Magnesite crushing

.jpg)

Magnesite Ore Processing: Separation and Calcination

At present, the beneficiation methods of magnesite ore mainly include washing, optical sorting, gravity separation, thermal separation, magnetic separation, flotation separation, and chemical separation 展开2009年2月1日 Precipitation of magnesite and silica has different dependence on pH and temperature, and detailed reaction mechanisms are addressed through the experiments A continuous process for manufacture of magnesite and silica properties with magnesite and the high commercial importance of magnesite, extensive scientific work has been carried out on magnesite beneficiation The target of the current paper is to MAGNESITE BENEFIATION METHODS: A REVIEW SEPRMThe magnesite mining process comprises the following stages: At Magnesites Navarras, we are firmly committed to restoring the areas in which we are operating Once the magnesite Mining process MAGNESITAS NAVARRAS

Engineering properties and sustainability evaluation of crushed

2023年11月1日 In this study, crushed low grade magnesite (CLGM) was prepared and then applied in mortar as fine aggregate to partially or entirely replace natural river sand (30%, TL;DR: In this paper, a fused magnesite crushing and separating method is disclosed, which includes steps of adding a raw material into a jaw crusher, performing first time of crushing A fused magnesite crushing and separating method SciSpace by 2013年5月22日 Magnesite recovered from a mine or quarry undergoes several stages of comminution before it is charged into a roasting furnace Pieces of magnesite smaller than System for sorting crude magnesite at the crushingconcentration 2024年3月1日 In this work, a novel ecofriendly approach is studied in a pilot plant with a capacity of 40 t/d input, to calcine natural magnesite grading as low as 40 % MgO, to carry out An ecofriendly approach to purify natural magnesite and to

.jpg)

Overview of Magnesite ResearchGate

Magnesite is a magnesium carbonate with the chemical formula MgC03 It is an industrial mineral and forms deposits, occurring partly as rock forming resource Three important deposits types Lowactive MgO was prepared through selecting, crushing, cleaning, drying, calcining, grinding and other processes, using Tibetan microcrystalline magnesite asPreparation of LowActive MgO from Microcrystalline Magnesite Offwhite to yellow mixture of pellets and powder of natural mineral obtained from natural magnesite by crushing Main component is magnesium carbonate Commonly used in refractory materials Bulk density: 1,500 1,700 kg/m 3 Uses: use in refractory materials NonIMSBC Code information: odourless, moisture content is between 25% 4%Magnesite Fines BIMCO2024年3月4日 The tailings are typically a byproduct of the crushing, grinding, and flotation processes used in the extraction of magnesite As the production of magnesite has risen over time, a huge amount of MMT has been created and disposed of in open landfills This has a major impact on the ecosystem in the areas surrounding the dumpsiteA reliabilitybased mechanicalempirical design method for flexible

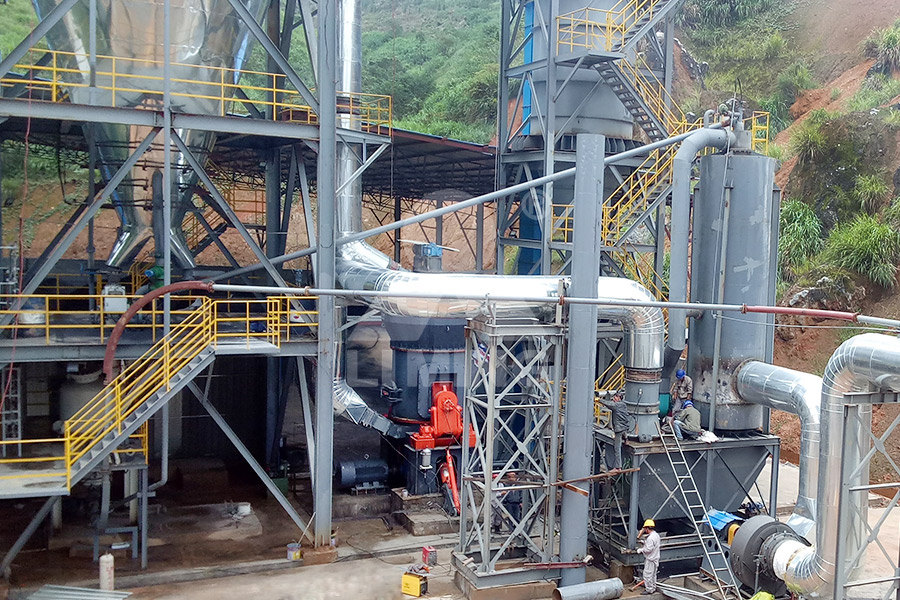

Magnesite Powder Process And Magnesite Grinding Mills

2024年1月24日 The beneficiation process may involve crushing, screening, washing, and magnetic separation to achieve the desired quality of magnesite Calcination: The next step involves calcination, which is a heating process that transforms magnesite into a more reactive form Calcination typically occurs at temperatures above 700 degrees CelsiusStrathmore Mine Strathmore Magnesite Mine is a large opencast quarry operation producing raw magnesite ore with known reserves of more than 100 million tons The magnesite ore is beneficiated by crushing, screening, washing, magnetic and hand separation The beneficiation plant processes in excess of 1 million tons of ore per annum producing close to 100,000 tons Strathmore Mine Chamotte2021年7月28日 Magnesite is a carbonate mineral of magnesium, in which magnesium oxide has strong fire resistance and adhesion Magnesite is the raw material for the production of refractory materials, as well as the main raw material for refining magnesium The purpose of beneficiation of magnesite is to remove impurities and improve product grade6 Magnesite Beneficiation Methods You need to KnowCold Crushing Strength ≥ MPa: 392: 49: 588: 392: 392: 392: 441: Apparent Porosity ≤ % 20: 20: 18: 20: 20: 18: 18: Initial Softening Temperature under MagnesiaChromite Brick 21 MagnesiaChromite Brick : This product uses dead burned magnesite and chromium oxide as raw materials and is made through high pressure shaping and high CMIE LMC Magnesiabased Bricks

A fused magnesite crushing and separating method SciSpace

A fused magnesite crushing and separating method is disclosed The method includes steps of adding a raw material into a jaw crusher, performing first time of crushing until the particle size of the raw material is 68 cm and the content of particles having a size of 40 meshes is 515%, feeding raw material particles after the first time of crushing into a verticalshaft impact crusher A new crushing installation resulted in improved magnesite liberation increasing the total yield In 2000 Grecian Magnesite acquired a 40% stake of the Spanish magnesia producer Magnesitas Navarras SA 2001 – 2011 In 2001 a new magnetic separation unit OUR HISTORY GRECIAN MAGNESITE2013年5月22日 Magnesite recovered from a mine or quarry undergoes several stages of comminution before it is charged into a roasting furnace Pieces of magnesite smaller than 1200 mm are delivered to a crushingconcentration plant (CCP) by rail and undergo coarse crushing in a jaw crusher to produce pieces smaller than 350 mmSystem for sorting crude magnesite at the crushing 2023年6月29日 This step removes any moisture and carbon dioxide present in the magnesite, leaving behind a more concentrated form of magnesia Fusion: The calcined magnesite is then fused at extremely high temperatures, typically exceeding 2,800 degrees Celsius, in electric arc furnaces This intense heat causes the magnesite to melt, forming a molten massUnderstanding the Composition of Fused Magnesia

(PDF) Kiln Technology Boosts Markets for

Exploration New kiln technology expands market opportunities for cryptocrystalline magnesite John Keeling1, Ric Horn2 and Ian Wilson3 1 Geological Survey of South Australia, Department for Energy and Mining 3 Huang et al [94] 2014 Reutilization of lowgrade magnesium oxides for flue gas desulfurization during calcination of natural magnesite: a closedloop process Effects of calcite and magnesite application to a declining Masson pine forest (PDF) Review on the elaboration and characterization Magnesite chrome brick Magnesite chrome brick is a kind of basic refractory products which containing 55% Cold crushing strength(MPa) ≥40 ≥40 ≥40 ≥40 02MPa refractoriness under load T06(o C) ≥1670 ≥1670 ≥1670 ≥1670 Thermal shock resistance (1300 o C air cooling) (1100 o C water cooling)Magnesite chrome brickChina Magnesite wholesale Select 2024 high quality Magnesite products in best price from certified Chinese Powder Metal manufacturers, Cold Crushing Sternth: 40MPa45MPa 1 / 6 Favorites Low Price Refractory Dead Burned Magnesite Fused Magnesite for Lime Kilns US$ 490850 / Ton 20 Tons (MOQ) Magnesite MadeinChina

Caustic Calcined Magnesite Ball

Caustic Calcined Magnesite Ball, Find Details and Price about Caustic Calcined Magnesite MGO from Caustic Calcined Magnesite Ball Haicheng Ms Magnesite Refractory Minerial Factory The annual mining capacity is more than 6 million tons, the magnesite ore through crushing, 2018年4月20日 1 Introduction Different mixtures of geomaterials (kaolin clay, red clay, marl, andalusite, perlite, pozzolana, schist, silica sand, magnesite, forsterite, etc), and additives (natural and synthetic) are used for the elaboration of ceramics and refractories [Citation 1]These industrial minerals and rocks are the raw materials of economic value that are not classified as Full article: Review on the elaboration and characterization of 2021年3月8日 In order to reduce the iron impurities in magnesite ore and improve the purity of magnesium products, the difference in floatability between magnesite and limonite has been studied by using (PDF) The Flotation Separation of Magnesite and Limonite2006年5月31日 Summary This chapter contains sections titled: Mining Operations Processing Magnesite Gravity Concentration Tertiary Crushing Postcalcination Screening and Grinding ReferencesMining and Processing Magnesite Wiley Online Library

Digital Solution for Remote Management of Magnesite Ore Sorting

MAGNESITE MINING PROCESS Mine Selective mining Crushing and screening Hand sorting PREbeneficiated Magnesite Crushing and screening DMS and Magnetic sorting Beneficiated Magnesite Kiln Feed CCM, DBM, EFM etcThe burnt magnesite brick is produced by crushing, smashing, mixing, forming, drying, and sintering process (shown in the Fig 1), which is similar with other refractory bricks The magnesia brick can be burnt in the inverted flame kiln or tunnel kiln with higher firing temperature than that of highalumina brick, generally 1550–1600 °C, and that of highpurity magnesia products is Magnesia Bricks, Production and Application of SpringerLink2024年6月1日 The main gangue minerals in magnesite are quartz, dolomite, and calcite, while those in brucite are serpentine, dolomite, and calcite Magnesiumcontaining minerals are required to undergo desilication to meet industrial production requirements because siliconcontaining gangue reduces magnesiumproduct quality and adversely affects subsequent Research advancement of efficient flotation separation Physical methods such as crushing, scrubbing, and magnetic separation are being used for improving the quality of magnesite However, these processes require well designed systems, expensive space One of the Kunwarara mines, Queensland, Australia

CHARACTERIZATION AND EVALUATION OF MAGNESITE

MAGNESITE MINE, LIMPOPO PROVINCE OF SOUTH AFRICA Sibanda Z, processing can be divided into crushing, sizing and washing (Shand, 2006 and Cardavelli, 2008) The mined2020年2月7日 Magnesite is used as a main material for producing fused magnesite, a plurality of pretreatment procedures are needed in the production process, wherein the crushing and grading of raw ore are particularly important, the conventional crushing and grading device can only simply grade the crushed ore, or the two steps are separately executed, so that the production Fused magnesia crushing and grading device Google Patents2011年9月11日 The primary aim of this study is the beneficiation of magnesite ores from eastern part of Iran by reverse flotation process For this purpose, the mineralogical and microstructural characteristics of the asreceived and the processed ores from Iranian Afzal Abad mine were established The liberation degree of ore was estimated at about 75 µm Then the asreceived Beneficiation of Iranian magnesite ores by reverse flotation Kamado Magnesite Mine (highest grade magnesite) Western China: Reserves of 48585 million tons, after calcination, MgO≥98% Xinjiang Harlehat Magnesite Mine Western China: Reserves of 44619 million tons, after calcination, MgO+CaO≥98% Haicheng Linli Magnesite Mine Eastern China – Liaoning: Reserves of 733 million tons, MgO 92 to 975% High Purity Magnesia Supply to New Overseas Refractory Plant

Turkey`s Magnesite for Production of Fused Magnesia, Properties

Magnesite processing (Fig 1) can be div ided into crushing, sizing and beneficiation stages The degree of beneficiation required depends on the quality of the ore and its in tended end use Cryptocrystalline ores may only need crushing, screening, washing and handsorting to produce a material suitable for Caustic Calcined Magnesia (CCM We are proud to announce our indulgence in manufacturing and exporting of premium quality magnesite bricks that are mainly used in front and back wall of open hearth furnaces and chemical industries Our Product Features Durable Strong in nature Sturdy High cold crushing strength Types Of Magnesite Bricks : 1) Burned Magnesite BrickMagnesite Bricks – Ravani Ceramicscrushing and screening equipment The crushing and screening plant usually consists of various equipment, such as belt conveyors, bidirectional feed hoppers, trommel screen, roller crushers, and bucket elevators, which together form the crushing and screening equipment Crushing equipment: double roller crusher, single roller crusher, knife Crushing and Screening Plant for Activated Carbon Plant AGICO2020年7月20日 In the coarse fractions the concentration of magnesite is often achieved by utilising selective extraction and crushing, manual and sensorbased sorting, density sorting and dry magnetic separation For achieving a separation effect in the fractions smaller than one millimetre wet processing technologies such as wet magnetic separation and flotation are Systematic Separation Studies on Finely Dispersed Raw Magnesite

.jpg)

Magnesite Fines BIMCO

Offwhite to yellow mixture of pellets and powder of natural mineral obtained from natural magnesite by crushing Main component is magnesium carbonate Commonly used in refractory materials Bulk density: 1,500 1,700 kg/m 3 Uses: use in refractory materials NonIMSBC Code information: odourless, moisture content is between 25% 4%2024年3月4日 The tailings are typically a byproduct of the crushing, grinding, and flotation processes used in the extraction of magnesite As the production of magnesite has risen over time, a huge amount of MMT has been created and disposed of in open landfills This has a major impact on the ecosystem in the areas surrounding the dumpsiteA reliabilitybased mechanicalempirical design method for flexible 2024年1月24日 The beneficiation process may involve crushing, screening, washing, and magnetic separation to achieve the desired quality of magnesite Calcination: The next step involves calcination, which is a heating process that transforms magnesite into a more reactive form Calcination typically occurs at temperatures above 700 degrees CelsiusMagnesite Powder Process And Magnesite Grinding MillsStrathmore Mine Strathmore Magnesite Mine is a large opencast quarry operation producing raw magnesite ore with known reserves of more than 100 million tons The magnesite ore is beneficiated by crushing, screening, washing, magnetic and hand separation The beneficiation plant processes in excess of 1 million tons of ore per annum producing close to 100,000 tons Strathmore Mine Chamotte

.jpg)

6 Magnesite Beneficiation Methods You need to Know

2021年7月28日 Magnesite is a carbonate mineral of magnesium, in which magnesium oxide has strong fire resistance and adhesion Magnesite is the raw material for the production of refractory materials, as well as the main raw material for refining magnesium The purpose of beneficiation of magnesite is to remove impurities and improve product gradeCold Crushing Strength ≥ MPa: 392: 49: 588: 392: 392: 392: 441: Apparent Porosity ≤ % 20: 20: 18: 20: 20: 18: 18: Initial Softening Temperature under MagnesiaChromite Brick 21 MagnesiaChromite Brick : This product uses dead burned magnesite and chromium oxide as raw materials and is made through high pressure shaping and high CMIE LMC Magnesiabased BricksA fused magnesite crushing and separating method is disclosed The method includes steps of adding a raw material into a jaw crusher, performing first time of crushing until the particle size of the raw material is 68 cm and the content of particles having a size of 40 meshes is 515%, feeding raw material particles after the first time of crushing into a verticalshaft impact crusher A fused magnesite crushing and separating method SciSpace A new crushing installation resulted in improved magnesite liberation increasing the total yield In 2000 Grecian Magnesite acquired a 40% stake of the Spanish magnesia producer Magnesitas Navarras SA 2001 – 2011 In 2001 a new magnetic separation unit OUR HISTORY GRECIAN MAGNESITE

System for sorting crude magnesite at the crushing

2013年5月22日 Magnesite recovered from a mine or quarry undergoes several stages of comminution before it is charged into a roasting furnace Pieces of magnesite smaller than 1200 mm are delivered to a crushingconcentration plant (CCP) by rail and undergo coarse crushing in a jaw crusher to produce pieces smaller than 350 mm2023年6月29日 This step removes any moisture and carbon dioxide present in the magnesite, leaving behind a more concentrated form of magnesia Fusion: The calcined magnesite is then fused at extremely high temperatures, typically exceeding 2,800 degrees Celsius, in electric arc furnaces This intense heat causes the magnesite to melt, forming a molten massUnderstanding the Composition of Fused Magnesia