HOME→Loesche vertical mill water spray system Loesche vertical mill water spray system Loesche vertical mill water spray system

Loesche vertical mill water spray system Loesche vertical mill water spray system Loesche vertical mill water spray system

PROCESS OPTIMISATION FOR LOESCHE GRINDING PLANTS

The core elements of these plants are the Loesche vertical mills for drygrinding the abovementioned grinding stock Loesche has developed and built the largest and most efficient • Lowvibration mill running, even in partial load ranges down to 20% of the mill load, thanks to individuallyguided grinding rollers • The speciallydeveloped hydraulic roller relief system LOESCHEMILLS• the hydropneumatic counter pressure system makes it possible to grind a multitude of different fuels – both hard and soft • mill design with 2, 3, 4 or 6 rollers for fuel throughputs up to 350 t/h OVER VIEW LoescheStudies for applications of LOESCHE mills for the dry comminution of ores and minerais have proven that in particular cases the recovery and the grade ofU Schaefer LOESCHE VERTICAL ROLLER MILLS FOR MINERAL

.jpg)

Review on vertical roller mill in cement industry its performance

2021年1月1日 With the grinding capacity of a vertical roller mill and the ability to dry, grind and sort in a single unit, the vertical roller mill offers a definite advantage over the ball mill system 2012年9月1日 Mills (VRM) installations and summarises the main benefits of the dry compressive Loesche grinding technologies in Airflow and OverflowMode Some of these Latest Installations And Developments Of Loesche Vertical Roller Vertical Roller Mills (VRM) represent the most widely spread milling technology for raw materials in the cement industry and for many years also for clinker and slag grinding The availability of Drive systems for LOESCHE VRM More availability @ lower TCOThanks to its grinding plants with throughputs of 2t/h to 1,000t/h for the cement industry and selfinert, central coalgrinding plants for hard and brown coal power stations, LOESCHE is the Loesche Mining Technology

.jpg)

Increase productivity of vertical roller mill using seven QC tools

2021年1月29日 In order to help the Vertical Roller Mill (VRM) working stably with higher automation level and lighter labor intensity, an intelligent automatic control system is designed Since 1906 worldwide market leader in designing, manufacturing and servicing vertical roller mills for the cement, power and industrial minerals industriesPlant engineering solutions for any mission LoescheWe are currently offering general training sessions on vertical roller mills as well as ‚customtailored‘ training units on: Grinding technology; Mechanic design of a vertical roller mill; Maintenance procedures for vertical roller mills; Operation, Services LoescheLoesche Mill LM 15200, Slavno, Poland, 2006 of the vertical roller grinding mill with driven grind The DIN EN ISO 9001 quality management system permits the delivery of mills complete or in easytotransport components with fast and precise assembly on site 7Loesche Mills for industrial minerals

DRIVE SELECTION FOR LARGE LOESCHE VERTICAL ROLLER MILLS

4247LoescheFahrlandCS6dd 42 270416 16:01 CEMENT INTERNATIONAL 4 2/2016 4 VOL 14 43 1 A background to drives of vertical roller mills The drive of a vertical roller mill – essentially the mill gearbox – has to fulfill two tasks: The first is to reduce the speed of the electric motor to the selected mill speed and to transmitFor the greenfield project in Thanh Thang LOESCHE will supply two vertical roller mills type LM 533+3 CSVertical Roller Mill Loesche2015年3月9日 Based on its positive experience in recent decades, SCG Cement commissions LOESCHE to deliver an LM 563+3 C vertical roller mill for the grinding of clinker for its cement works in Ta Luang, ThailandLOESCHE vertical roller mill for SCG Cement in ThailandHurriclon systems included with the delivery for improved dust separation provide higher process Engineering company gains a competitive edge with advanced mill technology yet again Read more New construction project with three LOESCHE VRMs in Four LOESCHE Vertical Roller Mills for Turkey By admin on Aug 18th, 2017 Coal Cement Raw Mill Loesche

.jpg)

Loesche Grinding Technology for the Power Industry

2010 Loesche Energy Systems supply 6x LM283 Mills to Gheco One Plant, Thailand Loesche have the mill to meet your needs Loesche vertical roller mills for solid fuels are offered with 2, please contact Loesche Energy Systems Limited Mill weight tonnes (short ton) LM 434 D 327 (360) LM 414 D 312 (343)production line with vertical roller mills made by Loesche, Germany, which were supplied via the company’s American subsidiary, Loesche America in Pembroke Pines, Florida 2 Cement raw material grinding The grinding of the entire cement raw material for the new line is carried out by a Loesche mill LM 606, which 1 Einleitung Am 5Trials on high quality cement with a Loesche vertical roller mill Loesche GmbH Hansaallee 243 40549 DüsseldorfGermany Tel +4921153 530 Fax +4921153 53500 Mail loesche@loesche Managing Directors: Dr Thomas Loesche Dr Joachim Kirchmann Amtsgericht Düsseldorf HRB 13611 loesche LOESCHE vertical roller mill for SCG Cement in Thailand Based on its positive experience in recentLOESCHE vertical roller mill for SCG Cement in Thailandspring system, roller bearings etc in the Loesche modular system can be exchanged between related mill sizes for cement raw material and cement grinding • Identical gearboxes can be supplied for similarly sized raw material and cement mills Outlet openings for foreign particles Welding of roller tyre in the mill Service drive 82 µm 5 µm Loesche

.jpg)

Four LOESCHE Vertical Roller Mills for Turkey

2017年8月18日 LOESCHE is contributing four of its highlymodern vertical roller mills to the new cement plant of the German technology firm AUNDE in the Turkish region of Soma: one mill for grinding up to 350 tonnes of raw material 2017年2月1日 Bangladesh plans to improve its cement supply significantly by an expansion of production with LOESCHE mill LM 563+3 CS For the Aman Group cement works, Haria 2 in Narayangonj – 20 km to the south of Dhaka, LOESCHE receives followon order for a vertical 12 Loesche mill 13 Filter 14 Volumetric flow measurement 15 Mill fan 16 Stack with flap 17 Recirculation gas line with flap 18 Hotgas generator 19 Rotary star gate feeder 20 Conveyor belt 21 Bucket elevator 22 Product silo, filler 23 Filler transportation 24 Metal Recovery and Filler Production LoescheGET IN TOUCH Call us or drop us a line via LOESCHE India Pvt Ltd D 83, Sector 2 Noida Uttar Pradesh, India Phone: +91 120 40 18 500LOESCHE India

.jpg)

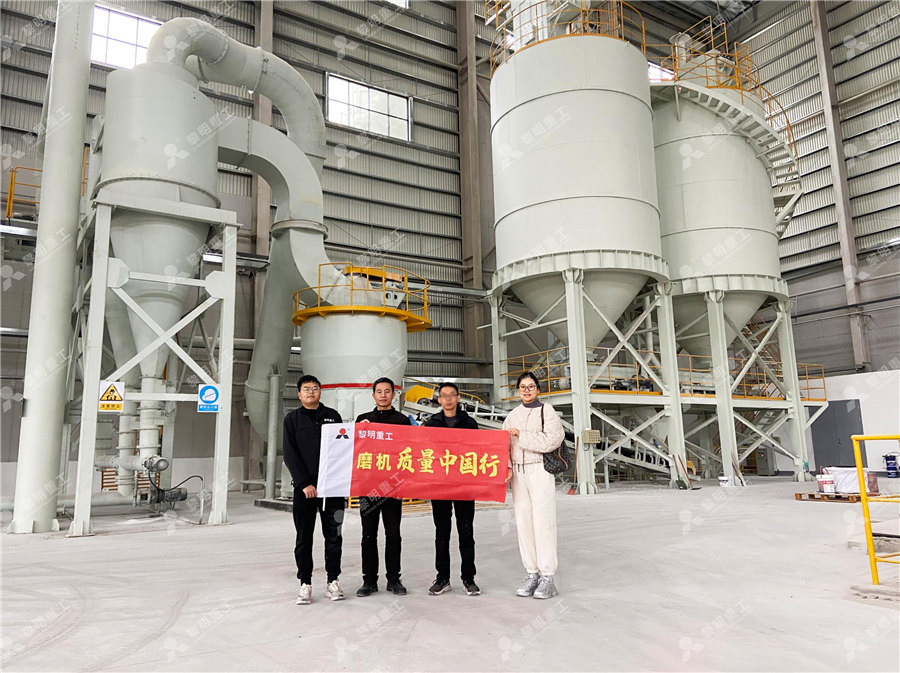

Chinese Light Metal Producer Relies on Proven Vertical Roller Mill

2018年10月2日 Ningde – Now, LOESCHE is delivering a vertical roller mill for grinding copper matte to China This is to be operated in the newly erected copper smelting plant of the Aluminium Corporation of China (Chinalco) Southeast Copper Limited in Ningde, in the southern Chinese province of Fujian – 500 km to the south of ShanghaiHere you can browse and find all our available technical brochures, and filter your search by SolutionBrochures LoescheThe Loesche vertical mill is characterised by the fact that several processes – comminution, drying and classifying – can be implemented in a single machine Since the birth of the Loesche mill back in 1927 we have devoted ourselves just as much to classifying as we have to the grinding process This is because only highly efficientOVER VIEW LoescheAlmost 30 years ago LOESCHE introduced the first vertical roller mill to grind both, cement clinker and granulated blast furnace slag, in one process The concept of M and Srollers was established in 1992, which is one of the most cost effective and Cement Blast Furnace Slag Loesche

.jpg)

About Us Loesche

Nowadays, Loesche vertical mills form the core of many plants used to drygrind coal, cement raw materials, granulated slag, industrial minerals and ores Thanks to its grinding plants with throughputs of 2 to 1000 t/h for the cement industry and selfinert, central coalgrinding plants for hard and brown coal power stations, Loesche is the global market leader for vertical mills and 2016年9月1日 The Loesche vertical roller mill is one such high compression grinding device which has undergone test studies in a minerals processing context (Altun et al, 2017 (Altun et al, , 2015van Drunick Operational parameters affecting the vertical roller mill 2001年10月1日 PRINCIPLE OF THE LOESCHE MILL LOESCHE has been manufacturing vertical roller mills for cement raw materials, clinker and slag, indus trial minerais, and for coal for cement kilns, for power plants and for blast fumaces for more than 90 years In the last three decades the cement industry demanded significantly higher mill capacitiesLoesche vertical roller mills for the comminution of ores and minerals 2018年10月1日 Another LOESCHE mill with a throughput of 200 t/h is used for the subsequent grinding of cement clinker to a fineness of 3,400 to 3,600 Blaine The other large 3roller mill with a capacity of 42 t/h is used for the grinding of With Three Grinding Plants with Proven Vertical Roller

.jpg)

Mills for minerals and ores Loesche

Significant Process Advantages of LOESCHE Mills The dry milling of ore in LOESCHE vertical roller mills has shown significant process advantages, as well as economic and ecological benefits To demonstrate these a mobile ore Up to date, the LOESCHE Mill type LM 352+2 is the sole vertical roller mill in this plant for cement grinding LOESCHE America to hold its 4th Annual Technical Seminar in South Florida LOESCHE America Inc has opened registrations for its fourth Technical Seminar, to take place in Downtown Miami, from 19 September through to 22 September, 2016Loesche Mining TechnologyLOESCHE's special series of industrial mineral mills LOESCHE has developed a special series of industrial mineral mills for the specific needs of grinding minerals The smallest mills in this series – LM 12200 and LM 15200 – are delivered to the customer complete or semicompleteIndustrial Minerals Loeschemill is used instead of the former system with two vertical roller mills operating in parallel Based on these investigations Loesche GmbH has developed a mill for producing raw meal that has an arrangement of six rollers on the grinding table This mill, designated the Redundancy and interchangeability – large vertical roller Loesche

.jpg)

History Loesche

In 1934, a new generation Loesche mill was launched, featuring a separate gearbox and horizontal grinding track By 1937, 400 Loesche mills had been sold and in the next two years sales rocketed By this time, Curt von Grueber had sold his shares to Ernst Curt Loesche, making him the sole owner Sadly, Ernst Curt Loesche passed away in November vertical roller grinding mill for cement grinding Naturally, LOESCHE technology is a ‚must‘ here Cementos Moctezuma is a joint venture company of Cementos Molins, Buzzi Unicem and the Mexican partner Grupo Carso The LOESCHE vertical roller grinding mill LM 533+3 C is used in the cement works in Apazapan for grinding clinker and will produceFIRST VERTICAL ROLLER MILL WITH COPE GEARBOX* IN THE 2011年3月1日 Loesche GmbH from Düsseldorf supplied the grinding plants for producing raw meal and pulverized fuel as well as two LM 533+3 CS vertical roller mills for grinding the cement for the new cement Trials on high quality cement with a Loesche vertical roller millLoesche Mill LM 15200, Slavno, Poland, 2006 of the vertical roller grinding mill with driven grind The DIN EN ISO 9001 quality management system permits the delivery of mills complete or in easytotransport components with fast and precise assembly on site 7Loesche Mills for industrial minerals

.jpg)

Services Loesche

We are currently offering general training sessions on vertical roller mills as well as ‚customtailored‘ training units on: Grinding technology; Mechanic design of a vertical roller mill; Maintenance procedures for vertical roller mills; Operation, Loesche Mill LM 15200, Slavno, Poland, 2006 of the vertical roller grinding mill with driven grind The DIN EN ISO 9001 quality management system permits the delivery of mills complete or in easytotransport components with fast and precise assembly on site 7Loesche Mills for industrial minerals4247LoescheFahrlandCS6dd 42 270416 16:01 CEMENT INTERNATIONAL 4 2/2016 4 VOL 14 43 1 A background to drives of vertical roller mills The drive of a vertical roller mill – essentially the mill gearbox – has to fulfill two tasks: The first is to reduce the speed of the electric motor to the selected mill speed and to transmitDRIVE SELECTION FOR LARGE LOESCHE VERTICAL ROLLER MILLSFor the greenfield project in Thanh Thang LOESCHE will supply two vertical roller mills type LM 533+3 CSVertical Roller Mill Loesche

.jpg)

LOESCHE vertical roller mill for SCG Cement in Thailand

2015年3月9日 Based on its positive experience in recent decades, SCG Cement commissions LOESCHE to deliver an LM 563+3 C vertical roller mill for the grinding of clinker for its cement works in Ta Luang, ThailandHurriclon systems included with the delivery for improved dust separation provide higher process Engineering company gains a competitive edge with advanced mill technology yet again Read more New construction project with three LOESCHE VRMs in Four LOESCHE Vertical Roller Mills for Turkey By admin on Aug 18th, 2017 Coal Cement Raw Mill Loesche2010 Loesche Energy Systems supply 6x LM283 Mills to Gheco One Plant, Thailand Loesche have the mill to meet your needs Loesche vertical roller mills for solid fuels are offered with 2, please contact Loesche Energy Systems Limited Mill weight tonnes (short ton) LM 434 D 327 (360) LM 414 D 312 (343)Loesche Grinding Technology for the Power Industryproduction line with vertical roller mills made by Loesche, Germany, which were supplied via the company’s American subsidiary, Loesche America in Pembroke Pines, Florida 2 Cement raw material grinding The grinding of the entire cement raw material for the new line is carried out by a Loesche mill LM 606, which 1 Einleitung Am 5Trials on high quality cement with a Loesche vertical roller mill

LOESCHE vertical roller mill for SCG Cement in Thailand

Loesche GmbH Hansaallee 243 40549 DüsseldorfGermany Tel +4921153 530 Fax +4921153 53500 Mail loesche@loesche Managing Directors: Dr Thomas Loesche Dr Joachim Kirchmann Amtsgericht Düsseldorf HRB 13611 loesche LOESCHE vertical roller mill for SCG Cement in Thailand Based on its positive experience in recentspring system, roller bearings etc in the Loesche modular system can be exchanged between related mill sizes for cement raw material and cement grinding • Identical gearboxes can be supplied for similarly sized raw material and cement mills Outlet openings for foreign particles Welding of roller tyre in the mill Service drive 82 µm 5 µm Loesche