Symptoms of coal mill cage blocking coal

.jpg)

Early Warning of Critical Blockage in Coal Mills Based on Stacked

2020年9月25日 Coal blockage is one of the main reasons for coal mill malfunction It is highly essential to accurately detect the critical blockage in coal mills to ensure a safe and stable operation of the unit2024年5月1日 To avoid abnormal operating conditions of coal mills in time and effectively, a dual fault warning method for coal mill is proposed Three typical faults of coal mill plugging, coal breakage and deflagration are warned by this methodDual fault warning method for coal mill based on ScienceDirectThe results demonstrated that the proposed method can effectively detect critical blockage in a coal mill and issue a timely warning, which allows operators to detect potential faults Coal mills have a significant influence on the reliability, efficiency, and safe operation of a Early Warning of Critical Blockage in Coal Mills Based on Stacked 2019年9月9日 This paper presents a fault early warning approach of coal mills based on the Thermodynamic Law and data mining The Thermodynamic Law is used to describe the working characteristics of coal mills and to determine the multiparameter vector that characterize the operating state of the coal millResearch on early fault warning system of coal mills based on the

Research and Application of Coal Blockage Early Warning

The experimental results show that it can effectively detect the coal blocking and coal breaking faults of the coal feeder and the coal mill, effectively reduce the system false alarm rate, accurately capture the abnormal moment of the indicator, and relatively manual observation is a little early, ensuring the stable operation of the milling 2020年8月12日 To understand the performance of a vertical roller coal mill, the real operational tests have been performed considering three different coal sources Obtained results indicate that grinding pressure, primary air (PA) temperature and mill motor current have a tendency to rise by increasing coal feeding mass flow rates for all used coalAn investigation of performance characteristics and energetic 2020年1月1日 Coal blockage is one of the main reasons for coal mill malfunction It is highly essential to accurately detect the critical blockage in coal mills to ensure a safe and stable operationEarly Warning of Critical Blockage in Coal Mills Based 2015年8月1日 In this paper, a review of researches done on the mill control and methods employed for fault diagnosis of coal mills is provided, with the aim of improving performance and operational efficiency of the coal millsReview of control and fault diagnosis methods applied to coal

.jpg)

Mill Inerting and Pulverizer/Mill Explosion Mitigation

flaming, smoking or smoldering coal inside the mill means a mill explosion could be occur at any time • Any burning or smoldering material inside the mill can evolve into an explosion because they provide an ignition source if the air to fuel (coal) ratio is elevated or higher than desiredCoal Bunker Anti Blocking Free download as PDF File (pdf), Text File (txt) or read online for free This document discusses solutions for common coal bunker problems like blockages and shedshaped coal piles It describes adjusting Coal Bunker Anti Blocking PDF Coal Fuel OilA simple energy balance model of the coal mill is derived in (Odgaard and Mataji 2006), this model is based on a more detailed model found in (Rees and Fan 2003)In this model the coal mill is seen as one body with the mass m mThe following variables are defined: T(t) is the temperature in the coal dust flow in the mill, ṁ PA (t) is the primary air mass flow, T PA (t) is Coal Mill an overview ScienceDirect TopicsReceived September 11, 2020, accepted September 20, 2020, date of publication September 25, 2020, date of current version October 7, 2020 Digital Object Identifier 101109/ACCESS2020Early Warning of Critical Blockage in Coal Mills Based on Stacked

Early Warning of Critical Blockage in Coal Mills Based on

2020年1月1日 Coal mills have a significant influence on the reliability, efficiency, and safe operation of a coalfired power plant Coal blockage is one of the main reasons for coal mill malfunction2023年12月16日 The characteristics of HGI fractions of the blend coal were investigated One rejected coal (A) with three imported coals, Indonesian coal (B), Russian coal (G) and Australian coal (H), and their blends were tested for their grindability indices as per standard ASTM D 409 The fractions obtained from HGI tests were further assessed for its quality using their Utilization of Rejected Coal Through Blending Techniques in 2017年8月1日 Smaller coal fineness means consuming more electricity power as well as more complete combustion It is very difficult to find the equilibrium or Pareto optimality of the running state which is Optimisation of coal fineness in pulverisedfuel boilers2016年8月19日 Reality is, you waste a LOT more coal unless you always remember to put in exactly 80 items If you accidentally drop in 81 to 99 items, you will burn two entire blocks of coal for only 99 If you use coal pieces, at most you'll waste 7 charges –minecraft java edition Does a block of coal or 9 pieces of coal

Sectional view of MBF coal mill Download Scientific Diagram

A control oriented model was then developed by Fan (1994) and Fan and Rees (1994) In 2009, coal flow and outlet temperature of mill were modelled using mass and heat balance equations for startup 2012年11月17日 20 131Fineness Fineness is an indicator of the quality of the pulverizer action Specifically, fineness is a measurement of the percentage of a coal sample that passes through a set of test sieves usually designated at 50, 100, and 200 mesh A 70% coal sample passing through a 200 mesh screen indicates optimum mill performance The mill wear and Coal mill pulverizer in thermal power plants PPT SlideShareStedman offers Pulverizers Cage Mill Crushers that crush, grind, or pulverize a variety of materials to specified degrees of fineness One of the first uses for the cage mill was as a coal pulverizer By 1900 Nathan Stedman had built more than Cage Mill Crushers Industrial Pulverizing Equipment Stedman which can scan a numbers of RTD / Thermocouple signal As we have eight numbers (08) of coal mill and each coal mill has four outlet coal pipes, so we have to measure 32 numbers of coal pipe temperature We design and procure 32 numbers of special type surface mounted RTD Fixed the RTD on each and every coal pipe beforeMeasurement and Control of Coal Pipe Temperature of Coal Mills

Experimental study on coal blockage removal based on pulverized coal

2022年10月1日 Most of the pulverized coal blocking the seepage channel are moved out by highpressure gas, and the GPP increases exponentially; 5) Within 163 min after gas discharge (Fig 5 (f)), the GPP returns to the initial value within about 10 min with the output of the last section of pulverized coal solution column2020年8月12日 In a power plant, the coal mill is the critical equipment, whose effectiveness impacts the overall power plant efficiency Uniform coal feeding mass flow rate and required particle size and temperature at the outlet channel throughout with better classifier performance are crucial indicators that characterize the coal mill performanceAn investigation of performance characteristics and energetic Dry grinding studies of coal in a rod mill SDasand J S Murty % Retained 20 100 210 220 180 60 210 It AbstractIn this paper, a report is given ofstudies The replacement of the rod mill with another cage mill was given serious thought The cost differential between a rod mill anda cage mill is appreciable (theDry grinding studies of coal in a rod mill2020年4月2日 represent the temperature distribution in the boiler while PCs pipes at level 1 are not in service In the meanwhile, the others PC still in service and produced 700MWnettAnalysis of the Coal Milling Operations to the Boiler Parameters

.jpg)

HSeries MultiCage Mill Resource Center

The HSeries cage mill is engineered and constructed to operate at or nearpeak efficiency longer, providing a greater return on capital investment over its life than competing equipment HSeries Features and Benefits Capable of producing a variety of product gradations, easily altered by changing the impact mill speed Quickopening housing for inspection and maintenance allows Key words: Coal mill classifier, Cut size, Nonswirling inlet, Particle image velocimetry, Impeller rotational speed 摘要: The classification performance of model coal mill classifiers with different bottom incoming flow inlets was experimentally and numerically studiedThe flow field adjacent to two neighboring impeller blades was measured using the particle image velocimetry techniqueClassification performance of model coal mill classifiers with cipCoal Mill PPT Free download as Powerpoint Presentation (ppt / pptx), PDF File (pdf), Text File (txt) or view presentation slides online The document provides an overview of coal mill operation, protections, and interlocks It discusses coal combustion theory, coal properties, coal mill components and operation, and troubleshooting The coal mill grinds coal into fine particles for Coal Mill PDF Combustion Chemistry2009年9月20日 A control oriented model was then developed by Fan (1994) and Fan and Rees (1994) In 2009, coal flow and outlet temperature of mill were modelled using mass and heat balance equations for startup Modeling and Parameter Identification of Coal Mill

.jpg)

(PDF) Study on the Recognition of Coal Miners’ Unsafe Behavior

2023年10月28日 The hoist cage is used to lift miners in a coal mine’s auxiliary shaft Monitoring miners’ unsafe behaviors and their status in the hoist cage is crucial to production safety in coal mines2023年10月28日 A visual detection model is proposed to estimate the number and categories of miners, and to identify whether the miners are wearing helmets and whether they have fallen in the hoist cage to improve the YOLOv5s model The hoist cage is used to lift miners in a coal mine’s auxiliary shaft Monitoring miners’ unsafe behaviors and their status in the hoist cage is [PDF] Study on the Recognition of Coal Miners’ Unsafe Behavior Have been burning coal in a multi fuel stove wrong all this time? In this video, I explain and review my new stove gadget, the Coal Cage For this must have Coal Cage YouTube2 Why stockpile? 6 IEA Coal Research Stockpiling of coals is carried out at a number of points along the transport chain to the end user: at coal mines; at coal preparation plants; at transhipment points and terminals importing or exporting coals; andManagement of coal stockpiles ICSC

(PDF) Modeling and Control of Coal Mill Academia

: pradeebhamit@gmail, npappa@rediffmail , vasanthi@annauniv Abstract: The paper presents development and validation of coal mill model (including the action of classifier) to be used for improved coal mill control The model is developed by using the mass and heat balance equations of the coal millSafe operation of coal grinding systems: Raw coal silo protection against fire and explosions Safe operation of coal grinding systems: Raw coal yard management The purchasing process for coal grinding systems needs changes Talk at a virtual seminar, November 2023 Accept the probability that the fire and explosion safety of your coal grinding system is nothing more than a mirageFire and explosion protection of coal grinding systems Where are For other coalrelated objects found in Minecraft, see Coal (disambiguation) The Block of Coal is a block that was added in the 13w18a snapshot Like other blocks of its kind, it's a compact way to store the material It may also be used as a building block However, it is less appealing than other compacted ores In addition to compact storage, the block of coal is also a better Block of Coal Minecraft WikiProximity to coalfired power plants and neurobehavioral symptoms in children Charlie H Zhang 1 , Lonnie Sears 2 , John V Myers 3 , Guy N Brock 3 , Clara G Sears 4 and Kristina M Zierold 5Proximity to coalfired power plants and neurobehavioral symptoms

ObserverBased Coal Mill Control Using Oxygen Measurements

2006年6月25日 With this estimate, it becomes possible to close an inner loop around the coal mill itself, Figure 2 shows a block diagram of the combustion system with emphasis on the oxygen control loop, as2020年9月25日 Coal mills have a significant influence on the reliability, efficiency, and safe operation of a coalfired power plant Coal blockage is one of the main reasons for coal mill malfunction It is highly essential to accurately detect the critical blockage in coal mills to ensure a safe and stable operation of the unit Taking advantage of unsupervised learning methods and Early Warning of Critical Blockage in Coal Mills Based on Stacked 2013年1月1日 The coal mills are key equipments in the power plant []Faults often happen because they work in the complex operating environment Through analyzing faults, we find that faults of the coal mills present characteristics of fuzzy and uncertain, which a kind of fault may exhibit a variety of different fault symptoms, and for different fault types may also produce the The Research on Fault Diagnosis Method of the Coal Mill Based Coal Bunker Anti Blocking Free download as PDF File (pdf), Text File (txt) or read online for free This document discusses solutions for common coal bunker problems like blockages and shedshaped coal piles It describes adjusting Coal Bunker Anti Blocking PDF Coal Fuel Oil

.jpg)

Coal Mill an overview ScienceDirect Topics

A simple energy balance model of the coal mill is derived in (Odgaard and Mataji 2006), this model is based on a more detailed model found in (Rees and Fan 2003)In this model the coal mill is seen as one body with the mass m mThe following variables are defined: T(t) is the temperature in the coal dust flow in the mill, ṁ PA (t) is the primary air mass flow, T PA (t) is Received September 11, 2020, accepted September 20, 2020, date of publication September 25, 2020, date of current version October 7, 2020 Digital Object Identifier 101109/ACCESS2020Early Warning of Critical Blockage in Coal Mills Based on Stacked 2020年1月1日 Coal mills have a significant influence on the reliability, efficiency, and safe operation of a coalfired power plant Coal blockage is one of the main reasons for coal mill malfunctionEarly Warning of Critical Blockage in Coal Mills Based on 2023年12月16日 The characteristics of HGI fractions of the blend coal were investigated One rejected coal (A) with three imported coals, Indonesian coal (B), Russian coal (G) and Australian coal (H), and their blends were tested for their grindability indices as per standard ASTM D 409 The fractions obtained from HGI tests were further assessed for its quality using their Utilization of Rejected Coal Through Blending Techniques in

.jpg)

Optimisation of coal fineness in pulverisedfuel boilers

2017年8月1日 Smaller coal fineness means consuming more electricity power as well as more complete combustion It is very difficult to find the equilibrium or Pareto optimality of the running state which is 2016年8月19日 Reality is, you waste a LOT more coal unless you always remember to put in exactly 80 items If you accidentally drop in 81 to 99 items, you will burn two entire blocks of coal for only 99 If you use coal pieces, at most you'll waste 7 charges –minecraft java edition Does a block of coal or 9 pieces of coal A control oriented model was then developed by Fan (1994) and Fan and Rees (1994) In 2009, coal flow and outlet temperature of mill were modelled using mass and heat balance equations for startup Sectional view of MBF coal mill Download Scientific Diagram2012年11月17日 20 131Fineness Fineness is an indicator of the quality of the pulverizer action Specifically, fineness is a measurement of the percentage of a coal sample that passes through a set of test sieves usually designated at 50, 100, and 200 mesh A 70% coal sample passing through a 200 mesh screen indicates optimum mill performance The mill wear and Coal mill pulverizer in thermal power plants PPT SlideShare

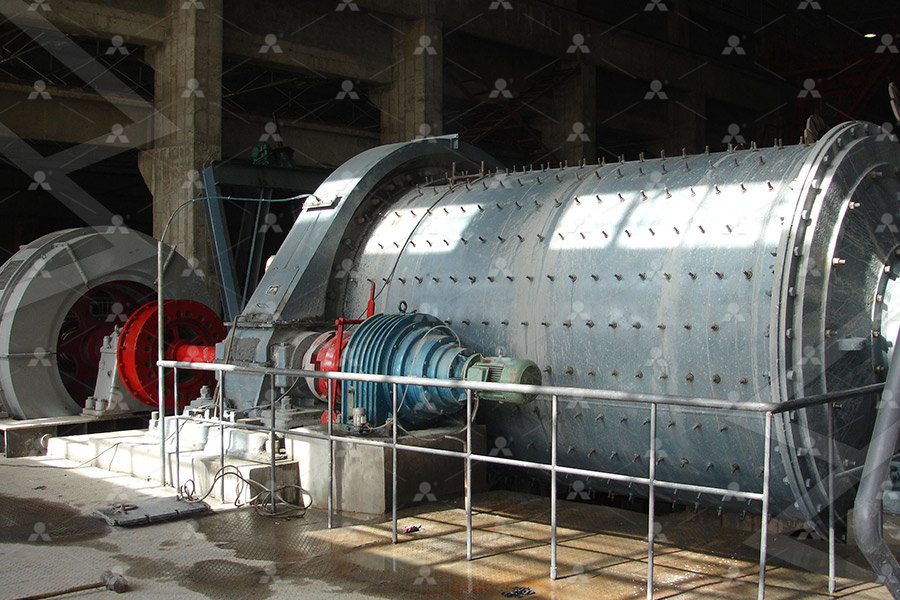

Cage Mill Crushers Industrial Pulverizing Equipment Stedman

Stedman offers Pulverizers Cage Mill Crushers that crush, grind, or pulverize a variety of materials to specified degrees of fineness One of the first uses for the cage mill was as a coal pulverizer By 1900 Nathan Stedman had built more than