Coal mill ventilation resistance

Research on optimization and reconstruction of ventilation system

sibility analysis of the three optimization schemes, Scheme 2 is finally determined as the best scheme After the modification, the resistance of the ventilation system of Tenghui Mine is 2016年1月1日 This article is based on the situation of too large coal mine ventilation resistance in the Majiagou coal mine According to Majiagou coal mine late production plans, it measuresStudy of Coal Mine Ventilation System Optimization 2024年2月1日 To achieve a superior inversion of resistance coefficients, we propose a DRL inversion method that continuously optimizes and adjusts resistance coefficient state variables Inversion of mine ventilation resistance coefficients enhanced by 2023年7月20日 The frictional resistance coefficient of ventilation of a roadway in a coal mine is a very important technical parameter in the design and renovation of mine ventilation Study on Mine Ventilation Resistance Coefficient Inversion Based

MINE VENTILATION SYSTEM VARIABLE RESISTANCE REGULATE

In coal mines, ventilation systems for air volume often due to the mining face of change and transfer of gas emission and other natural conditions change and change the fan performance In this paper, we study mine ventilation system and air volume control to determine the impact of factors that determine air quality and to identify quantitative conditions so as to formulate Mine Ventilation System Variable Resistance Regulate Air Quantity 2024年2月21日 Ventilation is critical in underground coal mining (UCM) for safety and productivity Challenges include mitigating hazardous gases, preventing coal dust Enhancing ventilation fan performance in underground coal As per existing norms, ie, Coal Mines Regulations No 153 sub clause 2 (a) of CMR 2017, to secure adequate ventilation in every ventilating district, not less than 6 m3 per minute of air Ventilation Air Requirement for MassProduction Panels (MPPs) in

Study of Coal Mine Ventilation System Optimization

2016年1月1日 This article is based on the situation of too large coal mine ventilation resistance in the Majiagou coal mine According to Majiagou coal mine late production plans, it measures resistance Vertical Coal Mill (VCM) is equipment for grinding and pulverizing coal into micron size Rotary kilns then use the powders as fuel burners The VCM has a housing section equipped with a lining The layout of the coal mill with a rotary classifierOptimization and transformation of 300MV units steel ball coal mill Pulverizing System and the ventilation capacity 213Separation efficiency test and resistance test of crude Optimization and transformation of 300MV units steel ball coal mill 2018年1月1日 Request PDF Study on Mine Ventilation Resistance Coefficient Inversion Based on Genetic Algorithm The frictional resistance coefficient of ventilation of a roadway in a coal mine is a very Study on Mine Ventilation Resistance Coefficient Inversion Based

Effect of mill outlet temperature on the coal volatile matter

Download scientific diagram Effect of mill outlet temperature on the coal volatile matter from publication: An investigation of performance characteristics and energetic efficiency of vertical 2024年3月12日 In order to study the problems of unreasonable airflow distribution and serious dust pollution in a heading surface, an experimental platform for forced ventilation and dust removal was built based on the similar principles Through the similar experiment and numerical simulation, the distribution of airflow field in the roadway and the spatial and temporal Experimental and numerical simulation study on forced ventilation Proper Ventilation: Ensuring adequate ventilation in the coal mill area helps disperse coal dust and reduce the risk of ignition Ventilation systems must be designed to handle the specific needs of the mill Regular Maintenance: Routine maintenance of coal mills and associated equipment is vital for preventing mechanical failuresCoal Mill Safety: A Critical Aspect of Power Plant Operations Coal Analysis of Coal Mill Operation Free download as PDF File (pdf), Text File (txt) or read online for free This document analyzes the comilling of coal and wood biomass in a ringball mill It describes tests conducted pulverizing hard coal with additions of 8% and 16% pine sawdust at different moisture contents Key findings include: 1) Biomass has weaker grinding properties Analysis of Coal Mill Operation PDF Mill (Grinding) Scribd

Study of Coal Mine Ventilation System Optimization based on

section Total 27983 100 0721 four surfaces ventilation system Air inlet section 138 738179 2642 3841 406012 1453 Air retuning section 41105 164978 5905section Total 27983 100 0721 four surfaces ventilation system Air inlet section 138 738179 2642 3841 406012 1453 Air retuning section 41105 164978 5905Study of Coal Mine Ventilation System Optimization based on research object, and based on the determination of ventilation resistance, a threedimensional ventilation system simulation model of Tenghui Mine is constructed based on Ventsim ventilation simulation software widely used in the optimization and transformation of the ventilation system of coal mines Zhang Yaming et alResearch on optimization and reconstruction of ventilation 2015年1月1日 The aim of this paper is to present the investigations of the possibilities of increasing the wear resistance of the ventilation mill parts for coal grinding in power plants, by application of Wear reducing of ventilation mill suction plates based

Technical specifications of vertical roller coal mill

Download scientific diagram Technical specifications of vertical roller coal mill from publication: An investigation of performance characteristics and energetic efficiency of vertical roller 2017年6月1日 The coal mill is assumed to be a lumped parameter object, and a calculation method based on the static heat balance of the coal mill calculates all heat input into or output from the coal mill quantitatively; however, a model of the coal mill has yet to be established on this basis (Feng et al, 1997, Ganapathy (2002), Magdalinović (1989))Optimization control of a pulverizing system on the basis of the 2010年5月1日 Request PDF CFD modeling of MPS coal mill with moisture evaporation Coal pulverizers play an important role in the functioning and performance of a PCfired boiler The main functions of a CFD modeling of MPS coal mill with moisture evaporation2015年9月22日 During the coal pulverizing, the working parts of the ventilation mill are being worn by the sand particles For this reason, the working parts are usually protected with materials resistant to (PDF) The Tribological Performance of Hardfaced/ Thermal Sprayed

Study on Mine Ventilation Resistance Coefficient Inversion Based

2023年7月20日 The frictional resistance coefficient of ventilation of a roadway in a coal mine is a very important technical parameter in the design and renovation of mine ventilation Calculations based on empirical formulae and field tests to calculate the resistance coefficient have limitations An inversion method to calculate the mine ventilation resistance coefficient by using a few Mine ventilation management plays an important role in safety mining production The ventilation performance directly influences the production efficiency and economic efficiency of coal mines Simulation of mine ventilation system refers to digitization of mine ventilation systemA SIMULATION STUDY ON THE RECONSTRUCTION OF COALMINE VENTILATION 2022年2月24日 Mining ventilation technology has become an irreversible trend of informationbased and agent development Realize realtime control of ventilation network, the coefficient of friction resistance Calculation model for ventilation friction resistance coefficient by The tendency for longwall panels to become longer and wider and for machinery to become larger increases panel resistance making the ventilation task more challenging, All longwalls, especially those which do not extract the full seam, leave some coal in the goaf as well as chain pillars each side, Ventilation/Gas Control Introduction underground COAL

.jpg)

ZGM type Mediumspeed Rolling coal millpower

1325 The diameter of grinding wheel is large, rolling resistance is small, coal block is easy to bite in, which is conducive to increase the output of coal mill, reduce the unit power consumption of coal mill and improve the service life of 2024年8月1日 It was found that the higher resistance at the wind ring was the main reason that led to the larger total pressure resistance of the mill, The larger the inlet mass ratio of air to coal is, the larger the ventilation rate is) The product size distributions obtained under different ventilation rates are plotted in Fig 7Experimental investigation on the preparation of macroscopic 0–1 This optimization makes the moving ring speed change gradually and smoothly, which helps to reduce the single consumption and ventilation resistance of the coal mill, and increase the maximum output Customizable: Dynamic rings and static rings can be customized according to specific requirements to accommodate different coal mill models and working conditionsChina Low Price Coal Mill Seal Dynamic Ring Manufacturers 2015年9月29日 Experimental Investigation of Flow Resistance in a Coal Mine Ventilation Air Methane Preheated Catalytic Oxidation Reactor September 2015 Journal of Chemistry 2015(11)Experimental Investigation of Flow Resistance in a Coal Mine

Numerical Study of the Erosion Process and Transport of Pulverized Coal

2022年1月26日 Fragment of pulverized coal channel M1 powered by coal 1 presenting the velocity [m/s] and diameter of individual coal dust particles [µm] Download scientific diagram aventilation mill in Drmno thermo power plant, breconstruction of ventilation mill: bmill wheel, and cimpact plates from publication: Redesign of impact plates aventilation mill in Drmno thermo power plant, breconstruction 2013年1月1日 Ventilation mill for grinding coal is one of the main steam power plants in the system that makes a significant technologies to increase wear resistance of impact plates in ventilation millResearch on crushing mechanism and separation characteristic of 2021年2月8日 Abstract Ball drum mills (BDM) are one of the main types of coalgrinding equipment in Russia A significant drawback of BDM is high power consumption (a significant part of the TPP’s own needs) With a huge scale of production, reducing these costs even by a few percent gives a significant economic effect The problem of minimizing the specific energy Determining Optimum Productivity of a Ball Drum Mill When

.jpg)

Analysis of the Coal Milling Operations to the Boiler Parameters

From the coal yard, the coal is transfer to the mill bunkers through conveyor belt The bunkers are sized for an effective capacity of twelve (12) hours at BMCR with design coal Each mill bunker has one hopper, connected to the feeders Mills operate when the bunker coal gate valves are opened, coal is allowed to flow to the gravimetric feeders2014年1月1日 Two mill systems are employed for most coal grinding applications in the cement industry These are, on the one hand, vertical roller mills (VRM) that have achieved a share of almost 90% and, on (PDF) MPS mills for coal grinding ResearchGate2016年1月1日 This article is based on the situation of too large coal mine ventilation resistance in the Majiagou coal mine According to Majiagou coal mine late production plans, it measures resistance Study of Coal Mine Ventilation System Optimization Vertical Coal Mill (VCM) is equipment for grinding and pulverizing coal into micron size Rotary kilns then use the powders as fuel burners The VCM has a housing section equipped with a lining The layout of the coal mill with a rotary classifier

.jpg)

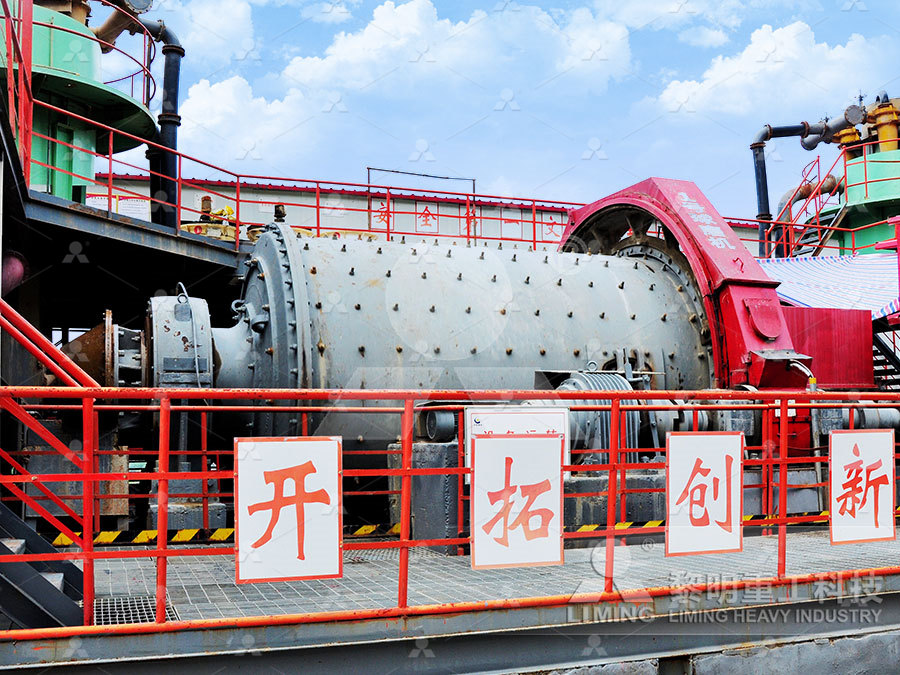

Optimization and transformation of 300MV units steel ball coal mill

Optimization and transformation of 300MV units steel ball coal mill Pulverizing System and the ventilation capacity 213Separation efficiency test and resistance test of crude 2018年1月1日 Request PDF Study on Mine Ventilation Resistance Coefficient Inversion Based on Genetic Algorithm The frictional resistance coefficient of ventilation of a roadway in a coal mine is a very Study on Mine Ventilation Resistance Coefficient Inversion Based Download scientific diagram Effect of mill outlet temperature on the coal volatile matter from publication: An investigation of performance characteristics and energetic efficiency of vertical Effect of mill outlet temperature on the coal volatile matter2024年3月12日 In order to study the problems of unreasonable airflow distribution and serious dust pollution in a heading surface, an experimental platform for forced ventilation and dust removal was built based on the similar principles Through the similar experiment and numerical simulation, the distribution of airflow field in the roadway and the spatial and temporal Experimental and numerical simulation study on forced ventilation

.jpg)

Coal Mill Safety: A Critical Aspect of Power Plant Operations Coal

Proper Ventilation: Ensuring adequate ventilation in the coal mill area helps disperse coal dust and reduce the risk of ignition Ventilation systems must be designed to handle the specific needs of the mill Regular Maintenance: Routine maintenance of coal mills and associated equipment is vital for preventing mechanical failuresAnalysis of Coal Mill Operation Free download as PDF File (pdf), Text File (txt) or read online for free This document analyzes the comilling of coal and wood biomass in a ringball mill It describes tests conducted pulverizing hard coal with additions of 8% and 16% pine sawdust at different moisture contents Key findings include: 1) Biomass has weaker grinding properties Analysis of Coal Mill Operation PDF Mill (Grinding) Scribdsection Total 27983 100 0721 four surfaces ventilation system Air inlet section 138 738179 2642 3841 406012 1453 Air retuning section 41105 164978 5905Study of Coal Mine Ventilation System Optimization based on section Total 27983 100 0721 four surfaces ventilation system Air inlet section 138 738179 2642 3841 406012 1453 Air retuning section 41105 164978 5905Study of Coal Mine Ventilation System Optimization based on