Limestone processing technology

.jpg)

Lime and Limestone: Chemistry and Technology, Production and

2007年12月21日 The burning process of limestones is an important process in the modern industries, which can be described in two parts, CaCO 3 decarbonation due to the thermal 1998年7月8日 Processing and Dispatch of Limestone Sampling and Testing of Limestone USES AND SPECIFICATIONS OF LIMESTONE Overview and Economic Aspects of the Lime and Limestone: Chemistry and Technology, Production and 2022年10月1日 In this review, the current state of the lime industry and its processing configurations is visualised This is followed by a detailed description of the current status of Decarbonising the lime industry: Stateoftheart ScienceDirect2021年7月15日 Since limestone is available in abundance, its quality has not drawn much attention and is largely ignored It may be noted further that the generation of highpurity or highgrade calcium from limestone for various uses in outer space applications may be required in future by the industry, and this can be derived only through limestone processingModern Technological Applications for Limestone Mining

What are the limestone processing technologies?

2021年2月26日 The above is the common processing technology and process of limestone If you have any questions about this, please contact us in detail 上一篇: What Equipment Is Suitable For Crushing Pebble?2009年2月1日 Journal of Materials Processing Technology Volume 209, Issue 3, 1 February 2009, Pages 16071611 Synthesis of needlelike aragonite from limestone in the presence of magnesium chloride Author links open overlay panel Zeshan Hu a, Minghao Shao a, Qiang Cai a, Sheguang Ding a, Chenghua Zhong a, Xiaopin Wei a, Yulin Deng bSynthesis of needlelike aragonite from limestone in the presence 2021年5月1日 The technology of autoclave leaching of Ukrainian petalite ores being discussed as well Presumably, autoclavebased methods are optimal for poor raw material processing with high efficiency In conclusion, technologies of Limica processing briefly considered, taking into account the issues of waste disposal and economic backgroundProcessing of lithium ores: Industrial technologies and case The LCI for limestone processing operations includes the inputs and outputs for each of the processes depicted in Figure 2 Specifically, processes and operations represented in this portion of the inventory include: • Primary shaping of stone into large, lessrefined pieces, such as tiles or Limestone Quarrying and Processing: A LifeCycle Inventory

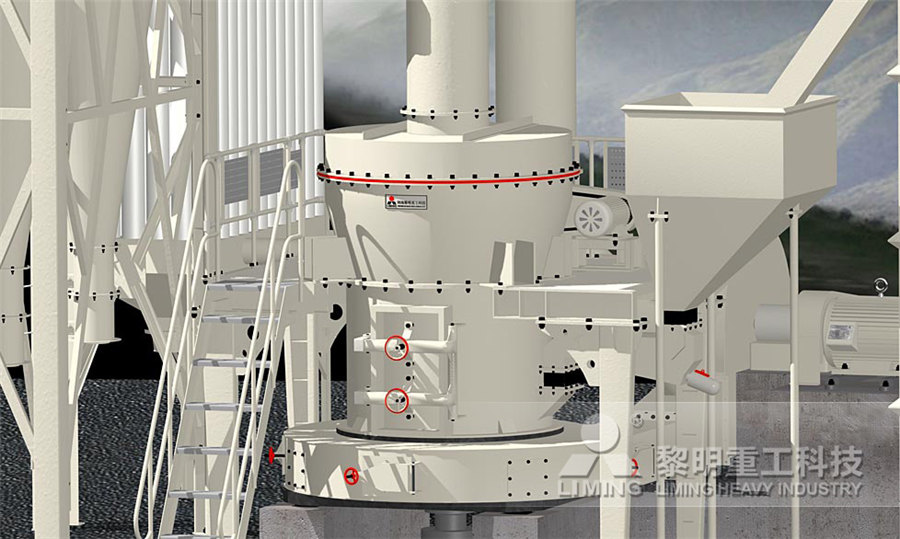

Limestone Processing Equipment Making

Find production technology for making Limestone, and connect directly with leading machine manufacturers worldwide Processing steps involved in limestone making Belt dryers Continuous milling solutions Conveyor belts Pelleting Presses Silos Belt dryers Continuous milling solutions2021年10月12日 Supported by the European Union, the LEILAC (Low Emissions Intensity Lime And Cement) projects are developing a breakthrough technology that aims to enable the cement and lime industries to capture those unavoidable CO2 Capturing cement's carbon: piloting LEILAC technology in Belgium Materials produced from heavilyclaybound Limestone processing such as overburden, scalpings and crushed rock fines are often considered unusable quarry waste byproducts CDE's sophisticated dual scrubbing technology turns these materials into highvalue saleable productsLimestone Processing Limestone Wash Plant CDE CDETECHNOLOGY Limestone Quarry Production Planning for Consistent Supply of Raw Materials to Cement Plant: A Case Study from Indian Cement Industry with a Captive Quarry1 D Joshia, S Chatterjeeb, and Sk Md Equeenuddinc aDepartment of Mining Engineering, National Institute of Technology, Rourkela , IndiaMINERAL MINING TECHNOLOGY Limestone Quarry Production

.jpg)

Main page limestone

Limestone Factories of Estonia OÜ Limestone Factories of Estonia OÜ, operating since 1959 (originally Paekivitoodete Tehase OÜ), has been the largest producer of crushed limestone in Estonia for many years, producing up to 30% of the local market Since privatisation, the company has continuously introduced and implemented new technologies, such as the blastfree miningprocessing of limestone Keywords: limestone, separation, purification, fluoride, phosphorus, calcite, dolom ite, magnesite, siderite INTRODUCTION The production activity of mankind is associated with the use of a variety of natural resources, covering most of the chemical elements A particularly importantIMPROVING THE EFFICIENCY OF PURIFICATION IN THE Uncover the future of enhanced limestone processing Technology Limitations: Current technology may limit the effectiveness of some beneficiation techniques, particularly in challenging situations such as very fine particle sizes or Limestone Beneficiation Techniques: Enhancing Materials produced from heavilyclaybound Limestone processing such as overburden, scalpings and crushed rock fines are often considered unusable quarry waste byproducts CDE's sophisticated dual scrubbing technology turns these materials into highvalue saleable productsLimestone Processing Limestone Wash Plant CDE CDE

.jpg)

Effect of the presence of NaCl vapour on indirect sulphation of limestone

Abstract The effects of the presence of NaCl vapour on limestone SO 2 capture behaviour were examined When NaCl was present in the sulphation atmosphere, the effects of the presence of H 2 O, reaction temperatures, particle sizes and NaCl concentrations on limestone SO 2 capturing were studied in a tailormade threesection control horizontal furnaceBrimstone's deeply decarbonized process is a breakthrough in cement production, making industrystandard portland cement with carbonfree calcium silicate rock instead of limestone Brimstone cement is chemically and physically identical to conventional portland cement, with the same quality and performance builders have trusted for over 150 yearsTechnology BrimstoneSince 1936, Meckley’s Limestone Products, Inc in Herndon, Pennsylvania has been a leader in the limestone processing field, and has been providing pulverized sorbent to the power industry since CFB technology was introduced in the United States in Greystone MaterialsLimestone is a common sedimentary rock that is used in a variety of applications, including construction, agriculture, and manufacturing Our equipment is designed to efficiently pulverize limestone into a fine powder, which is commonly used as a soil conditioner or as a component in cement productionLimestone DP Pulveriser

.jpg)

Decarbonising the lime industry: Stateoftheart ScienceDirect

2022年10月1日 The thermal treatment of limestone (mainly CaCO 3) to produce lime (CaO) is a major contributor to CO 2 emissions and the literature on decarbonising the lime industry is scarce Subsequent hydration of lime would lead to the synthesis of slaked/hydrated lime Ca(OH) 2; the production of a tonne of Ca(OH) 2 emits ∼12 tonnes of CO 2 arising mainly from the 2005年11月1日 Some aspects of using lime from limestone to sequester CO2 from combustion systems are examined in this review of the literature A typical sequestration technology would consist of two Review—calcination and carbonation of limestone during 2023年12月8日 Limestone Properties The main component of limestone is calcium carbonate (CaCO3), with a Mohs hardness of 3 After limestone is mined from limestone, it is crushed to form limestone particles, that is, stone and sand, or further ground to form limestone powder, which is widely used in industries such as building materials, highways, metallurgy, and Limestone crushing technology and equipment SBM Ultrafine 2021年7月15日 Limestone quarries and their restoration provide a major opportunity to protect and enhance biodiversity Most of the limestone captive mines of the cement industry have a long legacy of goodquality restoration Therefore, one can make a significant contribution in terms of environment preservation and protectionLimestone Mining, Industry, and Society SpringerLink

Morphology of Limestone Manufactured Sand

2017年2月1日 On limestone and sandstone, spun cotton yarns such as pore shape, pore size and the volumetric distribution of pores were extracted by using image processing technology(English units) include emission factors for the mechanical processing (crushing, screening, and grinding) of limestone and for some materials handling operations Section 1119, Construction Aggregate Processing, also includes stone processing emission factors that are based on more recent testing, and, therefore, may be1117 Lime Manufacturing US EPA2022年5月22日 Fine and ultrafine grinding of limestone are frequently used in the pharmaceutical, chemical, construction, food, and cosmetic industries, however, research investigations have not yet been published on the combination of energy and life cycle modeling Therefore, the first aim of this research work was the examination of main grinding parameters EnergyModel and Life CycleModel for Grinding Processes of Limestone 2021年6月18日 Primary Information Services offers several databases related to limestone production in India, including information on mining, lime kilns, technology, products, and the mineral industriesLimestone mining amp; processing PPT SlideShare

Welcome Limestone Polygraph by Lafayette Instrument Company

In August 2022, Limestone Technologies became a subidiary of Lafayette Instrument Company Lafayette will continue to provide customers with bestinclass products and support Learn More ParagonX Polygraph System The ParagonX delivers on performance, reliability, and innovation2022年8月26日 Limestone Grinding Process The limestone grinding process mainly includes two types: Open circuit process: the process of material passing through the mill as finished product for the next step of operation; Closed circuit process: when the material discharged from grinding mill after one or several levels of separation, the fine particles are used as the finished Which Grinding Mill Is Suitable For Processing Limestone?Most limestone is extracted through blasting Behind the rock face, holes are drilled to place the explosives When detonated, the explosion dislodges each time up to 30,000 tonnes of stone Today’s blasting makes use of the latest technology whereby modern electronic detonators are used to reduce vibration to a minimumProduction European Lime AssociationLimestone is used as a filler in a variety of products, including paper, plastic, and paint The purest limestone is even used in foods and medicines such as breakfast cereals and calcium pills Limestone is also the raw material for making lime (CaO) that is used to treat soils, purify water, and smelt copperLimestone: The Calcium Carbonate Chemical Sedimentary Rock

Mineral Beneficiation Potentialities of Archaean Limestone for

Proceedings of the International Seminar on Mineral Processing Technology 2006, Chennai, India pp 297 302 Mineral Beneficiation Potentialities of Archaean Limestone for Cement Manufacture DK Panda, NK Sharma and SK Gotecha National Council for Cement and Building Materials (NCB), New Delhi, India Abstract2021年7月15日 Since limestone is available in abundance, its quality has not drawn much attention and is largely ignored It may be noted further that the generation of highpurity or highgrade calcium from limestone for various uses in outer space applications may be required in future by the industry, and this can be derived only through limestone processingModern Technological Applications for Limestone Mining2021年2月26日 The above is the common processing technology and process of limestone If you have any questions about this, please contact us in detail 上一篇: What Equipment Is Suitable For Crushing Pebble?What are the limestone processing technologies?2009年2月1日 Journal of Materials Processing Technology Volume 209, Issue 3, 1 February 2009, Pages 16071611 Synthesis of needlelike aragonite from limestone in the presence of magnesium chloride Author links open overlay panel Zeshan Hu a, Minghao Shao a, Qiang Cai a, Sheguang Ding a, Chenghua Zhong a, Xiaopin Wei a, Yulin Deng bSynthesis of needlelike aragonite from limestone in the presence

Processing of lithium ores: Industrial technologies and case

2021年5月1日 The technology of autoclave leaching of Ukrainian petalite ores being discussed as well Presumably, autoclavebased methods are optimal for poor raw material processing with high efficiency In conclusion, technologies of Limica processing briefly considered, taking into account the issues of waste disposal and economic backgroundThe LCI for limestone processing operations includes the inputs and outputs for each of the processes depicted in Figure 2 Specifically, processes and operations represented in this portion of the inventory include: • Primary shaping of stone into large, lessrefined pieces, such as tiles or Limestone Quarrying and Processing: A LifeCycle InventoryFind production technology for making Limestone, and connect directly with leading machine manufacturers worldwide Processing steps involved in limestone making Belt dryers Continuous milling solutions Conveyor belts Pelleting Presses Silos Belt dryers Continuous milling solutionsLimestone Processing Equipment Making2021年10月12日 Supported by the European Union, the LEILAC (Low Emissions Intensity Lime And Cement) projects are developing a breakthrough technology that aims to enable the cement and lime industries to capture those unavoidable CO2 Capturing cement's carbon: piloting LEILAC technology in Belgium

.jpg)

Limestone Processing Limestone Wash Plant CDE CDE

Materials produced from heavilyclaybound Limestone processing such as overburden, scalpings and crushed rock fines are often considered unusable quarry waste byproducts CDE's sophisticated dual scrubbing technology turns these materials into highvalue saleable productsTECHNOLOGY Limestone Quarry Production Planning for Consistent Supply of Raw Materials to Cement Plant: A Case Study from Indian Cement Industry with a Captive Quarry1 D Joshia, S Chatterjeeb, and Sk Md Equeenuddinc aDepartment of Mining Engineering, National Institute of Technology, Rourkela , IndiaMINERAL MINING TECHNOLOGY Limestone Quarry Production Limestone Factories of Estonia OÜ Limestone Factories of Estonia OÜ, operating since 1959 (originally Paekivitoodete Tehase OÜ), has been the largest producer of crushed limestone in Estonia for many years, producing up to 30% of the local market Since privatisation, the company has continuously introduced and implemented new technologies, such as the blastfree miningMain page limestone