum coke, a carbonrich solid material – Why are Coke Drums Important?What is a Coke Drum? (How it Works)(Fully Explained)

[GYQ0R)ZQ]ESS4NJ.jpg)

Grinding Safety Precautions Hazards Control

2023年10月11日 There are many hazards involved in working with abrasive wheels for grinding These range from immediate physical hazards, such as abrasions from wheel contact or dangerous projectiles from wheel breakage, Petroleum Coke: Petcoke generally has a higher energy content (calorific value) compared to coal on a perunitmass basis Coal: The energy content of coal can vary depending on its type and grade 5 Applications: Petroleum Coke: What is Petroleum Coke or Petcoke? Its Types, Overview Employers are required under section 4 of Regulation 833, Control of Exposure to Biological or Chemical Agents (the “Regulation”), to limit the exposure of workers to specified hazardous biological or chemical agents in accordance with the values set out in the “Ontario Table” (which is Table 1 in the Regulation) or, if the agent is not listed in the Ontario Table, the Current occupational exposure limits for Ontario workplaces under 2023年7月18日 The length of time the coke jaw lasts varies depending on the extent of the damage and the individual's drug use frequent jaw clenching or grinding, and abnormal movement of the jaw from side to side Visible effects may also include tooth decay, gum disease, and in severe cases, tooth loss or a perforated oral palateCoke Jaw: The Answers You've Beening For

Clean Air Act Standards and Guidelines for the Metals

2024年7月1日 Regulations Regulation/Guideline Type; Aluminum Production: Primary Aluminum Reduction Industry: NESHAP: Aluminum Production: Standards of Performance for Primary Aluminum Production: NSPS: Aluminum Production: Secondary Aluminum Production: NESHAP: Chromium Electroplating: Chrome Electroplating: Decorative, Hard, and Chromic Acid 2021年8月16日 Over time, the metallurgical coke breakage in 40 cm balls presents significant variation with undergrinding for 05–1 min and overgrinding to grinding time from 3–10 min; 400 cm grinding media is perhaps too large, creating voids inside the ball charge and generating less normal forces into particlesParticle Size Distribution Models for Metallurgical Coke Grinding 2021年8月3日 Foundry coke comprises most of the balance and is used by foundries in furnaces for melting metal for casting Foundry coke production uses a different blend of coking coals, longer coking times, and lower coking temperatures relative to those used for metallurgical coke Coke causes upto 50 % of the costs during the hot metal productionAutomation, Control, and Measurement System of Coke Oven cokeoven plant achieves a production capacity of 264 million tons of coke per annum and 155,000 m3 cokeoven gas per hour, setting new standards worldwide The main milestones 09111998 First notice of approval for the construction of the Schwelgern cokeoven plant 30032000 Official groundbreaking 06072000 Laying of the foundation stoneThe new Schwelgern coke plant ThyssenKrupp

Good practice for industrial coalfired boilers

regulations placing limits on nitrogen oxides (NOx), sulphur dioxide (SO2) and other gases and particulates These regulations are to improve air quality as well as reduce greenhouse gas (GHG) emissions The options for reducing emissions through fuel substitution with biomass and improving efficiencies are also examinednumber of legislative acts by changing the existing rules on integrated permits, emission standards for installations and land protection The most important changes were introducedDust emission from wet, lowemission coke quenching processgrinding/ blending of the sample within the grinding vessel of the HPMP The right graph displays the standard deviation of the RMS acceleration over time (A, B) Examples of efficient grinding trials with only short periods of grinding blockage (C, D) Examples of inefficient trials with extended blockage periods exceeding 25 sRealtime monitoring of efficient grinding and blending of petroleum cokeWhat equipment is used for coke crushing? Coke is a material with low hardness and is easy to crush Many types of equipment can meet its crushing requirements in production Here we mainly introduce two coke crushing What equipment is used for coke crushing? clirik

.jpg)

Coke Reactivity in Simulated Blast Furnace Shaft

2016年4月27日 Larger sized coke (grain size 467 to 6 mm) was used in estimating the correlation between reactivity in 100 pct CO 2 and the simulated blast furnace shaft gas atmospheres, since it also includes the effects of Article published in International Cement Review Magazine August2016, on ‘’ Coal to pet Coke Grinding’’ on 20 tph Pet Coke Grinding Vertical Roller Mill System Supplied to M/s ACC Ltd in Himachal Pradesh (India) Details about 120 tph Clinker Grinding Unit Supplied to M/s Italcementi (Zuari Cement Ltd) near Chennai, Tamilnadu (India)Cement Plant Machinery Walchand2013年7月3日 At coke plants several pollutants are formed during coking, which are released to ambient air To protect human health and to avoid harmful impacts on ambient air quality effective control of coke oven emissions is most significant At coke plants the main source of emissions of NOx, SO2 and particulate matter is the flue gas from combustion of cleaned coke oven gas in Emissions at Coke Plants: European Environmental Regulations Not less than 5 yrs, and not more than 40 yrs If death or serious injury, not less than 20 or more than life Fine of not more than $5 millionFEDERAL TRAFFICKING PENALTIES DEAgov

Cylinder Head Decoke Problems, Questions and Technical

2010年1月15日 Cylinder Head Decoke posted in Problems, Questions and Technical: Hi, I am new to this forum (what a great place) and just about to upgrade my 1978 Mini Mayfair to a stage 1 Whilst I have the manifolds off I thought it might be a good time to take the head off and clean itn up, perhaps reseating the valves, replacing head gasket and the thermostatWorkplace exposure limits (WELs) are GB occupational exposure limits approved by HSE They are set to help protect workers’ health WELs are concentrations of hazardous substances in the air, averaged over a set period of time Find WELs in EH40 Many thousands of substances are used at work but only about 500 substances have WELsWorkplace exposure limits COSHH HSEFederal Regulation Myth: Coke ovens in Southwestern Pennsylvania are subject to the most stringent air pollution requirements in the nation Reality: As a result of the 1990 Clean Air Act Amendments, the role of the Environmental Protection Agency with respect to coke oven emissions has been significantly limited EPA regulations for charging operations (inserting How is Coke Regulated? – Clean Air Council PACokeOvens2015年9月30日 DRIVEN MACHINERY REGULATIONS, 2015 [Updated to 2 October 2015] Grinding machines; Shears, guillotines and presses; Slitting machines; are situated at such distance from the point of operation that none of the operators has enough time to reach the danger zone with any part of their body before the working stroke is completed DRIVEN MACHINERY REGULATIONS 2015 SAFLII

.jpg)

Granulation of Coke Breeze Fine for Using in the

2010年5月1日 The ball size of 254 cm shows slight changes in particle median diameter over time, while 30 cm ball size requires more grinding time to reduce metallurgical coke particles View Show abstract2024年3月8日 Understanding OSHA dust regulations is crucial for workplace safety Learn how to comply and protect your employees Using water sprays during activities such as cutting or grinding reduces dust formation and the OSHA Dust Regulations: What You Need to Know?2024年5月10日 For example, the Hazardous Products Regulation (for Workplace Hazardous Materials Information System (WHMIS) 2015) defines combustible dust as " a mixture or substance that is in the form of finely CCOHS: Combustible Dust Canadian Centre for Federal Regulation of Coke Ovens Under the National Emission Standards for Hazardous Air Pollutants Program years, since the time of the adoption of the standards in 1989 Sources: 54 Fed Reg 38,044 (Sep 14, 1989) 40 CFR 6113061139 (current regulations)1 Regulation of benzene (1989) Analysis: Federal Regulation of Coke

.jpg)

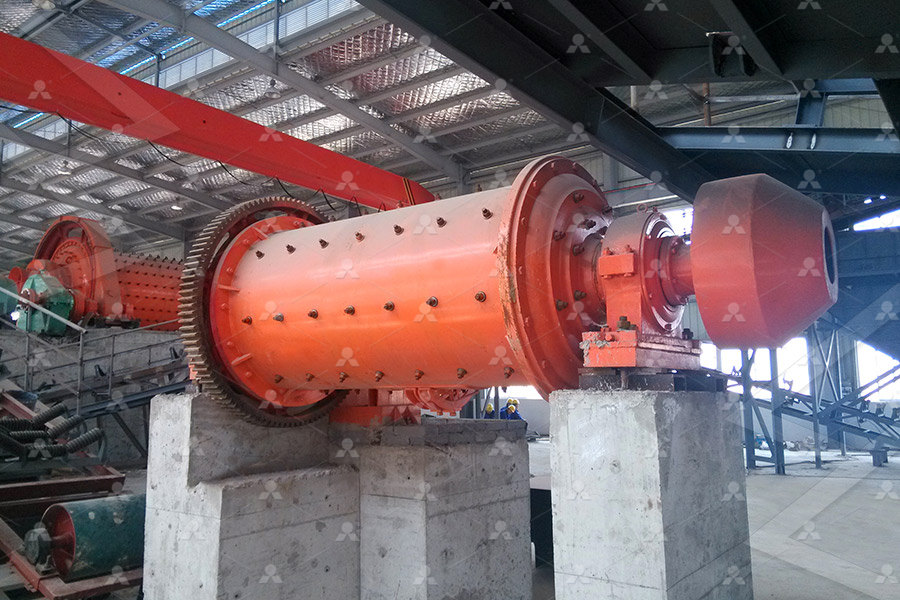

Intelligent optimal control system for ball mill grinding process

J Control Theory Appl 2013 11 (3) 454–462 DOI 101007/s1176801312103 Intelligent optimal control system for ball mill grinding process Dayong ZHAO 1†, Tianyou CHAI,2 1State Key Laboratory of Synthetical Automation for Process Industries, Northeastern University, Shenyang Liaoning , China;Federal Regulation of Coke Ovens Under the National Emission Standards for Hazardous Air Pollutants Program years, since the time of the adoption of the standards in 1989 Sources: 54 Fed Reg 38,044 (Sep 14, 1989) 40 CFR 6113061139 (current regulations)1 Regulation of benzene (1989) PACokeOvens2024年10月11日 Hazardous wastes do not cease to be dangerous simply because they are being reused, recycled, or reclaimed Many hazardous waste recycling operations may pose serious health and environmental hazards and should be subject to regulation under Subtitle C of the Resource Conservation and Recovery Act (RCRA) Reuse, recycling, and reclamation Regulatory Exclusions and Alternative Standards for the Recycling Chronic Pain: Over time, if Coke Jaw continues, it can result in chronic jaw pain and muscle fatigue, which can significantly affect a person's overall quality of life Dental Complications: Longterm teeth grinding related to Coke Jaw can lead to severe dental problems, including extensive tooth damage and temporomandibular joint (TMJ) disordersWhat Is Coke Jaw? A Side Effect of Cocaine Use Avenues Recovery

.jpg)

ENVIRONMENTAL REGULATIONS FOR WORKPLACES SAFLII

ENVIRONMENTAL REGULATIONS FOR WORKPLACES [Updated to 7 March 2003] GoN R2281, G 10988 from time to time modify the Schedule to these Regulations as he deems necessary (3) machines, rough grinding, medium buffing and polishing 200What are Coke Drums Used for? Coke drums are used in the oil refining process known as coking The primary function of a coke drum is to convert heavy oil residues into lighter, more valuable hydrocarbon fractions and petroleum coke, a carbonrich solid material – Why are Coke Drums Important?What is a Coke Drum? (How it Works)(Fully Explained)