Sanshui Shuikou lime quicklime grinding machine

Quicklime preparation Gebr Pfeiffer

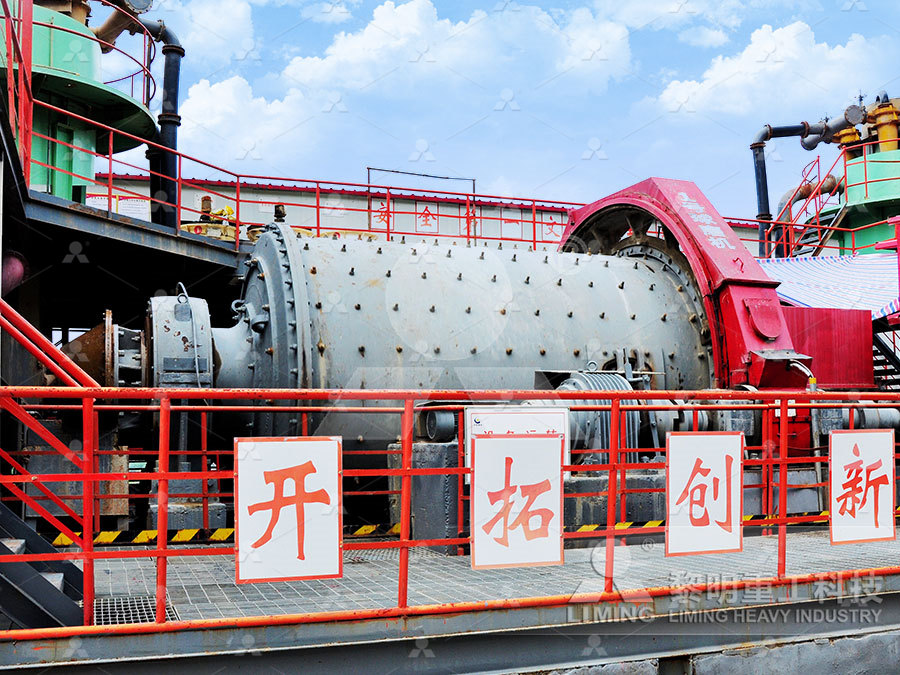

We have innovative processes for limestone grinding and separating as well as for lime hydration with Pfeiffer mills, hydrators, high efficiency separators, and distribution table separatorsIt is produced by hydrating quicklime, essentially calcium oxide, using a specific apparatus Limestone quality Calcium oxide properties (size and reactivity) Chemical properties and Developing a modular lime plant CimprogettiOffer tailored grinding mills for quicklime Wide application, highquality, energysaving and environmentally friendlyThe Right Grinding Machines for Your Quicklime Industry Liming The vertical mill stands out as the preferred equipment for quicklime production due to its high efficiency, energy savings, environmental protection, and ease of maintenance Its advanced Vertical mill: The preferred equipment for quicklime production

.jpg)

Quick Lime Plant MadeinChina

China Quick Lime Plant wholesale Select 2024 high quality Quick Lime Plant products in best price from certified Chinese Plant Equipment manufacturers, Plant Machinery suppliers, China Quick Lime Plant Equipment wholesale Select 2024 high quality Quick Lime Plant Equipment products in best price from certified Chinese Machine Equipment Control Quick Lime Plant Equipment MadeinChinaHydrated lime is an excellent, white, immoderate purity product specifically hydrated for handy, hasslefree use in mortar applications It`s a unique product, more stringent and necessary for LIME AS CONSTRUCTION MATERIAL: PROCESS APPLICATIONHebei lime grinding production line with output of 400,000 tons per hour Raw material: limestone Processing capacity: 400,000 tons/year Finished powder fineness: 325 mesh D90quicklime processing plant, quicklime grinding machine, quicklime

Optimization of Grinding Parameters of Quicklime CaO at

2016年10月19日 The grinding aids were found to influence the product size and decrease the grinding energy This is attributed to the prevention of agglomeration and coating of the The quicklime absorbs moisture or adds water to become slaked lime (also known as slaked lime) The main component is calcium hydroxide Ca(OH)2, which is used in waste incineration, Limestone mill Hengtu MachineryVertical Mill Slaker No matter the quality of lime or water, Westpro’s Vertical Mill Slaker provides excellent slaking of lime Additionally, our Vertical Mill’s high efficiency will ensure the complete use of the quicklime regardless of the LIME SLAKING AND LIME MIXING SYSTEMS Westpro In the lime hydrator, quicklime fines or quicklime lumps turn into lime hydrate Ca(OH)2 after the addition of water at a temperature of approx 100°C The requested residual moisture of the hydrate is regulated by a temperaturecontrolled water supply and a variable material retention time The vapors developing during hydration are dedustedLime hydrators from the specialist Gebr Pfeiffer

.jpg)

LIME SLAKING SYSTEMS Bulk Handling

Lime slaking is the process of converting quicklime to hydrated lime (CaO + H20 > Ca(OH)2) by mixing with water Lime slaking is an exothermic process which generates heat and creates steam Slaked or hydrated lime is often used in I understand how quicklime takes forever to make, and you really should consider running many firepits at the sane time to get around your problem Also consider using coal or charcoal for your fuel so you get longer burntime However, may I ask why you need so much quicklime?Quicklime mass production? : r/VintageStory Reddit2020年10月29日 Lime is a very general term applied to products of limestone, in popular treatises often incorrectly, including ground or pulverized limestone used in agriculture When used without qualifying adjective, the term usually means burned or calcined limestone, or quicklime, or calciaLime Quicklime Limestone 911Metallurgist2022年2月28日 ① Grinding stage The calcined lime raw material is directly (or once crushed) continuously and uniformly sent to the main machine grinding chamber through the feeder after being cooled in transit, and the ground fine powder is classified by the classifier under the action of the air flow of the fan and then sent to the main machineHow to do a good job of grinding in the lime industry?

Premium quick lime making machine For Industries

high throughput rate quick lime powder making machine and quick lime grinding mill machine $26,00000$69,00000 Min Order: 1 set Previous slide Next slide high efficiency high capacity Cement Making Machinery 100 1000 tpd rotary kiln for quick lime plant $12,00000$80,000002023年7月4日 A briquetting machine, also called a briquette press machine or briquettemaking machine, is a device that converts powdered or granular materials into larger, more convenient shapes called briquettes According to materials, there are 5 most popular briquette machines at present: charcoal briquette machine, coal briquette machine, metal powder briquette machine, 5 Types of Briquette Machines (With Budget Analysis)Lime Calcination Plant Finished products: active lime Limekiln: rotary kiln (vertical shaft kiln upon request) Capacity: 2001000t/d Limestone granularity: 2040 mm Fuel: gas, pulverized coal Get the solution now!Lime Calcination Plant Solution 2001000tpd Quicklime CNBM Limestone powder can produce quicklime by calcination Quicklime can be widely used for desulfurization in power plants, and after adding water treatment to get hydrated lime By mixing hydrated lime, lime slurry and lime paste can be obtained, which are used for coating materials and processing materials of brick and tile adhesivesLimestone Mill for Limestone Powder Grinding Limestone Crushing

.jpg)

Lime Slaking Systems Carmeuse

Carmeuse Systems knows that no two lime and water combinations are the same, and how these are slaked will have a major impact on the quality of the produced slurry We can help you select the correct equipment to minimize Company Introduction: Zhengzhou Zhongding Heavy Machinery Manufacturing Co, Ltd is a jointstock enterprise specializing in the production of mining machinery Is a professional beneficiation, crushing, screening, drying equipment solution provider, longterm commitment to provide crushing equipment, vibration screening equipment, washing equipment and belt conveyor High Pressure Quicklime Lime Powder Briquette Making MachineThe quality of the quicklime is largely dependent on the efficiency of the grinding process, which is where the vertical mill comes into play The vertical mill, also known as the vertical roller mill, has emerged as a leading piece of equipment for the production of quicklime due to its advanced technology and operational excellenceVertical mill: The preferred equipment for quicklime productionAmerican Pulverizer Company offers numerous solutions to handle lime material Lime can be efficiently processed using our hammermills, impactors, double and singleroll crushers, and our FCC Series Frozen Crackers Every American Pulverizer machine is designed for high production with minimal maintenanceLime Processing Equipment Shredders, Crushers, Impactors,

Limestone crushing technology and equipment SBM Ultrafine

2023年12月8日 Limestone Properties The main component of limestone is calcium carbonate (CaCO3), with a Mohs hardness of 3 After limestone is mined from limestone, it is crushed to form limestone particles, that is, stone and sand, or further ground to form limestone powder, which is widely used in industries such as building materials, highways, metallurgy, and 2018年11月12日 PDF In this work, the quicklime (CaO) was produced from the thermal decomposition of the limestone (CaCO3) using a lab kiln at 700, 900 and 1100 °C Find, read and cite all the research you (PDF) Characterization of quicklime as raw material to hydrated lime Quick Lime Making Production Line Machine, Quicklime Making Production Line 1 Quick Lime Ball Grinding Mill with Capacity 2030 Tons Per Hour US$12,0000099,00000 / Piece Active Lime Rotary Lime Kiln Plant Manufacturer [Hot Item] Quick Lime Making Production Line Machine2021年9月2日 In the lime slurry formed after quicklime slaked, the lime particles form a calcium hydroxide colloidal structure, the particles are extremely fine (particle size is about 1μm), the specific surface area is large (up to 1030m2/g), and a thicker layer is adsorbed on the surface Water film can absorb a large amount of water, so it has a strong ability to retain water, that is, The difference between quicklime and hydrated lime

.jpg)

Quicklime Preparation, Properties, and Applications with FAQs

Quicklime is known to be quite inexpensive and abundant It can also be noted that quicklime (along with another one of its derivatives, calcium hydroxide) is a very important commodity chemical Table of Contents Preparation of Quicklime; Health Hazards Associated with Quicklime; Difference Between Quicklime and Hydrated Lime; Properties of How to choose quicklime powder grinding mill? Date: 16:38:48 What is quicklime? Quicklime, also known as calcined lime, is mainly composed of calcium oxide (CaO)Any natural rock with calcium carbonate as the main How to choose quicklime powder grinding mill?Hydrated lime is produced from limestone in a twostep procedure Limestone is burnt to calcium oxide (quicklime) and in a second step water is added to create hydrated lime Bauermeister mills can be used for grinding natural limestone LIMESTONE GRINDING Bauermeister Size Reduction Business listings of Quicklime, Burnt Lime manufacturers, suppliers and exporters in Mumbai, Quick Flat Grinding Request Sample Alex Machine Tools Pvt Ltd Mumbai 8 S V Road Gaiwadi Industrial Estate Goregaon West Mumbai Suburban, Mumbai , Burnt Lime, Quicklime In Mumbai India Business Directory

.jpg)

Lime Briquetting Machine Zoneding Machine

Operation Guidance of Lime Briquetting Machine 1The selection of binder: the choice of binder has wide source and low price A good effect is an important issue, which is directly related with the hardness and density of the balls as well as the product quality and production costThe limestone grinding mill, also known as lime grinding, is a machine used to grind limestone into powder formLimestone remains in lumpy form after being processed through the limestone crusherBefore entering the calcination stage, limestone needs to be ground into powder form using a limestone grinding mill The main component of limestone is calcium carbonate, which Limestone Grinding Mill Solution Adjustable Powder FinenessThis quicklime/calcined briquetting machine can produce a variety of lime briquettes with all kinds of shapes The shape can also be customized according to the requirement of customer Fote lime briquette machine can compress lime powder to shape lime briquettes of high intensity, uniform size and original lime propertyLime Briquette Machine/ Quicklime/Calcined Lime Briquetting Machine 2021年11月24日 Which mill is better for slaked lime and quicklime to 1200 mesh? Lime can be divided into quicklime and slaked lime The main component of quicklime is calcium oxide (CaO), the white solid is refractory to fire The limestone with high content of (CaO) is calcined in a ventilated lime kiln to above 900°CPowder Grinder Equipment for Producing Lime Powder

Lime Production Process and Required Equipment Fote Machinery

2023年2月15日 FTM MachineryGreen and Intelligent Mining Machinery Manufacturing and Export BaseBased on high quality and perfect aftersales service, our products have been exported to more than 120 countries and regions FTM Machinery has become the first choice for over 2,000,000 customersmounted ball mills suitable for quicklime slaking and regrind applications The mills range from 600mm diameter for laboratory batch testing applications through to the largest mill currently available of 23m diameter with an effective grinding length of 46m SEW Eurodrive geared reducers are used exclusively on Lime SystemsCOMPLETE PLANT CAPABILITY LIME SYSTEMS LTDVertical Mill Slaker No matter the quality of lime or water, Westpro’s Vertical Mill Slaker provides excellent slaking of lime Additionally, our Vertical Mill’s high efficiency will ensure the complete use of the quicklime regardless of the LIME SLAKING AND LIME MIXING SYSTEMS Westpro In the lime hydrator, quicklime fines or quicklime lumps turn into lime hydrate Ca(OH)2 after the addition of water at a temperature of approx 100°C The requested residual moisture of the hydrate is regulated by a temperaturecontrolled water supply and a variable material retention time The vapors developing during hydration are dedustedLime hydrators from the specialist Gebr Pfeiffer

.jpg)

LIME SLAKING SYSTEMS Bulk Handling

Lime slaking is the process of converting quicklime to hydrated lime (CaO + H20 > Ca(OH)2) by mixing with water Lime slaking is an exothermic process which generates heat and creates steam Slaked or hydrated lime is often used in I understand how quicklime takes forever to make, and you really should consider running many firepits at the sane time to get around your problem Also consider using coal or charcoal for your fuel so you get longer burntime However, may I ask why you need so much quicklime?Quicklime mass production? : r/VintageStory Reddit2020年10月29日 Lime is a very general term applied to products of limestone, in popular treatises often incorrectly, including ground or pulverized limestone used in agriculture When used without qualifying adjective, the term usually means burned or calcined limestone, or quicklime, or calciaLime Quicklime Limestone 911Metallurgist2022年2月28日 ① Grinding stage The calcined lime raw material is directly (or once crushed) continuously and uniformly sent to the main machine grinding chamber through the feeder after being cooled in transit, and the ground fine powder is classified by the classifier under the action of the air flow of the fan and then sent to the main machineHow to do a good job of grinding in the lime industry?

Premium quick lime making machine For Industries

high throughput rate quick lime powder making machine and quick lime grinding mill machine $26,00000$69,00000 Min Order: 1 set Previous slide Next slide high efficiency high capacity Cement Making Machinery 100 1000 tpd rotary kiln for quick lime plant $12,00000$80,000002023年7月4日 A briquetting machine, also called a briquette press machine or briquettemaking machine, is a device that converts powdered or granular materials into larger, more convenient shapes called briquettes According to materials, there are 5 most popular briquette machines at present: charcoal briquette machine, coal briquette machine, metal powder briquette machine, 5 Types of Briquette Machines (With Budget Analysis)Lime Calcination Plant Finished products: active lime Limekiln: rotary kiln (vertical shaft kiln upon request) Capacity: 2001000t/d Limestone granularity: 2040 mm Fuel: gas, pulverized coal Get the solution now!Lime Calcination Plant Solution 2001000tpd Quicklime CNBM Limestone powder can produce quicklime by calcination Quicklime can be widely used for desulfurization in power plants, and after adding water treatment to get hydrated lime By mixing hydrated lime, lime slurry and lime paste can be obtained, which are used for coating materials and processing materials of brick and tile adhesivesLimestone Mill for Limestone Powder Grinding Limestone Crushing